Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Integra MINI 96

- Page 1 MINI 96 Operating instructions 129950_V00...

- Page 2 Declaration of conformity INTEGRA Biosciences AG – 7205 Zizers, Switzerland declares on its own responsibility that the devices Description Models MINI 96 4801, 4802, 4803, 4804 comply with: EU Standards Scope EN 9001:2015 Quality Management EN 61010-1:2010 Safety general laboratory equipment...

- Page 3 MINI 96– Declaration of conformity USA Standards Scope UL 61010-1:2012 Safety general laboratory equipment UL 61010-2-081:2015 Safety automatic laboratory equipment USA Regulations Scope 47 CFR Part 15 (FCC) Electromagnetic compatibility (EMC) 17 CFR Parts 240 & 249b Dodd frank “Conflict minerals”...

-

Page 4: Table Of Contents

3.2 Setting up and moving of the device ..........12 3.3 Installation of stages...............13 3.3.1 Base stage ................13 3.3.2 Second stage ..............13 3.3.3 Two position stage ..............13 3.4 Settings - adapt your MINI 96............14 3.4.1 Position settings..............14 3.4.2 Preferences.................15 3.4.3 Calibration & Services............17 3.4.4 Communications ..............18 3.4.5 Device Information ..............18... - Page 5 MINI 96 – Operating instructions V00 Chapter 4 Operation 4.1 Turn on/off the device..............20 4.2 Attaching and removing GripTips ...........20 4.2.1 Loading tips from a rack with 96 tips........20 4.2.2 Loading tips from a rack with 384 tips.........20 4.2.3 Partially tips loading ............21 4.2.4 Ejecting used GripTips............22...

- Page 6 MINI 96 – Operating instructions V00 Chapter 6 Maintenance 6.1 Cleaning ..................45 6.2 Decontamination ................45 6.2.1 Two position stage ..............45 6.3 Leak test ..................46 6.4 Servicing..................47 6.4.1 Changing O-rings of tip fittings..........47 6.5 Calibration ..................48 6.6 Equipment disposal ................48 Chapter 7 Technical Data 7.1 Environmental conditions ...............49...

-

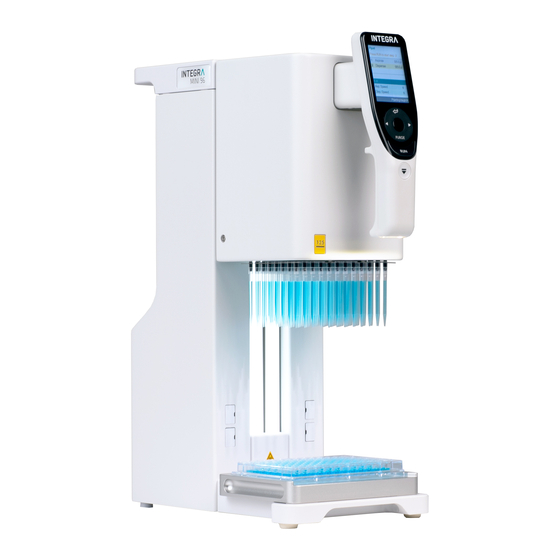

Page 7: Chapter 1 Introduction

0.5 µl to 1250 µl using GripTip pipette tips. MINI 96 is used like a hand held pipette. The movement and positioning of the pipette is supported by a servo assisted steering mechanism which allows fast, precise and stress free multichannel pipetting. -

Page 8: Safety Notes

MINI 96 – Operating instructions V00 Introduction Safety notes MINI 96 complies to the recognized safety regulations and is safe to operate. MINI 96 can only be operated when in perfect condition and while observing these operating instructions. The device may be associated with residual risks if it is used or operated improperly by untrained personnel. -

Page 9: Description Of The Device

MINI 96 – Operating instructions V00 Description of the device Description of the device Scope of delivery • MINI 96 device • Base stage • Second stage • Power cable • Mains adapter • Replacement O-rings and removal tool (for 300 µl and 1250 µl instruments) •... -

Page 10: Mini 96 Control Unit

MINI 96 – Operating instructions V00 Description of the device 2.2.2 MINI 96 control unit 13 Display 14 Back button, to navigate backward 15 Touch wheel, spin to scroll and move the cursor 16 OK button, to make a selection... -

Page 11: Touch Wheel

MINI 96 – Operating instructions V00 Description of the device 2.2.4 Touch wheel The Touch wheel is fully operational with only one hand. Rotational finger movements translate into up and down cursor movement on the display. The Touch wheel is fully functional with the use of latex gloves. -

Page 12: Chapter 3 Installation

Installation Installation Operating environment MINI 96 has been designed for use in a laboratory. It shall be operated in a dry and dust- free location with a temperature of 5–40 °C and a maximal (non-condensing) relative humidity of 80 %. -

