Summary of Contents for Optimum OPTidrill RD 4

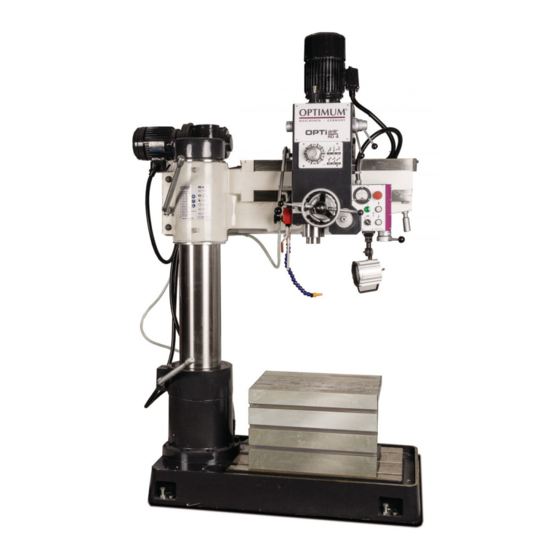

- Page 1 OPTIMUM M A S C H I N E N - G E R M A N Y Operating Manual Version 1.0 Radial drilling machine Part no. 3049040...

-

Page 2: Table Of Contents

OPTIMUM M A S C H I N E N - G E R M A N Y Table of contents Safety Type plate ..............................6 Safety instructions (warning notes)......................7 1.2.1 Classification of hazards .......................7 1.2.2 Other pictograms ...........................7 Intended use .............................8 Reasonably foreseeable misuse.......................9... - Page 3 OPTIMUM M A S C H I N E N - G E R M A N Y Safety ..............................30 Before starting work ..........................30 Adjusting shift rod ........................... 32 Moving drilling head ..........................32 Speed adjustment ..........................33 Switching the machine on ........................

- Page 4 OPTIMUM M A S C H I N E N - G E R M A N Y 8.5.3 Disposal of the old device ......................77 8.5.4 Disposal of electrical and electronic components ...............77 8.5.5 Disposal of lubricants and coolants .....................78 Disposal via municipal collection facilities ....................78...

- Page 5 Dear customer, Thank you very much for purchasing a product made by OPTIMUM. OPTIMUM metal working machines offer a maximum of quality, technically optimum solutions and convince by an outstanding price performance ratio. Continuous enhancements and prod- uct innovations guarantee state-of-the-art products and safety at any time.

-

Page 6: Safety

Always keep this documentation close to the radial drilling machine. INFORMATION If you are unable to rectify an issue using these operating instructions, please contact us for advice: Optimum Maschinen Germany GmbH Dr. Robert-Pfleger-Str. 26 D-96103 Hallstadt, Germany email: info@optimum-maschinen.de... -

Page 7: Safety Instructions (Warning Notes)

OPTIMUM M A S C H I N E N - G E R M A N Y Safety instructions (warning notes) 1.2.1 Classification of hazards We classify the safety warnings into different categories. The table below gives an overview of the classification of symbols (ideogram) and the warning signs for each specific danger and its (possible) consequences. -

Page 8: Intended Use

If the radial drilling machine is used in any way other than described above, modified without authorization of Optimum Maschinen Germany GmbH, then the geared drill is being used improperly. -

Page 9: Reasonably Foreseeable Misuse

OPTIMUM M A S C H I N E N - G E R M A N Y WARNING! Extremely severe injuries. It is forbidden to make any modifications or alternations to the operation values of the radial drilling machine! They could endanger the personnel and cause damage to the radial drilling machine. -

Page 10: Qualification Of Personnel

OPTIMUM M A S C H I N E N - G E R M A N Y at high speeds, with rotating parts, electrical voltage and currents. We have used design and safety engineering to minimize the health risk to personnel resulting from these hazards. -

Page 11: Authorized Persons

OPTIMUM M A S C H I N E N - G E R M A N Y Qualified electrician With professional training, knowledge and experience as well as knowledge of respective standards and regulations, qualified electricians are able to perform work on the electrical sys- tem and recognise and avoid any possible dangers. -

Page 12: User Positions

OPTIMUM M A S C H I N E N - G E R M A N Y secure against restarting, check that there is no voltage. User positions The operator position is in front of the radial drilling machine. -

Page 13: Safety Check

OPTIMUM M A S C H I N E N - G E R M A N Y 1.10 Safety check Check the radial drilling machine before each start-up or at least once per shift. Inform the per- son responsible immediately of any damage, defects or changes in the operating function. -

