Table of Contents

Advertisement

Quick Links

User Manual

Betriebsanleitung

Stratos®Pro

Aktuelle Produktinformation: www.knick.de

Latest Product Information: www.knick.de

Stratos MS A405

pH Measurement

Stratos Pro A2... pH

English

deutsch

Betriebsanleitung

Aktuelle Produktinformation:

www.knick.de

The Art of Measuring.

A2... PH

SENS

MEMO

II 1G Ex ia IIC T3/T4/T6

14163 Berlin

14163 Berlin

SE 706X/1-NMSN

SE 706X/2-NMS

14163 Berlin

BVS 10 ATEX E0

BVS 10 ATEX E089 X

II 1G Ex ia IIC T

SE 706X/1-NM

II 1G Ex ia IIC T3/T4/T6

BVS 10 ATEX E

14163 Berlin

II 1G Ex ia IIC

SE 706X/2-NMSN

14163 Berlin

SE 706X/2-NM

BVS 10 ATEX E089 X

II 1G Ex ia IIC T3/T4/T6

BVS 10 ATEX E

II 1G Ex ia IIC

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Knick Stratos MS A405

- Page 1 SE 706X/2-NMSN 14163 Berlin SE 706X/2-NM BVS 10 ATEX E089 X II 1G Ex ia IIC T3/T4/T6 BVS 10 ATEX E II 1G Ex ia IIC Stratos MS A405 User Manual Betriebsanleitung Stratos Pro A2... pH pH Measurement Stratos®Pro English deutsch A2...

-

Page 3: Table Of Contents

Table of Contents About This Manual .....................5 Documents Supplied ....................6 Introduction ..................7 Overview of the Stratos MS ............... 8 Package Contents .......................8 Mounting Accessories ....................9 Pipe Mounting, Protective Hood ............... 10 Panel Mounting ....................... 11 Terminal Assignments, Rating Plates..........12 Power Supply ...................... - Page 4 Table of Contents Alarm Delay, Sensocheck..................42 Temperature Compensation of Process Medium (pH) ......44 Relay Contacts: Function Assignment, Limit Values ........46 Relay Contacts: Limit Function, Hysteresis ............. 48 Relay Contacts: Alarm .................... 50 Relay Contacts: Controlling a Rinsing Probe ..........52 Protective Wiring of Relay Contacts..............

-

Page 5: About This Manual

About This Manual Subject to change without notice Return of Products Under Warranty Please contact our Service Team before returning a defective device. Ship the cleaned device to the address you have been given. If the device has been in contact with process fluids, it must be decontaminated/ disinfected before shipment. -

Page 6: Documents Supplied

Installation and first steps: • Operation • Menu structure • Calibration • Error messages and recommended actions Specific Test Report Electronic Documentation Manuals + Software Ex Devices: Control Drawings EU Declarations of Conformity Up-to date documentation available on our website: www.knick.de... -

Page 7: Introduction

For connecting the cables, the enclosure provides • 3 knockouts for cable glands M20x1.5 • 2 knockouts for NPT 1/2” or rigid metallic conduit Memosens sensors and connecting cables Please visit our website for more information on our product range: www.knick.de. -

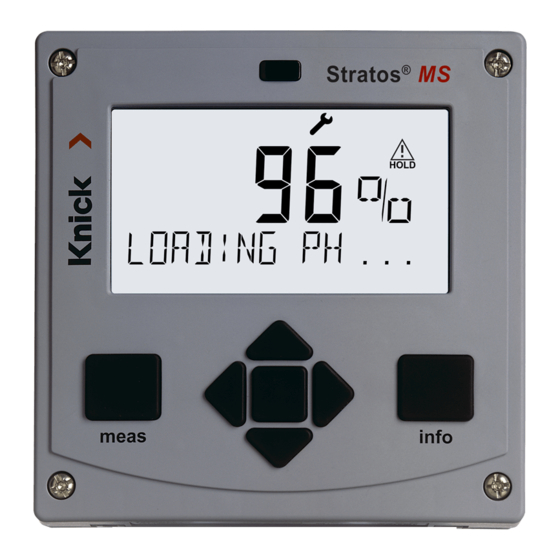

Page 8: Overview Of The Stratos Ms

Overview of the Stratos MS Package Contents Check the shipment for transport damage and completeness. The package should contain: Front unit, rear unit, bag containing small parts Specific test report Documentation Fig.: Assembling the enclosure 1) Jumper (3 x) 6) Sealing insert (1 x) 2) Washer (1 x), for conduit mounting: 7) Rubber reducer (1 x) Place washer between enclosure and... -