Page 13: Installation Of Stages

MINI 96 – Operating instructions V00 Installation Installation of stages 3.3.1 Base stage Put the Base stage (2) on the two Deck pins. It can be placed on either side. The graphic “96” or “384” must match the tip rack or well plate pattern. -

Page 14: Settings - Adapt Your Mini 96

Preferences Customizes the system parameters. Calibration / Service Sets calibration and service history options. Communications Enables communication between your MINI 96 and a PC. Device Information View your pipette’s serial number, software version and set a personal ID. Park Head Fixes the pipetting unit for safe shipping. -

Page 15: Preferences

MINI 96 – Operating instructions V00 Installation 3.4.2 Preferences Preferences customizes your system parameters. Use the Touch wheel to select an option and press OK to access. The desired settings are saved directly. Preferences Description Range Deck Bright- Sets brightness of the deck light from off, 1 (weak) to 10 ness (bright). - Page 16 MINI 96 – Operating instructions V00 Installation Pipetting Select an option and press OK. • PURGE Speed: Choose the desired purge speed. 1-10 • BlowIn Delay: Choose a timed delay between the blowout and the blowin at the end of a dispense, if no None/ two step blowout is performed, see “4.3.3 Blowout/...

-

Page 17: Calibration & Services

Range & Services Calibration Allows for re-calibration of MINI 96 to restore accuracy. The calibration factors for Pipet and Repeat type are displayed. To edit the calibration volumes, press . • Target Volume: This is the volume you are interested in using for the calibration. -

Page 18: Communications

MINI 96 – Operating instructions V00 Installation 3.4.4 Communications The latest firmware for MINI 96 can be loaded from a PC via a USB-C to USB communication cable. Communi- Description cations Connect the USB-C cable between MINI 96 and a PC. Press OK to begin bi-directional communication. -

Page 19: Write Protect

MINI 96 – Operating instructions V00 Installation 3.4.8 Write protect Select this option to protect programs and menu options from inadvertent modification. The pipetting programs can still be used. Write Description Range protect Select an option and press OK to switch protection on or /... -

Page 20: Chapter 4 Operation

Use only GripTips in boxes designated for benchtop pipetting systems, see “8 Accessories and consumables” on page 52 that fit to the Base stage and allow supported Griptip loading. To prevent contamination of MINI 96 pipetting unit, it is recommended to use filtered GripTips only. 4.2.1 Loading tips from a rack with 96 tips Insert the Base stage on the Deck (2). -

Page 21: Partially Tips Loading

MINI 96 – Operating instructions V00 Operation 4.2.3 Partially tips loading Partial tip loading requires the optional Two position stage, see 8.1"Accessories" on page 52. Place a rack on either the left or right position, and slide the two position stage to underneath the pipetting unit to correspond to the desired number of columns loaded. -

Page 22: Ejecting Used Griptips

MINI 96 – Operating instructions V00 Operation 4.2.4 Ejecting used GripTips If liquid is in the tips, empty them by pressing PURGE (18). Tips are ejected by pressing the Tip ejector (20). Confirm ejection by pressing the Tip ejector a second time. -

Page 23: Blowout/Blowin Modes

MINI 96 – Operating instructions V00 Operation 4.3.3 Blowout/blowin modes During aspiration, the piston of your electronic pipette moves up (1). During dispensing, the piston returns to the initial position (0). During the last dispense of a program, it automatically moves further down (2) and blows the remaining liquid from the tip (Blowout). -

Page 24: Recommendations For Pipetting

• Calibrate based on fluid type. MINI 96 is tested and calibrated at the factory for use with distilled water at room temperature. It may be necessary to re-calibrate your MINI 96 if the liquid to be used has different physical properties (specific gravity and vapor pressure) than water. -

Page 25: Pipetting Between 96-384 Well Plates

MINI 96 – Operating instructions V00 Operation 4.3.5 Pipetting between 96-384 well plates For fast and simple reformatting between 96 and 384 well microplates insert the Base stage on the Deck (2) with side “96” pointing upwards. Place a 96 well plate on the Base stage and aspirate liquid from the plate. -

Page 26: Pipetting Options And Settings

MINI 96 – Operating instructions V00 Operation Pipetting options and settings 4.4.1 Edit option The Edit option is available for each program. It enables you to access the variables that you can adjust for a program. These variables include Speed, Volume, Pace, Count, Mix Cycles, Rows and Direction. -

Page 27: Speed Selection

MINI 96 – Operating instructions V00 Operation • When in other programs, select the Edit option and press OK. The steps with volumes to be adjusted are displayed. Use the Touch wheel to highlight the desired volume and press Favorites to display the list of favorite volumes. -

