Graco A Series Manual

Hide thumbs

Also See for A Series:

- Instructions - parts manual (52 pages) ,

- Instructions-parts list manual (48 pages) ,

- Repair instructions (34 pages)

Table of Contents

Advertisement

Quick Links

Operation

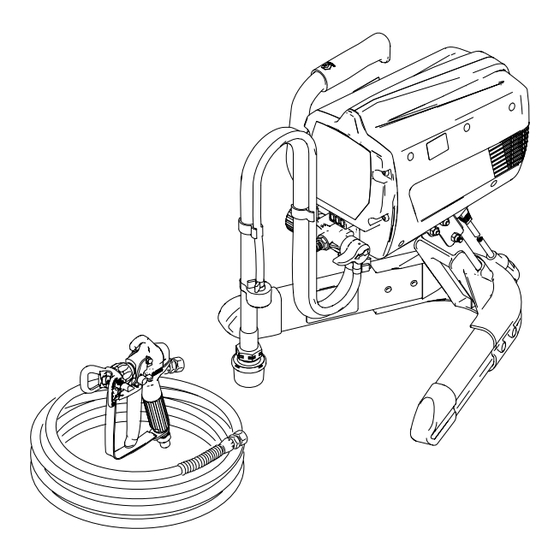

- For Portable Spray Applications of Architectural Paints and Coatings -

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

Model: 16J752, Series A, Series B

Maximum Working Pressure: 3000 psi (207 bar, 21 MPa)

- Not for Use in Explosive Atmospheres -

Use water-based or mineral spirit-type materials only.

Do not use materials having flash points lower than

100° F (38° C). This includes, but is not limited to, ace-

tone, xylene, toluene, or naptha. For more information

about your material, request MSDS from distributor or

retailer.

ti17229a

3A1782D

EN

Advertisement

Table of Contents

Summary of Contents for Graco A Series

- Page 1 Operation 3A1782D - For Portable Spray Applications of Architectural Paints and Coatings - - Not for Use in Explosive Atmospheres - Important Safety Instructions Read all warnings and instructions in this manual. Save these instructions. Use water-based or mineral spirit-type materials only. Model: 16J752, Series A, Series B Do not use materials having flash points lower than Maximum Working Pressure: 3000 psi (207 bar, 21 MPa)

-

Page 2: Table Of Contents

Tip Selection ......16 Graco Standard Warranty ....36 Choosing the Correct Tip . -

Page 3: Warnings

Warnings Warnings The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risks. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where appli- cable. - Page 4 All parts of the spray system, including the pump, hose assembly, spray gun, and objects in and around the spray area shall be properly grounded to protect against static discharge and sparks. Use Graco conductive or grounded high-pressure airless paint sprayer hoses.

- Page 5 Pressure Relief Procedure for turning off the unit. • Check hoses and parts for signs of damage. Replace any damaged hoses or parts. • This system is capable of producing 3000 psi. Use Graco replacement parts or accessories that are rated a minimum of 3000 psi.

- Page 6 Warnings WARNING WARNING WARNING WARNING ELECTRIC SHOCK HAZARD This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock. • Turn off and disconnect power cord before servicing equipment. • Connect only to grounded electrical outlets. •...

-

Page 7: Notes

Notes Notes 3A1782D... -

Page 8: Component Identification

Component Identification Component Identification Airless spray gun Dispenses fluid. Power switch Turns sprayer ON and OFF. Pressure control knob Increases (clockwise) and decreases (counter-clockwise) fluid pressure in pump, hose, and spray gun. Setting Indicator To select function, align symbol on pressure control knob with setting indicator, page 11. - Page 9 Component Identification Component Identification ti22144b 3A1782D...

