Chapters

Table of Contents

Summary of Contents for Festo CPA10-VI

- Page 1 Compact performance CPA pneumatics manual Valve terminal with CPA pneumatics Type CPA...−VI Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô...

- Page 3 173 515 ® AS−Interface is a registered trade mark of AS−Interface Association E (Festo AG & Co., D 73726 Esslingen, Federal Republic of Germany, 2003) Internet: http://www.festo.com E−Mail: service_international@festo.com The copying, distribution and utilization of this document as well as the communication of its contents to others without expressed authorization is prohibited.

- Page 4 Contents and general instructions Festo P.BE−CPA−EN en 0306d...

-

Page 5: Table Of Contents

Address assignment of the valves ........3−24 Festo P.BE−CPA−EN en 0306d... - Page 6 ............C−1 Festo P.BE−CPA−EN en 0306d...

-

Page 7: Designated Use

National and local safety regulations must also be observed. Target group This manual is directed exclusively at technicians trained in control and automation technology. Service Please consult your local Festo repair service if you have any technical problems. Festo P.BE−CPA−EN en 0306d... -

Page 8: Commissioning

Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Information on electric/electronic components: in this manual Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Festo P.BE−CPA−EN en 0306d... - Page 9 8 inputs Type CPA..−GE−ASI−8E8A−Z Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Information on electric/electronic components: see information supplied with the product Tab. 0/2: Connection variants of the CPA valve terminal Festo P.BE−CPA−EN en 0306d...

- Page 10 Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Tab. 0/3: Manuals on the CPA valve terminal with CPX terminal VIII Festo P.BE−CPA−EN en 0306d...

- Page 11 Ö Ö Ö Ö Ö Ö Ö Ö Ö Ö Ö Ö Ö Ö Ö Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Tab. 0/4: Manuals on the CP system Festo P.BE−CPA−EN en 0306d...

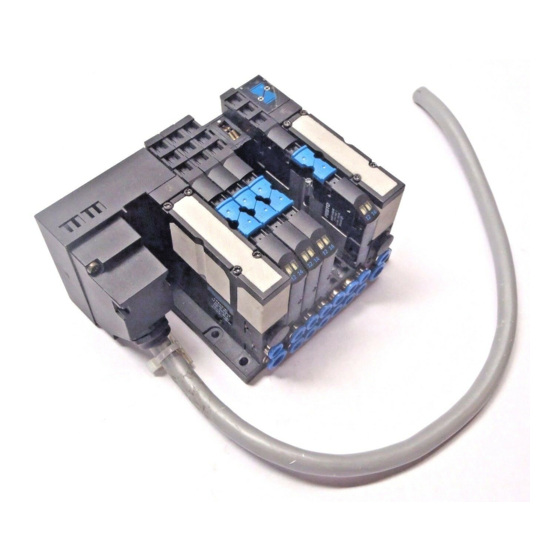

- Page 12 Fig. 0/1: Main components of the CPA valve terminal This manual contains the documentation of the valve plates with Ident. code B, E, G, H, J, K, M, N (see chapter System overview, description of components"). Festo P.BE−CPA−EN en 0306d...

-

Page 13: Important User Instructions

This means that failure to observe this instruction may result in damage to property. The following pictogram marks passages in the text which describe activities with electrostatically sensitive compo nents. Electrostatically sensitive components may be damaged if they are not handled correctly. Festo P.BE−CPA−EN en 0306d... - Page 14 Accessories: Information on necessary or sensible accessories for the Festo product. Environment: Information on environment−friendly use of Festo products. Text markings The bullet indicates activities which may be carried out in · any order. 1. Figures denote activities which must be carried out in the numerical order specified.

- Page 15 CPA valve terminal variant with Sub−D plug via which all valve solenoid coils with multipin con are centrally connected. nection (MP connec tion) CPX modules Common term for the various modules which can be incorporated in a CPX terminal CPX terminal Modular, electric terminal type 50 XIII Festo P.BE−CPA−EN en 0306d...

- Page 16 In this plate, the compressed air is diverted from work connection 2 so that the relevant valve plates can be supplied with compressed air. The exhaust air can also be expelled via connection 4. Tab. 0/5: Product−specific terms and abbreviations Festo P.BE−CPA−EN en 0306d...

-

Page 17: System Summary

System summary Chapter 1 1−1 Festo P.BE−CPA−EN en 0306d... - Page 18 ........1−7 1−2 Festo P.BE−CPA−EN en 0306d...

- Page 19 Connecting, display and operating elements Further information Information on the electric multipin can be found in the brief description of the CPA valve terminal with multipin connec tion. 1−3 Festo P.BE−CPA−EN en 0306d...

-

Page 20: Overview Of Variants

1. System summary Overview of variants Festo assists you in solving your automation task at the ma chine level with CPA valve terminals. The modular structure of the CPA valve terminal for the CP system enables you to adapt the CPA valve terminals optimally to your machine or system. - Page 21 This CPA valve terminal is available with 2 to maximum 22 connection valve locations. The electrical connection of the valve sole noid coils is made via individual connector plugs. Maximum 44 valve coils can be controlled. 1−5 Festo P.BE−CPA−EN en 0306d...

