Graco SaniForce 1040 Operation

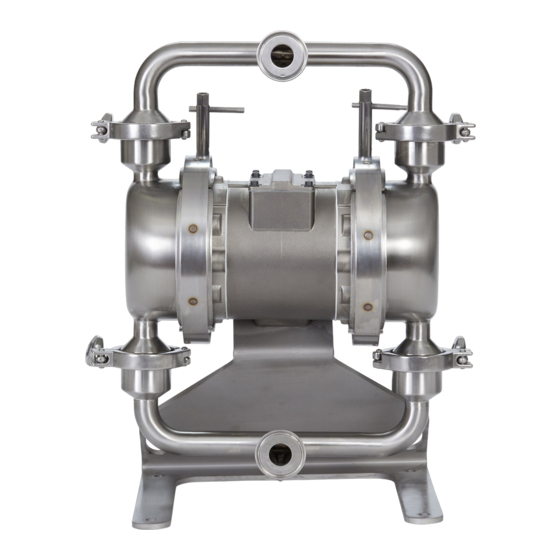

High sanitation diaphragm pumps

Hide thumbs

Also See for SaniForce 1040:

- Instruction manual (54 pages) ,

- Instructions - parts manual (32 pages) ,

- Instructions-parts list manual (32 pages)

Table of Contents

Advertisement

Quick Links

Operation

SaniForce

Diaphragm Pumps

Models 1040, 1590, 2150, 3150, 4150

For transfer of fluids in sanitary applications. Not approved for use in explosive

atmospheres or hazardous (classified) locations unless otherwise stated. See Approvals

page for more information. For professional use only.

120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure

120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

Important Safety Instructions.

Read all warnings and instructions in

this manual before using the

equipment. Save these instructions.

®

High Sanitation

3A5999E

EN

Advertisement

Table of Contents

Summary of Contents for Graco SaniForce 1040

- Page 1 Operation ® SaniForce High Sanitation Diaphragm Pumps 3A5999E Models 1040, 1590, 2150, 3150, 4150 For transfer of fluids in sanitary applications. Not approved for use in explosive atmospheres or hazardous (classified) locations unless otherwise stated. See Approvals page for more information. For professional use only. 120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure 120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure Important Safety Instructions.

-

Page 2: Table Of Contents

Start and Adjust the Pump ....14 Graco Information ......32 Pump Shutdown. -

Page 3: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. When these symbols appear in the body of this manual, refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable. - Page 4 Warnings WARNING EQUIPMENT MISUSE HAZARD Misuse can cause death or serious injury. • Do not operate the unit when fatigued or under the influence of drugs or alcohol. • Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

-

Page 5: Configuration Number Matrix

Configuration Number Matrix Configuration Number Matrix Check the identification plate (ID) for the Configuration Number of your pump. Use the following matrix to define the components of your pump. When you receive your pump, record the 9 character part number found on the shipping box (e.g., SP3F.0018): _____________ Also record the configuration number on the pump ID plate to assist you when ordering replacement parts:... -

Page 6: Fluid Temperature Range

Configuration Number Matrix Approvals II 2 GD Except for 3-A pumps, all Ex h IIA T6...T3 Gb pumps are approved to: Ex h IIIB T160°C Db ATEX T-code rating is dependent on the temperature of the fluid being Diaphragm materials coded pumped. -

Page 7: Ordering Information

2. Click on Where to Buy and use the Distributor Locator. To Specify the Configuration of a New Pump Please call your distributor. Use the Online Diaphragm Pump Selector at www.graco.com. Search for Selector. To Order Replacement Parts Please call your distributor. -

Page 8: Installation

The equipment must be grounded to reduce the risk of • Always use genuine Graco parts and accessories. static sparking. Static sparking can cause fumes to • Reference numbers and letters in parentheses refer ignite or explode. -

Page 9: Stand And Mounting

Installation Stand and Mounting Air Line A bleed-type master air valve (C) is required in the The pump may be very heavy (see Technical system to relieve air trapped between this valve and the Specifications for specific weights). If the pump must pump. -

Page 10: Fluid Suction And Outlet Lines

Viscous liquids are more difficult to pump and more prone to cavitation. Graco recommends taking all of the above factors into account in system design. To maintain pump efficiency, supply only enough air to the pump to achieve the required flow. -

