Table of Contents

Advertisement

General .............................................................................................................................................i

How To Use This Manual ............................................................................................................................i

How to Get Help From MicroCal............................................................................................................... ii

Section 1: VP-ITC System Introduction......................................................................................1

1.1 VP ITC - The Basics.............................................................................................................................2

1.2 Data Acquisition and Instrument Control..............................................................................................3

1.3 Suitable Laboratory Environment .........................................................................................................4

1.4 VP-ITC Parts and Accessories ..............................................................................................................5

1.5 Setting Up the VP-ITC Instrument ........................................................................................................7

1.6 Pipette Assembly ...................................................................................................................................9

1.7 The ThermoVac...................................................................................................................................11

Section 2: VPViewer and Origin Software................................................................................14

2.1 VPViewer and Origin Software Overview ..........................................................................................15

2.2 Powering Up the VP-ITC Instrument ..................................................................................................15

2.3 VPViewer Main Window ....................................................................................................................17

2.4 ITC Controls Window .........................................................................................................................21

2.5 Thermostat/Calibration Window .........................................................................................................26

2.6 Setup/Maintenance Window................................................................................................................27

2.7 Constants Window...............................................................................................................................30

2.8 Real Time Data Display in Origin .......................................................................................................31

2.9 ITC Cell Status ....................................................................................................................................33

Section 3: Running an ITC Experiment ....................................................................................35

3.1 Designing ITC Experiments ................................................................................................................36

3.2 Using the ThermoVac to Degas Samples ............................................................................................40

3.3 Cell Loading ........................................................................................................................................41

3.4 Loading the Auto-Pipette.....................................................................................................................42

3.5 Choosing The Run Parameters ............................................................................................................45

3.6 Carrying Out Experimental Runs ........................................................................................................46

3.7 Using the ThermoVac for Cleaning the ITC Sample Cell ...................................................................47

3.8 Cleaning Syringes................................................................................................................................49

Section 4: Experimental Tutorials .............................................................................................50

4.1 Water-Water Baselines ........................................................................................................................51

4.2 Methanol Tutorial................................................................................................................................60

4.3 Rnase-2'CMP Experiment Tutorial.....................................................................................................63

Section 5: Instrument Maintenance............................................................................................64

5.1 Cleaning The Cells and Pipette ...........................................................................................................65

5.2 Replacing Pipette Plunger Tips ...........................................................................................................68

5.3 Y-axis Calibration ...............................................................................................................................72

5.4 Replacing Injection Syringes & Height Adjustment ...........................................................................74

Section 6: Tips and Troubleshooting .........................................................................................76

6.1 User Tips and FAQs ............................................................................................................................77

6.2 Troubleshooting...................................................................................................................................78

6.3 A Note About Buffers .........................................................................................................................79

6.4 Selecting the Proper Stirring Rate .......................................................................................................79

6.5 Estimation of Required Concentrations...............................................................................................80

Section 7: Additional Features ....................................................................................................81

7.1 Extended Data Display ........................................................................................................................82

MAU130030 Rev. A

Table Of Contents

.......................................................................................................................82

12/3/02

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for MicroCal VP-ITC

-

Page 1: Table Of Contents

1.1 VP ITC – The Basics..........................2 1.2 Data Acquisition and Instrument Control....................3 1.3 Suitable Laboratory Environment ......................4 1.4 VP-ITC Parts and Accessories ......................5 1.5 Setting Up the VP-ITC Instrument ......................7 1.6 Pipette Assembly ...........................9 1.7 The ThermoVac...........................11 Section 2: VPViewer and Origin Software................14 2.1 VPViewer and Origin Software Overview ..................15... - Page 2 VP-ITC MicroCalorimeter User’s Manual (This page was intentionally left blank)

-

Page 3: General

Section 7 provides description of some more advanced features. Much of this manual provides descriptions of the VP-ITC instrument and software. Bullets or step numbers are typically used when the user is requested to perform an operation. -

Page 4: How To Get Help From Microcal

Problems that prevent users from operating the VP-ITC require immediate consultation with a MicroCal technician. Customers should not attempt to repair the VP-ITC hardware or software unless instructed to do so by a MicroCal service representative. - Page 5 Protective Earth (Ground) Terminal Origin® is a registered trademark of Origin Lab, Northampton, MA VP is a registered trademark of MicroCal, LLC, Northampton, MA MicroCal is a registered trademark of MicroCal, LLC, Northampton, MA Windows™ is a registered trademark of Microsoft Corporation...

