Integra MEDIAJET Operating Instructions Manual

Hide thumbs

Also See for MEDIAJET:

- Operating instructions (4 pages) ,

- Operating instructions (3 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Integra MEDIAJET

- Page 1 MEDIAJET Operating instructions 103950_V09...

- Page 2 Declaration of Conformity INTEGRA Biosciences AG – 7205 Zizers, Switzerland declares on its own responsibility that the devices Description Models MEDIAJET 103005, 103006 MEDIAJET vario 113000, 113001, 113002 comply with: EU Directives (DoW: Date of Withdrawal) Before DoW After DoW...

-

Page 3: Table Of Contents

Chapter 3 Installation 3.1 Unpacking ................... 15 3.2 Preconditions ................15 3.3 Removing and fitting the conversion set of MEDIAJET vario..17 3.4 Assembly..................19 3.5 Biplate option ................21 3.6 Turbo mode option ............... 22 3.7 TUBEFILLER option..............23... - Page 4 MEDIAJET – Operating instructions V09 Chapter 5 Maintenance 5.1 Cleaning ..................48 5.2 UV Lamp exchange..............50 5.3 Leak test..................51 5.4 Servicing..................52 5.5 Fault notifications .................52 5.6 Disposal..................53 Chapter 6 Technical data 6.1 Specification of the device............54 6.2 Petri dish specifications..............55 6.3 Configuration specifications ............56 6.4 Test tube compatibility chart............57...

-

Page 5: Chapter 1 Introduction

This is a general-purpose laboratory instrument. Any use of this instrument in a medical or IVD setting is the sole responsibility of the user. The MEDIAJET is used in laboratories to fill Petri dishes of various sizes, Petri dishes with two compartments or test tubes of various diameters and length. -

Page 6: Symbols Used

MEDIAJET – Operating instructions V09 Introduction Symbols used This operating instruction manual makes specific reference to residual dangers using the symbols shown. 1.3.1 Safety alert symbol SAFETY SIGN This is the general warning sign. It is used to alert the user to potential personal injury hazards. - Page 7 MEDIAJET – Operating instructions V09 Introduction 1.3.4 Warning labels on the device DANGER UV LAMP Do not directly stare into the UV lamp. MOVING PARTS Keep hands out of area of moving parts. ROTATING COG WHEELS Keep hands out of cog wheels, risk to squash your fingers.

-

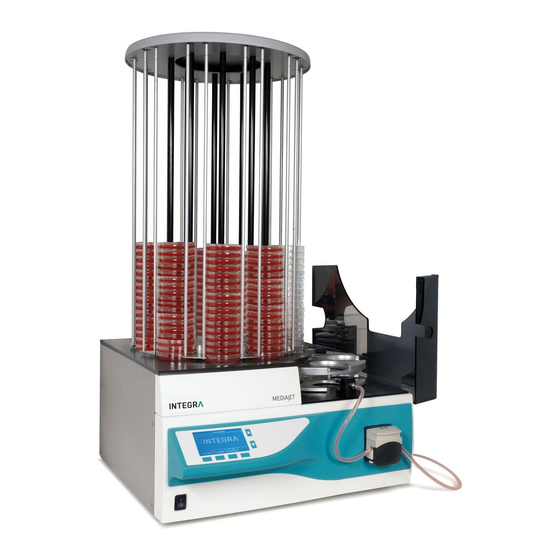

Page 8: Chapter 2 Description Of The Device

Description of the device Description of the device MEDIAJET is a laboratory device designed for the filling of Petri dishes with agar nutrient media. MEDIAJET is available in two different device versions. The standard version is limited to the filling of 90/100mm (nominal size) diameter Petri dishes. - Page 9 21 mm (MEDIAJET vario with biplate option only) (Part No. 113 821) Tubing set, including 1.5 m silicone tubing and filling nozzle (two sets for MEDIAJET vario with biplate option) (Part No. 103 030 or 113 030) Spirit level (Part No.

- Page 10 (Part No. 103 020, 103 021, 113 022, 113 020 or 113 021) 2.1.1 TUBEFILLER option The TUBEFILLER option (Part No. 103 010) converts the MEDIAJET into a test tube filler. Support plate, can accommodate 3 test tube racks. Filling arm, consisting of carrier piece (1), rod (2) and radial arm (3).