Page 9: Mounting Accessories

Overview of the Stratos MS Mounting Plan, Dimensions 1) Cable gland (3 x) 2) Knockouts for cable gland or ½“ conduit, dia. 21.5 mm (2 knockouts). Conduit couplings not included! 3) Knockout for pipe mounting (4 x) 4) Knockout for wall mounting (2 x) All dimensions in mm Mounting Accessories... -

Page 10: Pipe Mounting, Protective Hood

Overview of the Stratos MS Pipe Mounting, Protective Hood ø40...ø60 1) Hose clamp with worm gear drive to DIN 3017 (2 x) 2) Pipe-mount plate (1 x) 3) For vertical or horizontal posts or pipes 4) Self-tapping screw (4 x) Fig.: Pipe-mount kit, accessory ZU 0274 Fig.: Protective hood for wall and pipe mounting, accessory ZU 0737... -

Page 11: Panel Mounting

Overview of the Stratos MS Panel Mounting < 30 1) Circumferential sealing (1 x) 2) Screw (4 x) 3) Position of control panel 4) Span piece (4 x) 5) Threaded sleeve (4 x) Cutout 138 x 138 mm (DIN 43700) 1...22 Fig.: Panel-mount kit, accessory ZU 0738 All dimensions in mm... -

Page 12: Terminal Assignments, Rating Plates

Overview of the Stratos MS Overview of the Stratos MS Memosens Output 1 RS-485 Output 2 HOLD Power input Terminal Assignments, Rating Plates The terminals are suitable for single or stranded wires up to 2.5 mm (AWG 14). Application in Hazardous Locations When using the device in a hazardous location, observe the specifications of the Control Drawing. -

Page 13: Power Supply

Overview of the Stratos MS Power Supply Connect the power supply for Stratos MS to terminals 21 and 22 (80 ... 230 V AC, 45 ... 65 Hz / 24 ... 60 V DC) Terminal assignments Memosens connection 1 (BN) +3 V Brown 2 (GN) -

Page 14: Start-Up

Documenting and archiving meet the demands of FDA CFR 21 Part 11. Detailed reports can be output as csv export for Excel. MemoSuite is available as accessory and comes in the versions “Basic” and “Advanced”: www.knick.de. Settings and Connected sensor: sensor type, manufacturer,... -

Page 15: Memosens Cable

Memosens Cable CA/MS-... Memosens Cable Brown +3 V Green RS485 (A) Yellow RS485 (B) White Transparent Shield Specifications Material Cable diameter 6.3 mm Length up to 100 m Process temperature –20 °C … +135 °C / –4 … +275 °F Ingress protection IP 68 Order Codes Cable type Cable length Order code... -

Page 17: Measuring Mode

Operation Measuring Mode After the operating voltage has been connected, the analyzer automatically goes to “Measuring“ mode. To call the measuring mode from another operating mode (e.g., Diagnostics, Service): Hold meas key depressed (> 2 s). Sensoface indicator (sensor status) Time MEMO SENS... -

Page 18: The Keys And Their Functions

The Keys and Their Functions Up / Down Left / Right arrows arrows • Menu: • Menu: Increase/decrease a Previous/next numeral menu group • Menu: Selection • Number entry: Move between digits info meas • Retrieve • Return to last information menu level •... -

Page 19: Signal Colors (Display Backlighting)

The Display MEMO SENS 1 Temperature 13 Info available 2 Sensocheck 14 HOLD mode active 3 Interval/response time 15 Primary process value 4 Sensor data 16 Secondary display 5 Wear 17 Proceed using enter 6 Limit message: 18 Not used Limit 1 or Limit 2 19 Diagnostics... -

Page 20: Display In Measuring Mode

Display in Measuring Mode The MAIN DISPLAY is the display which is shown in measuring mode. To call the mea- suring mode from any other mode, hold the MEMO SENS meas key depressed for at least 2 sec. meas key enter key meas By pressing meas briefly you can step through... -

Page 21: Selecting The Mode / Entering Values

Selecting the Mode / Entering Values To select the operating mode: 1) Hold meas key depressed (> 2 s) (measuring mode) 2) Press menu key: the selection menu appears 3) Select operating mode using left / right arrow key 4) Press enter to confirm the selected mode Selection menu Selected mode (blinks) -