- Page 6 Product Safety We have used all means to design and produce the VP-ITC to prevent any damage to the instrument during normal usage. The instrument is solidly built using the latest in micro-technology in its components and design, but of course, this cannot prevent damage due to physical mistreatment.

- Page 7 Section 1: VP-ITC – General Information Instrument Specifications Model or Type VP-ITC Performance Specifications (2 second filter) Noise Level 1 nanocal/sec (4 nanowatts) (3 minute RMS windows averaged over 1 hour Baseline Constancy ±5 nanocal/sec (±20 nanowatts) (average one hour time intervals: 310 rpm stirring)

- Page 8 VP-ITC MicroCalorimeter User’s Manual Safety Specifications Instrument Specifications (excluding Controller) Electrical Specifications Electrical Ratings: Voltage 240 Volts Frequency 50 Hz Current (maximum) 1.0 Amp Fuses (2) Primary=1.0 A, 250 V, Time Delay Output Secondary/Data Connection only Protective Earth Terminals Internal/external marked...

- Page 9 Section 1: VP-ITC – General Information Cleaning the VP-ITC Instrument Case Always shut down the computer controller and VP-ITC instrument and disconnect the mains power supply cord before cleaning the case. To clean the instrument case, use a damp, lint-free cloth. Avoid abrasives or solvents that can permanently damage the finish.

- Page 10 VP-ITC MicroCalorimeter User’s Manual European Users: CE Mark Microcal VP-ITC calorimeters carry the CE marking which confirms that they meet the applicable European Community Technical Directives. We declare that we have followed the provisions of EMC Directive 89/336/EEC (Electromagnetic Compatibility) and Low Voltage Directive 72/23/EEC (Electrical Safety).

-

Page 11: Section 1: Vp-Itc System Introduction

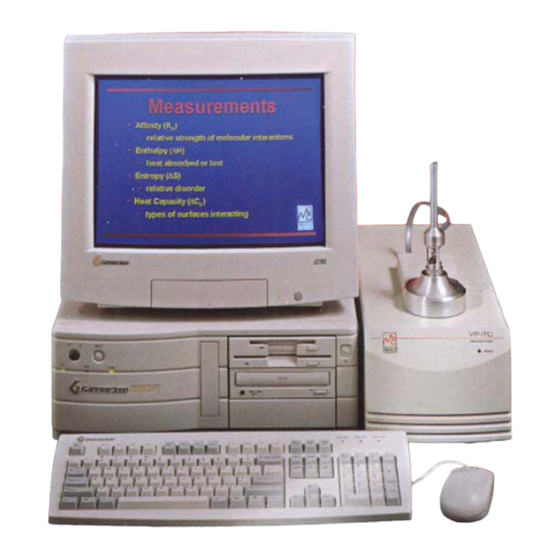

Section 1: VP-ITC System Introduction Section 1: VP-ITC System Introduction This section starts by providing some basic information about the VP-ITC and the computer controller. Then it provides instructions for setting up the VP-ITC instrument and accessories. It ends by providing information about the ThermoVac instrument. -

Page 12: Vp Itc - The Basics

VP-ITC MicroCalorimeter User’s Manual 1.1 VP ITC – The Basics The VP-ITC Unit directly measures heat evolved or absorbed in liquid samples as a result of mixing precise amounts of reactants. A spinning syringe is utilized for injecting and subsequent mixing of reactants. -

Page 13: Data Acquisition And Instrument Control

‘glitch’ the ITC baseline. Users are encouraged to avoid large file copying to disk drives, large print jobs and recursive control loops while the VP-ITC is in the midst of an injection run. Users can carry out routine data analysis while the VP-ITC is running. -