- Page 22 The variant with 8 inputs (type: CPA..−GE−ASI−8E8A−Z) is avail able with 2 to max. 8 single−solenoid valve locations or max. 4 double−solenoid valve locations. Maximum 8 valve coils can be controlled. 1−6 Festo P.BE−CPA−EN en 0306d...

-

Page 23: Description Of Components

Electric manifold sub−base (manifold or AS−interface with inputs: sub−base EV1 occupies 1 address, Adapter for fitting the CPX pneumatic EV2 occupies 2 addresses) interface or the AS−interface module Fig. 1/3: Electric components on the CPA valve terminal 1−7 Festo P.BE−CPA−EN en 0306d... - Page 24 Left−hand end plate with supply and exhaust connections Additional pressure supply plate or blanking plate Fig. 1/4: Pneumatic components on the CPA valve terminal 1−8 Festo P.BE−CPA−EN en 0306d...

- Page 25 All CPA valve terminal variants are available with micro minal valves (valve size 10 mm, CPA10) or with mini valves (valve size 14 mm, CPA14). Mixed fitting with both grid dimensions is not possible on a CPA valve terminal. 1−9 Festo P.BE−CPA−EN en 0306d...

- Page 26 Sub−base for pressure zone separation, compressed air channel (1) blocked Valve plate, 5/2−way, single−solenoid on two−coil valve location Tab. 1/2: Identification codes of the pneumatic components Further information on the valve plates can be found in ap pendix A. 1−10 Festo P.BE−CPA−EN en 0306d...

- Page 27 Supply connections (1, 12/14) and exhaust connection (3/5) on the right−hand end plate Work connections (2, 4), per valve plate Supply connection (1) and exhaust connections (3/5, 82/84) on the left−hand end plate Fig. 1/5: Pneumatic connecting and operating elements on the CPA valve terminal 1−11 Festo P.BE−CPA−EN en 0306d...

- Page 28 LED, shows signal states of the pilot solenoids Connecting lugs of pilot solenoid coil 12 Connecting lugs of pilot solenoid coil 14 Fig. 1/6: Electrical connecting and display elements of the CPA valve terminal with IC connection 1−12 Festo P.BE−CPA−EN en 0306d...

- Page 29 Î Î Î Î Î Î Inscription clips Yellow LEDs, signal status display of the pilot solenoids SUB−D multipin plug (25−pin) Fig. 1/7: Electrical connecting and display elements of the CPA valve terminal with MP connection 1−13 Festo P.BE−CPA−EN en 0306d...

- Page 30 Green LED, status display of the CP connection Incoming CP cable Yellow LEDs, signal status display of the pilot solenoids Continuing CP cable Earth/ground connection Inscription clips Fig. 1/8: Electrical connecting and display elements of the CPA valve terminal with CP connection 1−14 Festo P.BE−CPA−EN en 0306d...

- Page 31 Earth/ground connection Green LED, status display of the CP connection Cable socket for additional supply with black additional supply cable (optional) Fig. 1/9: Electrical connecting and display elements of the CPA valve terminal with AS−interface connection 1−15 Festo P.BE−CPA−EN en 0306d...

- Page 32 Status LEDs: Inscription fields for addresses Inputs (green) Cover Valves (yellow) DIL switch (under cover) Addressing socket Fig. 1/10: Electrical connecting and display elements of the CPA valve terminal with AS−in terface connection and inputs 1−16 Festo P.BE−CPA−EN en 0306d...

- Page 33 Yellow LED, signal status display of the pilot solenoids Fig. 1/11: Electrical connecting and display elements of the CPA valve terminal with CPX terminal Detailed information on the CPX pneumatic interface can be found in the supplementary description CPX I/O modules (P.BE−CPX−EA−..). 1−17 Festo P.BE−CPA−EN en 0306d...

- Page 34 1. System summary 1−18 Festo P.BE−CPA−EN en 0306d...

-

Page 35: Fitting

Fitting Chapter 2 2−1 Festo P.BE−CPA−EN en 0306d... - Page 36 ........2−8 2−2 Festo P.BE−CPA−EN en 0306d...

- Page 37 manual for the CPX I/O modules and in the information supplied with the product in the case of modules and components or dered at a later stage. 2−3 Festo P.BE−CPA−EN en 0306d...

-

Page 38: Fitting Variants

Fitting onto a hat rail Please note Mount the CPA valve terminal so that there is sufficient space for heat dissipation and so that the maximum limits for temperatures can be observed (see Technical Specifica tions). 2−4 Festo P.BE−CPA−EN en 0306d... -

Page 39: Fitting Onto A Wall

26 mm 10.6 mm x number of sub−bases 14.6 mm x number of sub−bases 4 holes for fitting onto a wall 4 holes for fitting onto a wall Fig. 2/1: Fastening holes, CPA valve terminal 2−5 Festo P.BE−CPA−EN en 0306d... - Page 40 113.1 mm 122 mm 46 mm + (10.6 mm x number of 52 mm + (14.6 mm x number of sub−bases) sub−bases) Fig. 2/2: Holes for wall fitting, CPA valve terminal with AS−interface and inputs 2−6 Festo P.BE−CPA−EN en 0306d...