Page 22: Operating Modes

Operating Modes Diagnostics Display of calibration data, display of sensor data, sensor monitor, performing a device self-test, viewing the logbook entries, display of hardware/software versions of the individual components. The logbook can store 100 events (00...99). They can be displayed directly on the device. HOLD Manual activation of HOLD mode, e.g., for replacing a sensor. -

Page 23: Hold Mode

HOLD Mode The HOLD mode is a safety state during configuration and calibration. Output current is frozen (LAST) or set to a fixed value (FIX). Alarm and limit contacts are disabled. HOLD mode, display icon: Output signal response • LAST: The output current is frozen at its last value. Recommended for short configuration procedures. -

Page 24: Operating Modes / Functions

Operating Modes / Functions Measuring TAG display CLK display mode (main display after 60 s after 60 s selectable) Pressing the menu key (down arrow) opens the selection menu. Select the menu group using the left/right arrow keys. Pressing enter opens a menu item. Press meas to return. ... - Page 25 Overview of Configuration The configuration steps are assigned to different menu groups. Using the left/right arrow keys, you can jump between the individual menu groups. Each menu group contains menu items for setting the parameters. Pressing enter opens a menu item. Use the arrow keys to edit a value. Press enter to confirm/save the settings.

-

Page 26: Connecting A Memosens Sensor

Connecting a Memosens Sensor Step Action/Display Remark When no Memosens sensor is connected, the error message “NO SENSOR” is displayed. Connect sensor Wait until the sensor data The hourglass in the display SENS MEMO blinks. are displayed. Check sensor data Sensoface is friendly when the MEMO SENS... -

Page 27: Replacing A Sensor

Replacing a Sensor Step Action/Display Remark Press menu key to call the Select HOLD mode Now the device is in HOLD mode. The HOLD mode can also A sensor should only be selection menu, be activated externally via the replaced during HOLD select HOLD using the HOLD input. -

Page 28: Configuration: Overview

Configuration: Overview Configuration (default in bold print) Sensor (“info“ shows nominal buffer values) Sensor Verification (TAG, GROUP) When Memosens sensors are calibrated in the lab, it is often useful and sometimes even mandatory that these sensors will be operated again at the same measuring points or at a defined group of measuring points. - Page 29 Configuration: Overview Current output 1 (Memosens ORP sensor) Current output 2 Default setting CHANNEL: TMP (other settings like OT1) Correction...

- Page 30 Configuration: Overview Configuration (default in bold print) Alarm Relay 1 The following submenu depends on the selected setting. Relay 2 Default LIMIT / FUNCTION: Hi LEVL (other settings like Relay 1)

- Page 31 Configuration: Overview Time/date Measuring points (TAG / GROUP) The entries are made in the text line. The entries are made in the text line.

-

Page 32: Device Type: Ph

Configuration Device Type: pH The device type is automatically selected upon first start-up. In the SERVICE menu you can change the device type. Afterwards, you must select the corresponding calibration mode in the CONF menu. Press menu. Select CONF using , press enter. - Page 33 Configuration (pH) Menu item Action Choices Temperature unit Select °C or °F using keys. Press enter to confirm. Calibration mode Select CALMODE using keys: AUTO: Calibration with Calimatic buffer set recognition MAN: Manual input of buffer solutions DAT: Input of adjustment data of premeasured sensors Press enter to confirm.

-

Page 34: Sensor Verification (Tag, Group)

Configuration Sensor Verification (TAG, GROUP) Press menu key. Select CONF using , press enter. Select SENSOR menu using keys, press enter. All items of this menu group are indicated by the “SNS:” code. Press enter to select menu, edit using arrow keys (see next page). Confirm (and proceed) by pressing enter. - Page 35 Configuration Menu item Action Choices Select ON or OFF using keys. Press enter to confirm. When switched on, the entry for “TAG” in the Memosens sensor is compared to the entry in the analyzer. If the entries differ, a message will be generated.

-

Page 36: Output Current: Range, Current Start/End

Configuring the Current Output Output Current: Range, Current Start/End (Example: current output 1) Press menu key. Select CONF using , press enter. Select OUT1 menu using keys, press enter. All items of this menu group are indicated by the “OT1:“ code. - Page 37 Configuring the Current Output Menu item Action Choices Current range Select 4-20 mA or 0-20 mA range using keys. Press enter to confirm. Process variable Example: current output 1, device type pH Select using keys: PH: pH value ORP: ORP value TMP: Temperature Press enter to confirm.

