Advertisement

Quick Links

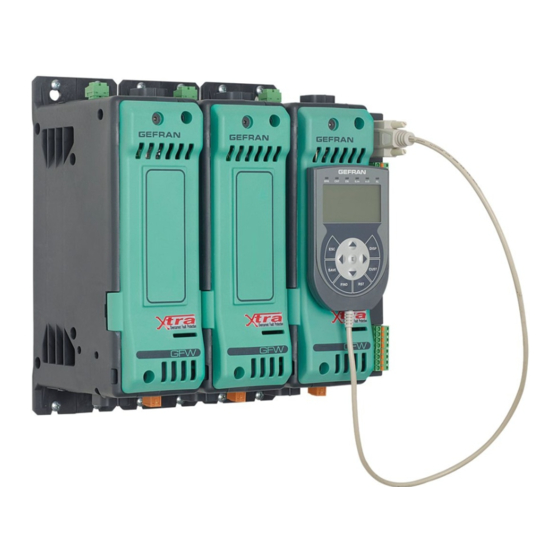

INSTALLATION AND CONNECTION

This section contains the instructions needed for correct installation of GFW modular power controller

on the machine/host system control panel and for correct connection of the power supply, inputs,

outputs and interfaces.

Carefully read the following warnings before installing the instrument!

Disregard of such warnings could create electrical safety and electromagnetic compatibility problems, as

well as void the warranty.

ELECTRICAL POWER SUPPLY

• the controller DOES NOT have an On/Off switch: the user must install switch/isolator conforming to safety

requisites (CE mark) to cut off the power supply up-line of the controller.

The switch must be installed in the immediate vicinity of the controller in easy reach of the operator.

A single switch can be used for multiple devices.

* the earth connection must be made with a specific lead

• if the product is used in applications with risk of harm to persons or damage to machines or materials, it

MUST be equipped with auxiliary alarm devices.

It is advisable to provide the ability to check for tripped alarms during regular operation.

NOTES ON ELECTRICAL SAFETY AND ELECTROMAGNETIC COMPATIBILITY:

CE: Conformity EMC (electromagnetic compatibility) conformity) in compliance with Directive 89/336/

CEE and following modifications. Series GFW are mainly intended for industrial use, installed on panels or

control panels of production process machines or systems.

For purposes of electromagnetic compatibility, the most restrictive generic standards have been adopted, as

shown on the table.

LV (low voltage) conformity in compliance with Directive 2006/95/CE.

EMC conformity has been verified with the connections indicated on table 1 (see user's manual).

RECOMMENDATIONS FOR CORRECT INSTALLATION FOR PURPOSES OF EMC

Instrument power supply

• The power supply for the electronic instrumentation on the panels must always come directly from a

cut-off device with fuse for the instrument part.

• Electronic instrumentation and electromechanical power devices such as relays, contactors, solenoids,etc.,

MUST ALWAYS be powered by separate lines.

• When the power supply line of electronic instruments is heavily disturbed by switching of thyristor power

groups or by motors, you should use an isolation transformer only for the controllers, grounding its sheathing.

• It is important for the system to be well-grounded:

- voltage between neutral and ground must not be > 1V

- Ohmic resistance must be < 6Ω;

• If the grid voltage is highly unstable, use a voltage stabilizer.

• In proximity of high-frequency generators or arc welders, use adequate grid filters.

• The power supply lines must be separate from instrument input and output lines.

• Supply from Class II or from limited energy source

Input and output connections

Before connecting or disconnecting any connection, always check that the power and control cables are iso-

lated from voltage.

Appropriate devices must be provided: fuses or automatic switches to protect power lines.

• Connected outside circuits must be doubly isolated.

• To connect analog inputs, strain gauges, linears, (TC, RTD), you have to:

- physically separate the input cables from those of the power supply, outputs, and power connections.

- use braided and shielded cables, with sheathing grounded at a single point.

Installation notes

- Moreover, the applications with solid-state units require a safety automatic switch to section the load power

line.

To ensure the high reliability of the device, it is necessary to install it properly inside the panel so to obtain

an adequate thermal exchange.

Fit the device vertically (maximum angle 10° to the vertical axis)

• Vertical distance between a device and the panel wall >100mm

• Horizontal distance between a device and the panel wall at last 10mm

• Vertical distance between a device and the next one at last 300mm.

• Horizontal distance between a device and the next one at last 10mm.

Check that the cable holder runners do not reduce these distances, in this case fit the cantilever units opposite

the panel so that the air can flow vertically without any obstacles.

• Dissipation of device thermal power with effects on installation room temperature.

• Thermal power dissipation with limits on installation room temperature.

• Requires exchange with external air or an air conditioner to transfer dissipated power outside the panel.

• Maximum limits of voltage and derived power of transients on the line, for which the solid state power unit

contains protective devices (based on the model).

• Presence of dispersion current in GFW in non-conducting state (current of a few mA due to RC Snubber

circuit to protect ).

GEFRAN S.p.A. assumes no liability for any damage to persons or property deriving from

tampering, from incorrect or improper use, or from any use not conforming to the characteristics

of the controller and to the instructions in this User Manual.