-

Page 10: Grounding And Electric Requirements

Grounding and Electric Requirements Grounding and Electric Requirements Fluid supply container: follow local code. Solvent pails used when flushing: follow local code. Use only conductive metal pails, placed on a grounded surface such as concrete. Do not place the pail on a Sprayer must be grounded. -

Page 11: Operation

Operation Operation Trigger Lock 2. Move Prime/Spray valve to PRIME to relieve pres- sure. Always engage the trigger lock when you stop spraying to prevent the gun from being triggered accidentally by hand or if dropped or bumped. ti22202a ti8908a 3. -

Page 12: Setup

Setup Setup Prime and Flush Storage Fluid 1. Unscrew tip and guard assembly from gun. NOTE: This unit is not intended for lacquers. Before you use your sprayer for the first time or begin a new spraying project, you need to prime the sprayer and flush the storage fluid out of the sprayer. - Page 13 Setup 5. Make sure the power switch is OFF and the sprayer 11. Push pump priming button two times. is unplugged. ti2018a ti15972a 6. Separate prime tube (smaller) from suction tube 12. Turn power switch ON. (larger). ti5580a 13. Align setting indicator with Prime/Clean setting on Pressure Control knob until pump starts, page 11.

-

Page 14: Install Tip And Guard On Gun

Setup 18. When you see paint coming out of prime tube: Install Tip and Guard on Gun a. Point gun into waste pail. b. Unlock gun trigger lock. 1. Engage trigger lock. ti8909a c. Pull and hold gun trigger. ti8908a d. -

Page 15: Spraying Techniques

Setup Spraying Techniques Getting Started Use a piece of scrap cardboard to practice these basic Preventing Excessive Tip Wear spraying techniques before you begin spraying the sur- face. • Spray should be atomized (evenly distributed, no gaps at edges). Start at low pressure setting, •... -

Page 16: Unclogging Spray Tip

Setup Unclogging Spray Tip 4. Unlock trigger lock. Pull trigger to clear clog. 1. To UNCLOG tip obstruction, engage trigger lock. ti8909a 5. When obstruction is cleared, engage trigger lock and rotate arrow-shaped handle back to SPRAY position. ti8908a 2. Point arrow-shaped handle backward to UNCLOG position. -

Page 17: Choosing The Correct Tip

Setup Choosing the Correct Tip Understanding the Tip Number The last three digits of tip number (example: 69-413) Consider the coating and the surface to be sprayed. contain information about hole size and fan width on the Make sure you use the best tip hole size for that coating surface when gun is held 30 cm (12 in.) from surface and the best fan width for that surface. -

Page 18: Shutdown And Cleaning

Shutdown and Cleaning Shutdown and Cleaning Pail Flushing 6. Place prime tube in waste pail. • For short term shutdown periods (overnight to two days) refer to Short Term Storage, page 21. • For flushing after spraying oil-based coatings, use compatible oil-based flushing fluid or mineral spirits. - Page 19 Shutdown and Cleaning NOTE: Step 12 is for returning paint in hose back to 14. Stop triggering gun. Engage the trigger lock. paint pail. One 50-ft hose holds approximately 1-quart (1-liter) of paint. 12. To preserve paint in hose: a. Point gun into paint pail. ti8908a b.

-

Page 20: Cleaning Gun Filter

Shutdown and Cleaning Cleaning Gun Filter 3. Remove filter and clean it in compatible solvent. Perform Pressure Relief Procedure, page 11. 1. Engage gun trigger lock. ti17499a NOTE: Do not soak entire gun in solvent. Prolonged exposure to solvent can ruin packings. ti8908a 2. -

Page 21: Storage

Storage Storage Short Term Storage Long Term Storage (up to 2 days) (more than 2 days) 1. Relieve pressure, page 11. Always circulate Pump Armor storage fluid through sys- tem after cleaning. Water left in sprayer will corrode and 2. Leave suction tube and prime tube in paint pail. damage pump. -

Page 22: Stowing Sprayer

Storage 5. When storage fluid comes out of prime tube (5-10 6. Move Prime/Spray valve to SPRAY to keep storage seconds) turn power switch OFF. fluid in sprayer during storage. ti2018a ti22207a Stowing Sprayer NOTICE • Before storing sprayer make sure all water is drained out of sprayer and hoses. -