Page 28: Custom

MINI 96 – Operating instructions V00 Operation 4.4.4 Custom You can convert any predefined program into a Custom program. After setting up a program with your parameters, use the Touch wheel to select Custom. You are prompted to enter a name. Use the Touch wheel to select characters and press OK. -

Page 29: Troubleshooting/Faq

MINI 96 – Operating instructions V00 Operation Troubleshooting/FAQ Problem Probable cause Remedy Device is drifting up/ Control unit was touched at Do not touch the control unit when down. switch on. switching on the MINI 96. Restart MINI 96 to initiate new homing routine. -

Page 30: Chapter 5 Programs

Programs Programs This chapter describes how to program the MINI 96 in two ways: • Function-based programs: You can select from ten predefined programs that you can quickly and easily edit and execute. They are described in the following sections. -

Page 31: Detailed Description Of Programs

Programs Detailed description of programs MINI 96 offers ten predefined programs. Most liquid handling protocols can be easily accommodated using one or more of these programs. The options and steps of the different programs are described in the following subsections. -

Page 32: Repeat Dispense

MINI 96 – Operating instructions V00 Programs 5.2.2 Repeat dispense Application: This program can be used for fast reagent addition to microplates from one source container. You can dispense a large aspirated volume of liquid in multiple aliquots to multiple targets. - Page 33 MINI 96 – Operating instructions V00 Programs The following parameters can be changed at any time: Options Steps Description Edit Dispense Sets the volume for repetitive dispensing. The aspirated volume is calculated automatically. Pre-Dispense A pre-dispense volume (typically 3-5% of the pipette's maximum volume) can be selected independently to improve accuracy and precision.

-

Page 34: Pipet/Mix

MINI 96 – Operating instructions V00 Programs 5.2.3 Pipet/mix Application: Use this program when mixing is required immediately after transfer of liquid. This program saves a programming step by incorporating the mix option after dispensing. Run steps Operation Aspirate Press and release RUN to initiate the aspiration. -

Page 35: Sample Dilute

MINI 96 – Operating instructions V00 Programs 5.2.4 Sample dilute Application: Accomplish accurate sample dilutions by using diluent to chase small sample volumes from the pipet tips. An air gap keeps liquid separated in the tips and helps to minimize carryover of diluent when aspirating the sample. -

Page 36: Manual Pipet

MINI 96 – Operating instructions V00 Programs 5.2.5 Manual pipet Application: This program can be used when the aspiration volume is not defined or unknown. You have control over the aspiration and dispense steps and can view the display to confirm how much liquid has been aspirated or dispensed. -

Page 37: Reverse Pipet

MINI 96 – Operating instructions V00 Programs 5.2.6 Reverse pipet Application: With this program the aspiration volume is higher than the volume dispensed. It is recommended for liquid transfers of viscous and high vapor pressure liquids. The dispense method prevents introduction of air into the sample because no blowout is made. -

Page 38: Variable Dispense

MINI 96 – Operating instructions V00 Programs 5.2.7 Variable dispense Application: Use this program when differing dispense volumes are required. This program could be used to quickly set up a dilution series in plates or for feeding similar samples to different assay plates where different sample volumes are needed. -

Page 39: Multi Aspirate

MINI 96 – Operating instructions V00 Programs 5.2.8 Multi aspirate Application: This program can be used for a variety of collection applications where the aspiration volume is well known. This program is also suited for supernatant collection in microplates. Run steps... -

Page 40: Sample Dilute/Mix

MINI 96 – Operating instructions V00 Programs 5.2.9 Sample dilute/mix Application: Use this program to perform sample dilutions where mixing of sample and diluent is required. This program could also be used to introduce and mix diluent and sample to the first column of a serial dilution plate. -

Page 41: 5.2.10 Serial Dilution Program

MINI 96 – Operating instructions V00 Programs 5.2.10 Serial dilution program Application: Use this program to perform serial dilutions. The Serial Dilution program enables aspiration of a specific volume followed by a mix sequence and ending with the original aspiration volume in the tips. -

Page 42: Custom Step-Based Program

MINI 96 – Operating instructions V00 Programs Custom step-based program Application: Use the Custom program to create personalized pipetting protocols. Select “Custom Programs” to create a personalized program. Programs can contain up to 98 individual steps based upon the following basic operations: Aspirate, Dispense, Mix, Purge, Prompt, Pipetting Height and Loop. - Page 43 MINI 96 – Operating instructions V00 Programs Step Description Mix NBO Sets the mixing volume and speed without a blowout after the last (No BlowOut) dispense. Residual liquid may remain in the tip, resulting in incomplete mixing and inaccurate and imprecise liquid delivery.