Page 11: Typical Installation

Installation Typical Installation Key: Master air valve (for accessories) Air regulator (required, not supplied) Bleed-type master air valve (for pump) (required, not supplied) Air supply line Air line coupler 1/2 npt (f) pump air inlet Flexible fluid outlet line Flexible fluid suction line Fluid shutoff valve (required, not supplied) Fluid drain valve (required, not... -

Page 12: Air Exhaust Ventilation

Installation Air Exhaust Ventilation NOTE: The air exhaust port is 3/4 npt(f). Do not restrict the air exhaust port. Excessive exhaust restriction can reduce pump performance. To provide a remote exhaust: Be sure the system is properly ventilated for your type 1. -

Page 13: Operation

Operation Operation Pressure Relief Procedure Sanitize the Pump Before First Follow the Pressure Relief Procedure when- ever you see this symbol. NOTE: The pump was built and tested using a food grade lubricant. This equipment stays pressurized until pressure is Properly sanitize the pump before first use. -

Page 14: Start And Adjust The Pump

Operation Start and Adjust the Pump 8. To prime the pump, slowly increase air pressure with the air regulator (B) until the pump starts to cycle. Do not exceed the maximum operating air 1. Confirm that the pump is properly grounded. See pressure as listed in the Technical Specifications, Grounding, page 8. -

Page 15: Maintenance

Maintenance Maintenance Lubrication 5. Remove the suction line from the sanitizing solution and drain pump. The pump is lubricated at the factory. It is designed to require no further lubrication for the life of the pump. Routine Cleaning of Product There is no need to add an inline lubricator under normal operating conditions. -

Page 16: 1040 Specifications

1040 Specifications 1040 Specifications 1040 Dimensions Ø 0.40 in (10 mm) A 19.3 in (49.0 cm) E 15.7 in (39.9 cm) B 13.7 in (34.8 cm) F 12.3 in (31.2 cm) C 10.5 in (26.7 cm) G 8.5 in (21.6 cm) D 2.6 in (6.6 cm) 3A5999E... -

Page 17: 1040 Performance Chart

1040 Specifications 1040 Performance Chart (9.7, 0.97) (8.3, 0.83) (6.9, 0.69) (5.5, 0.55) (4.1, 0.41) (2.8, 0.28) (1.4, 0.14) (19) (38) (57) (76) (95) (114) (132) (151) (170) FLUID FLOW -- gpm (lpm) AIR PRESSURE D 120 psi air (8.4 bar, 0.84 MPa) (1.87) C 100 psi air (7 bar, 0.7 MPa) B 70 psi air (4.8 b... -

Page 18: 1040 Technical Specifications

1040 Specifications 1040 Technical Specifications 3A5999E... -

Page 19: 1590 Specifications

1590 Specifications 1590 Specifications 1590 Dimensions Ø 0.43 in (11 mm) A 32.6 in (82.8 cm) E 21.0 in (53.3 cm) B 17.0 in (43.2 cm) F 23.8 in (60.5 cm) C 17.3 in (43.9 cm) J 14.5 in (36.8 cm) D 10.6 in (26.9 cm) K 21.0 in (53.3 cm) 3A5999E... -

Page 20: 1590 Performance Charts

1590 Specifications 1590 Performance Charts Ball Check pump (9.7, 0.97) (8.3, 0.83) (6.9, 0.69) (5.5, 0.55) (4.1, 0.41) (2.8, 0.28) (1.4, 0.14) (76) (151) (227) (303) (379) (454) FLUID FLOW -- gpm (lpm) Pump tested in water (4.28) with inlet submerged. (3.75) (3.21) AIR PRESSURE... - Page 21 1590 Specifications 1590 Performance Charts Continued Flapper Check pump (9.7, 0.97) (8.3, 0.83) (6.9, 0.69) (5.5, 0.55) (4.1, 0.41) (2.8, 0.28) (1.4, 0.14) (38) (76) (114) (151) (189) (227) (265) (303) (341) FLUID FLOW -- gpm (lpm) Pump tested in water with inlet submerged.

