Table of Contents

Advertisement

Quick Links

® ®

HYPRO

Installation, Operation, Repair Instructions

Hypro Centrifugal Pumps handle big, high-capacity

farm spraying jobs with ease. Use them for spraying

liquid fertilizers and other chemicals, including wettable

powder slurries for weed control. Make short work of

California Proposition 65 Warning -- This product and related accessories contain chemicals known to the

State of California to cause cancer, birth defects or other reproductive harm.

SERIES 9200

Cast Iron, Stainless Steel

Pedestal-Mount Centrifugal Pumps

SERIES 9500P

Polypropylene

Flange-Mount Centrifugal Pumps

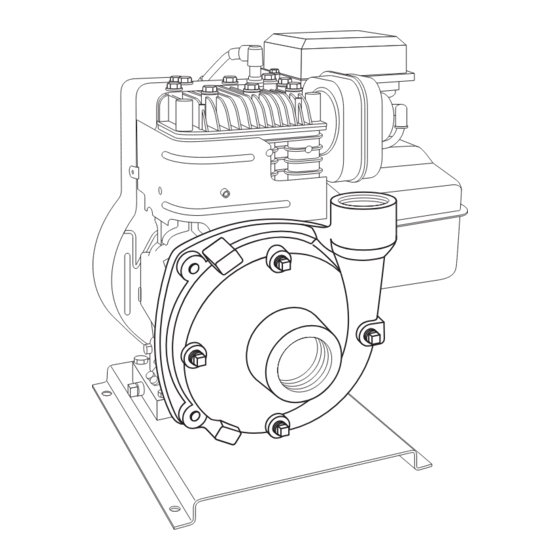

SERIES 1500

Close-Coupled, Gas Engine-Driven

Centrifugal Pumps

Series 9200, 9500 and 1536 through 1551

Direct and Gas Engine-Driven Centrifugal Pumps

Description

other farm jobs - filling nurse tanks, watering seed

beds, and transferring liquids.

Available in a variety of models, including lightweight

polypropylene (pump portion only) pumps for resistance

to corrosive liquids such as acid-based fertilizers.

This form replaces Form L-0300C. For individual

parts breakdowns, product outlines and performance

specifications, visit www.hypropumps.com.

See chart below for new form numbers.

Pump/Model

Number

9202C, 9202S,

9262C-C and 9262S-C ...........L-0300AG-1

9203C, 9203C-R,

9203S, 9203S-R,

9263C-C and 9263S-C ...........L-0300AG-2

9203C-SP, 9203S-SP,

9263C-C-SP, 9263S-C-SP.......L-0300AG-3

9203C-R-SP

and 9263C-CR-SP ................. L-0300AG-4

9203P-S

and 9253P-C.......................... L-0300AG-5

9204C......................................L-0300AG-6

9205C......................................L-0300AG-7

9205C-SP

and 9205C-BSP ......................L-0300AG-8

9206C and 9206S ...................L-0300AG-9

9513P................................... L-0300AG-10

1521, 1536, 1537, 1538,

1539 and 1540. .....................L-0300AG-11

1522C-65SP, 1536-SP, 1537-SP, 1538-SP,

1539-SP and 1540-SP. .........L-0300AG-12

1550, 1551 and 1552 Series...L-0300AG-13

Form L-0300AG

Rev. B

New Form

Number

Advertisement

Table of Contents

Summary of Contents for Pentair HYPRO 9500 Series

- Page 1 Series 9200, 9500 and 1536 through 1551 Direct and Gas Engine-Driven Centrifugal Pumps Form L-0300AG Rev. B ® ® HYPRO Installation, Operation, Repair Instructions Description Hypro Centrifugal Pumps handle big, high-capacity other farm jobs - filling nurse tanks, watering seed farm spraying jobs with ease.

-

Page 2: Safety Information

Safety Information 1. WARNING: Do Not Pump Flammable or 6. Secure the discharge lines before starting the pump. Explosive Fluids Such as Gasoline, Fuel Oil, An unsecured line may whip, causing personal injury Kerosene, etc. Do Not Use in Explosive and/or property damage. - Page 3 Belt/Pulley Drive Installation (cont'd.) To figure proper diameter of pump pulley, multiply motor/engine rpm by diameter of the motor/engine pulley and divide that figure by desired pump speed. Push the belt midway between Pump Motor RPM x Motor Pulley Size the pulleys, check the deflection (d) Pulley Size...

-

Page 4: Operation And Maintenance

Direct Drive - Flange Mount Installation GAS ENGINE MOUNT — Model 9513P fits most 5 hp gas engines with flange mount and 3/4" shaft. To install pump onto gas engine, first apply anti-seize compound to gas engine shaft and to inside of pump hollow shaft. -

Page 5: Repair Instructions

Repair Instructions Recommended repair tools for use with these instructions: Always flush pump with water, or neutralizing agent, Cleanup Of Pump Housing before servicing. 1. Using the circular bottle-type wire brush with air or hand Pump Housing Disassembly (All Models) drill, clean the discharge port, suction port and the sealing areas of the o-ring on the pump casing and mounting In most cases, seal replacement requires disassembly of only... -

Page 6: Plumbing Installation

Plumbing Installation Centrifugal Plumbing Hook-up REF. DESCRIPTION Tank Lid Vent Line #3430-0456 Jet Agitator Shut-off Ball Valves Centrifugal Pump Spray Control Console Centrifugal Pump Control Manifold Boom Valve Electromagnetic Flowmeter Compact Jet Turret Nozzle Body - 6 -... - Page 7 Plumbing Installation Pump Installation: Strainers The following are recommendations to achieve the The recommended placement of the strainer for a optimal performance out of your centrifugal pump and centrifugal pump is in the pump outlet line. This will your spraying system. eliminate any possible restriction that the strainer could create if it were installed in the inlet line.

- Page 8 Returns are to be shipped with the RMA number clearly marked on the outside of the package. Hypro shall not be liable for freight damage incurred during shipping. Please package all returns carefully. All products returned for warranty work should be sent shipping charges prepaid to: HYPRO / PENTAIR Attention: Service Department 375 Fifth Avenue NW...

Need help?

Do you have a question about the HYPRO 9500 Series and is the answer not in the manual?

Questions and answers