- Page 41 Two screws on the CPX pneumatic interface. Ó Ó Ó Ó Ó Ó Two screws on the left−hand end plate of the CPX terminal. Tab. 2/1: Removing the CPA valve terminal from a wall 2−7 Festo P.BE−CPA−EN en 0306d...

- Page 42 (weights see appendix A). 2. Fit the hat rail hat rail (support rail EN 50022 − 35x7.5; width 35 mm, height 7.5 mm). Make sure there is suffi cient space for connecting the supply cables and tubing. 2−8 Festo P.BE−CPA−EN en 0306d...

- Page 43 Ô Ô Ô Ô Ô Ô Ô Ô Ó Ó Ó Ó Ó Ô Ô Ô Ô Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ô Ô Ô Ô Fig. 2/3: Fitting the CPA valve terminal onto a hat rail 2−9 Festo P.BE−CPA−EN en 0306d...

- Page 44 Ô Ô Ô Ô Ò Ò Ò Ò Ò Ô Ô Ô Ô Ò Ò Ò Ò Ò Ô Ô Ô Ô Ò Ò Ò Ò Ò Ô Ô Fig. 2/4: Dismantling the CPA valve terminal 2−10 Festo P.BE−CPA−EN en 0306d...

-

Page 45: Installation

Installation Chapter 3 3−1 Festo P.BE−CPA−EN en 0306d... - Page 46 Address assignment of the valves ....... . . 3−26 3−2 Festo P.BE−CPA−EN en 0306d...

- Page 47 Instructions on connecting the CPA valve terminal with CP connection can be found in the CPsystem manual. Instructions on connecting the CPA valve terminal with CPX terminal can be found in the CPX system manual. 3−3 Festo P.BE−CPA−EN en 0306d...

-

Page 48: Preparing The Compressed Air

If possible, operate your system with non−lubricated com pressed air. This will not pollute the environment. Pneumatic valves and actuators from Festo are designed so that, if used as designated, they will not require additional lubrication and will still achieve a long service life. - Page 49 Incorrect additional oil and excessive residual oil content in the compressed air will reduce the service life of the valve terminal. Use special oil OFSW−32 from Festo or the alternative oil listed in the Festo catalogue (corresponding to DIN 51524−HLP32, basic viscosity 32 CST at 40 °C).

- Page 50 A further indication of over−lubrication is the colouring or status of the exhaust silencer. A clearly yellow colouring of the filter element or oil drops on the silencer indicate a too high lubricator setting. 3−6 Festo P.BE−CPA−EN en 0306d...

-

Page 51: Laying The Tubing

1 (see Fig. 3/1). 2. If necessary, pull the locking ring 2 over the tubing con nection. 3. For reasons of clarity bundle the tubing together with: tubing straps or multiple hose holders 3−7 Festo P.BE−CPA−EN en 0306d... - Page 52 Please note In order to loosen the tubing in the pin types, use loosen ing fork type QSO from Festo or a screwdriver. When using a screwdriver: Press down the locking ring only with the broad side of ·...

-

Page 53: Connecting The Cpa Valve Terminal

3−9 Festo P.BE−CPA−EN en 0306d... - Page 54 3 ... 8 bar, you can operate the pilot control of the valve solenoid coils with internally branched auxiliary pilot air. The auxiliary pilot air in the right−hand end plate is branched here from supply channel 1. 3−10 Festo P.BE−CPA−EN en 0306d...

- Page 55 If the operating pressure lies below 3 bar or above 8 bar, you must operate the pilot control of the valve solenoid coils with external auxiliary pilot air. The auxiliary pilot air is supplied here externally via pilot connection 12/14. 3−11 Festo P.BE−CPA−EN en 0306d...

-

Page 56: Auxiliary Pilot Air

1 [bar] Start−up pressure of the pilot control Fig. 3/4: Diagram for CPA10: External auxiliary pilot air depending on operating pres sure for valve plates with Ident. code N, K and H 3−12 Festo P.BE−CPA−EN en 0306d... -

Page 57: Cpa Valve Terminal With Pressure Zone Separation

Pressure zones 1 ... 12 1 ... 9 1 ... 3 Tab. 3/2: Maximum number of pressure zones The pressure zones are implemented with special sub−bases which block the compressed air channel (1). 3−13 Festo P.BE−CPA−EN en 0306d... - Page 58 1 on the end plates; the remaining pressure zones are supplied via con nection 2 on the sub−bases which are fitted with additional pressure supply plates (see diagram). In order to expel the 3−14 Festo P.BE−CPA−EN en 0306d...