-

Page 38: Output Current: Time Averaging Filter

Configuring the Current Output Output Current: Time Averaging Filter (Example: current output 1) Press menu key. Select CONF using , press enter. Select OUT1 menu using keys, press enter. All items of this menu group are indicated by the “OT1:“ code. - Page 39 Configuring the Current Output Menu item Action Choices Time averaging filter Enter value using keys. Press enter to confirm. Time averaging filter To smoothen the current output, a low-pass filter with adjustable filter time constant can be switched on. When there is a jump at the input (100 %), the output level is at 63 % after the time interval has been reached.

-

Page 40: Output Current: Error And Hold

Configuring the Current Output Output Current: Error and HOLD (Example: current output 1) Press menu key. Select CONF using , press enter. Select OUT1 menu using keys, press enter. All items of this menu group are indicated by the “OT1:“ code. - Page 41 Configuring the Current Output Menu item Action Choices Output current during The output current can be set to 22 mA in the case of error mes- error message sages or error messages. Select ON or OFF using keys. Confirm by pressing enter Output current during The output current can be set to 22 mA in the case of Sensoface...

-

Page 42: Alarm Delay, Sensocheck

Configuring the Alarm Alarm Delay, Sensocheck Press menu key. Select CONF using , press enter. Select ALARM menu using keys, press enter. All items of this menu group are indicated by the “ALA:” code. Press enter to select menu, edit using arrow keys (see next page). Confirm (and proceed) by pressing enter. - Page 43 Configuring the Alarm Menu item Action Choices Alarm delay Enter value using keys. Press enter to confirm. Sensocheck Select Sensocheck (continuous monitoring of glass and refer- ence electrode). Select ON or OFF using keys. Press enter to confirm. (At the same time, Sensoface is activated.

-

Page 44: Temperature Compensation Of Process Medium (Ph)

Temperature Compensation Temperature Compensation of Process Medium (pH) Press menu key. Select CONF using , press enter. Select CORRECTION menu using keys, press enter. All items of this menu group are indicated by the “COR:“ code. Confirm (and proceed) by pressing enter. Exit: Press meas key until the [meas] mode indicator is displayed. -

Page 45: Temperature Compensation

Temperature Compensation Menu item Action Choices Temperature compensa- For pH measurement only: Select temperature compensa- tion of process medium tion of the process medium. Linear: LIN Select using , press enter to confirm. Temperature compensa- Enter the linear temperature compensation of the process tion, linear medium. -

Page 46: Relay Contacts: Function Assignment, Limit Values

Configuring the Relay Contacts Relay Contacts: Function Assignment, Limit Values Press menu key. Select CONF using , press enter. Select RELAY1 menu using keys, press enter. Specify relay contact function: LIMIT. All items of this menu group are indicated by the “LM1:“ code. - Page 47 Configuring the Relay Contacts Menu item Action Choices Use of relays Select in the text line using keys: • Limit function (LIMITS) Note: The following submenu • Error message (ALARM) depends on the selected setting. • Rinse contact (WASH) Press enter to confirm.

-

Page 48: Relay Contacts: Limit Function, Hysteresis

Configuring the Relay Contacts Relay Contacts: Limit Function, Hysteresis (Example: relay 1) Press menu key. Select CONF using , press enter. Select RELAY1 menu using keys, press enter. Specify relay contact function: LIMIT. All items of this menu group are indicated by the “LM1:“ code. - Page 49 Configuring the Relay Contacts Menu item Action Choices Limit 1 hysteresis Select hysteresis using keys. Press enter to confirm. Limit 1 delay The contact is activated with delay (deactivated without delay) Adjust delay using keys. Press enter to confirm. Application of hysteresis: Limit Lo Limit Hi...

-

Page 50: Relay Contacts: Alarm

Configuring the Relay Contacts Relay Contacts: Alarm (Example: relay 1) Press menu key. Select CONF using , press enter. Select RELAY1 menu using keys, press enter. Specify relay contact function: ALARM. All items of this menu group are indicated by the “AL1:“ code. - Page 51 Configuring the Relay Contacts Menu item Action Choices Alarm Select error messages (FAIL) or Sensoface messages (FACE) as trigger signal using keys. Press enter to confirm. Contact response N/O: normally open contact N/C: normally closed contact Select using keys. Press enter to confirm.

