Advertisement

Quick Links

Installation, Operation,

and Maintenance Manual

Magnitude

®

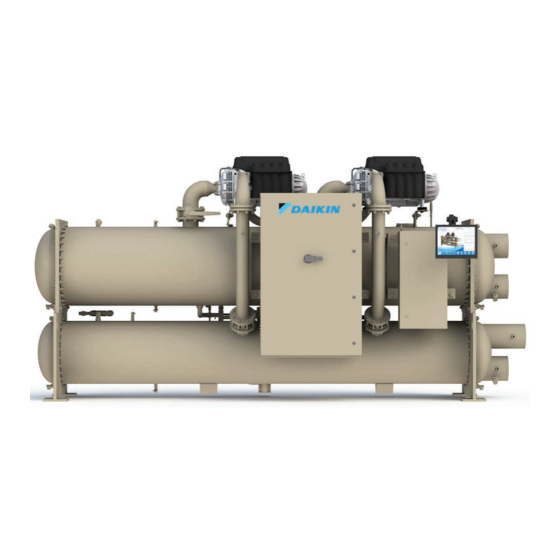

Magnetic Bearing Centrifugal Chillers

Model WMC-D, Model TMC

125 to 400 Tons (440 to 1400 kW)

HFC-134a Refrigerant

50/60 Hz

IOM 1210-7

Group: Chiller

Part Number: IOM1210-7

Date: June 2018

Supercedes: April 2018

Advertisement

Summary of Contents for Daikin Magnitude

- Page 1 Installation, Operation, IOM 1210-7 and Maintenance Manual Group: Chiller Part Number: IOM1210-7 Date: June 2018 Magnitude ® Supercedes: April 2018 Magnetic Bearing Centrifugal Chillers Model WMC-D, Model TMC 125 to 400 Tons (440 to 1400 kW) HFC-134a Refrigerant 50/60 Hz...

-

Page 2: Table Of Contents

Manufactured in an ISO 9001 & ISO 14001 certified facility ©2018 Daikin Applied. Illustrations and data cover the Daikin Applied product at the time of publication and we reserve the right to make changes in design and construction at any time without notice. - Page 3 From starter to chiller unit (remote mounted) Centrifugal chillers with water cooled oil coolers must have a 115 volt normally closed water solenoid valve installed in the oil cooler water supply line. Daikin Applied recommends ASCO Type 8210B27 solenoid valve or approved equal and 40-mesh strainer. Daikin Applied does not supply these components.

-

Page 5: Introduction

Operation of this equipment in a residential area is likely to cause harmful interference in which case the owner will be required to correct the interference at the owner’s own expense. Daikin Applied disclaims any liability resulting from any interference or for the correction thereof. HAZARD IDENTIFICATION INFORMATION DANGER Dangers indicate a hazardous situation, which will result in death or serious injury if not avoided. - Page 6 TMC Templifier units are equipped All Daikin Applied centrifugal chillers must be commissioned by with centrifugal compressors and are available as a a factory-trained Daikin Applied service technician. Failure to configuration, each with optional pass arrangements.

- Page 7 If the HMI should become inoperable, the controller LCD can display most of the same information as the HMI and can be used to operate the chiller independently of the HMI. “The Controller” on page 57 for information. www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

-

Page 8: Installation

If the drawings are not available, consult the local Daikin Applied sales office • Vessel nameplates are located on the evaporator and for assistance. - Page 9 Width is based on unit without optional harmonic filters. ** Shipping weight is based on unit with standard tube configuration. *** Denotes unit with economizer NOTE: See certified drawings for additional dimensional data www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 10 Width is based on unit without optional harmonic filters. ** Shipping weight is based on unit with standard tube configuration. *** Denotes unit with economizer NOTE: See certified drawings for additional dimensional data IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 11 Retrofit Knockdown It is estimated that fifty percent of retrofit applications require partial or complete disassembly of the chiller. Magnitude ® chillers are relatively easy to disassemble due to the small compressor size, simplified refrigerant piping, and the absence of a lubrication system with its attendant components and piping.

- Page 12 • Site reassembly must be supervised or completed • All associated piping and wiring remain attached, if by Daikin Applied service personnel. Cost for unit possible. resassembly and supervision by Daikin Applied service • Suction and discharge lines have bolt-on flanges and, if is not included in the purchase price of the equipment.

