Table of Contents

Advertisement

Quick Links

Installation, Operating &

Maintenance Instructions

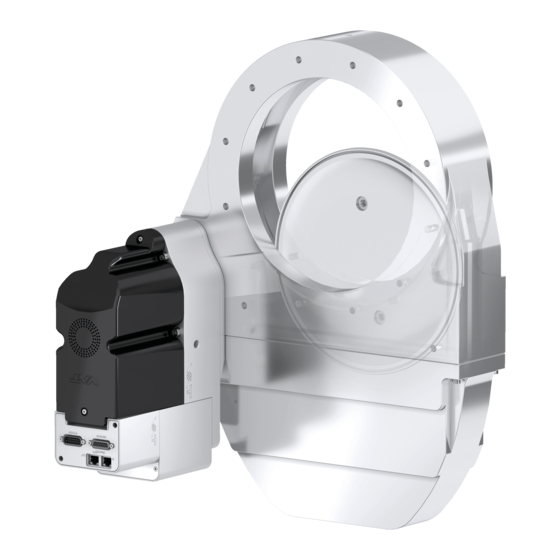

Pendulum control & isolation valve

with DeviceNet® interface

Series 655

DN 250 mm (I.D. 10")

This manual is valid for the valve ordering number(s):

65548 - . .GQ - . . . .

65548 - . .AQ - . . . .

65548. - . .HQ - . . . .

65548. - . .CQ - . . . .

SPS = Sensor Power Supply

Configured with firmware :

DeviceNet profile:

Sample picture

979645EA

(2 sensor inputs / analog outputs)

(2 sensor inputs / analog outputs / ±15V SPS)

(2 sensor inputs / analog outputs / PFO)

(2 sensor inputs / analog outputs / ±15V SPS / PFO)

PFO = Power Failure Option

F01.0C.28.xx

Generic C (compatible to IC1 DeviceNet firmware version C)

Edition 23.09.2019

Advertisement

Table of Contents

Summary of Contents for VAT 655 Series

- Page 1 Installation, Operating & Maintenance Instructions Pendulum control & isolation valve with DeviceNet® interface Series 655 DN 250 mm (I.D. 10") This manual is valid for the valve ordering number(s): 65548 - . .GQ - ..(2 sensor inputs / analog outputs) (2 sensor inputs / analog outputs / ±15V SPS) 65548 - .

- Page 2 The VAT firmware may not be used for purposes other than those intended nor is it permitted to make copies of the VAT firmware. In particular, it is strictly forbidden to give copies of the VAT firmware to other people.

-

Page 3: Table Of Contents

Series 655 Contents Description of product ................ 6 Identification of product ....................6 Use of product ......................... 6 Used abbreviations ......................6 Related documents......................6 Important information....................... 6 Technical data ......................... 7 1.6.1 Control and actuating unit ................. 7 1.6.2 Valve unit ...................... - Page 4 Series 655 4.10.1 Introduction ..................... 60 4.10.2 Messaging Format ................... 61 4.10.3 Objects ......................62 4.10.4 Identity Object (Class ID 1) ................63 4.10.5 Assembly Object (Class ID 4)................63 4.10.6 Connection Object (Class ID 5) ............... 65 4.10.7 Discrete Input Object (Class ID 8) ..............65 4.10.8 S-Device Supervisor Object (Class ID 48) ............

- Page 5 Series 655 12.1.2 Controller ...................... 110 12.1.3 Accessories ....................110 Appendix ..................111 979645EA Edition 23.09.2019 5/112...

-

Page 6: Description Of Product

This product is a throttling pendulum valve with isolation functionality. It is intended to use for downstream pressure control applications. Use product for clean and dry vacuum applications only. Other applications are only allowed with the written permission of VAT. Used abbreviations Abbreviation... -

Page 7: Technical Data

Series 655 DESCRIPTION OF PRODUCT Technical data 1.6.1 Control and actuating unit Description Power input +24 VDC (±10%) @ 0.5 V pk-pk max. connector: POWER [655 . . - . . A . - ../ 655 . . - . . H . - ..] 70 W max.(operation of valve with max. - Page 8 DESCRIPTION OF PRODUCT Series 655 battery pack [655 . . - . . C . - ../ 655 . . - . . H . - ..] charging time 2 minutes max. durability up to 10 years @ 25°C ambient;...