-

Page 44: Modify Existing Programs

MINI 96 – Operating instructions V00 Programs 5.3.2 Modify existing programs At the Custom program display, use the Touch wheel to highlight an existing program. Press Options, use the Touch wheel to select an option (View/Edit, Delete, Copy, Rename) to modify the program and press OK. -

Page 45: Chapter 6 Maintenance

6.2.1 Two position stage The Two position stage can also be cleaned the same way as the MINI 96. However, for a more thorough cleaning or autoclaving, disassemble according to the instructions below: • Unscrew the spring adjustment screw (a) all the way to the upper limit. -

Page 46: Leak Test

MINI 96 – Operating instructions V00 Maintenance Place the disassembled components inside an autoclave pouch. You may autoclave the components at 121°C, 1 bar overpressure for 20 minutes. Reassemble by following these instructions in reverse. If any small parts get lost, a spare parts bag is available, see “8 Accessories and consumables”... -

Page 47: Servicing

“Park Head”, see “3.4.6 Park Head” on page 18. Make sure GripTips have been ejected, clear the Deck and press RUN (to start the park routine. The unit moves to the park position and is anchored on the base with a bolt. Switch off MINI 96 and disconnect it from the electricity mains. -

Page 48: Calibration

Slide a new O-ring over the tip fitting (b). Calibration MINI 96 can be calibrated by adjusting a correction factor in the software. The correction factor is determined by a nominal volume and the measured volume. To assess the accuracy and precision of MINI 96, different methods can be used: •... -

Page 49: Technical Data

MINI 96 – Operating instructions V00 Technical Data Technical Data Environmental conditions Operation Temperature range 5–40°C Humidity range Max. rel. humidity 80 % for temperatures up to 31 °C, decreasing linearly to 50 % rel. humidity at 40 °C. Altitude range <... -

Page 50: Intellectual Property

MINI 96 – Operating instructions V00 Technical Data Intellectual Property The MINI 96 are covered under the following patents: Patent Number Country Title Apply to 7,811,522 Sample Reservoir Kits With Dispos- Reservoirs able Liners D599,031 A Liquid Sample Or Liquid Reagent... -

Page 51: Pipetting Speeds

MINI 96 – Operating instructions V00 Technical Data Pipetting Speeds Pipetting Unit Size Pipetting speed (micro litres per second) Speed 12.5 µl 125 µl 300 µl 1250 µl 12.4 49.6 10.4 24.8 99.3 25.9 61.9 248.2 33.7 80.5 322.7 41.5 99.0... -

Page 52: Accessories And Consumables

MINI 96 – Operating instructions V00 Accessories and consumables Accessories and consumables Accessories Stages and Covers Part No. Two position stage 4850 Spare parts for Two position stage 129935 Magnetic covers 4890 O-rings for tip fittings Part No. O-ring removal tool (for 4803 and 4804) 130-00731-00 300 μl... -

Page 53: Consumables

MINI 96 – Operating instructions V00 Accessories and consumables Consumables GripTips for benchtop pipetting systems are suitable for MINI 96. These GripTips are straightness tested and filled in sturdy racks. • GREEN CHOICE: environmentally friendly refills • LONG: longer design allows easy access into deep laboratory vessels •... - Page 54 MINI 96 – Operating instructions V00 Accessories and consumables GripTips for benchtop pipetting systems: Green 300 µl Part No. 300 µl 5 inserts of 96 tips, non-sterile, GREEN CHOICE 6432 5 racks of 96 tips, non-sterile 6433 5 racks of 96 tips, sterile...

- Page 55 MINI 96 – Operating instructions V00 Accessories and consumables Automation friendly Clear Advantage™ reagent reservoirs Part No. 150 ml 8 reservoir bases, automation friendly (microplate 6301 format), non-sterile 25 lids, sterile, polypropylene 6302 Polystyrene Trial pack (1 base, 1 reservoir and 1 lid), polystyrene,...

- Page 56 MINI 96 – Operating instructions V00 Accessories and consumables Standard footprint polypropylene reagent reservoirs Part No. 96 Well, 300 ml 25 reservoirs per case, pyramid bottom, non-sterile 6351 25 reservoirs per case, pyramid bottom, pre-sterilized 6352 12 Column 25 reservoirs per case, pyramid bottom,...

-

Page 57: Imprint

© 2021 INTEGRA Biosciences AG All rights to this documentation are reserved. In particular the rights of reproduction, processing, translation and the form of presentation lie with INTEGRA Biosciences AG. Neither the complete documentation nor parts thereof may be reproduced in any way, or stored and processed using electronic media or distributed in any other way without the written consent of INTEGRA Biosciences AG.

Need help?

Do you have a question about the MINI 96 and is the answer not in the manual?

Questions and answers