Page 14: Suitable Laboratory Environment

VP-ITC MicroCalorimeter User’s Manual 1.3 Suitable Laboratory Environment The VP-ITC with Computer Controller requires about 1 meter of normal bench space (ca. 70 cm wide). The ThermoVac degassing station will require another 25 cm of bench space. This location should be away from strong drafts, room temperature fluctuations, intense sunlight, vibrations and strong electrical or magnetic fields (as may be produced by an NMR, microwave oven, large motors or refrigeration units). -

Page 15: Vp-Itc Parts And Accessories

In addition to the VP-ITC instrument, Computer Controller and connecting cables, there are various accessories shipped with the VP-ITC for its normal operation. The parts and accessories may include, but are not limited to the items listed below and on the next page. - Page 16 VP-ITC MicroCalorimeter User’s Manual VP-ITC Accessories in Wooden Box (KIT130010) Icon Part Number Description Plunger Tips for Injection Syringe TIP130020 250 µL Tip Sizer (Glass Bore with Green Cap) ASS130360 Large Tube brush BRU130010 Reference Plug Assembly ASS130170 Hex driver (050”) for syringe clamps DRI130010 Hex driver (7/64") for injector stand...

-

Page 17: Setting Up The Vp-Itc Instrument

One end of the Flat Main Cable has a 37 pin male connector (labeled ‘Cell’) that attaches to the rear of the VP-ITC cell. The other end of the cable has two 37 pin male that attach to the rear of the computer. - Page 18 VP-ITC MicroCalorimeter User’s Manual earth ground, plug. Please Note: It is strongly recommended that the VP-ITC be provided a dedicated AC power line with no other equipment being powered on that line. (see page 4 for more information about selecting a location for the instrument)

-

Page 19: Pipette Assembly

The height must be adjusted for any syringe that was not part of the original shipment of your VP-ITC instrument. Please refer to Section 5.4 Replacing Injection Syringes & Height Adjustment (page 74) for instruction on adjusting the height of the syringe. - Page 20 VP-ITC MicroCalorimeter User’s Manual • Make sure the top syringe clamp is still seated against the top of the syringe holder, hold the bottom syringe clamp tightly against the bottom of the syringe holder and gently tighten the set screw using the accessory 0.050” Ball Point Hex Driver.

-

Page 21: The Thermovac

Section 1: VP-ITC System Introduction 1.7 The ThermoVac ThermoVac Description To facilitate degassing samples and cleaning the cells, you have been provided with the ThermoVac accessory, a device for thermostatting and degassing samples. The unit is capable of thermostatting a sample at any temperature from 0 to 80 °C, pulling a vacuum of 28.4 inches of... - Page 22 VP-ITC MicroCalorimeter User’s Manual ThermoVac Accessories The ThermoVac and accessories may include, but are not limited to the items listed below. A list of the actual items shipped with your order will be included in the documentation included with your shipment.

- Page 23 Section 1: VP-ITC System Introduction STIRRER This switch will activate a rotating magnetic field that will stir your sample when a small magnetic stir bar is placed in the tube containing your sample. You may adjust the speed of the Stirrer motor from 0 RPM (OFF) to the maximum speed of 800 RPM (full turn clockwise).

-

Page 24: Section 2: Vpviewer And Origin Software

VP-ITC instrument and conduct the experiment. Origin (in this project window) is used only for plotting the data received from the VP-ITC instrument. A separate project window for Origin (Origin for ITC) is used for analyzing data. -

Page 25: Vpviewer And Origin Software Overview

Section 2: VPViewer and Origin Software 2.1 VPViewer and Origin Software Overview The VPViewer 2000 software controls the operation of the VP-ITC calorimeter. It is within VPViewer 2000 that all ITC experimental parameters are entered, runs are controlled and data is saved to the hard disk of the Computer Controller. - Page 26 ITC injection system will be initialized as well. The VP-ITC was designed to have its power on for extended periods of time. This will keep the electronics at the normal operating temperature for better repeatability. It is recommended that the power to the ITC cell unit be turned off during extended periods of down time, such as holidays and vacations.