-

Page 9: Valve Unit

Series 655 DESCRIPTION OF PRODUCT Valve unit Description Pressure range at 20°C - Aluminum (655 . . - . A . . - ..) 1 × 10E-8 mbar to 1.2 bar (abs) - Aluminum hard anodized (655 . . - . H . . - ..) 1 ×... - Page 10 DESCRIPTION OF PRODUCT Series 655 Description DN 250 10" (65548 - ..) Max. differential pressure on plate during isolation 1200 mbar in either direction Max. differential pressure on plate 5 mbar during opening and throttling Min. controllable conductance Typ. 2 l/s molecular flow) Dimensions Refer to dimensional drawing of specific valve ordering number...

-

Page 11: Safety

Series 655 SAFETY Safety Compulsory reading material Read this chapter prior to performing any work with or on the product. It contains important information that is significant for your own personal safety. This chapter must have been read and understood by all persons who perform any kind of work with or on the product during any stage of its serviceable life. -

Page 12: Personnel Qualifications

SAFETY Series 655 Personnel qualifications WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. Safety labels Label Part No. Location on valve On protective foil covering of T-9001-156 valve opening 12/112... -

Page 13: Design And Function

Series 655 DESIGN AND FUNCTION Design and Function Design (symbol picture) 979645EA Edition 23.09.2019 13/112... -

Page 14: Function

DESIGN AND FUNCTION Series 655 Function The valve ‘gate’ (1) acts, due to its pendulum motion, as a throttling element and varies the conductance of the valve opening. The integrated controller IC2 calculates the required gate position to achieve the set point pressure. Actuation is performed by 2 stepper motors, one for pendulum and the second for stroke. -

Page 15: Pressure Control System Overview And Function

Series 655 DESIGN AND FUNCTION 3.2.1 Pressure control system overview and function Vacuum pressures are always absolute pressures unless explicitly specified as pressure differences. Valve Process chamber Gas inlet Pressure sensor(s) Sensor cable Controller and actuator Seff Cable to remote control unit Cable to power supply HV Pump Q / p... -

Page 16: Principle Of A Pressure Control System

DESIGN AND FUNCTION Series 655 3.2.1.1 Way of operation The controller compares the actual pressure in the process chamber given by the pressure sensor with the preset pressure. The controller uses the difference between actual and set pressure to calculate the correct position of the control valve. The controller drives the control valve into the correct position and the actual pressure again equals the set pressure. -

Page 17: Installation

Make sure that the supplied products are in accordance with your order. • Inspect the quality of the supplied products visually. If it does not meet your requirements, please contact VAT immediately. • Store the original packaging material. It may be useful if products must be returned to VAT. -

Page 18: Installation Into The System

INSTALLATION Series 655 Installation into the system WARNING Valve opening Risk of serious injury. Human body parts must be kept out of the valve opening and away from moving parts. Do not connect the controller to power before the valve is installed complete into the system. -

Page 19: Installation Space Condition

Series 655 INSTALLATION 4.2.1 Installation space condition Install the valve with space for dismantling and air circulation as shown in figure below. 4.2.2 Connection overview System: Valve Process chamber Gas inlet Pressure sensor(s) Sensor cable(s) Actuator Controller (IC2) Cable to remote control unit Cable to power supply 10 Pump 979645EA... -

Page 20: Tightening Torque

INSTALLATION Series 655 Controller: Tightening torque The torque values below are dependent on many factors, such as materials involved, surface quality, surface treatment, and lubrication. The torques below are valid if immersion depth of the mounting screws is at least once the thread diameter (min. -

Page 21: Mounting With Centering Rings

Series 655 INSTALLATION 4.3.1 Mounting with centering rings ISO-F ISO-F Valve size max. tightening torque max. tightening torque (Nm) (lbs . ft) DN250 / 10“ 17-20 13-15 65548 - ..- ..hole depth (mm) hole depth (inch) DN250 / 10“... -

Page 22: Admissible Forces

65548 - ..- ..For a combination of both forces (F and M) the values are invalid. Verify that the depth of the mounting screws is min. 1 x thread diameter. Please contact VAT for more information. 22/112 Edition 23.09.2019 979645EA... -

Page 23: Requirements To Sensor Connection

Series 655 INSTALLATION 4.3.4 Requirements to sensor connection To achieve fast and accurate pressure control a fast sensor response is required. Sensor response time: < 50ms. The sensor is normally connected to the chamber by a pipe. To maintain that the response time is not degraded by this connection it needs to meet the following requirements: •... -

Page 24: Electrical Connection

INSTALLATION Series 655 Electrical connection NOTICE Wrong connection Wrong connection may result in damage of controller or power supply. Connect all cables exactly as shown in the following descriptions and schematics. NOTICE Burned connector pins (spark) Connector pins or electronic parts could damage, if plugged and unplugged under power. -

Page 25: Sensor Supply Concepts

Series 655 INSTALLATION 4.4.2 Sensor supply concepts This valve offers 3 alternative concepts to supply the sensor(s) with power. This depends on the sensor type and valve version that is used. This valve is available with an optional sensor power supply module (SPS) that converts ±15 VDC from the 24 VDC. - Page 26 Low range sensor may be con- nected to sensor 1 or sensor 2 input. Do configuration accordingly • VAT fuse recommendation: (a) 7 AF • Use shielded sensor cable(s). Keep cable as short as possible, but locate it away from noise sources.