-

Page 22: 1590 Technical Specifications

1590 Specifications 1590 Technical Specifications 3A5999E... -

Page 23: 2150 Specifications

2150 Specifications 2150 Specifications 2150 Dimensions Ø 0.43 in (11 mm) A 35.7 in (90.7 cm) B 19.3 in (49.0 cm) C 17.3 in (43.9 cm) D 7.5 in (19.1 cm) E 27.0 in (68.6 cm) F 23.8 in (60.5 cm) J 14.5 in (36.8 cm) K 21.0 in (53.3 cm) 3A5999E... -

Page 24: 2150 Performance Chart

2150 Specifications 2150 Performance Chart (9.7, 0.97) (8.3, 0.83) (6.9, 0.69) (5.5, 0.55) (4.1, 0.41) (2.8, 0.28) (1.4, 0.14) (76) (151) (227) (303) (379) (454) (530) (606) (681) (757) FLUID FLOW -- gpm (lpm) (Pump tested in water with inlet submerged) (6.70) (5.36) -

Page 25: 3150 Specifications

3150 Specifications 3150 Specifications 3150 Dimensions Ø 0.43 in (11 mm) A 39.5 in (100.3 cm) E 33.2 in (84.3 cm) B 20.5 in (52.1 cm) F 23.8 in (60.5 cm) C 17.3 in (43.9 cm) J 14.5 in (36.8 cm) D 4.5 in (11.4 cm) K 21.0 in (53.3 cm) 3A5999E... - Page 26 3150 Specifications 3150 Horizontal Mount Ø 0.53 in (13.5 mm) G 19.9 in (50.5 cm) L2 23.0 in (58.4 cm) H 22.4 in (56.9 cm) M 13.8 in (35.1 cm) J 14.0 in (35.6 cm) N 12.2 in (31.0 cm) K 15.2 in (38.6 cm) L 54.5 in (138.4 cm) 3A5999E...

-

Page 27: 3150 Performance Chart

3150 Specifications 3150 Performance Chart (9.7, 0.97) (8.3, 0.83) (6.9, 0.69) (5.5, 0.55) (4.1, 0.41) (2.8, 0.28) (1.4, 0.14) (76) (151) (227) (303) (379) (454) (530) FLUID FLOW -- gpm (lpm) Pump tested in water with (6.70) inlet submerged (5.36) AIR PRESSURE D 120 psi air (8.4 bar, 0.84 MPa) (4.02) -

Page 28: 4150 Specifications

4150 Specifications 4150 Specifications 4150 Dimensions Ø 0.53 in (13.5 mm) A 45.9 in (116.6 cm) E 39.0 in (99.1 cm) B 23.1 in (58.7 cm) F 21.2 in (53.8 cm) C 11.6 in (29.5 cm) G 16.0 in (40.6 cm) D 4.5 in (11.4 cm) 3A5999E... - Page 29 4150 Specifications 4150 Horizontal Mount Ø 0.53 in (13.5 G 19.9 in (50.5 cm) H 24.4 in (62.0 cm) J 14.0 in (35.6 cm) K 16.0 in (40.6 cm) L 58.5 in (148.6 cm) L2 23.7 in (60.2 cm) M 13.8 in (35.1 cm) N 12.2 in (31.0 cm) 3A5999E...

-

Page 30: 4150 Performance Chart

4150 Specifications 4150 Performance Chart (9.7, 0.97) (8.3, 0.83) (6.9, 0.69) (5.5, 0.55) (4.1, 0.41) (2.8, 0.28) (1.4, 0.14) (38) (76) (114) (151) (189) (227) (265) (303) (341) (379) FLUID FLOW -- gpm (lpm) (6.70) Pump tested in water with inlet submerged (5.36) AIR PRESSURE D 120 psi air (8.4 bar, 0.84 MPa) -

Page 31: 2150, 3150, 4150 Technical Specifications

2150, 3150, 4150 Technical Specifications 2150, 3150, 4150 Technical Specifications California Proposition 65 CALIFORNIA RESIDENTS WARNING: Cancer and reproductive harm – www.P65warnings.ca.gov. 3A5999E... -

Page 32: Graco Information

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the SaniForce 1040 and is the answer not in the manual?

Questions and answers