- Page 59 Pressure zone 2 (compressed air supply via connection 2 on the sub−base with additional pressure supply plate) Pressure zone 3 (compressed air supply via connection 1 on the right−hand end plate) Fig. 3/6: Example: Pressure zone separation and external pilot air 3−15 Festo P.BE−CPA−EN en 0306d...

- Page 60 B), blocked (Ident. code G) or exhausted (Ident. code E) 3.3.4 Connecting the pneumatic tubing Please note Seal connections which are not required for the function · ing of the CPA valve terminal with blanking plugs. 3−16 Festo P.BE−CPA−EN en 0306d...

- Page 61 Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó 12/14 82/84 Fig. 3/7: Pneumatic connections on the CPA valve terminal 3−17 Festo P.BE−CPA−EN en 0306d...

- Page 62 Pin−type inserts 2. Check whether the seal of the pin type is greased. If necessary grease the seal with Festo F2 grease. 3. Press the pin−type inserts into the connecting holes. 4. Make sure that the pin−type inserts are seated as far as possible in the holes.

- Page 63 Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó 5.5 mm (CPA10) or 6.5 mm (CPA14) Fig. 3/8: Checking the pin−type fitting 3−19 Festo P.BE−CPA−EN en 0306d...

- Page 64 Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Fig. 3/9: Fitting and fastening the pin−type inserts 6. Fit the tubing as shown in Fig. 3/1. 3−20 Festo P.BE−CPA−EN en 0306d...

- Page 65 82/84, in order to avoid impairment of function due to back pressures. CPA valve terminal 1 common 3/5 central 82/84 central 3/5 CPA valve terminal 2 common 82/84 Fig. 3/10: Common lines with non−return valves 3−21 Festo P.BE−CPA−EN en 0306d...

-

Page 66: Connecting The Electric Cables

Note:By the use of PELV power units, protection against elec tric shock (protection against direct and indirect contact) is guaranteed with Festo valve terminals in accordance with EN 60204−1 / IEC 204. Safety transformers with the adjacent symbol must be used for supplying PELV networks. The valve terminals must be earthed to ensure that they function cor rectly (e.g. - Page 67 With this variant of the CPA valve terminal, each valve sole noid coil is connected separately. Use the connecting socket type KMYZ−7−24−...−LED from Festo for connecting the valve solenoid coils. The holding current reduction for the valve solenoid coil and an LED are built into the transparent plug of this connecting socket.

- Page 68 (see diagram) with low impedance (short cable with large cross−sectional area) to the earth potential. You can thereby avoid faults due to electromagnetic in fluences and ensure electromagnetic compatibility in ac cordance with EMC guidelines. 3−24 Festo P.BE−CPA−EN en 0306d...

- Page 69 Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ô Ó Ó Ó Ó Ó Ó Ó Ó Earth/ground connection Fig. 3/12: Earthing the CPA valve terminal with CP connection 3−25 Festo P.BE−CPA−EN en 0306d...

-

Page 70: Address Assignment Of The Valves

Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Ó Fig. 3/13: Identifying the manifold sub−bases Counting begins from left to right, on the individual valves from the rear to the front (see diagram). 3−26 Festo P.BE−CPA−EN en 0306d... - Page 71 Ó Ó Ó Ó Ó Ó Ó Addresses of coil Ó Ó Ó Ó Ó Ó Ó Ó Fig. 3/14: Example: Address assignment of the CPA valve terminal with MP connection and 8 valve locations (top view) 3−27 Festo P.BE−CPA−EN en 0306d...

- Page 72 (see diagram). Valve plate with 2 solenoid coils Valve plate with one solenoid coil Blanking plate Fig. 3/15: Address assignment of the CPA valve terminal with IC connection and 8 valve locations (top view) 3−28 Festo P.BE−CPA−EN en 0306d...

- Page 73 Commissioning Chapter 4 4−1 Festo P.BE−CPA−EN en 0306d...

- Page 74 ........4−17 4.5.2 Operating states of the pneumatic system ....4−18 4−2 Festo P.BE−CPA−EN en 0306d...

- Page 75 The commissioning of the CP system is described in the rel evant manual for the CP node. The commissioning of the CPX terminal is described in the relevant manual for the CPX field bus node. 4−3 Festo P.BE−CPA−EN en 0306d...

- Page 76 This may cause damage to the machine or system and injury to human beings. Operate the valve terminal with external auxiliary pilot · air (3 ... 8 bar). Branch the auxiliary pilot air in front of the safety start−up valve (see diagram). 4−4 Festo P.BE−CPA−EN en 0306d...

- Page 77 Externally supplied auxiliary pilot air (3 to 8 bar), branched in front of the safety start−up valve Safety start−up valve (slow pressure build−up of the complete supply) Fig. 4/1: Example of valve−cylinder combination with slow pressure build−up of the complete system 4−5 Festo P.BE−CPA−EN en 0306d...

- Page 78 By actuating the manual override you can switch the valve without an electric signal. Only the compressed air supply needs to be switched on. The manual override has been designed to be used as fol lows: 4−6 Festo P.BE−CPA−EN en 0306d...