-

Page 11: Overview Of Mediajet

MEDIAJET – Operating instructions V09 Description of the device 2.1.2 Turbo mode option The turbo mode option accelerates the filling process by using a second pump head installed. This option requires the turbo mode kit (Part No. 103 036) including: Extension pump head (Part No. -

Page 12: Operating Panel

14 Filling nozzle The filling nozzle is part of the tubing set and establishes contact between the MEDIAJET and the media preparator (MEDIACLAVE). It is positioned correctly in the device by the filling nozzle holder. INTEGRA Biosciences AG... -

Page 13: Mediajet Vario In Detail

MEDIAJET – Operating instructions V09 Description of the device MEDIAJET vario in detail MEDIAJET vario can be adapted to different diameters of Petri dishes, using a conversion set. The different parts of the conversion set are already installed on the device. -

Page 14: Reverse Side And Interfaces

MEDIAJET – Operating instructions V09 Description of the device Reverse side and interfaces Interface Function 26 FOOT- Connection for the foot-switch SWITCH 27 RS232(1) Service connection 28 RS232(2) Connection to an external protocol printer or to MEDIACLAVE 29 INKJET Connection for an inkjet printer... -

Page 15: Chapter 3 Installation

MEDIAJET – Operating instructions V09 Installation Installation Purpose This chapter shows the unpacking and installation of MEDIAJET. Unpacking ASSISTANCE Check the scope of delivery for any transport damage and notify your local INTEGRA Biosciences AG representative (see last page of the operating instructions). - Page 16 MEDIAJET – Operating instructions V09 Installation 3.2.2 Setting up CAUTION The basic device must only be set up on a cleaned, dry and perfectly horizontal surface, capable of supporting a minimum weight of 80 kg. ASSISTANCE Leave sufficient space behind the device to allow easy connection of the mains cable.

-

Page 17: Removing And Fitting The Conversion Set Of Mediajet Vario

MEDIAJET – Operating instructions V09 Installation Removing and fitting the conversion set of MEDIAJET vario The MEDIAJET vario can handle different Petri dish sizes. To adapt the device to the desired Petri dishes, the appropriate conversion set must be mounted. 3.3.1 Overview ... - Page 18 Remove the two flanges. NOTICE For an error free performance of MEDIAJET vario with the desired Petri dish size, make sure that the corresponding conversion set, including the adaptation insert, extension gripper lever, head plates and flanges is completely installed and that the correct rotor and carousel are mounted.

-

Page 19: Assembly

MEDIAJET – Operating instructions V09 Installation Assembly 3.4.1 Rotor Slide the rotor under the black plate. Turn the rotor until the anchor bolt locks into position. 3.4.2 Safety cover Hang the safety cover into the two hinges ... - Page 20 Now switch on the device at the main switch. Wait until the device has completed the automatic software initialization. When the main menu with INTEGRA logo appears on the screen, the device has been installed and is ready for use. INTEGRA Biosciences AG...

-

Page 21: Biplate Option

Put the screw caps on the screws. For MEDIAJET vario with biplate option, a special base plate must be mounted, if Petri dishes with a height above 21 mm are filled: Remove the two screws of the filling nozzle ... -

Page 22: Turbo Mode Option

“6.1 Specification of the device” on page 54. WARNING Always switch off the MEDIAJET when assembling the double pump head. Be aware of the sharp edges of the pump heads when assembling them and when opening and closing the first pump head for tubing insertion. -

Page 23: Tubefiller Option

Installation TUBEFILLER option ASSISTANCE In order to install and use the TUBEFILLER option, MEDIAJET has to be equipped with the software version 1.12 or higher. In case you need to upgrade your MEDIAJET software version please contact your local INTEGRA BIOSCIENCES dealer for support. - Page 24 MEDIAJET – Operating instructions V09 Installation Mount the radial arm onto the rod and tighten it with the side lever in order to prevent it from moving during the dispensing phase. The TUBEFILLER is now installed. NOTICE To avoid contact of the side lever with the test-tubes during the filling process make sure the lever is always on the right side of the rod.

