Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Silca OLYMPIC

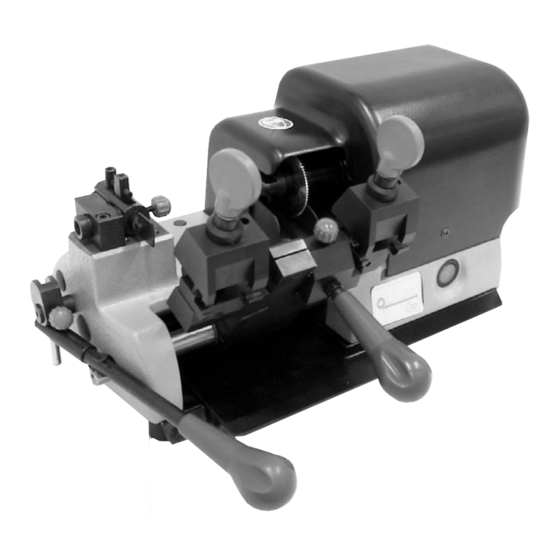

- Page 1 Operating manual D424321XA vers. ®...

- Page 2 ® KEY-CUTTING MACHINE OLYMPIC Operating Manual code: D424321XA - vers. 2.0...

- Page 3 © 2002 SILCA S.p.A - Vittorio Veneto This manual has been drawn up by Silca S.p.A. All rights reserved. No part of this publication may be reproduced or used in any form or by any means (photocopying, microfilm or other) without the written permission of Silca S.p.A.

-

Page 4: Table Of Contents

INDEX GUIDE TO THE MANUAL ......................5 GENERAL INSTRUCTIONS ....................6 TRANSPORT ......................7 Packing ..........................7 Transport ......................... 7 Unpacking ........................7 Machine handling ......................7 WORKING PARTS .....................8 MACHINE DESCRIPTION ..................9 Technical data ......................... 9 Electrical circuit ......................10 ACCESSORIES PROVIDED ..................11 MACHINE INSTALLATION AND PREPARATION ..........12 Checking for damage .................... -

Page 6: Guide To The Manual

Operating manual - English OLYMPIC GUIDE TO THE MANUAL This manual has been produced to serve as a guide for users of the OLYMPIC key-cutting machine. Read it carefully; it is essential if you wish to operate your machine safely and efficiently. Consultation... -

Page 7: General Instructions

The material used in the manufacture of this machine and the components employed during use of the machine are not dangerous and their use complies with standards. The OLYMPIC key-cutting machine must be installed and used in the way laid down by the manufacturer, as illustrated in this manual. -

Page 8: Transport

The packed machine can be carried by one person. Packing The OLYMPIC key-cutting machine comes in a strong cardboard box, the dimensions of which are shown in fig.3, designed to protect the machine and all its parts even when it is stored for long periods. -

Page 9: Working Parts

M - Clamp, cutter side N - Tracer O - Cutter P - Anti-rocking knob W - Carriage locking device X - Safety device (supplied with the 230V machines) X1- Safety main switch X2- Warning light X3- Plug Copyright Silca 2002... -

Page 10: Machine Description

It has been designed to avoid the accumulation of cutting dust or chippings. • Cutting tool (O) The cutting tool is the part of the OLYMPIC machine which cuts the key blank. The tool is in hard metal (carbide) and is protected by a special cover (H) to ensure safe operation. •... -

Page 11: Electrical Circuit

The OLYMPIC key-cutting machine is provided with a single phase one-speed motor: 1350 rpm, consumes approximately 0.18 Kw, absorption 2A; The main parts of the electric circuit on the OLYMPIC are listed below: 1) Safety device inlet. 2) Safety main switch... -

Page 12: Accessories Provided

It is advisable to always have a tool box containing: tools, cutting tools, and small replacement parts. OLYMPIC is supplied with a full range of accessories. The accessories provided by Silca are all that is necessary to carry out the operations for which the machine is designed. -

Page 13: Machine Installation And Preparation

Operating manual - English MACHINE INSTALLATION AND PREPARATION The OLYMPIC key-cutting machine can be installed by the purchaser and does not require any special skills. However, some checks and preparation for use need to be carried out by the operator. -

Page 14: Graphics

THE USE OF PROTECTIVE GOGGLES IS COMPULSORY Separate parts The detachable parts of the machine are packed separately and must be fitted to the OLYMPIC by the operator, as follows: Power cable First connect the safety device (X) to the key-cutting machine and the power cable then connect the free end of the power cable to the power mains (fig.7). -

Page 15: Regulation And Use Of The Machine

Operating manual - English REGULATION AND USE OF THE MACHINE The cutting tool on the OLYMPIC is used to cut the key blanks and must be periodically checked and replaced. Periodically, and whenever the cutting tool is replaced, check the key-cutting machine settings, to ensure perfect machine efficiency. -

Page 16: 6.1.2 Setting The Cutting Spaces

- move the tracer unit next to the gauge in the left clamp (L). - fasten the screw (N1). - make sure the above mentioned condition occurs before the adjustment of the machine can be con- sidered correct. Fig. 10 Fig. 11 Copyright Silca 2002... -

Page 17: Cutting Operations

- CHUBB (bit key with collar) Fig. 12 Nota bene:to position the clamp on the side required, loosen the knob (I) slightly, hold the bottom part of the clamp, lift, turn 180° and place in position in its seat. Copyright Silca 2002... -

Page 18: Bit And Double Bit Keys

Nota bene:move the carriage by raising the knob (C), this makes it move towards the cutter with the key tilted thus aiding the cut (fig.13). 6) carry out the cut. 7) round off the cuts by tilting the (C) knob from top to bottom. Fig. 13 Copyright Silca 2002... -

Page 19: Pump Keys

3) To trim externally the bit, don’t round off the cuts (fig. 13, page 17). 4) Stop the right clamp from tilting by fastening the knob (P). 5) To cut the bit, round off the cuts (ch. 6.4). Copyright Silca 2002... -

Page 20: Maintenance

ATTENTION: for repairs or replacement of parts for maintenance, the ‘CE’ mark is guaranteed only if original spare parts provided by the manufacturer are used Although the OLYMPIC key-cutting machine does not require special maintenance, it is advisable to check and, if necessary, replace the parts subject to wear (cutting tool, tracer point). -

Page 21: Replacing The Fuses

3) replace the fuses (U). 4) close the fuses box and connect the power cable ATTENTION: fuses must always be replaced with others of the same type (rapid) and with the same Amps (4 Amps). Fig. 18 Copyright Silca 2002... -

Page 22: Disposing Of Machine

Recycling is ecologically recommended. Packing The OLYMPIC is consigned in a cardboard packing box which can be re-used if undamaged. When it is to be thrown away it is classified as solid urban waste and should be placed in the special paper collecting bins. -

Page 23: After-Sales Service

How to request service The guarantee attached to the OLYMPIC ensures free repairs or replacements of faulty parts within 12 months of the date of purchase. All other service calls must be arranged by the customer with Silca or specialized Silca service centres. - Page 24 Vittorio Veneto VITTORIO VENETO 11/11/2005 CE DECLARATION OF MACHINE COMPLIANCE SILCA S.p.A. - VIA PODGORA 20 ( Z.I.) 31029 VITTORIO VENETO (TV) - (ITALY) TEL. 0438 9136 - FAX. 0438 913800 Declares under its own responsibility that the Key-cutting machine model...

Need help?

Do you have a question about the OLYMPIC and is the answer not in the manual?

Questions and answers