-

Page 27: Vpviewer Main Window

Section 2: VPViewer and Origin Software 2.3 VPViewer Main Window When you launch VPViewer, the Main Window of VPViewer is displayed (as shown below). VPViewer Data Channel Display By default, VPViewer displays three data channels and the status of the instrument. Instrument Status In the above illustration, the instrument is Thermostatting (ITC) at 30 °C. - Page 28 µCal/sec. or µWatts. Experimental data will always be saved in units of µCal/sec. Whenever the VP-ITC is equilibrated the DP value should be positive and stable. The power level of the equilibrated DP signal should be close (+/- 1 uCal/sec.) to the ‘Reference Power’...

- Page 29 ITC is in its idle state. The Stop, Update Run Param. and Display Run Param. buttons are available when the VP-ITC is active, in a prerun, run or postrun state.) Load Run File: Clicking on this button will display the file open dialog box to load previously saved run parameters into the ITC Controls Window.

- Page 30 Start. Click this button to start an ITC experiment, using the parameters entered into the ITC Controls Window. Stop. This button terminates the current run. Available only when the VP-ITC is in a non-idle state. Compact/Standard Mode Button Clicking this button will shrink VPViewer’s Main Window and change...

-

Page 31: Itc Controls Window

Section 2: VPViewer and Origin Software 2.4 ITC Controls Window The ITC Controls window (shown below) is the main access point for operating the VP-ITC instrument. Below is a description for each of the run parameters displayed in the ITC Controls window. - Page 32 VP-ITC MicroCalorimeter User’s Manual at or below the experimental temperature. If the loaded sample is at a higher temperature, there will be a long equilibration period before the experiment will begin. (See page 78 more information). µ Reference Power ( Cal/sec.)

- Page 33 .ITC for an extension name, so that the raw data file will be recognized by Origin as a VP-ITC data file. Do not start the filename with a number nor include any hyphens, periods or spaces in the filename, as Origin will not accept the file. Please note:...

- Page 34 VP-ITC MicroCalorimeter User’s Manual Injection Parameters The Injection Parameters group allows you to define the volume, duration, spacing between injections, and the filter period for each injection. At the bottom of this group is a summary table that lists, by row number, these parameters. You may select an injection to edit by clicking on a row to highlight it;...

- Page 35 Section 2: VPViewer and Origin Software Apply To Rest – Selecting this option, you will be assigning the injection parameters for the currently highlighted injection (in the summary table), to all ensuing injections. Likewise, editing an injection parameter while this option is selected affects the currently highlighted injection (in the summary table), as well as all ensuing injections.

-

Page 36: Thermostat/Calibration Window

Using a pulse which is relatively large ( > +/- 5 mCal/min.) will expose DP calibration errors that are greater than 1%. Any users who feel that the y-axis calibration requires adjustment should contact MicroCal prior to attempting any changes to the VP-ITC calibration constants. -

Page 37: Setup/Maintenance Window

Systems having multiple users may benefit from having customized settings. User Setup Data File Path: Indicates the path (excluding file name) where VP-ITC data files will be saved. The path should be located on a local hard drive and not on any floppy or CD-ROM drive. - Page 38 Default Shield DT: The default temperature difference between the ITC adiabatic jacket and the outer shield of the VP-ITC. The default setting of a 1 degree difference has been found to be ideal for all ITC applications and should not be changed without consultation with a MicroCal engineer.

- Page 39 Section 2: VPViewer and Origin Software Pipette Maintenance This group of buttons provides controls for replacing plunger tips. It is recommended to replace tips once a month when using the VP- ITC daily. (For more information refer to the section on Replacing Pipette Plunger Tips starting on page 68).

-

Page 40: Constants Window

2.7 Constants Window Provides viewing access to the calibration constants for your particular VP-ITC instrument. Shown below are calibration constants that are typical of the VP-ITC. This window is password protected and should not be changed without instructions by a MicroCal Engineer. -

Page 41: Real Time Data Display In Origin

Pictured below is the main Origin window for VP-ITC data display. The ITC Cell Status, the VP-ITC Numeric Display and the Buttons For VP-ITC Data tools (as indicated above) have been added for user convenience in viewing data generated by the VP-ITC. - Page 42 VP-ITC MicroCalorimeter User’s Manual Buttons for VP-ITC Data Display This group of buttons allows you to rescale the y-axis by simply clicking on a single button. Alternatively, you may graph all the data by selecting Plot:Rescale to Show All from the Main Display menu...

-

Page 43: Itc Cell Status

Seeking Temperature (Heating/Cooling Jacket/Cells to Set Temperature) The function of this first prerun state is to heat or cool the VP-ITC cells and adiabatic jacket to the entered starting temperature for the experimental run. This is accomplished when the cell temperature is within 0.1 degrees (of the entered temperature), and the DeltaT (temperature... - Page 44 VP-ITC MicroCalorimeter User’s Manual PreRun Thermostat Once the cells and jacket have reached the starting temperature, the ITC will enter the 2 prerun state, the Prerun Thermostat state. The purpose of the PreRun Thermostat state is to maintain the starting temperature, for the requested period of time. This will allow time for thermal gradients within the ITC cell thermal core, to minimize before the experiment starts to reduce their affect during the experiment.

-

Page 45: Section 3: Running An Itc Experiment

Section 3: Running an ITC Experiment Section 3: Running an ITC Experiment This section provides detailed information about conducting an experiment, from designing, sample preparation, loading samples, running the experiment and finally cleaning the equipment after the experiment. New users may find this section too detailed for their immediate needs and may proceed to the Section 4 tutorials for a ‘hands on’... -

Page 46: Designing Itc Experiments

VP-ITC MicroCalorimeter User’s Manual 3.1 Designing ITC Experiments For a ligand X binding to a single set of n identical sites on a macromolecule M, i.e., M + X = MX MX + X = MX 2 MX n-1 + X = MX n... - Page 47 Section 3: Running an ITC Experiment It is well-known that ∆C p is a good indicator of changes in hydrophobic interactions with binding, being negative if hydrophobic bonds are formed and positive if they are broken. The critical parameter which determines the shape of the binding isotherm is the unitless constant c, which is the product of the binding constant K times the total macromolecule concentration in the cell at the start of the experiment, M tot , times the stoichiometry parameter, n.

- Page 48 VP-ITC MicroCalorimeter User’s Manual VP-ITC sensitivity is ca. 0.1 µcal so for precise measurement each injection should have an average of at least 3-5 µCal of heat absorbed or evolved into the 1.3 ml cell. How these factors impinge on your choice of macromolecule concentration can be seen by considering a particular example of the binding of 2'CMP to ribonuclease A, where the binding constant is approximately 1 x 10 6 M -1 and the ∆H o is approximately -15000 cal/mole for the...

- Page 49 Section 3: Running an ITC Experiment that you plan to use. For c values larger than ca. 10, the final concentration of ligand in the cell after all injections are completed should be ca. 1.5 times the total concentration of macromolecule binding sites in the cell at the beginning of the experiment, i.e., X tot x ∆v/V = n x M tot x 1.5, Where ∆v is the total volume of injectant to be used, V is the cell volume (ca.

-

Page 50: Using The Thermovac To Degas Samples

VP-ITC MicroCalorimeter User’s Manual 3.2 Using the ThermoVac to Degas Samples Degas cell and syringe samples that may contain dissolved gas to insure bubble free loading of each. This is particularly important if samples recently were at refrigerator temperatures. A ThermoVac sample degassing and Thermostat station is provided with each instrument. -

Page 51: Cell Loading

Section 3: Running an ITC Experiment boiling the sample in the chamber you should adjust the adjusting knob of the bleeder valve counterclockwise to reduce the vacuum. Any customers with a ThermoVac that does not include this option may request one through our sales department. To degas solutions before placing into the cells or injection syringe, please do the following. -

Page 52: Loading The Auto-Pipette

Care should be taken not to over flow the reservoir. If an overflow does occur, the injector should be removed and the bearings on the underside should be wiped dry. If internal contamination is expected you should consult with MicroCal personnel for further recommendations. 3.4 Loading the Auto-Pipette Please refer to the diagram below. - Page 53 Section 3: Running an ITC Experiment • Select the ITC Controls window. In the lower right corner you will find the Pipette Controls button. • Click on the Open Fill Port button. The auto-pipette will move the plunger of the injection syringe till the Teflon tip is just above the filling port of the syringe.