- Page 27 Low range sensor may be connected to sensor 1 or sensor 2 input. Do configuration accordingly. • VAT fuse recommendation: (a) 5 AF • Use shielded sensor cable(s). Keep cable as short as possible, but locate it away from noise sources. •...

- Page 28 Low range sensor may be connected to sensor 1 or sensor 2 input. Do configuration accordingly. • VAT fuse recommendation: (a) 5 AF • Use shielded sensor cable(s). Keep cable as short as possible, but locate it away from noise sources. •...

- Page 29 Low range sensor may be connected to sensor 1 or sensor 2 input. Do configuration accordingly. • VAT fuse recommendation: (a) 5 AF • Use shielded sensor cable(s). Keep cable as short as possible, but locate it away from noise sources. •...

- Page 30 Low range sensor may be connected to sensor 1 or sensor 2 input. Do configuration accordingly. • VAT fuse recommendation: (a) 7 AF • Use shielded sensor cable(s). Keep cable as short as possible, but locate it away from noise sources. •...

-

Page 31: Digital In- Output And Analogue Output Connections

Series 655 INSTALLATION 4.4.3 Digital in- output and analogue output connections This interface allows for remote operation by means of a command set based on the DeviceNet protocol. In addition there are 2 digital inputs and 2 digital outputs. Digital inputs may be operated either by switches or by voltage sources. - Page 32 INSTALLATION Series 655 4.4.3.2 Power connector: Configuration with voltage source for digital inputs 32/112 Edition 23.09.2019 979645EA...

- Page 33 Series 655 INSTALLATION 4.4.3.3 Digital inputs Function Description This function will close the valve. • The input has priority over the remote interface • The input can be inverted INTERLOCK • CLOSE The input can be switched off • The function can be set to function INTERLOCK OPEN •...

-

Page 34: Devicenet® Interface Connection

INSTALLATION Series 655 4.4.4 DeviceNet® interface connection Connector type: Micro-style male (5 pin), connector is shown on panel refer to chapter «Installation into the system». At valve controller DeviceNet® cable Name Wire color Description Drain Bare Shield DeviceNet® power supply + Black DeviceNet®... -

Page 35: Initial Operation

Series 655 INSTALLATION Initial operation To enable the valve cluster for pressure control setup steps 1 to 6 must be performed. In case position control is required only it’s sufficient to perform steps 1 to 3. Setup step Description Turn on external + 24VDC power supply (and external ±15 VDC for sensor power supply if required). -

Page 36: Valve Configuration

INSTALLATION Series 655 Valve configuration Basic valve configuration must be adapted according to application needs. Definition of valve plate position in case of: • After power up, default is ‘close‘. • Power failure, default is ‘not defined‘. Only for versions that have Power Fail Option equipped [655 . -

Page 37: Power Failure Option

Series 655 INSTALLATION 4.6.2 Power Failure Option These settings define what the valve is doing in case the power fails. Parameter Description Enable ‘True’ enables the power fail reaction, in case of ‘False’ there is no reaction on a power fail State Current power fail state Functionality... -

Page 38: Sensor Configuration

INSTALLATION Series 655 Sensor configuration 4.7.1 Sensor configuration It’s important to do proper sensor configuration. The valve internally calculates in absolute values, so the valve has to know what sensors are connected. Parameter Description Available Set to ‘True’ if a sensor is connected Enable Set to ‘True’... -

Page 39: Sensor Crossover (2 Sensor Operation Mode)

Series 655 INSTALLATION 4.7.2 Sensor crossover (2 sensor operation mode) When two sensors are used for pressure control the crossover handles the two pressure signals to building one system pressure (Actual Pressure). Parameter Description Crossover Mode Crossover between 2 sensors (see below) Threshold High [SFS low sensor] Defines the crossover area (see below) Threshold Low [SFS low sensor]... -

Page 40: Zero Adjust

INSTALLATION Series 655 4.7.3 Zero adjust Zero Adjust allows for the compensation of the sensor offset voltage. When Zero Adjust is performed the current value at the sensor input is equated to Zero.Adjust Target Pressure. In case of a 2 sensor system both sensor inputs will be adjusted. Note: A maximum offset voltage of +/- 1.4 V can be compensated. -