-

Page 52: Relay Contacts: Controlling A Rinsing Probe

Configuring the Relay Contacts Relay Contacts: Controlling a Rinsing Probe (Example: relay 1) Press menu key. Select CONF using , press enter. Select RELAY1 menu using keys, press enter. Specify relay contact function: WASH. All items of this menu group are indicated by the “WS1:“ code. - Page 53 Configuring the Relay Contacts Menu item Action Choices Use of relays Select in the text line using keys: • Limit function (LIMITS) Note: The following submenu • Error message (ALARM) depends on the selected • Rinse contact (WASH) setting. Press enter to confirm.

-

Page 54: Protective Wiring Of Relay Contacts

Protective Wiring of Relay Contacts Protective Wiring of Relay Contacts Relay contacts are subject to electrical erosion. Especially with inductive and capac- itive loads, the service life of the contacts will be reduced. For suppression of sparks and arcing, components such as RC combinations, nonlinear resistors, series resistors and diodes should be used. - Page 55 Protective Wiring of Relay Contacts Typical Protective Wiring Measures DC application with inductive load AC/DC applications with capacitive load Connection of incandescent lamps Inductive load Free-wheeling diode, e.g.,1N4007 (Observe polarity) Contact Capacitive load Resistor, e.g., 8 Ω / 1 W at 24 V / 0.3 A Contact Incandescent lamp, max 60 W / 230 V, 30 W / 115 V Contact...

-

Page 56: Time And Date, Measuring Point

Configuring the Time/Date Time and Date, Measuring Point Press menu key. Select CONF using , press enter. Select CLOCK or TAG using keys, press enter. All items of this menu group are indicated by the “CLK:” or “TAG” code. Press enter to select menu, edit using arrow keys (see next page). - Page 57 Configuring the Time/Date Time and Date Control of the calibration and cleaning cycles is based on the time and date of the integrated real-time clock. In measuring mode the time is shown in the lower display. When using digital sensors, the calibration data is written in the sensor head.

-

Page 58: Calibration

Calibration Note: • All calibration procedures must be performed by trained personnel. Incorrectly set parameters may go unnoticed, but change the measuring properties. • The response time of the sensor and temperature probe is considerably reduced when the sensor is first moved about in the buffer solution and then held still. •... - Page 59 Calibration Calibration is used to adapt the device to the individual sensor characteristics, namely asymmetry potential and slope. Access to calibration can be protected with a passcode (SERVICE menu). First, you open the calibration menu and select the calibration mode: CAL_PH Depending on configuation setting: AUTO...

-

Page 60: Automatic Calibration

Automatic Calibration The AUTO calibration mode must have been preset during configuration. Make sure that the buffer solutions used correspond to the configured buffer set. Other buffer solutions, even those with the same nominal values, may demonstrate a different temperature response. This leads to measurement errors. Display Action Remark... - Page 61 Automatic Calibration Display Action Remark Note: Stability check. The measured value [mV] is Stability check can be displayed, “CAL2” and “enter” stopped after 10 sec (by pressing enter). are blinking. Calibration with the first However, this reduces buffer is terminated. Remove calibration accuracy.

-

Page 62: Manual Calibration

Manual Calibration The MAN calibration mode and the type of temperature detection are selected during configuration. For calibration with manual buffer specification, you must enter the pH value of the buffer solution used in the device for the proper tempera- ture. - Page 63 Manual Calibration Display Action Remark Note: At the end of the stability check, the value will be Stability check can be saved and the asymmetry stopped after 10 sec (by pressing enter). potential will be displayed. Calibration with the first However, this reduces buffer is terminated.

