Subscribe to Our Youtube Channel

Summary of Contents for Magnetrol STI R Series

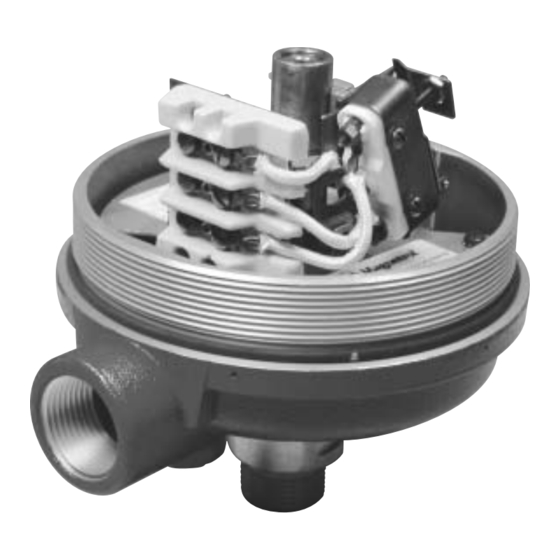

- Page 1 Electric Switch Mechanisms Installation and Operating Manual Series R with aluminum, carbon steel, or cast iron housings...

- Page 2 Notes do not normally contain determined to be covered under the warranty; then, actions. They follow the procedural steps to which Magnetrol will repair or replace the control at no cost to they refer. the purchaser (or owner) other than transportation.

-

Page 3: Table Of Contents

Series R Electric Switch Mechanisms Table of Contents 1.0 Reference Information.............1 1.1 Principle of Operation ..........1 1.2 Operating Cycle ............1 1.3 Description ...............2 1.3.1 Features ............2 1.3.2 Applications ...........2 1.3.3 Basic Switch Ratings........2 2.0 Installation...............3 2.1 Replacing Switch Mechanism........3 2.2 Replacing Dry Contact Switches .......4 3.0 Wiring ................5 3.1 SPDT Terminal Connections ........5 3.1.1 Single float with one switch......5... -

Page 4: Reference Information

Reference Information Principle of Operation Figures 1 & 2 illustrate the simple, reliable operating prin- ciple of a float level switch. Switching action is obtained through the use of a magnetic sleeve and a float displacer or flow sensing element and a switching mecha- nism . -

Page 5: Description

The Series R dry contact switches are specifically designed for use in applications with extremely high process temper- atures. This switch is available on most of Magnetrol’s buoyancy products and can also be retrofit onto many existing controls. Designed to Magnetrol’s usual high stan- dards, the Series ‘R’... -

Page 6: Installation

Installation Replacing Switch Mechanism Caution: Before attempting to remove a switch mechanism, be cer- tain to pull disconnect switch or otherwise assure that electrical circuit through control is de-energized. 1. Disconnect wiring from supply side of terminal block on switch mechanism. Note and record lead wire terminal locations. -

Page 7: Replacing Dry Contact Switches

Replacing Dry Contact Switches 1. Disconnect control from power supply. 2. Disconnect switch leads from terminal block. Note and record terminal connections of switch to be replaced. 3. Remove two mounting screws holding existing switch, refer to Figure 5. 4. Remove existing switch and install replacement switch in the same position, tightening mounting screws securely. -

Page 8: Wiring

Wiring Circuits shown are for direct acting level switches and are reversed in side mounting float-in-tank models, which uti- lize a reversing float pivot. SPDT Terminal Connections 3.1.1 Single float with one switch 1. Rising level closes contacts 5 & 6, see Figure 6. 2. -

Page 9: Replacement Part Numbers

Switch Housing Replacement Assemblies When ordering replacement parts for an existing Magnetrol instrument, please specify: 1. Model and serial numbers of control. 2. Description and part number of replacement kit. Use the chart in section 5.4 on page 8 to choose the appropriate replacement housing kit. -

Page 10: Cast Iron Housings

Cast Iron Housings Cast Iron NEMA 7/9 housing replacements are available for hazardous atmosphere locations. Both Class I, Div. 1, Groups C & D and Group B versions are available. The grey iron cover and base are finished with a baked-on poly- ester powder coat paint. -

Page 11: Replacement Housing Kits

Replacement Housing Kits NEMA Cover NEMA NEMA 7/9 Housing Material NEMA 1 NEMA 4X NEMA 7/9 Group B 4X/7/9 Height 4X/7/9 with drain with drain CS cover, aluminum base 89-6511-003* 89-6509-003* Short Cast aluminum 89-6582-023 89-6582-023 89-6582-032 89-6582-028 Cast Iron 89-6582-002 89-6582-003 CS cover, aluminum base 89-6512-003* 89-6510-003*... - Page 12 No claims for misapplication, labor, direct or consequen- tial damage will be allowed. 5300 Belmont Road • Downers Grove, Illinois 60515-4499 • 630-969-4000 • Fax 630-969-9489 • www.magnetrol.com 145 Jardin Drive, Units 1 & 2 • Concord, Ontario Canada L4K 1X7 • 905-738-9600 • Fax 905-738-1306 Heikensstraat 6 •...

Need help?

Do you have a question about the STI R Series and is the answer not in the manual?

Questions and answers