Page 41: Pressure Control Configuration

Series 655 INSTALLATION pressure reading is the result. Pressure control configuration The valve has four identical pressure controller units. Controller Selector defines which unit is used for the pressure control. Most applications do not need more than one controller units. But if the result of the pressure control does not meet the expectations, the different controller units can be an option for optimization: With the four controller units it’s possible to use an own controller unit for a specific pressure working point. -

Page 42: Control Algorithm

INSTALLATION Series 655 4.8.1 Control Algorithm Algorithm Description Adaptive This is the most dynamic control algorithm. Before using adaptive control algorithm, a special procedure called “learn” must be executed first (see chapter below). The valve will observe the behavior of the vacuum system by moving the valve to different positions. -

Page 43: Choose Correct Control Algorithm

Series 655 INSTALLATION 4.8.2 Choose correct control algorithm Select the configuration what your application needs. Constant gas flow available Constant gas flow System Configuration not available Tv*<= 500 sec Tv* > 500 sec Downstream Process Adaptive pressure chamber Fixed pressure controller controller Control valve... -

Page 44: Learn (Adaptive Control Algorithm)

INSTALLATION Series 655 4.8.3 Learn (adaptive control algorithm) LEARN adapts the PID controller of the valve to the vacuum system and its operating conditions. LEARN must be executed only once during system setup. The LEARN routine determines the characteristic of the vacuum system. - Page 45 Series 655 INSTALLATION Parameter Description Bank Selection Select one of four learn bank to place the result of the learn procedure. Important: It’s important that after the learn pressure controller select this learn bank! Pressure Limit [SFS] Set learn limit pressure (to which pressure the learn shall be executed). The value is related to the sensor full scale of high sensor.

- Page 46 INSTALLATION Series 655 Gasflow calculation for LEARN: Do not apply a different gasflow for learn than determined below. Otherwise pressure control performance may be insufficient. Required pressure / flow regime must be known to calculate the most suitable learn gas flow for a specific application. 1.

-

Page 47: Pressure Ramp

Series 655 INSTALLATION 4.8.4 Pressure ramp Basically, the pressure ramp is used to limit the rate of pressure change. It can also be used to minimize over- / undershoot of pressure. Actual Pressure Pressure Controller Target Pressure Target Pressure Used Ramp Target Pressure without... - Page 48 INSTALLATION Series 655 4.8.4.1 Pressure ramp configuration Time Mode (Ramp Mode = Time) Slope Mode (Ramp Mode = Slope) The time within Target Pressure Used (ramp) reaches a After setting a new Target Pressure, Target Pressure new Target Pressure is defined in parameter value Used will converge the Target Pressure in the slope Ramp Time.

-

Page 49: Tuning Of Control Performance

Series 655 INSTALLATION 4.8.5 Tuning of control performance • Tuning of pressure control performance with adaptive control, refer to chapter: Tuning of control performance with adaptive pressure controller • Tuning of pressure control performance with PI control, refer to chapter: Tuning of control performance with fixed PI pressure controller •... - Page 50 INSTALLATION Series 655 Gain factor adjustment The gain factor effects: Stability, Response time Adjustment range is from 0.0001 to 7.5. - Higher gain results in: faster response / higher over- / undershoot of pressure - Lower gain results in: slower response/ lower over- / undershoot of pressure Adjustment procedure: 1.

- Page 51 Series 655 INSTALLATION Setpoint ramp adjustment Setpoint ramp effects: Undershoot of pressure, Response time Adjustment range for Setpoint Ramp is from 0 to 10 s. This parameter defines the time that is used to decrease / raise pressure between 2 setpoints. Especially in pressure decrease situations at low flows pressure response can be improved much by adapting setpoint ramp time.

- Page 52 Pressure / flow / gas conditions to be controlled • Chamber volume • Pumping speed (l/s) and pump type (e.g. turbo pump) • System description • Problem description Send diagnostic file with and all required information to tuning-support@vat.ch 52/112 Edition 23.09.2019 979645EA...

- Page 53 Series 655 INSTALLATION 4.8.5.2 Tuning of control performance with fixed PI pressure controller Optimizing P gain and I gain This valve may be used for downstream or upstream pressure control depending on configuration. The PI parameters of the pressure controller require correct adjustment. These parameters must be set once during system setup and are stored in the device memory which is power fail save.

- Page 54 INSTALLATION Series 655 Optimizing P gain While optimizing P gain, the gas flow determined above has to be constant all the time. Start optimization with P gain set to 1.0 and I gain set to 0.0. Set chamber pressure to SP2, wait until the pressure is stable. Set pressure to SP1. If the transition from SP2 to SP1 results in a significant pressure over shoot or even does not stabilize at all, the P gain is too high.