- Page 79 Slide of the locking manual override to Slide of the non−locking manual pilot solenoid 12 override to pilot solenoid 12 Fig. 4/2: Manual override variants of the CPA valve terminal with MP, CP, AS−interface connection or CPX terminal 4−7 Festo P.BE−CPA−EN en 0306d...

- Page 80 The assignment of the manual override to the valve solenoid coils is shown below. Locking/non−locking manual override to pilot solenoid Locking/non−locking manual override to pilot solenoid Fig. 4/3: Position of the manual override on CPA valve ter minals with IC connection 4−8 Festo P.BE−CPA−EN en 0306d...

- Page 81 Commissioning variants The commissioning of the pneumatic components by means of the manual override is described below. The commissioning of the CPX terminal is described in the relevant manual for the CPX field bus node. 4−9 Festo P.BE−CPA−EN en 0306d...

- Page 82 A valve, which has been switched by an electric signal, cannot be reset by the manual override. The electric signal is dominant in this case. Reset the electric signal before actuating the manual · override. 1. Switch on the compressed air supply. 4−10 Festo P.BE−CPA−EN en 0306d...

-

Page 83: Testing The Valves

3. On CPA valve terminals with locking manual override actuations: After checking the valves, make sure that all manual override actuations are reset to their basic posi tions. 4. Switch off the compressed air supply after testing the valves. 4−11 Festo P.BE−CPA−EN en 0306d... - Page 84 Release the plunger (spring re returns to the sets the plunger of the manual basic position override to the basic position). (not with double−sole noid valve type Tab. 4/4: Operating the non−locking manual override 4−12 Festo P.BE−CPA−EN en 0306d...

- Page 85 CPA valve terminal with IC con nection Then turn the plunger in an · anti−clockwise direction as far as possible. Then release the plunger. · Tab. 4/5: Operating the locking manual override 4−13 Festo P.BE−CPA−EN en 0306d...

- Page 86 14; with man ual override 12 you can control the valve on control side 12 (see switching symbols for valve plates in Appendix In this way, you can avoid undefined switching states when commissioning the machine/system. 4−14 Festo P.BE−CPA−EN en 0306d...

- Page 87 14 LED and manual override for pilot solenoid 12 Fig. 4/4: Assignment of the LED to the manual override actuations on CPA valve ter minals with MP, CP, AS−interface connection or CPX terminal 4−15 Festo P.BE−CPA−EN en 0306d...

- Page 88 V to 26.4 V DC) Compressed air supply not OK pilot exhaust blocked servicing required *) The LEDs light up on double−solenoid valves (Ident. code J) only when there are electric pulses. Tab. 4/6: Meaning of the LED display 4−16 Festo P.BE−CPA−EN en 0306d...

-

Page 89: Impairment Of Function

· again (if necessary set as a factor of the operat ing pressure, see chapter 3) servicing required · Tab. 4/7: Impairment of function of the pneumatic system 4−17 Festo P.BE−CPA−EN en 0306d... - Page 90 Slow start up after If control signals are present, the au EMERGENCY STOP xiliary pilot air must have a pressure of 3 ... 8 bar immediately after being switched on Tab. 4/8: Pneumatic operating states 4−18 Festo P.BE−CPA−EN en 0306d...

-

Page 91: Maintenance And Conversion

Maintenance and conversion Chapter 5 5−1 Festo P.BE−CPA−EN en 0306d... - Page 92 ........5−27 5−2 Festo P.BE−CPA−EN en 0306d...

-

Page 93: Maintenance And Conversion

CPA valve terminal with multipin or AS−interface connection can be found in the information supplied with the product. Instructions on connecting the CPA valve terminal with CP connection can be found in the CP system manual. 5−3 Festo P.BE−CPA−EN en 0306d... -

Page 94: General Precautionary Measures

· stress the seals must be checked for damage (IP 65) · connecting surfaces must be dry and clean (sealing ef · fect, avoid leakage and contact faults) 5−4 Festo P.BE−CPA−EN en 0306d... -

Page 95: Dismantling The Cpa Valve Terminal

2. Loosen the locking screws of the connecting plugs. 3. Pull the plugs carefully away from the connecting lugs. CPX terminal 1. Mark all electrical connecting cables. 2. Loosen and remove these cables. Tab. 5/1: Loosen the electrical connections. 5−5 Festo P.BE−CPA−EN en 0306d... - Page 96 5. Maintenance and conversion Loosening the pneumatic connections Loosening the pneumatic connections is described in chapter 3. Removing the CPA valve terminal Removing the CPA valve terminal from the fastening surface is described in chapter 2. 5−6 Festo P.BE−CPA−EN en 0306d...

