Comeup CWG-30375 Instruction Manual

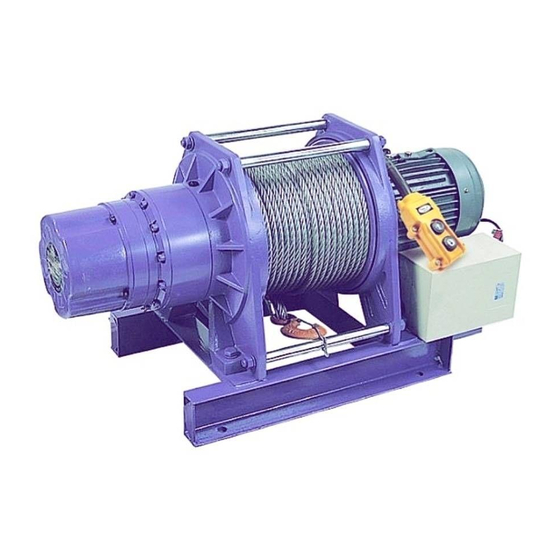

Electric winch

Hide thumbs

Also See for CWG-30375:

- Instruction manual (25 pages) ,

- Manual (4 pages) ,

- Quick start manual (2 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Comeup CWG-30375

-

Page 2: Electric Winch

Electric Winch Thank you for purchasing a Winch. This manual covers operation and maintenance of the winch. All information in this publication is based on the latest production information available at the time of printing. General Safety Precautions Winch is designed to give safe and dependable service if operated according to the instructions. -

Page 3: Environment Precautions

Environment Precautions DANGER ●The following environmental conditions may result in the possible causes of winch trouble. ●Low temperature ●In a organic ℃ below -10 ,high chemistry or temperature explosive powder ℃ r above 40 condition humidity above 90% conditions ※ ※... - Page 4 Length 50Hz 60Hz 50Hz 60Hz Diameter Diameter 13 ~ 20.6 15.6 ~ 24.7 3.8 x 4 CWG-30375 48:1 8.5 ~ 13.5 10.2 ~ 16.2 2.2 x 6 14 ~ 25 16.8 ~ 30 5.5 x 4 CWG-30565 50:1 1,100 1,000 3 Phase 9.2 ~ 16.4...

-

Page 5: Performance Data

II. Performance Data 2-1. CWG-30375 / 30565 Model CWG-30375 CWG-30565 Motor kw x p 3.8 X 4 2.2 X 6 5.5 X 4 3.8 X 6 10.0 12.0 Wire Size Breaking Rope 5,020 6,680 50Hz 1,420 1,960 Rated Load (kg) - Page 6 2-2. CWG-30750 / 31500 / 34000 Model CWG-30750 CWG-31500 CWG-34000 Motor kw x p 5.5 X 4 3.8 X 6 5.5 X 6 3.8 X 8 11 X 4 7.5 X 6 22.4 Wire Size Breaking Rope 11,900 15,000 23,300 50Hz 4,000 4,800...

- Page 7 Ⅲ Ⅲ Ⅲ Ⅲ Winching Principles 3-1.Load Rated Load and speed vary according to how much wire rope is on the drum. The first layer of rope on the drum delivers the slowest speed and the maximum load. A full drum delivers the maximum speed and the minimum load.

- Page 8 Therefore the correct distance between center of drum and of should be derived as follow. Fleet angle of 1.5∘is the equivalents of approximately 19 cm of lead for each centimeter of overall drum width. Model Drum Width (mm) Fleet Angle Correct Distance (m) CWG-30375 CWG-30565 CWG-30750 1.5° CWG-31500 CWG-34000...

-

Page 9: Lubricant Specifications

3-6.Wire Rope Selection in Vertical Lifting Recommended Wire Rope Safety Factor Model Dia. mm Length ( m ) Const. Breaking Load ( kg ) 50Hz 60Hz CWG-30375 6 x 24 4,640 CWG-30565 6 x 24 6,680 CWG-30750 6 x 24 11,900 CWG-31500... - Page 10 Ⅳ Ⅳ Ⅳ Ⅳ Maintenance and Inspection The specified person performs the checking of winch. Divide the checking into daily checking and periodic checking The checking items, checking method and checking reference in daily checking and periodic checking are to be in accordance with checking reference 1 & 2. 4-1.Checking Reference1 Classification of checks Checking Item...

- Page 11 4-2.Checking Reference Classification of Checks Periodical Checking Daily Checking Item Checking Method Three Reference month month year Breaking of base Less than ◎ Visual wire Decreasing of 7% of normal ◎ Visual diameter diameter max Kink phenomena To be free ◎...

-

Page 12: Ⅴ Ⅴ Ⅴ Ⅴ . Trouble Shooting

Brake disc wear down Replace brake disc Crossed rotation Wrong connection Connect the wirings correctly Grease leakage Damaged oil seal Replace oil seal 5-1.Standard value for brake disc Model CWG-30375 CWG-30565 AC Voltage 220V 380V 415V 440V 220V 380V 415V 440V 25Ω... -

Page 13: Wiring Diagram

Ⅵ Ⅵ Ⅵ Ⅵ . Wiring Diagram... - Page 14 Ⅶ Ⅶ Ⅶ Ⅶ . Replacement parts List CWG-30375 ► Ver01...

- Page 15 CWG-30565 ► Ver00...

- Page 16 CWG-30750 ► Ver01...

- Page 17 CWG-31500 ► Ver00...

- Page 18 CWG-34000 ► Ver00...

- Page 20 CWG02-2008-02-2000...

Need help?

Do you have a question about the CWG-30375 and is the answer not in the manual?

Questions and answers