- Page 55 Pressure / flow / gas conditions to be controlled • Chamber volume • Pumping speed (l/s) and pump type (e.g. turbo pump) • System description • Problem description Send diagnostic file with and all required information to tuning-support@vat.ch 979645EA Edition 23.09.2019 55/112...

- Page 56 The VAT soft pump controller requires a pump down time shorter than 10 sec. for good control results. If the required pump down time is longer than 10 sec., the pump down curve has to be partitioned into sections shorter than 10 sec.

- Page 57 Series 655 INSTALLATION Optimizing P gain WE start by setting the P gain to 1.0 as a trial value and adjust according to the response. The pump down routine has to be controlled as follows: Move control valve into close position Start pump down by opening the pump isolation valve or starting the pump and sending the first pressure set point to the valve controller.

- Page 58 Pressure / flow / gas conditions to be controlled • Chamber volume • Pumping speed (l/s) and pump type (e.g. turbo pump) • System description • Problem description Send diagnostic file with and all required information to tuning-support@vat.ch 58/112 Edition 23.09.2019 979645EA...

-

Page 59: Interface Configuration (Devicenet®)

® VAT offers valve-related but not general DeviceNet support. Contact us under: devicenet- support@vat.ch 1. The node number is the device address and can be selected by two rotary switches which are on the panel. -

Page 60: Devicenet Interface

INSTALLATION Series 655 4.10 DeviceNet interface 4.10.1 Introduction The following Object Modeling related terms are used when describing services and protocol: Object – An abstract representation of a particular component within a product. Class – A set of objects that all represent the same kind of system component. A class is a generalization of an object. -

Page 61: Messaging Format

Series 655 INSTALLATION 4.10.2 Messaging Format 4.10.2.1 Explicit Messaging Connections Explicit Messaging Connections, (see figure below) provide generic, multi-purpose communication paths between two devices. An Explicit Message consists of a Connection ID and associated messaging protocol information. Explicit messaging connections utilize a direct request / response format which allow you to access any attribute data. Explicit messaging is typically used for the setup, configuration, and calibration of your device. -

Page 62: Objects

Centralizes application object state definitions and related status S-Device Supervisor information S-Analog Sensor Models the acquisition of a reading from a physical sensor in a device Models a closed-loop control system within a device S-Single Stage Controller Pressure Controller VAT specific attributes 62/112 Edition 23.09.2019 979645EA... -

Page 63: Identity Object (Class Id 1)

Series 655 INSTALLATION 4.10.4 Identity Object (Class ID 1) The Identity Object provides general information about the device Service Service Service Code Class ID Instance ID Attribute ID data length data field Command (number of bytes) Description RESET ® 0 = This command resets the DeviceNet interface. - Page 64 INSTALLATION Series 655 4.10.5.1 Assemblies Input Number Composition Integer Float Start Length Total Start Length Total EXCEPTION STATUS PRESSURE (default) POSITION EXCEPTION STATUS PRESSURE SETPOINT EXCEPTION STATUS PRESSURE SETPOINT POSITION EXCEPTION STATUS EXCEPTION DETAIL ALARM EXCEPTION DETAIL WARNING EXCEPTION STATUS PRESSURE POSITION VALVE CLOSED / OPEN CHECK...

-

Page 65: Connection Object (Class Id 5)

Series 655 INSTALLATION 4.10.6 Connection Object (Class ID 5) Manage the characteristics of a communication connection Service Service Service Code Class ID Instance ID Attribute ID data length data field Command (number of bytes) Description POLL OUTPUT output assembly object number (7,8,102) Contains the instance number of the assembly used by the poll connection to send data. -

Page 66: S-Device Supervisor Object (Class Id 48)

INSTALLATION Series 655 4.10.8 S-Device Supervisor Object (Class ID 48) Centralizes application object state definitions and related status information Service Service Service Code Class ID Instance ID Attribute ID data length data field Command (number of bytes) Description self test idle self test exception executing... - Page 67 Series 655 INSTALLATION Service Service Service Code Class ID Instance ID Attribute ID data length Command data field (number of bytes) Description 13 Alarm See below 14 Warning Table with EXCEPTION DETAIL ALARM resp. EXCEPTION DETAIL WARNING bits. Data Component Bit 7 Bit 6 Bit 5...

