Table of Contents

Advertisement

Operating Instructions

1387.82/01-10

These

operating

information and precautionary notes. Please read the

manual thoroughly prior to installation of unit, electrical

connection and commissioning.

It is imperative to comply with all other operating instructions

referring to components of individual units.

instructions

contain

fundamental

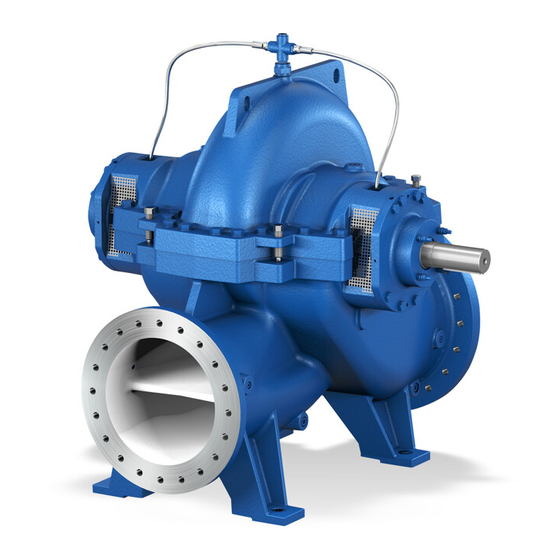

RDLO

Volute Casing Pump

with Radial Impeller

Advertisement

Table of Contents

Summary of Contents for KSB RDLO Series

- Page 1 RDLO Operating Instructions 1387.82/01-10 Volute Casing Pump with Radial Impeller These operating instructions contain fundamental information and precautionary notes. Please read the manual thoroughly prior to installation of unit, electrical connection and commissioning. It is imperative to comply with all other operating instructions referring to components of individual units.

-

Page 2: Table Of Contents

RDLO Contents Page General Safety Marking of Instructions in the Manual Personnel Qualification and Training Non-compliance with Safety Instructions Safety Awareness Safety Instructions for the Operator / User Safety Instructions for Servicing, Inspection and Installation Work Unauthorised Modification and Manufacture of Spare Parts Impermissible Modes of Operation Transport and Interim Storage Safety Instructions... - Page 3 RDLO Commissioning, Start-up/ Shutdown Commissioning Shaft Seal Venting Commissioning 6.4.1 Checking the Direction of Rotation 6.4.2 Start-up 6.4.3 Pump Operating Range 6.4.4 Shutdown Shutdown / Storage / Preservation 6.5.1 Storage of New Pumps 6.5.2 Measures to Be Taken for Prolonged Shutdown Returning to Service after Storage Servicing / Maintenance General Instructions...

-

Page 4: General

General Marking of Instructions in the Manual The safety instructions contained in this manual This KSB pump has been developed in accordance whose non-observance might cause hazards to with state-of-the-art technology, it is manufactured persons are specially marked with the general... -

Page 5: Non-Compliance With Safety Instructions

RDLO Non-compliance with Safety Safety Instructions for Servicing, Instructions Inspection and Installation Work Non-compliance with safety instructions The operator is responsible for ensuring that all jeopardise the safety of personnel, the environment servicing, inspection and installation work be and the machine itself. Non-compliance with these performed authorised, qualified... -

Page 6: Transport And Interim Storage

RDLO Transport and Interim Storage Safety Instructions Transport unit requires proper preparation and handling. Observe the following explanations and safety instructions. Transport Transport in horizontal position is recommended in all cases, since this ensures stable positioning of the unit without any risk of accident, whatever the method of transport is, e.g. -

Page 7: Description Of The Product And Accessories

The accessories supplied with the pump are specified in the relevant individual operating instructions in chapter 9. Technical Specification The KSB pump of the RDLO type series is a horizontally installed, single-stage, axially split Dimensions and Weights volute casing pump with double-entry radial For dimensions and weights please refer to the impeller. -

Page 8: Connecting The Piping

RDLO Prior to installation, the personnel involved must be load on the pump. With short pipelines, the nominal informed on the local safety regulations by the site diameters should be at least equal to the nominal management. diameters of the pump nozzles. For long pipelines the most economical nominal diameter has to be determined from case to case. -

Page 9: Coupling Guard

RDLO The rolling element bearings have been packed Coupling Guard with grease or (if applicable) the constant-level oilers have been mounted and filled with oil? (See section 7.2.3) In compliance with the accident prevention regulations the pump must not be operated without The pump has been vented as specified in section a coupling guard. -

