Graco A Series Instructions - Parts Manual

Low flow fluid regulator

Hide thumbs

Also See for A Series:

- Instructions - parts manual (52 pages) ,

- Instructions-parts list manual (48 pages) ,

- Manual (36 pages)

Table of Contents

Advertisement

Quick Links

Instructions-Parts

Low Flow Fluid

Regulator

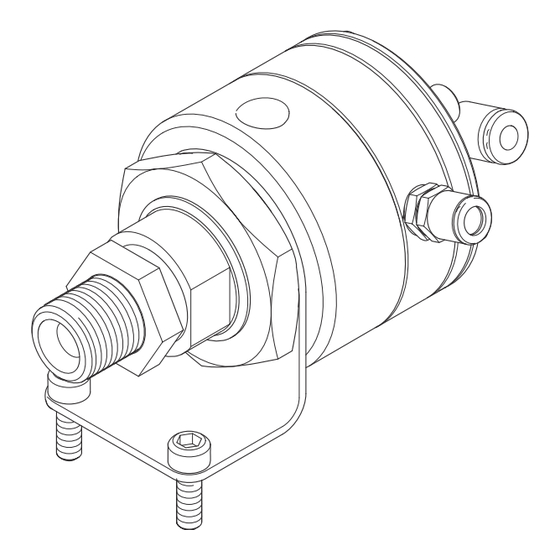

Pneumatic controlled fluid regulator provides accurate, positive pressure control of

finishing coatings in low flow applications. For professional use only.

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

300 psi (2.1 MPa, 21 bar) Maximum Fluid Inlet Pressure

90 psi (0.63 MPa, 6.3 bar) Maximum Regulated

Fluid Pressure (High Pressure Port, All Models)

Part No. 24C375, Series A

1:1 Ratio, 90 psi (0.63 MPa, 6.3 bar) Maximum

Regulated Fluid Pressure (Low Pressure Port)

Part No. 24E471, Series A

1:2 Ratio, 50 psi (0.35 MPa, 3.5 bar) Maximum

Regulated Fluid Pressure (Low Pressure Port)

Part No. 24E472, Series A

1:3 Ratio, 30 psi (0.21 MPa, 2.1 bar) Maximum

Regulated Fluid Pressure (Low Pressure Port)

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

3A0427B

EN

TI15288a

Advertisement

Table of Contents

Summary of Contents for Graco A Series

- Page 1 Instructions-Parts Low Flow Fluid Regulator 3A0427B Pneumatic controlled fluid regulator provides accurate, positive pressure control of finishing coatings in low flow applications. For professional use only. 100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure 300 psi (2.1 MPa, 21 bar) Maximum Fluid Inlet Pressure 90 psi (0.63 MPa, 6.3 bar) Maximum Regulated Fluid Pressure (High Pressure Port, All Models) Part No.

-

Page 2: Table Of Contents

Pressure Relief Procedure ....7 Graco Standard Warranty ....18 Available Pressures . - Page 3 Warnings WARNING WARNING WARNING WARNING PRESSURIZED EQUIPMENT HAZARD Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and cause serious injury. • Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or servicing equipment.

-

Page 4: Installation

(E) which is con- fluid. To avoid contaminating your system, flush the nected to a true earth ground. Follow local code. Graco equipment with a compatible solvent before using the Part No. 222011 Ground Wire and Clamp is available as equipment. - Page 5 Installation Pilot air signals from a manual air regulator or electronic air control To fluid dispense point From fluid supply TI15498a . 1: Typical Installation Key: Air Supply Line to High Port Air Supply Line to Low Port Low Flow Fluid Regulator Mounting Bracket (supplied) Grounded Mounting Surface Regulated Fluid Outlet Line...

- Page 6 Installation 3A0427B...

-

Page 7: Operation

Operation Operation Pressure Relief Procedure High Port Operation Use the high port for: • commanding a higher pressure for faster flushing • higher fluid viscosities 1. Shut off the fluid supply. To operate, shut off the air to the low pressure inlet and 2. -

Page 8: Troubleshooting

Troubleshooting Troubleshooting Relieve the pressure (page 7) before checking or repairing the equipment. To repair the regulator, refer to page 10. Problem Cause Solution No fluid flow. Plugged fluid inlet. Flush fluid line and regulator. Exhausted fluid supply. Check fluid supply and supply pump. - Page 9 Troubleshooting Problem Cause Solution Fluid flow will not shut off. Dirty needle (6) and seat (5). Remove and clean. Replace if worn or damaged. See page 10. Inlet air is not shut off. Shut off inlet air. Seat retainer (7) is loose. Tighten.

-

Page 10: Repair

Repair Repair Disassembly 2. Insert the needle (6◆) in the fluid chamber housing (1). Hold in place with a screwdriver or allen wrench. Install the fluid chamber piston (8), o-ring (11*), ptfe 1. Flush the regulator with a compatible solvent. See diaphragm (9a*), and nylon/buna-N diaphragm page 7. - Page 11 Repair Torque oppositely and alternately to 25 in-lb (2.8 N•m). Apply thread sealant. Apply pipe sealant. White PTFE diaphragm (9a) must always face the fluid. *9b (nylon/buna-N) *9a (ptfe) 5*◆ 6◆ 7◆ 15*† 3† 14† TI15290a . 2. Regulator Assembly 3A0427B...

-

Page 12: Parts

Parts Parts 24C375 1:1 Ratio Fluid Regulator, Series A 24E471 1:2 Ratio Fluid Regulator, Series A 24E472 1:3 Ratio Fluid Regulator, Series A Ref. Ref. Part No. Description Qty. Part No. Description Qty. KIT, bracket, regulator; includes HOUSING, fluid chamber items 19a and 19b HOUSING, air chamber SCREW, cap, socket hd;... - Page 13 Parts *9b (nylon/buna-N) *9a (ptfe) 5*◆ 6◆ 7◆ 15*† 3† 14† TI15290a See parts breakdown above TI15289a 3A0427B...

-

Page 14: Dimensions

Dimensions Dimensions 2.70 in. (69 mm) 1.81 in. (46 mm) diameter) 1.91 in. (49 mm) TI15288a Bracket Mounting Hole Diagram 1.08 in. 0.194 in. (5 mm) (27.43 mm) diameter holes TI15291a 3A0427B... -

Page 15: Technical Data

Technical Data Technical Data Maximum air inlet pressure ..... . 100 psi (0.7 MPa, 7 bar) Maximum fluid inlet pressure ..... 300 psi (2.1 MPa, 21 bar) Maximum regulated fluid pressure (high pressure port) All Models . -

Page 16: Performance Data

Performance Data Performance Data Use the following charts to choose the best ratio for your • A higher ratio (1:3) will have a flatter response curve application, depending on the desired fluid pressure and will not react as strongly to changes in the air range and pressure losses due to flow rate, fluid viscos- pilot signal. - Page 17 Performance Data 1100 1000 1:1 Ratio, 25 centipoise 1:1 Ratio, 75 centipoise 1:2 Ratio, 25 centipoise 1:3 Ratio, 25 centipoise 1:2 Ratio, 75 centipoise 1:3 Ratio, 75 centipoise (MPa, bar) (0.14, 1.4) (0.28, 2.8) (0.42, 4.2) (0.56, 5.6) (0.7, 7.0) Pilot Air Pressure NOTE: Tested using a 1.0 mm nozzle and 10 ft x 1/4 in.

-

Page 18: Graco Standard Warranty

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

Need help?

Do you have a question about the A Series and is the answer not in the manual?

Questions and answers