-

Page 68: S-Analog Sensor Object (Class Id 49)

INSTALLATION Series 655 Service Service Service Code Class ID Instance ID Attribute ID data length data field Command (number of bytes) Description 3,11 X,XY X: Index (3 byte, range 000 .. 103, ASCII coded) Y: Data (8 byte) UPLOAD This command loads the learn data sets from the valve up to the host. LEARN DATA There are a total number of 104 data sets which need to be uploaded separately. - Page 69 Series 655 INSTALLATION Service Service Service Code Class ID Instance ID Attribute ID data length data field Command (number of bytes) Description 1 Pressure 4 float 3 Position Gain, max. value is 3.2767, data type is floating point This command selects the gain for PRESSURE/POSITION and allows for scaling. Default value is 1.0 GAIN Example:...

-

Page 70: S-Single Stage Controller Object (Class Id 51)

INSTALLATION Series 655 4.10.10 S-Single Stage Controller Object (Class ID 51) Models a closed-loop control system within a device Service Service Service Code Class ID Instance ID Attribute ID data length data field Command (number of bytes) Description SETPOINT TYPE instance 1 - pressure control (Single Stage Controller Instance) Instance 2 - position control... - Page 71 Series 655 INSTALLATION Service Service Service Code Class ID Instance ID Attribute ID data length data field Command (number of bytes) Description ADAPTIVE CONTROL 0 = 0, 1 = 0.02, 2 = 0.04, 3 = 0.06, 4 = 0.08, 5 = 0.10, 6 = 0.15 SENSOR DELAY 7 = 0.20, 8 = 0.25, 9 = 0.30, 10 = 0.35, 11 = 0.4, 12 = 0.5, 13 = 0.6 14 = 0.8, 15 = 1.0...

-

Page 72: Pressure Controller Object (Class Id 100)

INSTALLATION Series 655 4.10.11 Pressure Controller Object (Class ID 100) VAT specific attributes Service Service Service Code Class ID Instance ID Attribute ID data length data field Command (number of bytes) Description This command returns the device status. 1 = synchronization, 2 = POSITION CONTROL, 3 = CLOSED... - Page 73 Series 655 INSTALLATION Service Service Command Service Code Class ID Instance ID Attribute ID data length data field (number of bytes) 2 integer 4 float SENSOR 1 READING Nominal range is 0 … 10’000 but it may be scaled. Refer also to command GAIN and picture on the following page for details. 2 integer 4 float SENSOR 2 READING...

-

Page 74: Operation

OPERATION Series 655 Operation WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. WARNING Valve opening Risk of serious injury. Human body parts must be kept out of the valve opening and away from moving parts. Do not connect the controller to power before the valve is installed complete into the system. -

Page 75: Local Operation

Series 655 OPERATION 5.1.2 Local operation Local operation means that the valve is operated via the service port using a computer. You can use our software 'Control Performance Analyzer' for Local operation, which is integrated in the controller. The software is beneficial especially for setup, testing and maintenance. How to start: 1. -

Page 76: Close Valve

OPERATION Series 655 Close valve Local operation: CPA Remote operation: Refer to chapter ‘Device Net interface’ Explicit: • Set EXECUTING in S-Device Supervisor (if not already done) • Set CONTROL MODE of active S-Single Stage Controller to ‘Close’ • See SETPOINT TYPE for active S-Single Stage Controller Push button Cyclic:... -

Page 77: Display Information

Series 655 OPERATION Display information There is a 4 digit display located on the controller. It displays configuration, status and position information. For details refer to following tables. 5.6.1 Power up Description Digit 1 Digit 2 Digit 3 Digit 4 ●... -

Page 78: Operation

OPERATION Series 655 5.6.2 Operation Control Mode Digit 1 Digit 2 Digit 3 Digit 4 Init (start up) Init (start up, leak tight) Close Open C, 0…100 Pressure control valve position = closed, leak tight Position control = minimal conductance = maximum opened Interlock Valve closed or open by digital input... -

Page 79: Operation During Power Up

Refer also to chapter: «Power Failure Option». Provide that battery pack of the VAT controller is charged. Charging time after power up is 2 minutes max.. All settings are stored in a power fail save memory. -

Page 80: Operation Under Increased Temperature

OPERATION Series 655 5.10 Operation under increased temperature CAUTION Hot valve Heated valve may result in minor or moderate injury. Do not touch valve and heating device during operation. Once heating is switched off (valve and system) await until the valve is cooled down complete before doing any work. This valve may be operated in the temperature range mentioned in chapter «Technical data». -

Page 81: Trouble Shooting

• Check power supply 1 2 Motion controller: Internal voltage error • Check for a heat accumulation 1 3 Motion controller: Internal error temperature Contact vat support • Axis inverted 1 4 Motion controller: Unexpected behavior • Encoder not connected •... - Page 82 • Check Parameter “Isolation Position [r]” 2 0 Break slippery detected Replace actuator SFV: Motion controller failure in master-slave Contact vat support communication 4 0 Compressed air error Check compressed air Check if power supply is ok and is able to deliver needed...