-

Page 25: Chapter 4 Operation

(see “5.1 Cleaning” on page 48). DOSING FUNCTION: Function for independent volumetric dosing applications using the peristaltic pump of MEDIAJET (see “4.8 Dosing function” on page 41). SYSTEM PARAMETER: To adapt the general device parameters (see “4.2 Adapt system parameter” on page 26). -

Page 26: Adapt System Parameter

• Pump Options: OFF (Enabling this function allows pumping back the medium to the source.) • Biplate alignment (only MEDIAJET vario with biplate option): OFF Cooler Allows to switch off the cooling plate, in case the option is (optional) installed. - Page 27 MEDIAJET – Operating instructions V09 Operation 4.2.1 Language selection Press >>> in order to reach the second page of the MAIN MENU. Select a language under SYSTEM PARAMETER / LANGUAGE SELECTION. Press SAVE. The screen will appear in the language selected.

-

Page 28: Loading Petri Dishes

Batch mode, see “4.4 Adapting a dish filling program” on page 30. MEDIAJET now carries out an automatic self-calibration process. ASSISTANCE The two positions refer to the two locations situated directly in the front side of the carousel towards the operator above the two cavities in the black cover plate. - Page 29 Fill only nine of the ten positions in the carousel with dishes to ensure perfect functioning of the device. If using the Batch mode, only every second position must be filled. Press BACK and MAIN MENU in order to return to the MAIN MENU. The MEDIAJET is now loaded with dishes. www.integra-biosciences.com...

-

Page 30: Adapting A Dish Filling Program

Operation Adapting a dish filling program ASSISTANCE If you are using the MEDIAJET for the first time, please adjust the program parameters to your requirements before starting the filling process. Press FILL DISHES in the MAIN MENU in order to reach the stored programs. - Page 31 MEDIAJET – Operating instructions V09 Operation Program Description Value Basic parameter range setting Dish height (mm) Stacking height of the Petri 12-25 mm 16 mm dishes used (see below). To use dishes with a height of more than 21 mm, underlay the filling nozzle holder with the supplied base plate (see “3.4.5...

- Page 32 MEDIAJET – Operating instructions V09 Operation Program Description Value Basic parameter range setting Biplate To fill Petri dishes with two alignment compartments (with automatic (option) alignment of the dividing wall, has to be enabled in program configuration, see “4.2 Adapt system parameter”...

- Page 33 MEDIAJET – Operating instructions V09 Operation Continuous filling If the program parameter continuous filling is switched on, the MEDIAJET fills the total number of programmed plates without pause and the exchange of the Petri dishes must be performed during the filling process.

-

Page 34: Run Dish Filling Program

MEDIAJET – Operating instructions V09 Operation 4.4.4 Shaker level (pour plate) Total viable count determination is often carried out by using the pour plate method. The built in shaker supports the mixing of the sample with the agar medium. To enable this option, see “4.2 Adapt system parameter” on page 26. - Page 35 For programs with the parameter “Biplate alignment ON” place a second tubing set into the double pump head to allow the filling of two compartments in parallel (MEDIAJET vario with biplate option only). The tubing set is now connected. www.integra-biosciences.com...

- Page 36 Before you start the actual filling process, you have the option of carrying out a calibration of the dosing volume. This is particularly important if you work with tubing(s) not obtained from INTEGRA Biosciences, as the dosing quantity is directly dependent on the diameter of the tubing.

- Page 37 Operation 4.5.4 Start the filling process CAUTION While the MEDIAJET is in operation, pay attention to your fingers when operating the carousel. Be particularly careful if your hands are in the immediate vicinity of the loading positions. Press START. ...

-

Page 38: Removing Filled Petri Dishes

Press LOAD CAROUSEL in the MAIN MENU. Press UNLOAD. CAUTION While the MEDIAJET is in operation, pay attention to your fingers when operating the carousel. Be particularly careful if your hands are in the immediate vicinity of the loading positions. INTEGRA Biosciences AG... -

Page 39: Process Documentation

1.9.1 or higher and communication interface cable (see “7.1 General accessories” on page 58). If using MEDIACLAVE 10 (Part No. 136 0xx) or MEDIACLAVE 30 (Part No. 136 05x) all process relevant data of the MEDIAJET will also shown up in the MEDIACLAVE electronic log file. www.integra-biosciences.com... - Page 40 MEDIAJET – Operating instructions V09 Operation The following data (example) is printed out: Following calibration When starting the filling Following completion of the process filling process ======================== ======================== ======================== MEDIAJET (SN:12345678) MEDIAJET (SN:12345678) MEDIAJET (SN:12345678) ***Calibration done Time: hh:mm ***Start Filling Process...

