Summary of Contents for wtw LF 170

- Page 1 Operating instructions LF 170 LF 170 mg/l 1 5 6 ° ° Tref20 REL1 REL1 Conductivity Monitor ba54104e09 11/2010...

- Page 2 © Copyright Weilheim 2010, WTW GmbH Reprinting - even as excerpts - is only allowed with the explicit written authorization of WTW GmbH, Weilheim. Printed in Germany. ba54104e09 11/2010...

-

Page 3: Table Of Contents

Contents LF 170 - Contents Overview ............71 General features . - Page 4 Contents LF 170 4.6.2 Limit indicator ........... 102 4.6.3...

-

Page 5: Overview

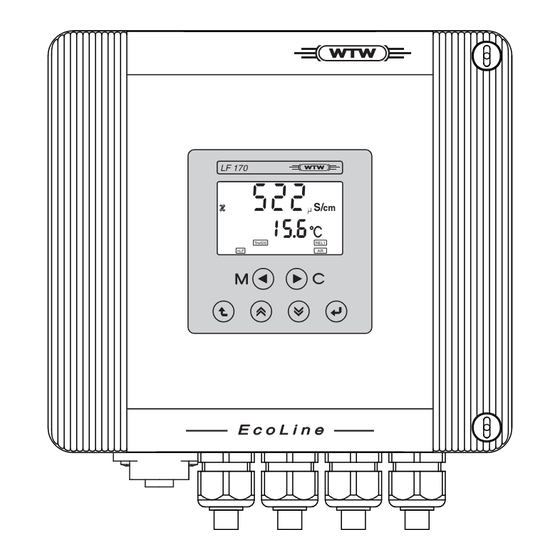

LF 170 Overview Overview General features LF 170 mg/l 1 5 6 ° ° Tref20 REL1 REL1 Fig. 1-1 LF 170 Watertight housing (IP 66) Display Operating keys Sensor input socket Cable glands ba54104e09 11/2010... -

Page 6: Outputs And Interfaces

2 x freely configurable 1 additional analog output relays for the measured temperature value LF 170 RT RS as RT option as RT option 1 x RS 485 1.2.2 Freely configurable relay (RT and RT RS option) Both potential-free K1 and K2 relays of the RT and RT RS instrument... -

Page 7: Rs 485 Digital Interface (Rt Rs Option)

LF 170 Overview 1.2.3 RS 485 digital interface (RT RS option) The monitor can communicate with other instruments via the RS 485 digital interface of the RS instrument versions. The following operating modes are possible: Master mode ( mode): Unidirectional mode for the output of measured values. - Page 8 Overview LF 170 ba54104d09 11/2010...

-

Page 9: Safety Instructions

This operating manual contains essential instructions that have to be followed during the commissioning, operation and maintenance of the LF 170 monitor. Thus, it is essential for the operator to read this component operating manual before carrying out any work with the system. -

Page 10: Authorized Use

Safety instructions LF 170 Authorized use The authorized use of the LF 170 monitor consists solely of stationary measurement in water and wastewater applications, seawater, brackish water and aquacultures. Read the technical specifications in accordance with chapter 8 T . Only operation and use ECHNICAL DATA according to the instructions in this operating manual is authorized. -

Page 11: Installation

Netz Option Option Mains Fig. 3-1 Mounting boreholes of the LF 170 The clearances of the boreholes are given in the dimensional drawing in the chapter 8 T . For wall mounting, use the suitable ECHNICAL DATA material (screws, wall plugs, etc.). -

Page 12: Electrical Terminal Strip

Installation LF 170 Electrical terminal strip The terminal strip of the LF 170 is accessible after the housing cover has been opened: 13 12 11 Sensor/Probe Rec2 Rec1 g f e d Netz Option Option Mains Fig. 3-2 Terminal strip LF 170 inside the housing... -

Page 13: Electrical Connection

Seal all open cable glands with matching blind plugs. WARNING Free wires must not protrude into the housing of the LF 170. Danger of short-circuit and fire! Touch-proof circuits can also come into contact with dangerous voltages if touched and lead to life threatening situations when working with the LF 170. -

Page 14: Line Power Connection

Installation LF 170 3.3.2 Line power connection WARNING If the power supply is connected incorrectly, it may represent a danger to life from electric shock. Pay attention to the following points during installation: The monitor must only be connected by an electrician. -

Page 15: Relay Contacts And Current Outputs

LF 170 Installation 3.3.3 Relay contacts and current outputs WARNING If external electrical circuits that are subject to the danger of physical contact are incorrectly connected to the relay contacts, there may be a danger of life threatening electric shock. Electrical... -

Page 16: Connecting A Conductivity Measuring Cell

Installation LF 170 Connecting a conductivity measuring cell 3.4.1 Measuring cell types and connection options Note Ordering information on the respective articles (connection cables, adapters, terminal boxes etc.) is given in chapter 7 A CCESSORIES Measuring cell Connection type Connection cable/... -

Page 17: Measuring Cells With 8-Pin Plug

LF 170 Installation LF 170 mg/l LF 170 1 5 6 ° ° Tref20 REL1 REL1 ® Example: TetraCon Fig. 3-3 Connection of conductivity measuring cells with plug adapters 3.4.3 Measuring cells with 8-pin plug This section describes the connection of the following conductivity measuring cells: ®... -

Page 18: Cable Extension

Installation LF 170 LF 170 mg/l LF 170 1 5 6 ° ° Tref20 REL1 REL1 ADA/AMPH-LAB-LF ® Example: TetraCon Fig. 3-4 Connection of a conductivity measuring cell with 8-pin plug 3.4.4 Cable extension The EK 170 cable (order no. 108 206) can be used in conjunction with the KI/S terminal box (order no. -

Page 19: Operation

LF 170 Operation Operation Display Display elements LF 170 Baud 8 8 8 8 ° Ident Tref25 Tref20 REL1 REL2 ARng Upper display line: Measured conductivity value, operator guidance Sensor symbol Lower display line: Measured temperature value, operator guidance Status displays, depending on instrument status... -

Page 20: Operating Keys

Operation LF 170 Operating keys The monitor is operated via the following six keys below the display: Key functions Function Call up measuring mode <M> Start calibration (only active in measuring mode) <C> In measuring mode: Display the sensor slope Confirm current selection <ENTER>... -

Page 21: Operating Levels And General Operating Principles

LF 170 Operation Operating levels and general operating principles OPERATING LEVEL (Measurement and calibration) 3.) Password entry for editing (optional) or viewing only with PARAMETERIZATION LEVEL ( ) Parameterization settings CONFIGURATION LEVEL ( ) Configuration settings Fig. 4-1 Operating levels... -

Page 22: Configuration

Operation LF 170 Configuration 4.4.1 Call up configuration level Call up the configuration level from the operating level as follows: 1 Press <DOWN>. 2 Press <ENTER>. 3 The menu for the password prompt appears. When delivered, no password protection is set up. In this case proceed to the next operating step by pressing <ENTER>... -

Page 23: Configuration Setting Table

LF 170 Operation 4.4.2 Configuration setting table General operating The starting point for the settings is the start display of the configuration instructions level (see section 4.4.1): Swap to the first setting with <ENTER>. Operation: All settings of the following setting table are run through step by step. - Page 24 Operation LF 170 Setting table: Setting Selection/Values Explanation (values in bold typeface = values on delivery) Connected sensor type: ® TetraCon 700 (SW) ® TetraCon ® TetraCon Cell with cell constant, 10 cm Cell with cell constant, 1 cm Cell with cell constant, 0.1 cm =01 Cell with cell constant, 0.01 cm...

- Page 25 LF 170 Operation Setting Selection/Values Explanation (values in bold typeface = values on delivery) Auto Measuring range. !999 This menu item only appears if the µS/cm conductivity measuring mode ( ) is 1)99 µS/cm selected. 19)9 µS/cm The set value indicates the upper measuring 1999 µS/cm...

- Page 26 Operation LF 170 Setting Selection/Values Explanation (values in bold typeface = values on delivery) The following settings are possible: , Measuring range 0.000 ... 1.999 µS/cm: (continued) Upper final value: 0,000 µS/cm Lower final value: 1.999 µS/cm (fixed range) , Measuring range 0,00 ... 19,99 µS/cm: Upper final value: 2.00 ...

- Page 27 LF 170 Operation Setting Selection/Values Explanation (values in bold typeface = values on delivery) , Measuring range 0.0 ... 199.9 mS/cm or Auto: (continued) Upper final value: 50.0 ... 199.9 mS/cm Lower final value: 0.0 ... 149.9 mS/cm Minimum spacing:...

- Page 28 Operation LF 170 Setting Selection/Values Explanation (values in bold typeface = values on delivery) °C Other sensor types: Upper final value: 15 ... 50 ... 130 °C (continued) Lower final value: -5 ... 0 ... 110°C Minimum spacing: 20 °C (step size 1 °C)

-

Page 29: Parameterization

LF 170 Operation Parameterization 4.5.1 Calling up the parameterization level Call up the parameterization level from the operating level as follows: 1 Press <DOWN>. 2 Press <ENTER>. 3 The menu for the password prompt appears. When delivered, no password protection is set up. In this case proceed to the next operating step by pressing <ENTER>... -

Page 30: Setting Table Of Parameterization

Operation LF 170 4.5.2 Setting table of parameterization Overview of the settings Instrument version (main level) Display Description Stan- RT RS dard Current output 1 Current output 2 Relay limits RS 485 interface Password protection Temperature balancing Reference temperature Temperature compensation... - Page 31 LF 170 Operation skipped. From any point of the main level press <ESC> to return to the starting point of the parameterization level. From here change to the operating level with <M> or <ESC> or to the configuration level with <UP><DOWN>.

- Page 32 Operation LF 170 Setting Selection/Values Explanation (values in bold typeface = values on delivery) (depending on the Settings for the REL 1 and REL 2 relays UL / LL REL 1/2 configuration) configured as limit indicators. The parameterization of the limit indicator is described in detail in section 4.6.

- Page 33 LF 170 Operation Setting Selection/Values Explanation (values in bold typeface = values on delivery) -=5 ... =5 °C Comparison of the measured temperature value against a reference thermometer. Notes: – Due to the thermal capacity of the sensor, it is necessary to place it in a container with at least 2 liters of water.

- Page 34 Operation LF 170 Setting Selection/Values Explanation (values in bold typeface = values on delivery) Temperature compensation and =50 ... 3.00 %/K temperature function. ---- This menu item only appears if the conductivity measuring mode ( ) is selected. The following settings are possible: –...

-

Page 35: Freely Configurable Relays (Rt And Rt Rs Option)

LF 170 Operation Freely configurable relays (RT and RT RS option) 4.6.1 Configuration Relay functions The two potential-free relays of the RT and RT RS instrument variants can be freely configured. The following functions are possible: Note The relay functions are selected in the configuration level under the setting Crc (see section 4.4.2). -

Page 36: Limit Indicator

Operation LF 170 Function Description CS (Cleaning System) The relay controls an external sensor cleaning unit. The relay works as a closer (i.e. normally open). During the cleaning process the measured value is frozen. The parameterization of the relay is described in section 4.6.3. - Page 37 LF 170 Operation Relay state Example: Monitoring of limit values with one or two relays Relay 1 Relay 2 Time Measured value Relay 1 Hysteresis HS1 Hysteresis HS1 Hysteresis HS2 Hysteresis HS2 Relay 2 Time Fig. 4-2 Switching points of relays working as limit indicators The selected limit value (UL/LL) is exceeded/undercut.

- Page 38 Operation LF 170 Setting table for limit indicators: Setting Selection/Values Explanation UL or LL Any within the Upper or lower limit. measurement range Setting tolerance according to the measured value display. Operating note: – Set the first (flashing) digit with <UP><DOWN>...

-

Page 39: Timer For External Sensor Cleaning System

LF 170 Operation 4.6.3 Timer for external sensor cleaning system Function The cleaning function enables the timing of a sensor cleaning system through one relay of the monitor. The relay always works as a closer (normally open). Setting table for sensor cleaning:... -

Page 40: Display Of The Relay States In The Operating Level

Operation LF 170 4.6.4 Display of the relay states in the operating level For an active relay the REL 1 or REL 2 status display appears in the operating level. Depending on the selected switching behavior the relay contact is either open or closed. -

Page 41: Checking/Setting The Cell Constant

LF 170 Operation Checking/Setting the cell constant Normally the cell constant specified by the manufacturer is given in the delivery documentation or the relevant labeling on the sensor. Note For conductivity measuring cells with the cell constants, 1 cm (see configuration, setting CIn), the cell 0.1 cm... - Page 42 Operation LF 170 Checking/Setting 1 In the measured value display: routine Press <C>. Note: The states of all relays and current outputs linked with the measured conductivity value are frozen during the checking/setting routine. 2 Immerse the conductivity measuring cell in the control standard.

- Page 43 LF 170 Operation With the 700, 600 and 300 sensor types, the entry is invalid if the Invalid setting value deviates from the nominal cell constant by more than ±10 %: Sensor Validity range type 0.826 ... 1.008 cm (0.917 cm ±10 %)

-

Page 44: Display Of Instrument Information

Operation LF 170 Display of instrument information The following information can be called up: Configuration data. For this, switch to the configuration level. Press <ESC> during the password prompt to view all settings in view mode (see section 4.4.1 C ALL UP CONFIGURATION LEVEL Parameterization data. -

Page 45: Test Mode

LF 170 Operation Test mode General information Test mode can be used for the following purposes: Set specific current values on the current outputs for test purposes Switch the relays on and off for test purposes (RT and RT RS... - Page 46 Operation LF 170 Test of current output 2 t s t (only for RT and RT RS option). 6 Press <ENTER>. REL1 REL2 Here a fixed current value can be set on current output 2: – Set 0.1 mA with <M>...

- Page 47 LF 170 Operation Test of current output 2 t s t (only for RT and RT RS option). 6 Press <ENTER>. REL1 REL2 Here a fixed current value can be set on current output 2: – Set 0.1 mA with <M>...

- Page 48 Operation LF 170 The tSt display flashes. The RS 485 communication test is active. The RS 485 interface works as a repeater, i.e. all received blocks are sent back again. Special commands: REL1 REL2 – The monitor sends the instrument identification according to the RS command "RSID"...

-

Page 49: Maintenance And Cleaning

LF 170 Maintenance and cleaning Maintenance and cleaning Maintenance The measurement instrument is maintenance free. Cleaning Occasionally wipe the outside of the measuring instrument with a soft, damp cloth. CAUTION Do not use high-pressure water blasters for cleaning (danger of water penetration!). - Page 50 Maintenance and cleaning LF 170 ba54104d09 11/2010...

- Page 51 LF 170 What to do if ... What to do if ... The conductivity Cause Remedy measuring cell cannot – Contact problems – Check the connections of the be activated conductivity measuring cell Display OFL Cause Remedy – The measured conductivity or –...

- Page 52 What to do if ... LF 170 Cause Remedy – Incorrect reference – Correct set reference temperature set temperature The current output Cause Remedy delivers no current – When wiring with the flow – Check the current output in test control its switching threshold mode (see section 4.9).

-

Page 53: Accessories

Cable and terminal box Description Model Order for cable extension Cable plug K170 109 508 Cable EK/170 108 206 Passive terminal box KI/S 108 606 Note More accessories are available in the WTW catalog or on the Internet under www.WTW.com. ba54104e09 11/2010... - Page 54 Accessories LF 170 ba54104d09 11/2010...