-

Page 83: Maintenance

Before carrying out any maintenance, please contact VAT. It has to be individually decided whether the maintenance can be performed by the customer or has to be carried out by VAT. Please write down the fabrication number of the valve before contact VAT. Refer to chapter «Identification of product»... -

Page 84: Maintenance Procedures

In this case grease will separate to PTFE and oil. The oil may flow and contaminate the valve parts. VAT can give the following recommendations for preventive maintenance: heated ≤ 80 °C Replacement of unheated heated >... -

Page 85: Replacement Of Isolation Seals And Cleaning

Series 655 MAINTENANCE 7.2.1 Replacement of isolation seals and cleaning 7.2.1.1 Required tools • • Allen Wrench 5 mm Maintenance-Tool (813330) • • O-ring removal tool (see Protection cover (833841) chapter: Accessories) • Clean room wiper • Clean room gloves •... - Page 86 MAINTENANCE Series 655 Description Required tool Loosen the 4 bonnet Allen wrench 5mm screws Remove the bonnet Take care to valve body and sealing surface Protection cover Place the protection cover at valve body. 10. Fasten the screw on the left by hand 11.

- Page 87 Series 655 MAINTENANCE Description Required tool 13. Loosen the gate fixation Open end wrench screw 17 mm 14. Remove the gate from valve body 15. Place the gate on a clean surface • 16. Remove gate seal with O-ring removal tool the O-ring removal tool.

- Page 88 MAINTENANCE Series 655 Description Required tool 19. Install the new gate seal at gate (without grease) Not OK, twisted seam of the OK: o-ring seam straight on the side. o-ring. The seam of the o- ring must be straight on the side, not twisted! OK: no visible o-ring seam after pressing o-ring into the Not OK, twisted seam of the...

- Page 89 Series 655 MAINTENANCE Description Required tool 22. Lift up the gate with the maintenance tool until a position is reached on Maintenance-Tool which the gate can be moved in Take care to valve body and sealing surface 23. Move the gate into valve body by hand 24.

- Page 90 MAINTENANCE Series 655 Description Required tool 28. Close the bonnet 29. Fasten the 4 bonnet Allen torque wrench screws with: 6 Nm 30. Connect power cable to controller. 31. Do power ON for the valve The valve move to home position 32.

-

Page 91: Replacement Of Actuator And Actuator Shaft Seal

Series 655 MAINTENANCE 7.2.2 Replacement of actuator and actuator shaft seal 7.2.2.1 Required tools • • Allen Wrench 5 mm Maintenance-Tool (813330) • • Open end wrench 17 Protection cover (833841) • Clean room wiper • O-ring removal tool • Isopropyl alcohol (see chapter: Accessories) - Page 92 MAINTENANCE Series 655 Description Required tool Loosen the 4 bonnet Allen wrench 5mm screws Remove the bonnet Take care to valve body and sealing surface Protection cover Place the protection cover at valve body. 10. Fasten the screw on the left by hand 11.

- Page 93 Series 655 MAINTENANCE Description Required tool 13. Loosen the gate fixation Open end wrench screw 17 mm 14. Remove the gate from valve body 15. Place the gate on a clean surface 16. Place the Maintenance- Tool at actuator shaft The Maintenance- Maintenance-Tool Tool restrain the actuator...

- Page 94 MAINTENANCE Series 655 Description Required tool The the actuator is a heavy component. VAT do recommend two person for the next 2 steps. 17. The 1 person dismounts the 4 actutor screws. The 2 person holds the Maintenance-Tool at actuator shaft, see...

- Page 95 Series 655 MAINTENANCE Description Required tool 20. Remove inner and outer O-ring removal tool O-ring 21. Clean both rotary O-ring grooves Isopropyl alcohol Clean room wiper 22. Lubricate the new lower O-ring with 0.1 ml vacuum grease. Rub the O-Ring in with grease and assemble it to the Vacuum grease inner groove (S1).

- Page 96 MAINTENANCE Series 655 Description Required tool 25. Lubricate the rotary feed through shaft of actuator Vacuum grease around 360° with 0.1 ml vacuum grease 26. Distribute the grease with gloves around 360° 27. Reassemble the Allen wrench 5mm actuator at valve body 28.

- Page 97 Series 655 MAINTENANCE Description Required tool 31. Press up the shaft to the maximum height 32. Clean the shaft on remaining areas • Isopropyl alcohol • Check Clean room wiper cleanliness with high bright LED lamp Not OK, grease is visible OK, whole shaft is cleaned 33.