-

Page 41: Dosing Function

Operation Dosing function This function uses the peristaltic pump of the MEDIAJET for volumetric dosing with a 6 mm ID tubing. The dosing can be optionally controlled with a foot switch (see available accessories in “7.6 Accessories for dosing function” on page 62). -

Page 42: Mixing Additives Into The Agar

side of the electrical interface cable into the socket marked with “Pump” on the back of the MEDIAJET and the other side to the foot switch socket on the back side of the DOSE IT pump. When connecting a sterilized Tubing set for the... - Page 43 Exit the program by pressing START. In case you are connecting the DOSE IT and the MEDIAJET for the first time or when working with a new Tubing set it is recommended to confirm the pump settings again and to perform the calibration routine of the DOSE IT.

-

Page 44: Tubefiller Option

4.10 TUBEFILLER option The TUBEFILLER option allows to automatically fill test-tube racks on MEDIAJET. Please ensure that the option is correctly installed as described in “3.7 TUBEFILLER option” on page 23. 4.10.1 Adapting a TUBEFILLER program Press TUBE FILLER in the MAIN MENU to reach the individually stored ... - Page 45 MEDIAJET – Operating instructions V09 Operation 4.10.2 Prepare tube filling process Select the desired program in the TUBEFILLER menu using the arrow keys and press START PROGRAM. The dialogue window TUBE FILLING appears again summarizing the most important settings of the selected program.

- Page 46 4.10.3 Start the filling process NOTICE To avoid spillage during the filling process, only use test tubes with an outer diameter matching the available racks from INTEGRA BIOSCIENCES. Find a test tube compatibility chart in “6.4 Test tube compatibility chart” on page 57. ...

- Page 47 MEDIAJET – Operating instructions V09 Operation Manually move the filling arm to align the tip of the dispensing needle with the first tube all to the right in the rack position 1 on the support plate. Make sure that the dispensing needle is exactly centred over the tube to ensure a smooth filling process.

-

Page 48: Chapter 5 Maintenance

Do not clean the Plexiglas safety cover with organic solvent, Acetone or pure alcohol. ASSISTANCE Regular cleaning of the MEDIAJET is important in order to maintain the device in a good condition and thus ready for operation. We recommend carrying out the cleaning protocol described below following each filling process. - Page 49 Remove the O-ring of the drive wheel by dismounting the filling nozzle holder and wash it with water. Replace the O-ring if, if necessary (only MEDIAJET vario with biplate option). Subsequently disinfect the filling chamber using 70 % Ethanol.

-

Page 50: Uv Lamp Exchange

85% of initial output after 4000 hours. Risk of failure during a run can be minimized by changing the bulb after 1000 operating hours. When 1000 operating hours are achieved a message is displayed after switching on the MEDIAJET. Proceed as follow to replace the UV Lamp: Switch off the MEDIAJET. ... -

Page 51: Leak Test

If the system is leaking, you have to check whether the tubing or the pumphead is worn: Repeat the leak test with a new tubing (only use original INTEGRA tubings, see “7.3 Consumables” on page 60). • If system is tight, the tubing was worn and the problem is solved. -

Page 52: Servicing

We recommend that you have the MEDIAJET serviced once per year. ASSISTANCE If the MEDIAJET is one year in operation since the last service, a service reminder is displayed in the MAIN MENU and stored in SYSTEM PARAMETER - SYSTEM MESSAGES, where it can be re-displayed. -

Page 53: Disposal

Maintenance Disposal The MEDIAJET is labelled with the “crossed-out bin” symbol to indicate that this equipment must not be disposed of with unsorted municipal waste. Instead, it is your responsibility to correctly dispose of your waste equipment by handing it over to an authorised facility for separate collection and recycling. -