Page 10: Start-Up

If system-induced changes occur, an valve only during the start-up and shutdown phase, NPSH check must be carried out. If necessary, as otherwise impermissible temperature increases consult KSB's nearest customer service centre. occur, which lead to damage. 6.4.3 Pump Operating Range 6.4.4... -

Page 11: Shutdown / Storage / Preservation

Operating Range“ must be observed. Shutdown / Storage / Preservation Upon completion of the work, all safety- Each KSB pump leaves the factory carefully related and protective equipment must be properly assembled. If commissioning is to take place some refitted and/or reactivated before starting the pump time after delivery, we recommend that the following set. -

Page 12: Servicing / Inspection

RDLO water collecting in the bearing, or that the grease Servicing / Inspection has become resinous or that it has run out, the bearing has to be filled with a new supply of grease 7.2.1 Supervision of Operation before commissioning/start-up of the pump. In The pump should run quietly and addition, the grease has to be changed each time Caution... -

Page 13: Dismantling

RDLO reservoir must be filled with oil. If this oil level is underrun, top up with oil. The oil level must always be Caution Sight glass below the vent opening arranged at the top edge of the connection elbow! Make sure the opening is always perfectly dry! Oil Change Intervals Gasket... - Page 14 RDLO Repair and servicing work on the pump must only Secure the bearing on the non- Caution be carried out by specially trained personnel, using driven against falling original spare parts. down. Observe the safety regulations laid down. Any Should the non-driven end bearing be a cylindrical work on the motor shall be governed by the roller bearing, the entire bearing housing on the specifications and regulations of the respective...

-

Page 15: Reassembly

RDLO The impeller (234) has a sliding fit on the shaft and Place the casing wear rings on the running surfaces can normally be removed easily. Should there be of the impeller. Make sure that the bezels of the any difficulty, use a wooden mallet and knock on rings are on the outside (towards the bearing). - Page 16 RDLO The bearings are secured by the disc (550.1) and wear rings and the sealing faces of the shaft seal the circlip (932). housing (441) as described in the assembly instruction. To fit the spacer sleeve (525.3), shaft seal housing (441) altogether with mechanical seal or gland Insert and align the rotor, making sure that the packing, shaft protecting sleeve (524.1 or 524.2),...

-

Page 17: Instructions For Replacement Of Assemblies / Parts

RDLO Instructions for Replacement of Assemblies / Parts 7.5.1 Replacing the Shaft Seal Gland Packing See the relevant instructions in sections 7.3 and 7.4. Mechanical Seal Prior to replacing the mechanical seal, the bearing housings including the rolling elements and the coupling must be removed. -

Page 18: Routine Servicing And Inspection Intervals

RDLO Routine Servicing and Inspection Intervals Interval Number of Time Servicing work personnel (hours) required Daily 1/10 Check mechanical seal for leakage or leakage rate of gland packing Check pump operation (suction Weekly pressure, discharge head, bearing temperature, noises and vibrations) Check torsional clearance of the coupling (see operating instructions Monthly... -

Page 19: Supervision Plan

RDLO Supervision Plan For the exact description of the pump design as well as the pump components and accessories supplied by KSB, please refer to section 9 (technical annex) of this instruction manual. Point to be supervised Supervisory action Value to be met... -

Page 20: Spare Parts

7.8.1 Purchasing of Spare Parts If spare parts are needed, these should be ordered from KSB's nearest customer service centre. When ordering spare parts please always quote the following particulars which are stated on the name plate or in the technical data of the pump in section 9.2): Type series;... -

Page 21: Trouble-Shooting

NPSH A . The duty point B is the intersection of the system curve H A and the pump curve H. If it is not possible to determine the cause of the trouble, contact KSB's nearest KSB customer service centre. Capacity... -

Page 22: Causes Of Faults And Their Remedies

- Alter the piping pump - If required, alter the suction / inlet pipe, if the resistances are too high - Check the piping layout for swirl or irregular flow profile (e.g. downstream of an elbow) 1) Consult KSB Page 22 of 24... - Page 23 - Alter the pump characteristic H 1) Shaft run-out - Replace the shaft Impeller rubs against casing - Check the rotor components - Check the impeller position - Check whether pipe connections are free from stresses or strains 1) Consult KSB Page 23 of 24...

- Page 24 RDLO KSB Aktiengesellschaft Page 24 of 24 Johann-Klein-Str. 9 • 67227 Frankenthal • Germany Phone: +49 6233 86-2656 • 67227 Fax: +49 6233-3412 • E-mail: • www.ksb.com info@ksb.com...

Need help?

Do you have a question about the RDLO Series and is the answer not in the manual?

Questions and answers