Page 14: Prohibition, Warning And Mandatory Signs

OPTIMUM M A S C H I N E N - G E R M A N Y 1.10.1 Prohibition, warning and mandatory signs INFORMATION All warning signs must be legible. They must be checked regularly. 1.11 EMERGENCY STOP push button... -

Page 15: Main Switch

OPTIMUM M A S C H I N E N - G E R M A N Y 1.12.1 Main switch WARNING! Dangerous voltage even if the main switch is switched off. The areas marked by the pictogram might contain live parts, even if the main switch is switched off. -

Page 16: Safety During Operation

OPTIMUM M A S C H I N E N - G E R M A N Y 1.15 Safety during operation We specifically point out the dangers when describing the work with and on the radial drilling machine. WARNING! Before switching on the radial drilling machine make sure that there are ... -

Page 17: Mechanical Maintenance

Check if they are working properly! 1.18 Accident report Inform your supervisors and Optimum Maschinen Germany GmbH immediately in the event of accidents, possible sources of danger and any actions which almost led to an accident (near misses). There are many possible causes for "near misses". -

Page 18: Delivery, Interdepartmental Transport, Unpacking

OPTIMUM M A S C H I N E N - G E R M A N Y Delivery, interdepartmental transport, unpacking INFORMATION The machine is pre assembled. It is delivered in a transport box. After the unpacking and the transportation to the installation site it is necessary to mount and assemble the individual com- ponents of the machine. -

Page 19: Load Suspension Point

OPTIMUM M A S C H I N E N - G E R M A N Y Load suspension point The machine can be raised with a lift truck or forklift truck underneath the packing case. “Weight including packaging“ on page 48 ... - Page 20 OPTIMUM M A S C H I N E N - G E R M A N Y Lift the Machine from the Pallet The machine load impact is illustrated as follows. Remove the fastening bolts that are used to fasten the machine on the pallet.

-

Page 21: Standard Accessories

OPTIMUM M A S C H I N E N - G E R M A N Y Standard Accessories Toolbox contains: - 1 x oil bottle for oiler - 1 x grease press for grease nipple - 1 set of Allen keys... -

Page 22: Installation Plan

OPTIMUM M A S C H I N E N - G E R M A N Y Installation plan Set-up and assembly 2.6.1 Installation site requirements In order to achieve sufficient safety against falls by slipping, the accessible area in the mechani- cal machining zone of the machine must be equipped with a slip resistance. -

Page 23: Assembly

OPTIMUM M A S C H I N E N - G E R M A N Y Please observe the following points: The device must only be installed and operated in a dry and well-ventilated place. Avoid places close to machines which cause chips or dust. -

Page 24: Fixing

OPTIMUM M A S C H I N E N - G E R M A N Y precisely the cantilever has been aligned with a possible inclination with the adjusting screws to the machine base, the smaller the cantilever can turn by itself around the col- umn, when the clamping lever is released. -

Page 25: Top Up Oil, Check Oil Level

OPTIMUM M A S C H I N E N - G E R M A N Y 5/8" x 250mm ATTENTION! Tighten the nuts of the anchor bolts or threaded rods only so far that they are safely fixed and the machine foot cannot break away or the machine can tilt over. -

Page 26: Coolant Tank

This process is not reversible, i.e. the binding agent can- not be re-softened. The company Optimum Maschinen Germany GmbH does not assume any guarantee for sub- sequent damages due to unsuitable cooling lubricants. -

Page 27: Electrical Connection

Only use the tool holders (e.g. drill chuck) which were delivered with the machine or which are offered as optional equipment by OPTIMUM. Only use tool holders in the intended admissible speed range. Tool holders may only be modified in compliance with the recommendation of OPTI- MUM or of the manufacturer of the clamping devices. -

Page 28: Warming Up The Machine

OPTIMUM M A S C H I N E N - G E R M A N Y WARNING! There is a danger to persons and equipment, if the first commissioning of the radial drilling machine is carried out by inexperienced personnel. -

Page 29: Operation

OPTIMUM M A S C H I N E N - G E R M A N Y Operation Control and indicating elements Pos. Designation Pos. Designation clamping lever Selection of spindle sleeve feed Move hand wheel drill head Quill lever... -

Page 30: Safety

OPTIMUM M A S C H I N E N - G E R M A N Y Safety Commission the machine only under the following conditions: The machine is in proper working order. The machine is used as prescribed. - Page 31 OPTIMUM M A S C H I N E N - G E R M A N Y Examples: CAUTION! When lifting workpiece on the machine table, reasonable stress loads on the operator or assembler may be exceeded. Turn the cantilever towards the rear and load the table with a crane or another suitable loading device.