-

Page 97: Servicing The Cpa Valve Terminal

4. Make sure that the seal is fitted correctly. It must lie in the recess in the end plate. 5. Fasten the large surface−mounted silencer only with the original screws. Tighten these in diagonally opposite se quence with: CPA10: 0.7 Nm (±0.1 Nm) CPA14: 0.8 Nm (±0.1 Nm) 5−7 Festo P.BE−CPA−EN en 0306d... -

Page 98: Replacing Cpa Valve Terminal Components

1. Loosen the fastening screws of the relevant components (position of the fastening screws see diagram). In order to do this, use a screwdriver with a narrow blade. 2. Remove the components from the sub−base of the CPA valve terminal. 5−8 Festo P.BE−CPA−EN en 0306d... - Page 99 Fig. 5/1: Removing valve plates Fitting Proceed as follows: 1. Check the seal for damage. 2. If necessary, replace damaged seals. 3. Make sure that the seal is fitted correctly. It must lie in the recess in the sub−base. 5−9 Festo P.BE−CPA−EN en 0306d...

-

Page 100: Replacing The Large Surface−Mounted Silencer

1. Check the seal between the end plate and the large sur face−mounted silencer for damage. If necessary, replace the seal. 2. Replace the large surface−mounted silencer. 3. Make sure that the seal is fitted correctly. It must lie in the recess in the end plate. 5−10 Festo P.BE−CPA−EN en 0306d... -

Page 101: Replacing The End Plate, Sub−Base Or Manifold Sub−Base

Remove the pin−type inserts from the sub−base to be re placed. Unlock the pin−type inserts by using a screwdriver to remove the clamping spring. Pull the pin−type inserts out of the sub−base (see diagram). In order to do this use a screwdriver. 5−11 Festo P.BE−CPA−EN en 0306d... - Page 102 Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Pin−type inserts Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Fig. 5/2: Removing the pin−type inserts 5−12 Festo P.BE−CPA−EN en 0306d...

- Page 103 Fig. 5/3: Loosening components on sub−bases 5. Replacing a sub−base or a manifold sub−base Remove the components on the sub−base to be replaced (see this chapter, Replacing valve plates, blanking plates or additonal pressure supply plates"). 5−13 Festo P.BE−CPA−EN en 0306d...

- Page 104 Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Fastening screws Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô of the sub−base Fig. 5/5: Loosening the sub−base or manifold 5−14 Festo P.BE−CPA−EN en 0306d...

- Page 105 Ò Ò Ò Ò Ò Ò Ò Ò Ò Ò Ò Fig. 5/6: Removing sub−bases Unlocking the manifold sub−base Removing the manifold from the sub−base Fig. 5/7: Removing the manifold sub−base Fitting Proceed as follows: 5−15 Festo P.BE−CPA−EN en 0306d...

- Page 106 (see Fig. 5/8). Tighten the screws as follows (position see Fig. 5/5): CPA10: 0.7 Nm (±0.1 Nm) CPA14: 0.8 Nm (±0.1 Nm) 5−16 Festo P.BE−CPA−EN en 0306d...

- Page 107 7. Tighten the screws of the tie rods in 2 stages as follows: Stage CPA10 CPA14 0.5 Nm 0.5 Nm 1.5 Nm 2 Nm Tab. 5/2: Tightening torques of the tie rods 5−17 Festo P.BE−CPA−EN en 0306d...

-

Page 108: Connecting The Supply, Exhaust And Work Lines

12. Mount the CPA valve terminals on the fastening surface (see chapter 2 Fitting, onto a wall" or onto a hat rail"). 13. Then complete the pneumatic and electrical connections (see chapter 3 Installation, connecting the CPA valve terminal"). 5−18 Festo P.BE−CPA−EN en 0306d... -

Page 109: Converting The Cpa Valve Terminal

Proceed as follows: If you wish to use the locking clip again Use a thin object (e.g. a spatula) in order to lift the lock · ing clip out of its fastening (Fig. 5/9, 1 ) 5−19 Festo P.BE−CPA−EN en 0306d... - Page 110 (Fig. 5/10, 2 ). The locking clip will then bend and snap out of the fastening. Removing the locking clip by lifting it Removing the locking clip by pressing out (the Clip can be used again) it out Fig. 5/9: Converting the manual override 5−20 Festo P.BE−CPA−EN en 0306d...

-

Page 111: Conversion To Internal Or External Auxiliary Pilot Air

The available right−hand end plates are listed in the following table. Check whether the right−hand end plate, with which your CPA valve terminal is fitted, is intended for pilot control with internal or external auxiliary pilot air. 5−21 Festo P.BE−CPA−EN en 0306d... - Page 112 Non−used connections must be sealed. Tab. 5/4: Right−hand end plate The method of fitting the relevant end plate into your CPA valve terminal is described in this chapter under Replacing the end plate, sub−base or manifold sub−base." 5−22 Festo P.BE−CPA−EN en 0306d...

-

Page 113: Conversion Of The Cpa Valve Terminal To Different Pressure Zones

The method of replacing the sub−bases and fitting the addi tional pressure supply plate is described in this chapter under Replacing the end plate, sub−base or manifold sub− base" or Replacing valve plates, blanking plates or addi tional pressure supply plates." 5−23 Festo P.BE−CPA−EN en 0306d... - Page 114 Connection 1 of the right−hand end plate for compressed air supply to the 3rd. pressure zone. Valve plates of the 3rd. pressure zone Fig. 5/10: Example of CPA valve terminal with three pressure zones 5−24 Festo P.BE−CPA−EN en 0306d...