This device conforms to European Union Directive 2004/108/CE e 2006/95/CE with refe-

rence to generic standards: EN 60947-4-3 (product) EN 61010-1 (safety)

DERATING CURVES

ELECTRICAL CONNECTIONS

C

onneCtions

(Ref. V_load) 4 / T2

3 / L2 (Ref. V_line)

J 10

Line / load voltage

connector

1 / L1

"Line"

J1

Connection

GFW-OP

keypad

connector

Screw front cover

(allows access to fuse)

Magnetic area

Outputs

GFW-OP

J2

(only GFW-M

model)

Supply

J4

Status Led

IN2

J3

IN3

Digital input

IN4

IN5

Key HB

Address x 10

mV / TC input

Address Rotary

Address x 1

Switch

J5

(optional)

INA- Control

analog

input connector

2 / T1

J6

"Load"

Connection

IN1- Analog

input connector

PID (optional)

Low view

With option

GND

Fieldbus

SUPPLY

-

+

24 vdc

J7

2 / T1

2 / T1

fan power

"Load"

"Load"

supply

Connection

Connection

Connector board

Fieldbus PORT 2 (optional)

Dip Switch

serial line

Protection

J8, J9

fan

Connector RJ10

serial RS485

Modbus (PORT 1)

INSTALLATION AND OPERATION MANUAL

Side 1

Installation and Connection

Electrical connections

Side 2

Technical-Commercial information

General Information

Dimensions

Top View

Fixing/Installation

Derating curves

Protection

fan

1 / L1

Tel. 03098881 - fax 0309839063- Internet: http://www.gefran.com

"Line"

Connection

COM (OUT 5 - 8)

OUT 5

OUT 6

Optional outputs

OUT 7

OUT 8

OUT 9 (Relay N.O.)

OUT 10 (Relay N.O.)

RUN............ (green)

RECOMMENDED WIRE GAUGES

ERROR.......(red)

+24 vdc

DI1.............. (yellow)

GND-SUPPLY

DI2.............. (yellow)

EARTH

01................(yellow)

GFW

02................(yellow)

03................(yellow)

CURRENT

TERMINAL

+INDIG 1

BUTTON..... (yellow)

+INDIG 2

LEVEL

+INDIG 3 (PWM

input)GND - INDIG

40A

1/L1, 2/T1

OUT +5 V (Potentiometer)

+ IN

SHUNT - mA

GND - INPUT

EARTH

60A

1/L1, 2/T1

I1 -

I1 +

IN1 (RTD)

Low view

Without option

GND

Fieldbus

SUPPLY

-

+

24 vdc

100A

1/L1, 2/T1,

J7

fan power

supply

3/L2

(Ref. Vline)

Dip Switch

---

serial line

4/T2

J8, J9

(Ref. Vload)

Connector RJ10

serial RS485

Note: Cables must be copper "Stranded Wire" or "Compact-Stranded Wire" type with maximum operating

Modbus (PORT 1)

temperature 60/75°C

GFW-Xtra

MODULAR POWER CONTROLLER WITH

OVERCURRENT PROTECTION

code 80314A - 07/2015 - ENG

GEFRAN spa

via Sebina, 74 - 25050 Provaglio d'Iseo (BS)

TIGHTENING /

WIRE GAUGE

TERMINAL TYPE

TOOL TORQUE

Wire stripped for 25 mm or

5 Nm /

10 mm

with crimped pre-insulated

2

Flat-head screwdriver

7 AWG

terminal tube

tip 1 x 5.5 mm

CEMBRE PKC1018

Wire stripped for 25 mm or

5 Nm /

16 mm

with crimped pre-insulated

2

Flat-head screwdriver

5 AWG

terminal tube

tip 1 x 5.5 mm

CEMBRE PKC1618

Wire stripped for 25 mm or

5 Nm /

35 mm

with crimped pre-insulated

2

Flat-head screwdriver

2 AWG

terminal tube

tip 1 x 5.5 mm

CEMBRE PKC35025

0.5 ... 0.6 Nm /

0.25 ...2.5 mm

Wire stripped for 8 mm

2

Flat-head screwdriver

23...14 AWG

or with tag terminal

tip 0,6 x 3.5 mm

Advertisement

Summary of Contents for gefran GFW-Xtra

- Page 1 0.25 ...2.5 mm Wire stripped for 8 mm Fieldbus PORT 2 (optional) Dip Switch Flat-head screwdriver GEFRAN S.p.A. assumes no liability for any damage to persons or property deriving from serial line Dip Switch 23...14 AWG or with tag terminal...

- Page 2 This option eliminates the need for an external extra-rapid fuse to protect the device. In case of load short-circuit, the Protection) internal IGBT device is instantaneously switched off and the alarm status is signaled. GFW-Xtra 40 Nominal current 40Arms @40°C in continuous service Rated current AC51non- GFW-Xtra 60 Nominal current 60Arms @40°C in continuous service inductive or slightly inductive GFW-Xtra 100 Nominal current 100Arms @40°C in continuous service...

Need help?

Do you have a question about the GFW-Xtra and is the answer not in the manual?

Questions and answers