Table of Contents

Advertisement

Quick Links

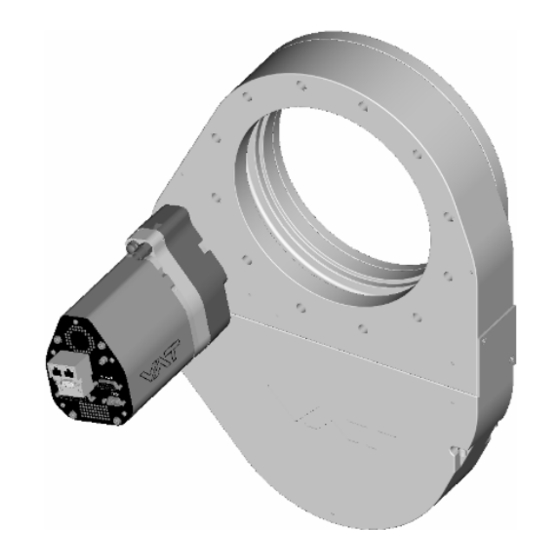

Pendulum control & isolation valve

with RS485 interface

with valve cluster functionality

This manual is valid for the valve ordering number(s):

650 . . - . . TJ - . . . .

650 . . - . . TK - . . . .

650 . . - . . VJ - . . . .

650 . . - . . VK - . . . .

650 . . - . . UJ - . . . .

650 . . - . . UK - . . . .

650 . . - . . WJ - . . . .

650 . . - . . WK - . . . .

650 . . - . . GS - . . . .

650 . . - . . HS - . . . .

SPS = Sensor Power Supply

Master configured with firmware

Slave configured with firmware

The fabrication number is indicated on each product as per the label

below (or similar):

made in Switzerland

Fabrication No.:

patented

650 . . – . . . . – . . . . / . . . .

A – . . . . . .

Explanation of symbols:

Read declaration carefully before you start any other

action!

Attention!

Product is in conformity with EC guidelines!

Disconnect electrical power and compressed air

lines. Do not touch parts under voltage!

Read these «Installation, Operating & Maintenance Instructions» and the enclosed «General

Safety Instructions» carefully before you start any other action!

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email

Installation, Operating & Maintenance Instructions

Series 650 DN 100-250 (I.D. 4" - 10"), RS485

(Master / 1 sensor input)

(Master / 2 sensor inputs)

(Master / 1 sensor input / ±15V SPS)

(Master / 2 sensor inputs / ±15V SPS)

(Master / 1 sensor input / PFO)

(Master / 2 sensor inputs / PFO)

(Master / 1 sensor input / ±15V SPS / PFO)

(Master / 2 sensor inputs / ±15V SPS / PFO)

(Slave)

(Slave / PFO)

PFO = Power Failure Option

650C.1E.06

650C.1E.06

. .

Fabrication number

reception@vat.ch www.vatvalve.com

sample picture

Keep body parts and objects away from the valve

opening!

Hot surfaces; do not touch!

Loaded springs and/or air cushions are potential

hazards!

Wear gloves!

271149EA

2007-06-12

1/77

Advertisement

Table of Contents

Need help?

Do you have a question about the 650 TJ Series and is the answer not in the manual?

Questions and answers