- Page 98 MAINTENANCE Series 655 Description Required tool 36. Lift up the gate with the maintenance tool until a position is reached on Maintenance-Tool which the gate can be moved in Take care to valve body and sealing surface 37. Move the gate into valve body by hand 38.

- Page 99 Series 655 MAINTENANCE Description Required tool 41. Fasten the 4 bonnet Allen torque wrench screws with: 6 Nm 42. Connect power cable to controller. 43. Do power ON for the valve The valve move to home position 44. Enable the PFO in menu: Valve >...

-

Page 100: Replacement Of Option Board

MAINTENANCE Series 655 7.2.3 Replacement of Option board NOTICE Electrostatic discharge Electronic components could be damage. All work on the control and actuating unit has to be done under ESD protected environment to prevent electronic components from damage. NOTICE Burned connector pins (spark) Connector pins or electronic parts could damage, if plugged and unplugged under power. - Page 101 Series 655 MAINTENANCE 7.2.3.1 Durability of power fail battery The curves in the graph show the estimated life of Ultra Cap PFO in the worst condition (max. sensor load = 1 A, valve heating temperature = 150 °C). If the SPS is not fully loaded (< 1 A) or heating temperature of valve body is lower than 150 °C, the corresponding life time curve will be somewhere in between the upper and the lower curve.

-

Page 102: Repairs

Series 655 Repairs Repairs may only be carried out by the VAT service staff. In exceptional cases, the customer is allowed to carry out the repairs, but only with the prior consent of VAT. Please contact one of our service centers. You will find the addresses on our website www.vatvalve.com. -

Page 103: Dismounting And Storage

Series 655 DISMOUNTING AND STORAGE Dismounting and Storage WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the described work. Dismounting NOTICE Contamination Gate and other parts of the valve must be protected from contamination. Always wear clean room gloves when handling the valve. -

Page 104: Storage

DISMOUNTING AND STORAGE Series 655 Storage NOTICE Wrong storage Inappropriate temperatures and humidity may cause damage to the product. Valve must be stored at: – relative humidity between 10% and 70% – temperature between +10 °C and +50 °C – non-condensing environment NOTICE Inappropriate packaging Product may get damaged if inappropriate packaging material is used. -

Page 105: Packaging And Transport

If products are radioactively contaminated, the VAT form «Contamination and Radiation Report» must be filled out. Please contact VAT in advance. • If products are sent to VAT in contaminated condition, VAT will carry out the decontaminating procedure at the customer's expense. 979645EA Edition 23.09.2019... -

Page 106: Packaging

Valve mechanism may get damaged if valve is in open position. Make sure that the valve is closed. Cover all valve openings with a protective foil. Pack valve appropriately, by using the original packaging material. VAT disclaims any liability for damages resulting from inappropriate packaging. 10.2 Transport NOTICE Inappropriate packaging Product may get damaged if inappropriate packaging material is used. -

Page 107: Disposal

Series 655 DISPOSAL Disposal Observe the local regulations for disposal WARNING Harmful substances Environmental pollution. Discard products and parts according to the local regulations. WARNING Unqualified personnel Inappropriate handling may cause serious injury or property damage. Only qualified personnel are allowed to carry out the disposal. CAUTION Risk of damage Indicates a hazardous situation which, if not avoided, may result in minor or moderate... -

Page 108: Spare Parts

«Identification of product». This is to ensure that the appropriate spare parts are supplied. • VAT makes a difference between spare parts that may be replaced by the customer and those that need to be replaced by the VAT service staff. •... -

Page 109: Valve Unit With Seals And Grease

Other on request N-5100-226 Viton Rotary feedthrough vacuum atmosphere Other on request Actuator 206792 (2ml) Syringe of vacuum grease 206793 (5ml) Use only spare parts manufactured by VAT to assure safe and reliable operation All “ 979645EA Edition 23.09.2019 109/112... - Page 110 Part number 24 VDC power supply unit 369877 (input: 100 – 240 VAC) Adapter cable for power supply unit 735567 From VAT: 809474 Service cable (USB A–B male-male) Customer side (PC to valve Service connector) Example by: http://www.datapro.net/products/usb-2-0-a- to-b-device-cable.html O-ring removal tool 234859 12.1.3.1...

- Page 111 Series 655 APPENDIX Appendix 979645EA Edition 23.09.2019 111/112...

- Page 112 Series 655 This page left blank intentionally. 112/112 Edition 23.09.2019 979645EA...

Need help?

Do you have a question about the 655 Series and is the answer not in the manual?

Questions and answers