-

Page 64: Premeasured Sensors

Premeasured Sensors The DAT calibration mode must have been preset during configuration. You can directly enter the values for slope and asymmetry potential of a sensor. The values must be known, e.g., determined beforehand in the laboratory. Display Action Remark Select Calibration. -

Page 65: Slope: Converting % To Mv

Slope: Converting % to mV Converting slope [%] to slope [mV/pH] at 25 °C 46.2 47.4 48.5 49.7 50.9 52.1 53.3 54.5 55.6 56.8 58.0 59.2 60.4 Converting asymmetry potential to sensor zero point [mV] ZERO = 7 - = Sensor zero ZERO S [mV] = Asymmetry potential... -

Page 66: Orp (Redox) Calibration

ORP (Redox) Calibration The potential of a redox sensor is calibrated using a redox (ORP) buffer solution. In the course of that, the difference between the measured potential and the poten- tial of the calibration solution is determined according to the following equation. During measurement this difference is added to the measured potential. - Page 67 ORP (Redox) Calibration Display Action Remark Select ORP calibration. Press enter to proceed. Remove the sensor and Display (3 sec) temperature probe, clean Now the device is in them, and immerse them in HOLD mode. the redox buffer. Enter setpoint value for redox buffer.

-

Page 68: Product Calibration

Product Calibration Calibration by Sampling (One-Point Calibration). During product calibration the sensor remains in the process. The measurement process is only interrupted briefly. Procedure: 1) The sample is measured in the lab or directly on the site using a portable meter. To ensure an exact calibration, the sample temperature must correspond to the measured process temperature. - Page 69 Product Calibration Display Action Remark The device returns to mea- From the blinking suring mode. CAL mode indicator, you see that product calibration has not been terminated. Product calibration step 2: Display (3 sec) When the sample value has Now the device is in been determined, open the HOLD mode.

-

Page 70: Measurement

Measurement Display Remark From the configuration or calibration menus, you can MEMO SENS switch the device to measuring mode by pressing the meas key. In the measuring mode the upper display line shows the configured process variable (pH, ORP [mV] or tem- or AM/PM and °F: perature), the lower display line shows the time and the second configured process variable (pH, ORP [mV]... -

Page 71: Diagnostics

Diagnostics In the Diagnostics mode you can access the following menus without interrupting the measurement: CALDATA Viewing the calibration data SENSOR Viewing the sensor data SELFTEST Starting a device self-test LOGBOOK Viewing the logbook entries MONITOR Displaying currently measured values VERSION Displaying device type, software version, serial number Access to diagnostics can be protected with a passcode (SERVICE menu). - Page 72 Diagnostics Display Menu item Displaying the calibration data Select CALDATA using, confirm by pressing enter. Use thekeys to select from the bottom line of the display (LAST_CAL ZERO SLOPE NEXT_CAL). The selected parameter is shown in the upper display line. Press meas to return to measurement.

- Page 73 Diagnostics Display Menu item Device self-test (To abort, you can press meas.) 1 Display test: Display of all segments with changing background colors (white/green/red). Proceed by pressing enter 2 RAM test: Hourglass blinks, then display of --PASS-- or --FAIL-- Proceed by pressing enter 3 EEPROM test: Hourglass blinks, then display of --PASS-- or --FAIL-- Proceed by pressing enter...

- Page 74 Diagnostics Display Menu item Displaying the logbook entries Select LOGBOOK using, press enter to confirm. With the keys, you can scroll backwards and forwards through the logbook (entries -00-...-99-), -00- being the last entry. If the display is set to date/time, you can search for a particular date using the keys.

- Page 75 Diagnostics Display Menu item Displaying the currently measured values (sensor monitor) Select MONITOR using, press enter to confirm. Use the keys to select the desired parameter from the bottom line of the display. The selected parameter is shown in the upper display line.

-

Page 76: Service

Service In the Service mode you can access the following menus: MONITOR Displaying currently measured values OUT1 Testing current output 1 OUT2 Testing current output 2 RELAIS Testing the relay function CODES Assigning and editing passcodes DEVICE TYPE Selecting the device type (pH, Oxy, Cond) DEFAULT Resetting the device to factory settings Note:... - Page 77 Service Menu item Remark Displaying currently measured values (sensor monitor) with HOLD mode activated: Select MONITOR using, press enter to confirm. Select the process variable in the bottom text line using. The selected parameter is shown in the upper display line. As the device is in HOLD mode, you can perform validations using simulators without influencing the signal outputs.

- Page 78 Service Menu item Remark Setting the passcodes: In the “SERVICE - CODES“ menu you can assign passcodes to DIAG, HOLD, CAL, CONF and SERVICE modes (Service preset to 5555). When you have lost the Service passcode, you have to request an “Ambulance TAN“...