Page 23: Maintenance And Service

Do not use hoses shorter than 7.5 m (25 ft). or worn. Valve repair kits are available from Graco/Mag- Wrench tighten, using two wrenches. num authorized service dealers. -

Page 24: Troubleshooting

Troubleshooting Troubleshooting Check everything in this Troubleshooting Table before you bring the sprayer to a Graco/M authorized AGNUM service center. Problem Cause Solution Power switch is on and sprayer is Pressure is set at zero pressure. Turn pressure control knob clockwise plugged in, but motor does not run, to increase pressure setting. - Page 25 Tighten suction tube connection. Inspect for cracks or vacuum leaks. If cracked or damaged, replace suction tube. Prime/Spray Valve is worn or Take sprayer to Graco/M AGNUM obstructed with debris. authorized service center. Pump check ball is stuck. Read Pump does not prime section...

- Page 26 Troubleshooting Problem Cause Solution Pump cycles, but paint only dribbles Pressure is set too low. Slowly turn Pressure Control Knob or spurts when spray gun is trig- clockwise to increase pressure set- gered. ting which will turn motor on to build pressure.

- Page 27 Choose tip with larger hole size. Choose tip with narrower fan. Make sure gun is close enough to surface. Fan pattern varies dramatically while Pressure control switch is worn and Take sprayer to Graco/M AGNUM spraying. causing excessive pressure varia- authorized service center. tion.

-

Page 28: Parts

Parts Parts ESP240V Model 16J752 Series A ti17240a 3A1782D... - Page 29 Parts Parts List ESP 240V Model 16J752 Series A Ref. Part Description Qty. Ref. Part Description Qty. 122233 BOLT, carriage 112689 SCREW 102040 NUT, lock, hex 16D684 FRAME 16D576 LABEL, Made in USA 16G224 ENCLOSURE, sprayer, black 16F567 BRACKET, control board/EMI filter (includes 10, 11, 17, 54, 115) 115492 SCREW, mach, slot hex wash hd 115477 SCREW, mach, torx pan hd...

- Page 30 Parts Parts ESP 240V Model 16J752 Series B ti17240c 3A1782D...

- Page 31 Parts Parts List ESP 240V Model 16J752 Series B Ref. Part Description Qty. Ref. Part Description Qty. 16D576 LABEL, Made in USA 112689 SCREW 16W317 BRACKET, control board/EMI filter 16D684 FRAME (Includes 121 and 57 qty. 2) 16X022 ENCLOSURE, sprayer, black 115492 SCREW, mach, slot hex wash hd (includes 10, 11, 17, 54, 115) 121423 RETAINER, wire...

- Page 32 Parts Parts ESP 240V Model 16J752 Series A and B ti17512d 3A1782D...

- Page 33 Parts Parts List ESP 240V Model 16J752 Series A and B Ref. Part Description Qty. Ref. Part Description Qty. 195400 CLIP, spring 16G227 PUMP, assembly, 240V (includes 195697 STRAINER 1a, 1b, 1c, 1d, 1e, 1f, 1g, 72) 244035 DEFLECTOR, barbed 235014 DUMP VALVE 16W319 COVER, gear 24E578 BASE, valve...

-

Page 34: Technical Data

Technical Data Technical Data Working pressure range 0-207 BAR, 0-21 Mpa (0-3000 psi) Electric Motor 4.5A (open frame, universal) Operating horsepower Maximum delivery (with tip) 1.02 lpm (.27 gpm) Paint hose 6.4mm X 7.5 m (1/4 in. x 25 ft) Maximum tip hole size 0.015 in (0.38 mm) Weight, Sprayer only... -

Page 35: Notes

Notes Notes 3A1782D... -

Page 36: Graco Standard Warranty

Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers