Advertisement

Advertisement

Table of Contents

Summary of Contents for KSB RDL

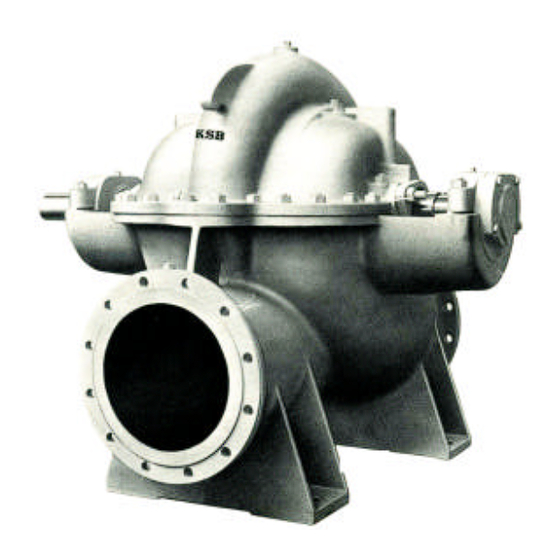

- Page 2 Operating Instructions KSB RDL Nº A1385.8E/3 Axially split volute casing pump acc. to Directive 98/37/EC Works Nº: _______________________________ Type Series: _________________________ These operating instructions contain fundamental information and precautionary notes. Please read the manual thoroughly prior to installation of unit, electrical connection and commissioning.

- Page 3 0. Introduction KSB has supplied you an equipment that has been designed and manufactured with the latest technology. Due to its simple and tough construction, it will need little maintenance. With the aim to provide our clients with satisfactory, trouble free operation, we recommend to install and maintain our equipment according to the instructions contained in this service manual.

- Page 4 1 General This KSB pump has been developed accordance with state-of-the-art technology; it is manufactured with utmost care and subject o continuous quality control. These operating instructions are intended to facilitate familiarization with the pump and its designated use. The manual contains important information for reliable, proper and efficient operation. Compliance with the operating instructions is of vital importance to ensure reliability and a long service life of the pump and to avoid any risks.

- Page 5 2.2 Personnel qualification and training All personnel involved in the operation, maintenance, inspection and installation of the machine must be fully qualified to carry out the work involved. Personnel responsibilities, competence and supervision must be clearly defined by the operator. If the personnel in question is not already in possession of the requisite know-how, appropriate training and instruction must be provided.

- Page 6 2.9 Explosion protection If the pumps/units are installed in hazardous areas, the measures and instructions given in the following sections 2.9.1 t be ad to 2.9.6 must be adhered without fail, to ensure explosion protection. 2.9.1 Unit fill It is assumed that the system of suction and discharge lines and thus the wetted pump internal are completely filled filled with the product to be handled at all times during pump operation, so that an explosive atmosphere is prevented.

-

Page 7: Transport And Interim Storage

The maximum permissible fluid temperature depends on the temperature class to be complied with. Due to its design, temperature limit for pumps RDL could be acc. to temperature class T4 to EN 13463-1 and the resulting theoretical temperature limit of the fluid handled is 120 ºC. In stipulating this temperature, any temperature rise in the shaft seal area has already been taken into account. -

Page 8: Interim Storage (Indoors) / Preservation

Note: Take care to not lose or damage coupling guard or foundation bolts during transport. Interim Storage (indoors) / Preservation KSB and its Dealer Network perform the following procedures of service and storage until effective delivery of the pump. It is client responsibility to continue with these procedures after receiving the pump. -

Page 9: Description Of The Product

Thickness of applied layer Protecting Liquid Drying Time Removal Manufacturer µm (in) TECTYL 506 80 to100 (.003 to .004) ½ up to 1 hour Gasoline/Benzene/Diesel Oil BRASCOLA RUSTILO DW301 6 to 10 (.0002 to .0004) 1 up to 2 hours Gasoline/Benzene CASTROL ≤... - Page 10 Pumps 200-620A, 250-620A, 300-500A, 300-620A and 350-620A can operate in 1750rpm, Casted carbon steel multiply values by 1.7 with reinforced bearings, subject to release by the KSB Product Department Casted chrome steel, please consult KSB For lubrication with oil, please consult KSB Product Department...

- Page 11 ‚ Pumps 200-620A, 250-620A, 300-500A, 300-620A and 350-620A can operate in 1750rpm, Casted carbon steel multiply values by 1.7 with reinforced bearings, subject to release by the KSB Product Department Casted chrome steel, please consult KSB ƒ For lubrication with oil, please consult KSB Product Department …...