-

Page 79: Error Messages

Error Messages Info text Problem Error (is displayed in case of fault when Possible causes the Info key is pressed) ERR 99 DEVICE FAILURE Error in factory settings EEPROM or RAM defective This error message only occurs in the case of a total defect. The device must be repaired and recalibrated at the factory. - Page 80 Error Messages Info text Problem Error (is displayed in case of fault when Possible causes the Info key is pressed) ERR 60 OUTPUT LOAD Load error ERR 61 OUTPUT 1 TOO LOW Output current 1 < 0 (3.8) mA ERR 62 OUTPUT 1 TOO HIGH Output current 1 >...

-

Page 81: Sensocheck And Sensoface

Sensocheck and Sensoface Sensocheck, Sensoface Sensor Monitoring Sensocheck continuously monitors the sensor and its wiring. The three Sensoface indicators provide information on required maintenance of the sensor. Additional icons refer to the error cause. Pressing the info key shows an information text. Note: The worsening of a Sensoface criterion leads to the devaluation of the Sensoface indicator (Smiley gets “sad”). -

Page 82: Operating States

Operating States Operating status Measure DIAG 60 s CONF SERVICE SERVICE OUT 1 SERVICE OUT 2 SERVICE RELAY Cleaning function HOLD Explanation: as configured (Last/Fix or Last/Off ) active manual... -

Page 83: Product Range

Mounting accessories Pipe-mount kit ZU 0274 Panel-mount kit ZU 0738 Protective hood ZU 0737 M12 socket for sensor connection ZU 0860 with Memosens cable / M12 connector Up-to-date information: www.knick.de Phone: +49 30 80191-0 Fax: +49 30 80191-200 Email: info@knick.de... -

Page 84: Specifications

Manual calibration with entry of individual buffer values Data entry of premeasured sensors Product calibration Calimatic buffer sets * -01- Mettler-Toledo 2.00/4.01/7.00/9.21 -02- Knick CaliMat 2.00/4.00/7.00/9.00/12.00 -03- Ciba (94) 2.06/4.00/7.00/10.00 -04- NIST technical 1.68/4.00/7.00/10.01/12.46 -05- NIST standard 1.679/4.006/6.865/9.180 -06- HACH 4.01/7.00/10.01... - Page 85 Specifications HOLD input Galvanically separated (optocoupler) Function Switches device to HOLD mode Switching voltage 0 ... 2 V AC/DC HOLD inactive 10 ... 30 V AC/DC HOLD active Output 1 0/4 ... 20 mA, max. 10 V, floating (terminals 8 / 9, galvanically connected to output 2) Overrange * 22 mA in the case of error messages Characteristic...

- Page 86 Specifications Relays 1 / 2 Two relay contacts, floating (terminals 14 / 15 / 16) Contact ratings AC < 250 V / < 3 A / < 750 VA DC < 30 V / < 3 A / < 90 W Usage Limit value Alarm...

- Page 87 Parameters, calibration data, logbook > 10 years (EEPROM) Electrical safety Protection against electric shock by protective separation of all extra- low-voltage circuits against mains according to EN 61010-1 Explosion protection see Control Drawing or www.knick.de (A405B) EN 61326 Emitted interference Class B (residential environment)

-

Page 88: Buffer Tables

Buffer Tables -01- Mettler-Toledo (corresponds to former “Knick technical buffers”) °C... - Page 89 Buffer Tables -02- Knick CaliMat (Values also apply to Merck-Titrisols, Riedel-de-Haen Fixanals.) °C...

- Page 90 Buffer Tables -03- Ciba (94) buffers Nominal values: 2.06 4.00 7.00 10.00 °C * extrapolated...

- Page 91 Buffer Tables -04- Technical buffers to NIST °C * Values complemented...

- Page 92 Buffer Tables -05- NIST standard buffers NIST Standard (DIN 19266 : 2015-05) °C 1.666 4.000 6.984 9.464 1.668 3.998 6.951 9.395 13.207 1.670 3.997 6.923 9.332 13.003 1.672 3.998 6.900 9.276 12.810 1.675 4.000 6.881 9.225 12.627 1.679 4.005 6.865 9.180 12.454 1.683...

- Page 93 Buffer Tables -06- HACH buffers Nominal values: 4.01 7.00 10.01 (± 0,02 at 25 °C) °C * Values complemented...

- Page 94 Buffer Tables -07- WTW techn. buffers °C...

- Page 95 Buffer Tables -08- Hamilton Duracal buffers °C * Values complemented...