Page 54: Chapter 6 Technical Data

MEDIAJET – Operating instructions V09 Technical data Technical data Specification of the device Dimensions Basic device (H x W x D) 330 mm x 655 mm x 634 mm With 360 carousel (H) 1070 mm With 540 carousel (H) 1405 mm... -

Page 55: Petri Dish Specifications

“4.4 Adapting a dish filling program” on page 30. The lid outer diameter (2) and the ground clearance (3) are critical for an optimal performance of MEDIAJET and have to be in the range specified in the table below. Manu-... -

Page 56: Configuration Specifications

MEDIAJET – Operating instructions V09 Technical data Configuration specifications The table below shows all available MEDIAJET configurations listing the corresponding accessories compatible with the different Petri dish sizes specified above. A detailed overview of all the listed parts is shown in “7.2 Accessories for different Petri dish sizes”... -

Page 57: Test Tube Compatibility Chart

Technical data Test tube compatibility chart In order to avoid spillage, INTEGRA BIOSCIENCES recommends to work with test tubes of an outer diameter fitting the racks as tight as possible. The chart below lists the maximal test tube diameter compatible with the available racks and gives a recommendation on the maximal possible variations in size which ensure an error free dosing process. -

Page 58: Chapter 7 Optional Functions And Required Accessories

Rotor for Ø 90 mm Petri dishes and the corresponding tubing set. The MEDIAJET vario base units (Part No. 113 000, 113 001 and 113 002) are convertible for various Petri dish sizes. One of the following conversion sets, carousels and rotors must be added. - Page 59 Optional functions and required accessories Accessories Part No. Conversion set for 90 mm Petri dishes for 113 051 MEDIAJET vario, including all adaptation parts and tubing set with filling nozzle. Conversion set for large 90 mm ( 90L) Petri...

-

Page 60: Consumables

MEDIAJET – Operating instructions V09 Optional functions and required accessories Accessories Part No. Filling nozzle for 90 mm Petri dishes, 103 032 6 x 9 mm tubing. Filling nozzle for 60 or 35 mm Petri dishes, 113 032 6 x 9 mm tubing. -

Page 61: Turbo Mode Option

Petri dishes. Connection kit for LINX 5900 (4900) inkjet 113 840 printer (bottom printing) with interface cable MEDIAJET to Linx 4900, ex factory. Connection kit for LINX 5900 (4900)/CJ400 113 845 inkjet printer (side wall printing), including the fixing device and the interface cable, for Ø 90 and Ø... -

Page 62: Accessories For Dosing Function

Optional functions and required accessories Accessories for dosing function The MEDIAJET pump can be used independently for other applications, such as for the manual filling of small tubes or bottles. The delivery can be controlled comfortably with the foot-switch available as an option. -

Page 63: Driving A Second Pump

Optional functions and required accessories Driving a second pump The MEDIAJET permits the control of a second, independent DOSE IT peristaltic pump. This accessory is particularly useful for the continuous mixing in of additives, such as blood, into the agar immediately prior to filling of the dishes, through which the thermal denaturing of the additive is minimized. -

Page 64: Tubefiller Option

Optional functions and required accessories TUBEFILLER option The TUBEFILLER option is a perfect expansion to the functionality of MEDIAJET. It allows quick conversion of MEDIAJET into a test tube filler. The option has to be ordered separately from INTEGRA BIOSCIENCES. Device Option Part No. - Page 65 MEDIAJET – Operating instructions V09 Optional functions and required accessories Consumables Part No. Tubings Silicone tubing 2.0 mm ID, 2 m length 171 022 Silicone tubing 3.0 mm ID, 2 m length 171 023 Silicone tubing 4.0 mm ID, 2 m length 171 024 Silicone tubing 2.0 mm ID, 25 m length, bulk...

-

Page 66: Imprint

INTEGRA Biosciences AG. Neither the complete documentation nor parts thereof may be reproduced in any way, or stored and processed using electronic media or distributed in any other way without the written consent of INTEGRA Biosciences AG. ©...

Need help?

Do you have a question about the MEDIAJET and is the answer not in the manual?

Questions and answers