- Page 54 The user should be aware that the design of the VP-ITC instrument is such that during an experiment the syringe barrel is spinning (usually at ca. 310 RPM) while the plunger and Teflon tip remain stationary.

-

Page 55: Choosing The Run Parameters

Section 3: Running an ITC Experiment 3.5 Choosing The Run Parameters Prior to carrying out a ITC run, the experimental run parameters must be entered into the ITC Controls window. Run parameters may also be loaded from a parameter setup file (*.inj) or a previous experimental file (*.itc). -

Page 56: Carrying Out Experimental Runs

Cleaning After the Run The VP-ITC sample cell need not be cleaned with detergent solution after each experiment, since rinsing with water or buffer from a syringe is often adequate. However, after every 3-5 experiments (or at the end of each day’s experiments) solids that cannot be removed by rinsing will adhere to the cell interior and these can cause baseline problems if not removed periodically by a thorough cleaning with a detergent solution. -

Page 57: Using The Thermovac For Cleaning The Itc Sample Cell

Section 3: Running an ITC Experiment 3.7 Using the ThermoVac for Cleaning the ITC Sample Cell The ThermoVac may be used to flush copious amounts of detergent solution followed by a thorough rinse with distilled water. • Insert the Cell Cleaning Apparatus into the Adapter, until the top flange is touching the top of the Adapter (see below). - Page 58 VP-ITC MicroCalorimeter User’s Manual • Turn on the ThermoVac vacuum pump. The vacuum will pull the detergent solution from the beaker, through the cell and into the waste flask. NOTE: DO NOT ALLOW THE VOLUME OF FLUID IN THE WASTE FLASK TO BECOME SUCH THAT IT WOULD RISE UP TO THE LEVEL OF THE SIDE ARM AND BE SUCKED INTO THE THERMOVAC’S VACUUM PUMP.

-

Page 59: Cleaning Syringes

Section 3: Running an ITC Experiment 3.8 Cleaning Syringes. Cleaning Injection Syringes • Disconnect the syringe from the pipette and insert the accessory plunger into the top of the syringe. • Attach the plastic loading syringe tube to the filling port at the top of the syringe •... -

Page 60: Section 4: Experimental Tutorials

VP-ITC MicroCalorimeter User’s Manual Section 4: Experimental Tutorials Once the VP-ITC is setup and running properly, new users may proceed directly to the tutorials in this section for a ‘hands-on’ approach to learning the instrument. When more detail is required about the software or experiment the user may refer back to sections 2 or 3. -

Page 61: Water-Water Baselines

The following experimental tutorial is designed to acquaint the new user with the basic features of both the hardware and software of the VP-ITC instrument, as well as to provide experience with several manipulations that must be mastered in order to get the highest quality data from your instrument. - Page 62 VP-ITC MicroCalorimeter User’s Manual Now that the cells are filled, it is a good time to check the VP-ITC thermostat temperature and make sure it is set to the desired run temperature of 30 degrees. If the current thermostat temperature is not set to 30 degrees, set it now.

- Page 63 Section 4: Experimental Tutorials • Slowly withdraw the plunger of the plastic filling syringe to draw up the titrant solution till you see the solution exit through the top filling port. • Click on the Close Fill Port button as soon as you see the liquid exit the top filling port. The pipette will lower the plunger of the injection syringe till the white Teflon tip is completely below the filling port (ca.

- Page 64 VP-ITC MicroCalorimeter User’s Manual • Carefully insert the pipette into the sample cell access tube. Watch the end paddle of the long needle to insure it is inserted directly into the access hole, hold the pipette vertical and slowly lower the pipette. When the pipette is almost completely inserted you may have to push down slightly to compensate for the resistance of the rubber o’ring to seat the pipette.

- Page 65 Section 4: Experimental Tutorials • You may enter a filename or accept the default.itc name. Refer to page 23 for Data File Name conventions. • Select the Start button, to start the experiment. You may receive the query displayed below. This is simply indicating that you have not entered a concentration.