- Page 12 Fig.4 – Sealing clearance and impeller diameter Fig.5 – Permissible forces and moments on the flanges (see table 1) 4.4 Design details 4.4.1 Casing Horizontal, axially split volute casing, with upper and lower casing. Horizontal and opposite suction and discharge nozzle, in the lower casing.

- Page 13 1000 Peripheral speed limit for impeller in: A536 60-40-18 CuSn10-C-GS A743 CA6NM A743 CF8M 1000 1500 2000 2500 3000 3500 4000 Q (l/h) Peripheral speed=40m/s Peripheral speed=60m/s Fig.6 – Peripheral Speed Fig.7 – Liquid flow of external source size curve size curve size...

- Page 14 Please refer to the mechanical seal drawing for details of the mechanical seal installed in the pump. Other seal configurations and types may only be used in exceptional cases and after consultation with KSB. The relevant seal version is shown in the mechanical seal drawing.

-

Page 15: Installation At Site

4.5.3 Coupling guard For a safety operation a coupling guard should be installed. Made according to KSB standards, of steel or brass. Installed on the transversal beam in case of common baseplate (see fig. 9) or on the foundation floor (see fig. 10). - Page 16 Secondary treatment of the concrete to DIN 1045 is an absolute necessity. Fig. 11: Fitting required shims To ensure low-noise operation, the unit can be mounted on vibration dampers (please confirm with KSB first). Expansion joints can be fitted between pump and suction/discharge line.

- Page 17 5.4 Rotation direction KSB RDL Pumps can be coupled to the drive on both shaft ends. The rotation can be clockwise or counter-clockwise, a function of drive position and suction and discharge nozzles. To determine the rotation direction, be in front of the shaft drive side and look at the pump, follow the pumped liquid flow, which enters through the suction flange (bigger diameter), makes a complete turn inside the pump and goes out through the discharge flange (smaller diameter).

- Page 18 This alignment should be performed with the help of a dial indicator for the control of the radial and axial displacements. Fix the bottom of the instrument to the periphery of one of the coupling halves, adjust the position of the dial indicator perpendicular to the periphery of the another half of the coupling.

- Page 19 Please check if a strainer/filter should be fitted in the suction line during the commissioning stage, in order to protect both the pump and the shaft seal from dam age due to contamination from the plant. In order to avoid any marked deterioration of the NPSH available, which would have an adverse effect on the pump, the strainer has to be cleaned whenever required.

- Page 20 The dimensions and locations of the auxiliary connections (sealing liquid, flushing liquid etc.) are indicated on the G.A. drawing and below. These connections are required for proper functioning of the pump and are therefore of vital importance! Modifications are only permitted after consulting KSB (see 2.7)! Description of piping and auxiliary connection From RDL 200-280 up to...

- Page 21 If the customer specifically requests not to include a coupling guard in our delivery, then the operator must supply one. In this case, it is important to make sure that the materials selected for coupling and coupling guard are non-sparking in the event of mechanical contact. KSB’s scope of supply meets this requirement. Final check Re-check the alignment as described in section 5.3.

- Page 22 6. Comissioning, start-up/shutdown Commissioning, Start-up / Shutdown Compliance with the following requirements is of paramount importance. Damage resulting from non- compliance shall not be covered by the scope of warranty. Commissioning Before starting up the pump make sure that the following requirements have been checked and fulfilled. If a constant-level oiler is provided, screw same into the upper tapping hole of the bearing bracket prior to adding the oil (see 6.1.1).

- Page 23 6.1.3 Priming the pump and checks to be carried out Before start-up, the pump, the suction line and (if applicable) the thermosiphon tank must be vented and primed. The shut-off element in the suction line must be fully open. Fully open all auxiliary lines provided (flushing, sealing, cooling liquid etc.) and check the through flow. For water cooling, use suitable non-aggressive cooling water not liable to form deposits and not containing suspended solids.

- Page 24 After the operating temperature has been reached, re-check the coupling alignment as des cribed in section 5.5 and re-align, if necessary. 6.1.7.1 Necessary steps for 1 operation Tighten the pump and driver on the baseplate; Set suction and discharge piping; Connect and run piping and auxiliary connections (when required);...

- Page 25 Do not operate the pump at temperatures exceeding those specified on the data sheet unless the written consent of the KSB has been obtained. Damage resulting from disregarding this warning will not be covered by the KSB warranty. Bearing bracket temperatures as described in section 7.2.1 must be observed.

- Page 26 The intervals recommended for servicing and maintenance shall be shortened. 6.3 Shutdown / Storage / Preservation Each KSB pump leaves the factory carefully assembled. If commissioning is to take place some time after delivery, we recom- mend that the following measures be taken for indoors pump storage.