- Page 96 Buffer Tables -09- Reagecon buffers °C * Values complemented...

- Page 97 Buffer Tables -10- DIN 19267 buffers * Values extrapolated...

-

Page 98: U1- Specifiable Buffer Set

-U1- Specifiable Buffer Set You can specify a buffer set with 2 buffer solutions in the temperature range of 0 ... 95 °C, step width: 5 °C. To do so, select buffer set -U1- in the configuration menu. As delivered, the Ingold technical buffer solutions pH 4.01 / 7.00 are stored as buffer set and can be edited. - Page 99 -U1- Specifiable Buffer Set Step Action/Display Remark Select buffer set -U1- (CONFIG / SNS menu) Select buffer solution 1 You are prompted for for editing. confirmation to prevent accidental changes of the settings. Select “YES“ using up/ down arrow. Editing the values Enter the values for the Buffer solution 1 first buffer solution in...

- Page 100 -U1- Specifiable Buffer Set Buffer set U1: Fill in your configuration data or use the table as original for copy. Temperature (°C) Buffer 1 Buffer 2...

-

Page 101: Index

Index Accessories 83 Alarm delay 42 Alarm, relay contacts 50 Ambulance TAN 78 Assembly 8 Assigning measured values, current start/end 37 Asymmetry potential to sensor zero point 65 Automatic calibration 60 Backlighting 19 Buffer set, selection 33 Buffer tables 88 Buttons and functions 18 Cable glands 7 Cable type Memosens 15... - Page 102 Index Configuration, relay contacts 46 Configuration, Sensocheck 42 Configuration, sensor verification (TAG, GROUP) 34 Configuration, temperature compensation 44 Configuration, time and date 56 Configuration, time averaging filter 38 Connecting a Memosens sensor, menu 26 Connecting a Memosens sensor, terminal assignments 13 Control Drawings 6 Controlling a rinsing probe via relay contacts 52 Converting slope to mV 65...

- Page 103 HOLD, output signal response 23 Hose clamps 10 Hysteresis of relay contacts 48 Icons 19 Inductive loads, protective wiring of relay contacts 54 Info text 79 Installation, terminal assignments 13 Introduction 7 Keys and functions 18 Knick CaliMat buffers, buffer table 89...

- Page 104 Index Limit values (relay contacts) 46 Linear temperature compensation (pH) 45 LOGBOOK 74 Logbook entries, display 74 Loss of passcode 78 MAIN DISPLAY 20 Manual calibration 62 Measured values, display 75 Measuring function (device type) 76 Measuring mode 70 Measuring point (TAG/GROUP) 56 Memosens cable (specifications, order code) 15 Memosens sensor (connection, menu) 26 Memosens sensor (connection, terminal assignments) 13...

- Page 105 Index Output signal during HOLD (configuration) 41 Output signal during HOLD, overview 23 Overview of configuration 28 Package contents, complete 8 Package contents, documentation 6 Panel mounting 11 Passcode lost 78 Passcodes, setting 78 P_CAL, product calibration (calibration with sampling) 68 pH calibration, presetting 59 pH configuration 32 Post/pipe mounting 10...

- Page 106 Index Safety instructions 6 Selecting the device type 76 Sensocheck (configuration) 43 Sensocheck, description 81 Sensoface, configure output current 41 Sensoface, description 81 Sensoface messages, overview 80 Sensor data, display 72 Sensor monitor, diagnostics 75 Sensor monitor, Service mode 77 Sensor replacement 27 Sensor verification (TAG, GROUP) 34 Serial number, display 75...

- Page 107 Index Tag number, display 70 TAG of measuring point 57 Technical buffers to NIST, buffer table 91 Technical data 84 Temperature compensation 44 Temperature dependence of reference systems against SHE 66 Temperature unit 32 Terminal assignments 13 Terminals 12 Time and date, usage 57 Time averaging filter 39 Time, display 70 Time format, setting 56...

- Page 108 Knick Elektronische Messgeräte GmbH & Co. KG Beuckestraße 22 14163 Berlin Germany Phone: +49 30 80191-0 Fax: +49 30 80191-200 Web: www.knick.de Email: info@knick.de 090888 Stratos MS A405: pH Measurement TA-212.100-pH-KNE02 20170831 Software version: 1.x...

Need help?

Do you have a question about the Stratos MS A405 and is the answer not in the manual?

Questions and answers