- Page 66 VP-ITC MicroCalorimeter User’s Manual Observe the Baseline while Equilibrating At the start of the experiment the instrument may rapidly bypass certain stages of operation. If the instrument’s temperature is at the selected starting temperature the instrument will skip the seeking temperature and pre run thermostatting phase and move immediately on to the final baseline equilibration phase.

- Page 67 Section 4: Experimental Tutorials has equilibrated in the Pre-stirring mode you may want a closer look at the data, so click on the Auto-View 1 button. This will put the current data point at the center of the graph with a Y-axis full scale of 0.1.

- Page 68 VP-ITC MicroCalorimeter User’s Manual You may want a closer look at the final baseline before proceeding. Click on the Auto-View 1 button. You should see a view similar to that below. When VPViewer determines that the Final Baseline has equilibrated properly, the display in the DP box will turn from red to green.

- Page 69 Section 4: Experimental Tutorials • Select Auto View 2 and you should see a plot similar to the one below. You may also want to get an even closer look at the baseline. • Click on Auto View 1 button. Using a y axis display range of 0.1 µCal/sec.

-

Page 70: Methanol Tutorial

4.2 Methanol Tutorial Experimental Procedure A methanol injection run requires a higher level of precision operation of the VP-ITC instrument than a water-water run to obtain optimal results. The integrated heats of each injection should be linear with the probable exception of the first peak. - Page 71 Section 4: Experimental Tutorials • Click on the Read Data button, to import your VP-ITC data into the plot window. Find your way to the data folder and select the file containing your experimental methanol data, (for this example we will use an example file named methanol.itc, your data folder contains a slightly different data file named methanol.itc with methanol data collected using your instrument,...

- Page 72 VP-ITC MicroCalorimeter User’s Manual right you will notice a Divide by Factor of 1000 (which is normally used to convert from cal to kcal). Edit to put a 1 in the factor text box, rather than 1000, and click OK.

-

Page 73: Rnase-2'Cmp Experiment Tutorial

Before your instrument was shipped from MicroCal, we used aliquots of the same samples to generate a binding isotherm and have provided you with a copy of the results we obtained, including the run parameters and the fitting parameters obtained from data analysis in Origin. -

Page 74: Section 5: Instrument Maintenance

VP-ITC MicroCalorimeter User’s Manual Section 5: Instrument Maintenance The maintenance requirements of the VP-ITC are simple, but essential for quality experiments. • The cells, injection and filling syringes must be kept clean. • The Plunger Tips for the Pipette Injection Syringe must be replaced regularly to prevent excess wear that would allow the titrant to leak from the syringe. -

Page 75: Cleaning The Cells And Pipette

Rinsing with water after using any cleaning agent is important. WARNING: The cells of the VP-ITC are fabricated from Hastelloy C-276, and should never be cleaned with strong acids of any kind. Please consult the booklet provided on corrosion resistance of Hastelloy C-276 before using any substances that have corrosive properties. - Page 76 VP-ITC MicroCalorimeter User’s Manual CAUTION-Contrad-70 is highly caustic and a severe eye irritant; use latex gloves and safety glasses; make sure the cells are at room temperature or below before adding or removing Contrad-70; follow the manufacturer’s instructions on the container.

- Page 77 65°C for one hour. The cells are then cooled and rinsed with 300 ml or more of water using the cleaning device. Do not exceed one hour unless advised by a MicroCal engineer to do so.

-

Page 78: Replacing Pipette Plunger Tips

VP-ITC MicroCalorimeter User’s Manual 5.2 Replacing Pipette Plunger Tips It is recommended that when using the VP-ITC instrument on a daily basis, that the plunger tips of the pipette be replaced approximately once every month or two. The tools for replacing syringe... - Page 79 Section 5: Instrument Maintenance • Insert the Guide Sleeve into the Pipette Injector. • Thread on the Threaded Cap, to lock the Guide Sleeve in place. Never replace or polish plunger tips without the Guide Sleeve and Threaded Cap in place.

- Page 80 VP-ITC MicroCalorimeter User’s Manual Inserting the new syringe plunger tip To insert the new tip: • The Guide Sleeve and Adjustment Collar must be in place as described on the previous page. • Select the Install New Tip button •...