-

Page 32: Adjusting Shift Rod

OPTIMUM M A S C H I N E N - G E R M A N Y Adjusting shift rod Pull out the suitable length of shift rod. When shift rod comes into contact with something or when the workpiece or the clamp breaks loose, the machine must shut down. -

Page 33: Speed Adjustment

OPTIMUM M A S C H I N E N - G E R M A N Y Speed adjustment Guide values for speeds: Speed [ rpm] 1247 Steel (S235JR) Ø25 - 32 Ø19 - 25 Ø12 - 19 Ø10 - 12 Ø6 - 10 Ø3 - 6... -

Page 34: Switching Off The Machine

OPTIMUM M A S C H I N E N - G E R M A N Y The spindle only turns if the cantilever has been firmly clamped. ATTENTION! To protect the mechanical end stop of the drilling sleeve, the spindle is switched off on reaching the lowest position. -

Page 35: Adjusting The Drill Depth Shutdown

OPTIMUM M A S C H I N E N - G E R M A N Y Ammeter Spindle sleeve lever Emergency stop mushroom button Drill depth vernier Rotation direction shift lever Img.3-5: Drill head INFORMATION The ammeter shows you the current consumption of the drive motor. -

Page 36: Disassembly, Assembly Of Drill Chucks And Drill Bits

OPTIMUM M A S C H I N E N - G E R M A N Y Zero marker Scale Marking boring depth Dial disc Clamping lever Drill depth vernier Img.3-6: Drill depth 3.12 Disassembly, assembly of drill chucks and drill bits CAUTION! Make sure that the clamped tool is firmly and correctly fitted. -

Page 37: Coolant Equipment

OPTIMUM M A S C H I N E N - G E R M A N Y Put the ejection wedge into the ejection opening and hit with a hammer onto the ejection wedge. Hold the tool firmly when doing this. -

Page 38: Maintenance

OPTIMUM M A S C H I N E N - G E R M A N Y Maintenance In this chapter you will find important information about Inspection, Maintenance and Repair. ATTENTION! Properly performed regular maintenance is an essential prerequisite for ... -

Page 39: Inspection And Maintenance

OPTIMUM M A S C H I N E N - G E R M A N Y WARNING! Before starting the machine you must be sure that no dangers generated for persons, the machine is not damaged. - Page 40 OPTIMUM M A S C H I N E N - G E R M A N Y Interval Where? What? How? Grease the spindle once a week withMobil Greaserex 47 with one stroke of the grease press. Lubricating...

- Page 41 OPTIMUM M A S C H I N E N - G E R M A N Y Interval Where? What? How? Oil column once a day until it is completely filled with Mobilgear 626 oil. Oiling Oiler on column ...

- Page 42 OPTIMUM M A S C H I N E N - G E R M A N Y Interval Where? What? How? Check oil level, Max. fill level Visual inspection Check oil level, Max. fill level Visual inspection ...

- Page 43 OPTIMUM M A S C H I N E N - G E R M A N Y Interval Where? What? How? Change the oil on the spindle gearbox. Oil change Change the oil on the lifting device of the cantilever.

- Page 44 OPTIMUM M A S C H I N E N - G E R M A N Y Interval Where? What? How? Cleaning opening Replace Cleaning Disinfect Drain screw "Cooling lubricants and tanks“ on page 69 "Inspection plan for water-mixed cooling lubricants“...

-

Page 45: Recommended Wear And Tear Parts

OPTIMUM M A S C H I N E N - G E R M A N Y Interval Where? What? How? "Obligations of the operating company“ on page 11 "Electrical system“ on page 17 Electrical inspec- tion... -

Page 46: Adjustment Of Clearance On Cantilever And Drilling Head

OPTIMUM M A S C H I N E N - G E R M A N Y Adjustment of clearance on cantilever and drilling head If needed, reduce the guide clearance between the cantilever arm and the drilling head. -

Page 47: Position Switch Spindle Sleeve

If the repairs are carried out by qualified technical personnel, they must follow the indications given in these operating instructions. Optimum Maschinen Germany GmbH accepts no liability nor does it guarantee against damage and operating malfunctions resulting from failure to observe these operating instructions. -

Page 48: Technical Specification

OPTIMUM M A S C H I N E N - G E R M A N Y Technical specification The following information represents the dimensions and indications of weight and the manu- facturer‘s approved machine data. The calculated envisaged life of the machine to EN ISO... -

Page 49: Emissions

OPTIMUM M A S C H I N E N - G E R M A N Y Minimum distance from the spindle nose to the surface of the machine base [mm] Environmental conditions temperature +5 to +40 °C Environmental conditions of rel. humidity 30% to 95% at 40°C ;... -