-

Page 115: Conversion Of Valve Location For Controlling One Or Two Solenoid Coils

Ô Ô Ô Ô Ô Ô Ô Ô Ô Ô Manifold Ô Ô Ô Ô Ô Ô Ô Ô Ô sub−base for controlling two Ô Ô Ô solenoid coils Fig. 5/11: Identifying the manifold sub−bases 5−25 Festo P.BE−CPA−EN en 0306d... - Page 116 Please note: manifold sub−base CPA..−EV1 occupies 1 address manifold sub−base CPA..−EV2 occupies 2 addresses The method of replacing a manifold sub−base is described in this chapter under Replacing an end plate, sub−base or manifold sub−base." 5−26 Festo P.BE−CPA−EN en 0306d...

-

Page 117: Adding/Removing Valve Locations

Short tie rod screw (extension of this CPA valve terminal to 8 valve locations) 7. and 8th. new valve location Long tie rod screw (extension of this CPA valve terminal to 9 valve locations) Fig. 5/12: Extending the CPA valve terminal 5−27 Festo P.BE−CPA−EN en 0306d... - Page 118 Short tie rod screw, if necessary (for valve terminals with even number of valve locations) CPA..−ZA−SK Long tie rod screw, if necessary (for valve terminals with odd number of valve locations) CPA..−ZA−SL Tab. 5/7: Tie rod extension 5−28 Festo P.BE−CPA−EN en 0306d...

- Page 119 Long tie rod screw, if necessary (for valve terminals with odd number of valve locations) CPA..−ZA−SL Tab. 5/9: Tie rods and tie rod screws The following table lists the tie rod components which you will require in order to adapt the tie rod length. 5−29 Festo P.BE−CPA−EN en 0306d...

- Page 120 Remove the relevant valve locations (see this chapter, Replacing end plates, sub− bases or manifold sub−bases"). 4. Adapt the tie rods to the new number of valve locations (see tables of the tie rod components and Fig. 5/11). 5−30 Festo P.BE−CPA−EN en 0306d...

- Page 121 (see this chapter, Replacing valve plates, blanking plates or additional pressure supply plates"). 3. Fit the CPA valve terminals onto the fastening surface (see chapter 2 Fitting, onto a wall" or onto a hat rail"). 5−31 Festo P.BE−CPA−EN en 0306d...

- Page 122 5. Maintenance and conversion 5−32 Festo P.BE−CPA−EN en 0306d...

- Page 123 Technical appendix Appendix A A−1 Festo P.BE−CPA−EN en 0306d...

-

Page 124: Technical Appendix

..........A−11 A−2 Festo P.BE−CPA−EN en 0306d... -

Page 125: General Specifications

1. Step 0.5 Nm (CPA10/CPA14) 2. Step 1.5 Nm (CPA10) or 2.0 Nm (CPA14) Fastening for CPA valve terminal on 2.0 Nm (±0.4 Nm) CPX terminal Materials Plates, covers PPS, PA6T/X−GF40 Valve plate AL−DG, PPS, ST, AL Seals A−3 Festo P.BE−CPA−EN en 0306d... - Page 126 1000 shocks in each direction 0.35 mm path at 10−60 Hz; ±30 g at 11 ms duration; −−−−− 5 g acceleration at 60−150 Hz 5 shocks in each direction Tab. A/2: Values for vibration and shock as per DIN/IEC68 A−4 Festo P.BE−CPA−EN en 0306d...

- Page 127 Preparing the compressed air. In the case of CPA valve terminals with internally branched auxiliary pilot air, the above−mentioned in struction also applies to the supply air (connection 1). A−5 Festo P.BE−CPA−EN en 0306d...

- Page 128 12/14) 12/14: 3 ... 8 bar Valve plates Ident. code N, K, H: 1: 3 ... 10 bar 12/14: siehe diagrams Manual override locking or non−locking Tab. A/4: Technical specifications: Medium and pressure ranges A−6 Festo P.BE−CPA−EN en 0306d...

- Page 129 Fig. A/1: External pilot air diagram for valve plates CPA10 Ident. code N, K, H Control pressure 12/14 (bar) Work pressure P1 (bar) Start−up control pressure Fig. A/2: External pilot air diagram for valve plates CPA14 Ident. code N, K, H A−7 Festo P.BE−CPA−EN en 0306d...

- Page 130 2 ⇒ 3/5 or 4 ⇒ 3/5 5/2−way valve (single−solenoid) 5/2−way valve (double−solenoid) N, K, H, all 3/2−way valves 5/3 valve, pressurized 550 (400) 5/3 valve, closed 5/3 valve, exhausted 550 (400) Tab. A/5: Technical specifications: Rated flows A−8 Festo P.BE−CPA−EN en 0306d...