-

Page 55: Technical Data

LF 170 Technical data Technical data General data Front view: Dimensions LF 296 mg/l 1 5 6 ° ° Tref20 REL1 REL1 Rear view: Side view: Fig. 8-1 Dimension drawing of the LF 170 (dimensions in mm) Test certificates ba54104e09 11/2010... - Page 56 Technical data LF 170 Mechanical Housing material Glass fiber reinforced Polycarbonate construction Membrane keyboard Polyester Weight approx. 2,2 kg Type of protection IP 66 Ambient conditions Temperature Operation -25 °C ... +55 °C (-13 ... 131 °F) Storage -25 °C ... +65 °C (-13 ... 149 °F) Relative humidity ≤...

- Page 57 LF 170 Technical data Electrical connections 13 12 11 Rec2 Rec1 Sensor/Probe g f e d Netz Option Option Mains Fig. 8-2 Terminal strip Connection technique Connections – 7-pin sensor input jack on the underside of the housing – Screwless plug-in connections in the...

- Page 58 Technical data LF 170 Current outputs Output Galvanically separated from the sensors Current range Adjustable: – 0 - 20 mA – 4 - 20 mA Accuracy 0.1 % of current value ± 50 µA, load max. 600 Ω Functions – 1 x analog output for measured conductivity value –...

-

Page 59: Measurement Characteristics

0.50 ... 3.00 %/K Nonlinear 5 ... 35 °C (41 ... 95 °F) according to DIN EN 27888 / ISO 7888 35 ... 60 °C (95 ... 140 °F) according to WTW procedure None ba54104e09 11/2010... -

Page 60: Salinity Measurement

Technical data LF 170 8.2.2 Salinity measurement Display and 0.0 ... 70.0 Sal measuring range Resolution 0,1 Sal reference 20 °C temperature 8.2.3 Temperature measurement Temperature sensor NTC (integrated in the sensor) Measuring range 0.0 ... 130.0 °C (depending on the measuring... -

Page 61: Indexes

LF 170 Indexes Indexes This chapter provides additional information and orientation aids. List of display abbreviations (see section 9.1) Definition of terms (see section 9.2) Index (see section 9.3) Display abbreviations Configuration Password Starting point of the configuration level Measuring mode and range... - Page 62 Indexes LF 170 Temperature compensation Variable cell constant Nonlinear function Cleaning system Parameterization Upper limit Lower limit relay Hysteresis Switching delay Cleaning interval Cleaning duration Adjustment duration Parameterization Attenuation of current outputs Miscellaneous Software version Test mode ba54104d09 11/2010...

-

Page 63: Glossary

LF 170 Indexes Glossary The glossary briefly explains the meaning of the specialist terms. However, terms that should already be familiar to the target group are not described here. AutoRange Name of the automatic selection of the measuring range. Cell constant, k Characteristic parameter of a conductivity measuring cell, depending on the geometry. - Page 64 Indexes LF 170 Temperature Name of a function that considers the temperature influence on the compensation measurement and converts it accordingly. Depending on the measured parameter to be determined, the temperature compensation functions in different ways. For conductimetric measurements, the measured value is converted to a defined reference temperature.

-

Page 65: Index

LF 170 Index Index ........77 Outdoor mounting .........122 Ambient conditions .........76 Authorized use ......87 Parameterization level Password ........... 88, 95 Entry ........108 Calibration routine ..........98 Setting ........87 Configuration level ......73 PROFIBUS connection Current output ........97 Attenuation ........97... - Page 66 Index LF 170 ba54104e09 11/2010...

- Page 68 Wissenschaftlich-Technische Werkstätten GmbH Dr.-Karl-Slevogt-Straße 1 D-82362 Weilheim Germany Tel: +49 (0) 881 183-0 +49 (0) 881 183-100 Fax: +49 (0) 881 183-420 E-Mail: Info@WTW.com Internet: http://www.WTW.com...

Need help?

Do you have a question about the LF 170 and is the answer not in the manual?

Questions and answers