Page 50: T-Slots, Seats For Clamping Table

OPTIMUM M A S C H I N E N - G E R M A N Y Furthermore, it is possible that the admissible exposure level might be different from country to country due to national regulations. This information about the noise emission should, however, allow the operator of the machine to more easily evaluate the hazards and risks. -

Page 51: Space Required For The Machine

OPTIMUM M A S C H I N E N - G E R M A N Y Space required for the machine 700mm 1280mm 5.3.1 Work area Keep a work area of at least one metre around the machine free for operation and mainte- nance. -

Page 52: Ersatzteile - Spare Parts

OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteile - Spare parts Kühlmitteleinrichtung - Cooling device Abb.6-1: Kühlmitteleinrichtung - Cooling device Ersatzteilliste Kühlmitteleinrichtung - Spare part list cooling device Menge Grösse... -

Page 53: Höhenverstellung - Height Adjustment

OPTIMUM M A S C H I N E N - G E R M A N Y Höhenverstellung - Height adjustment Abb.6-2: Höhenverstellung - Height adjustment Ersatzteile - Spare parts DE│GB Version 1.0 2017-03-13 Originalbetriebsanleitung... - Page 54 OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteilliste Höhenverstellung - Spare part list adjustment Menge Grösse Artikelnummer Bezeichnung Designation Quan- Size Article no. tity Getriebegehäuse Gear housing 03049040201 Schneckenrad...

-

Page 55: Säule - Column

OPTIMUM M A S C H I N E N - G E R M A N Y Säule - Column Abb.6-3: Säule - Column Ersatzteile - Spare parts DE│GB Version 1.0 2017-03-13 Originalbetriebsanleitung... - Page 56 OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteilliste Säule- Spare part list column Menge Grösse Artikelnummer Bezeichnung Designation Quan- Size Article no. tity Grundplatte Base 03049040301 Spaltfilter Filter Screen...

-

Page 57: Bohrkopf - Drill Head

OPTIMUM M A S C H I N E N - G E R M A N Y Bohrkopf - Drill head Abb.6-4: Bohrkopf - Drill head Ersatzteile - Spare parts DE│GB Version 1.0 2017-03-13 Originalbetriebsanleitung... - Page 58 OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteilliste Bohrkopf- Spare part list drill head Menge Grösse Artikelnummer Bezeichnung Designation Quan- Size Article no. tity Getriebekasten Gear Box 030490405 Getriebeabdeckung...

- Page 59 OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteilliste Bohrkopf- Spare part list drill head Menge Grösse Artikelnummer Bezeichnung Designation Quan- Size Article no. tity Schraube Bolt M6x12 Buchse Bushing...

- Page 60 OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteilliste Bohrkopf- Spare part list drill head Menge Grösse Artikelnummer Bezeichnung Designation Quan- Size Article no. tity Zahnradwelle Gear Shaft 030490405111 Sicherungsring...

-

Page 61: Steuerung - Control 1 - 3

OPTIMUM M A S C H I N E N - G E R M A N Y Steuerung - Control 1 - 3 Abb.6-5: Steuerung - Control 1 - 3 Ersatzteile - Spare parts DE│GB Version 1.0 2017-03-13 Originalbetriebsanleitung... -

Page 62: Steuerung - Control 2 - 3

OPTIMUM M A S C H I N E N - G E R M A N Y Steuerung - Control 2 - 3 Abb.6-6: Steuerung - Control 2 - 3 DE│GB Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0 2017-03-13... -

Page 63: Steuerung - Control 3 - 3

OPTIMUM M A S C H I N E N - G E R M A N Y Steuerung - Control 3 - 3 Abb.6-7: Steuerung - Control 3-3 Ersatzteilliste Steuerung- Spare part list control Menge Grösse Artikelnummer Bezeichnung Designation... - Page 64 OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteilliste Steuerung- Spare part list control Menge Grösse Artikelnummer Bezeichnung Designation Quan- Size Article no. tity Exzenterwelle Eccentric Shaft 03049040618 Lager Bearing 6204-2Z 0406204.2R...

-

Page 65: Schaltschrank, Abdeckungen- Switch Box, Covers

OPTIMUM M A S C H I N E N - G E R M A N Y Schaltschrank, Abdeckungen- Switch box, covers Abb.6-8: Schaltschrank, Abdeckungen- Switch box, covers Ersatzteilliste Schaltschrank, Abdeckungen- Spare part list switch box, covers Menge Grösse... -

Page 66: Schaltplan - Wiring Diagram

OPTIMUM M A S C H I N E N - G E R M A N Y Schaltplan - Wiring diagram DE│GB Ersatzteile - Spare parts Originalbetriebsanleitung Version 1.0 2017-03-13... - Page 67 OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteile - Spare parts DE│GB Version 1.0 2017-03-13 Originalbetriebsanleitung...