- Page 131 3/2−way valves On: 9 Off: 28 5/3 valve, pressurized On: 13 Off: 39 5/3 valve, closed On: 13 Off: 30 5/3 valve, exhausted On: 13 Off: 39 Tab. A/6: Technical specifications: Valve switching times A−9 Festo P.BE−CPA−EN en 0306d...

- Page 132 Further data on the electric components of the CPA valve ter minal with CP connection can be found in the relevant manual for the CP field bus node. A−10 Festo P.BE−CPA−EN en 0306d...

- Page 133 Individual connector plug with LED and holding current reduction KMYZ−7−24−...−LED CPA valve terminal with MP connection Ready−to−use multipin cable with socket KEA−1−25P−... (IP65), KMP4−25P−... (IP65) KMP6−25P−... (IP20) Multipin socket SD−SUB−D−BU25 (IP65) Tab. A/8: Festo accessories for the CPA valve terminal A−11 Festo P.BE−CPA−EN en 0306d...

- Page 134 A. Technical appendix A−12 Festo P.BE−CPA−EN en 0306d...

- Page 135 Supplementary component summary and installa tion instructions Appendix B B−1 Festo P.BE−CPA−EN en 0306d...

-

Page 136: Supplementary Component Summary And Installation Instructions

........B−3 Removing the electronic components from the CPA valve terminal ..B−6 B−2 Festo P.BE−CPA−EN en 0306d... - Page 137 Ident. code: H 82/84 Function: single−solenoid 3/2−way valve, on control side 14 in basic position blocked and single−solenoid 3/2−way valve, on control side 12 in basic position open 12/14 Tab. B/1: Valve plates with 3/2−way valves B−3 Festo P.BE−CPA−EN en 0306d...

- Page 138 Number of assigned outputs: Valve location with manifold sub−base EV1: 1A 12/14 Valve location with manifold sub−base EV2: 2A Ident. code: J 82/84 Function: 5/2−way double−solenoid valve 12/14 Tab. B/2: Valve plates with 5/2−way valves B−4 Festo P.BE−CPA−EN en 0306d...

- Page 139 5/3−way valve, in mid−position pressurized 12/14 Ident. code: G 82/84 Function: 5/3−way valve, in mid−position blocked 12/14 Ident. code: E 82/84 Function: 5/3−way valve, in mid−position exhausted 12/14 Tab. B/3: Valve plates with 5/3−way valves B−5 Festo P.BE−CPA−EN en 0306d...

- Page 140 Fig. B/1: Pneumatic interface and pneumatic adapter Dismantling Proceed as follows: 1. Loosen the electrical and pneumatic connections and re move the CPA valve terminal from the fastening surface (see this chapter, Dismantling the CPA valve terminal"). B−6 Festo P.BE−CPA−EN en 0306d...

- Page 141 Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Fig. B/2: Removing the CPA valve terminal from the CPX ter minal B−7 Festo P.BE−CPA−EN en 0306d...

- Page 142 Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Î Fig. B/4: Removing the CPA valve terminal from the CPX ter minal B−8 Festo P.BE−CPA−EN en 0306d...

- Page 143 AS−interface module). Fig. B/5: Fitting the elctrical bridge 2. Push the CPA valve terminal together with the CPX ter minal. Check that the electrical bridge is positioned cor rectly in the terminal strips. B−9 Festo P.BE−CPA−EN en 0306d...

- Page 144 3. Press and hold the CPA valve terminal against the CPX terminal. 4. Place the dowel pins in the locating holes of the pneuma tic adapter. Knock the dowel pins as far as possible into the holes. B−10 Festo P.BE−CPA−EN en 0306d...

- Page 145 CPX system (electric compo nents) in chapter 3 of this manual (pneumatic components) Instructions on connecting the electrical components of the CPA valve terminal with AS−interface and inputs can be found in the documentation supplied with the product. B−11 Festo P.BE−CPA−EN en 0306d...

- Page 146 B. Supplementary component summary and installation instructions B−12 Festo P.BE−CPA−EN en 0306d...

- Page 147 Index Appendix C C−1 Festo P.BE−CPA−EN en 0306d...

-

Page 148: Index

............C−3 C−2 Festo P.BE−CPA−EN en 0306d... - Page 149 ........C−3 Festo P.BE−CPA−EN en 0306d...

- Page 150 ........2−8 C−4 Festo P.BE−CPA−EN en 0306d...

-

Page 151: Hat Rail Fitting

....... . . 1−13 Notes on the use of this manual ..... C−5 Festo P.BE−CPA−EN en 0306d... - Page 152 ......5−8 Replacing the end plate ......5−11 C−6 Festo P.BE−CPA−EN en 0306d...

- Page 153 ........5−8 Valve switching times ......A−9 C−7 Festo P.BE−CPA−EN en 0306d...

- Page 154 C. Index C−8 Festo P.BE−CPA−EN en 0306d...

Need help?

Do you have a question about the CPA10-VI and is the answer not in the manual?

Questions and answers