- Page 81 Section 5: Instrument Maintenance Polishing a new plunger tip After replacing a tip it will need to be polished to remove any high spots that may exist on the Teflon plunger, due to the manufacturing process. To polish a new tip: •...

-

Page 82: Y-Axis Calibration

VP-ITC MicroCalorimeter User’s Manual 5.3 Y-axis Calibration All necessary calibrations of your VP-ITC are carried out at MicroCal prior to shipment. Still, it is a good idea that the user performs a y-axis calibration check every 2-3 months. Y-axis calibration is achieved by dissipating a known power through a resistive heater located on the cell wall, and by then adjusting the software coefficient for DP. - Page 83 In general, users can anticipate that the reported error in deflection or energy will be less than 1%. If the error is reported as higher than 1%, please call MicroCal and speak to a Service Representative. If a more thorough analysis of y-axis calibration results is desired, the calibration data file can be read into Origin just as a titration data file can for detailed analysis.

-

Page 84: Replacing Injection Syringes & Height Adjustment

VP-ITC MicroCalorimeter User’s Manual 5.4 Replacing Injection Syringes & Height Adjustment If you order a replacement syringe for the pipette you will need to adjust syringe height (i.e. the position the stirring paddle in relation to the bottom of the cell). Each titration syringe comes with a round ‘height disk’... - Page 85 Section 5: Instrument Maintenance 11. Lower the upper Syringe Clamp so that it is flush to the top of the syringe holder. 12. Tighten the set-screw of the upper Syringe Clamp so that the disk is fixed to the syringe glass.

-

Page 86: Section 6: Tips And Troubleshooting

VP-ITC MicroCalorimeter User’s Manual Section 6: Tips and Troubleshooting This section provides tips for optimizing the performance of the ITC instrument and troubleshooting techniques for commonly encountered problems. After a new user has gained a working knowledge of the instrument and software, it is strongly urged for the user to read through this section in its entirety before proceeding with experiments involving precious samples. -

Page 87: User Tips And Faqs

2. Turn on VP-ITC power 3. Launch VPViewer 2.) After initial power up of the VP-ITC, the data channels will display incorrect values until the power LED on the front of the cell unit becomes lit. Once the power indicator light comes on, all data channel readings will be accurate and the instrument is ready to use. -

Page 88: Troubleshooting

PROBLEM: Long equilibration period before an experiment starts. There is no capability for directly cooling the cells nor the inner jacket of the VP-ITC, as was also the case for our earlier ITC instruments. If the operator is carrying out a series of experiments in the VP-ITC at 25.0 °C, for example, and if the freshly loaded sample solution has a temperature... -

Page 89: A Note About Buffers

Section 6: Tips and Troubleshooting Bent injection syringe needle – Remove the syringe from the pipette and roll on flat tabletop. Watch the needle to see if there is any wobble, indicating it is not straight. A machinist using a lathe can sometimes straighten bent needles. -

Page 90: Estimation Of Required Concentrations

VP-ITC MicroCalorimeter User’s Manual of sites in the sample cell ) is in excess of 1000, you may obtain better values for the binding constant at 580 RPM. The reason for this is that when binding is extremely tight, a significant error is encountered near the equivalence point if the injected ligand solution does not mix completely throughout the entire volume of the sample cell. -

Page 91: Section 7: Additional Features

Section 7: Additional Features Section 7: Additional Features This section contains information that the user may find useful, but is not necessary for successful operation of the instrument. This section is arranged as follows: Section 7: Additional Features ....................81 7.1 Extended Data Display ........................82 7.2 Customizing VPViewer........................82... -

Page 92: Extended Data Display

7.2 Customizing VPViewer In instances of multiple users operating the same VP-ITC system, it may be advantageous for those users to be able customize some aspects of the VPViewer application and recall those custom settings. - Page 93 The following descriptions detail the parameters that you may wish to alter for each user. Data File Path Indicates the complete path (excluding file name) where all VP-ITC data files will be saved. The specified path should be located on a hard drive and not on any floppy or CD-ROM drives.

Need help?

Do you have a question about the VP-ITC and is the answer not in the manual?

Questions and answers