- Page 68 OPTIMUM M A S C H I N E N - G E R M A N Y Ersatzteilliste - Spare part list - Elektrische Bauteile - Electric components Hersteller Artikelnummer Bezeichnung Designation Manufacturer Item no. Hauptschalter Main switch FS 203003B...

-

Page 69: Cooling Lubricants And Tanks

OPTIMUM M A S C H I N E N - G E R M A N Y 6.10 Cooling lubricants and tanks CAUTION! The cooling lubricant can cause diseases. Avoid direct contact with cooling lubricant or parts covered in cooling lubricant. -

Page 70: Inspection Plan For Water-Mixed Cooling Lubricants

OPTIMUM M A S C H I N E N - G E R M A N Y 6.10.1 Inspection plan for water-mixed cooling lubricants Company: No.: Date: used cooling lubricant size to be checked Inspection methods Inspection Procedure and comment... - Page 71 Viskosität Schmierstoffe Viskosity Kennzeich- Lubricant nung nach Viscosité ISO VG DIN 51502 Lubrifiant DIN 51519 mm²/s (cSt) Aral Degol BG BP Energol SPARTAN Klüberoil Mobilgear Shell Omala VG 680 CLP 680 Meropa 680 GR-XP 680 EP 680 GEM 1-680 Aral Degol BG BP Energol SPARTAN Klüberoil...

- Page 72 Graisse pour bro- ches à haute vitesse Schneidöl Aquacut B, Kühlschmiermittel 5 L Gebinde, Artikel Nr. 3601751 Cooling lubricants EG Sicherheitsdatenblatt Chevron Aral Emusol BP Sevora Esso Kutwell Mobilcut Shell Adrana Soluble Oil B Lubrifiants de refro- http://www.optimum-daten.de/data- idissement sheets/EG-Datenblatt_Aquacut- B.pdf...

-

Page 73: Malfunctions

OPTIMUM M A S C H I N E N - G E R M A N Y Malfunctions Cause/ Malfunction Solution possible effects Spindle does not turn • Motor circuit breaker has tripped or • Check motor protective switch or is defective. -

Page 74: Appendix 8.1 Copyright

OPTIMUM M A S C H I N E N - G E R M A N Y Appendix Copyright This document is protected by copyright. All derived rights are reserved, especially those of translation, re-printing, use of figures, broadcast, reproduction by photo-mechanical or similar means and recording in data processing systems, either partial or total. -

Page 75: Storage

Example: not stackable - do not stack further pack- ing case on top of the first one. Consult Optimum Maschinen Germany GmbH if the machine and accessories are stored for more than three months or are stored under different environmental conditions than those spec- ified here. -

Page 76: Liability Claims/Warranty

V-belts, ball bearings, illuminants, filters, sealings, etc. - Non reproducible software errors Any services, which OPTIMUM GmbH or one of its agents performs in order to fulfil any additional warranty are neither an acceptance of the defects nor an acceptance of its obli- gation to compensate. -

Page 77: Decommissioning

OPTIMUM M A S C H I N E N - G E R M A N Y 8.5.1 Decommissioning CAUTION! Used devices need to be decommissioned in a professional way in order to avoid later misuses and endangerment of the environment or persons. - Page 78 Modified settings Any experiences with the radial drilling machine which might be important for other users Recurring malfunctions Optimum Maschinen Germany GmbH Dr.-Robert-Pfleger-Str. 26 D-96103 Hallstadt Fax +49 (0) 951 - 96 555 - 888 email: info@optimum-maschinen.de Appendix...

- Page 79 M A S C H I N E N - G E R M A N Y EC - declaration of conformity in accordance with the Machinery Directive 2006/42/EC Annex II 1.A Optimum Maschinen Germany GmbH The manufacturer/ Dr.-Robert-Pfleger-Str. 26...

- Page 80 OPTIMUM M A S C H I N E N - G E R M A N Y Index During operation ..........16 Safety devices ............12 Accessories ............21 Safety instructions ..........7 Accident report ............. 17 Scope of delivery ..........18 Ammeter ............... 35 Shift rod Assembly ............

Need help?

Do you have a question about the OPTidrill RD 4 and is the answer not in the manual?

Questions and answers