-

Page 27: Maintenance & Repair

7. Maintenance/Repair 7.1 General instructions The operator is responsible for ensuring that all maintenance inspection and installation work is carried out by authorized duly qualified staff who are thoroughly familiar with these operating instructions. A regular maintenance schedule will help avoid expensive repairs and contribute to trouble-free, reliable operation of the pump with a minimum of maintenance expenditure and work. - Page 28 7.3.1 Bearings lubricated with grease During assembly in our factory bearings receive a grease charge and after lubricating interval (number of hours of continuous functioning) they must be lubricated to avoid metallic contact between rolling parts and also to protect them against corrosion and wear.

- Page 29 7.4 Shaft Seal Maintenance 7.4.1 Mechanical Seal Maintenance In case of supply of pump with mechanical seal, additional instructions from seal manufacturer should be followed. 7.4.2 Packing Maintenance If shaft sealing has already been tightened equivalent to a packing ring thickness and even so it presents excessive leakage, it must be checked as follow: Stop the pump Loosen nuts of gland cover and push it to the bearing housing direction in order to have enough space for work...

- Page 30 7.6.1 Disassembly sequence for pumps with packing Close suction (if any) and discharge valves. Drain pump removing threaded plugs (903.3) and (903.1). Close valves and disconnect auxiliary pipings, manometers and vacuometers (if any). Remove coupling guard (if any). Disconnect coupling sleeve of driver. Loosen nuts (920.4) and gland cover (452) of its studs (902.4), displacing into bearing direction.

- Page 31 Pass a rope around the shaft between the gland covers and bearing housings and lift the rotor to extract it from lower casing. See fig. 27. Take care to not damage the studs (902.1) and that the extracting is done without effort due to friction or bent position of rotor.

- Page 32 the lower casing when fixing the studs (902.1). For pumps sizes 400 up to 800 assembly procedure for D.E. changes. Mount spacer ring (504) on the shaft. Mount heated the internal ring of bearing on the shaft (120ºC, 30 minutes). Mount the external ring of bearing inside the bore of the bearing housing (use uniform pressure) and mount the set in the shaft.

-

Page 33: Spare Parts

8. Spare Parts Recommended spare parts for 2 years operation, according to DIN 24296 standard. Nº of Pumps (including stand-by ones) Part nº Denomination 6 and 7 8 and 9 10 or more Spare parts quantity Impeller Bearing set (pair) • Neck ring (pair) Lantern ring (pair) Packing (5 rings) -

Page 34: Sectional Drawing

9. Sectional Drawing 9.1 Sizes 125 up to 300 Figure 29 Note: • Not used at pump sizes 125-250/310, 150-430, 200-340/620, 300-340/400. ‚ Not used at pump sizes 200-500/620, 250-340/400. ƒ Only for pump size 300-400. „ Not used for pumps with ANSI flanges. - Page 35 9.2 Sizes 400 up to 500 Figure 30 Note: • Applicable for pump size 400-390, 500-510/640/790. ‚ Used only for pumps 400-480/620. ƒ Not used for pumps with ANSI flanges. „ Not used for pump size 400-480.

- Page 36 9.3 Sizes 600 up to 800 Figure 31 Note: • Not used for pump size 800-840. ‚ Not used for pumps with ANSI flanges.

-

Page 37: Parts List

Parts List Denomination Part nº Qtty. Lower casing 105.1 A48CL30 A48CL30 A536-60-40-18 Upper casing 105.2 A48CL35 A48CL35 Shaft SAE1045 Double entry impeller A48CL30 A743CF8M A48CL30 A743CF8M Radial ball bearing STEEL Radial roller bearing (2) Bearing bracket (3) Bearing housing A48CL30 Bearing cover (L.A.) 360.1 Bearing cover (L.B.) -

Page 38: Troubleshooting

45. Dirty bearings. 22. Parallel operation with different hydraulic characteristics. 46. Oxidation of bearings due to water or moisture in bearing housings. KSB has the right to change any information contained in this manual without previous notice. - Page 39 KSB Compañía Sudamericana de Bombas S.A. KSB Bombas Hidráulicas SA Av. Ader 3625 - B1606 DVE- Carapachay- Buenos Aires Rua José Rabello Portella, 400 Várzea Paulista SP 13220-540 Argentina Brasil http://www.ksb.com.br Tel. 54-11-4766-3021/3121/3221 Tel.: 11 4596 8500 Fax: 11 4596 8580 e-mail: servicio@ksb.com.ar...

Need help?

Do you have a question about the RDL and is the answer not in the manual?

Questions and answers