- Page 13 TAKEN TO PROTECT PIPING. CTSW CTSW LEFT SIDE VIEW 334401501 LEFT SIDE VIEW KEY SHEET OUTLINE WMC*CS (WMC400 only) NOTE: See following page for overall unit length, width, and height dimensions for WMC models. www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 14 Label 043S 048S 036D 036D 060S 043D 048D 043D 048D 060D CTSW 1118 CTSH EDW1 1423 1147 1210 1160 EDW2 1522 2316 1535 2379 2328 ETSW ETSH LLTS 1554 1632 1897 IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 15 * Component weights based on unit with standard tube configuration Compressor Removal 1. Loosen and remove bolts on the suction elbow to butterfly valve flange. Remove suction elbow and install a flange cover on the valve.(see Figure 13, flag #6). www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 16 1. Set compressor on mounting brackets and install the (4) Standard torque specs must be followed when re-installing mounting bolts loosely. bolts. Contact Daikin Applied service for this information. 2. Reinstall suction and discharge elbows with new gaskets 1. Reassemble the vessel stack, if disassembled, and and O-rings.

- Page 17 (Models 036D12, 043D12, 048D12, 060D12) Minimum 3’ Clearance Minimum 4’ Clearance in front of control boxes and electrical panels NOTE: Hinged type waterboxes may require more clearance. Consult a Daikin Applied sales representative for details. www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS...

- Page 18 Piping must be supported to eliminate weight and strain on the fittings and connections. Chilled water piping must be adequately insulated. IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 19 II controller has a “lenient flow” feature that acts as an override of the flow sensor while protecting the chiller by monitoring a condenser pressure setting that is below the high pressure cutout. www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 20 Relief Valves condenser head pressure. Figure 17: Three-Way Valve, Front Seated Position Contact your local Daikin Applied representative for more information on this application. Relief Valves As a safety precaution and to meet code requirements, each...

- Page 21 The formula and tables are factory-wired to individual disconnect switches for each contained in ASHRAE Standard 15-2001. compressor. Refer to the unit nameplate and the Daikin Tools selection report for the correct electrical ratings. Using the ASHRAE formula and basing calculations on the 225 psi design yields a conservative pipe size.

- Page 22 AND have the HMI and PC used on the WMC-D model. If trying to connect WMC A to B, C or D models, consult a Daikin Applied service representative. WMC chillers cannot be pLAN interconnected with WSC, WDC, WCC or WME chillers.

- Page 23 IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 24 Figure 20: Wiring Index IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 25 IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 26 Figure 21: Controller Box Wiring IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 27 IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 28 Figure 22: Power Box Single and Multi Point Wiring IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 29 IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

-

Page 30: Operation

During impeller speed. Maximum capacity at a given operating the initial startup of the chiller, the Daikin Applied technician will condition can be found either when the compressors be available to answer any questions and instruct the proper have reached their maximum speed limit (Mechanical operating procedures. - Page 31 47.) The three options for “Control Source” are: 5. Remote Switch - This switch will disable the chiller in a similar manner as the Unit Switch. 1. Switches - This is the default mode. This mode will www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 32 Note that the chiller displayed on this screen, as well as on all other screens that display an image of the chiller, will show • COMPRESSOR either one or two compressors depending on the chiller model. • CONDENSER • EXPANSION IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 33 #1 and #2 for dual compressor units), is MODE followed by STATE followed by the SOURCE that is the device or signal that created the STATE. The possible combinations are shown in Table www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 34 COMP button will bring up a display of the Compressor State Information (Figure 26) on the right side of the Detail View Screen. Use the COMP button to toggle between the two compressors’ data. IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 35 Figure 28 Figure from the Detail View Screen. Reference the Information figures respectively. in the "Detail View Screen" section starting on page 32 Power Information more details. Figure 28: Evaporator Information www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 36 Appropriate whichever of the two was used last. When in any Setpoint setpoints are factory set and checked by a Daikin Applied Screen, pressing the SET button again will toggle to the service representative during commissioning;...

- Page 37 2001 for manager level. The technician selected. level password is only provided to Daikin Applied technicians) There is a small delay between pressing the 8. Additional setpoints can be changed by selecting another keypad and recording the entry.

- Page 38 • M = Manager Level (The password number for manager level is 2001.) • T = Technician Level (the password number for technician level is only provided to technicians who have completed Service training with the Daikin Learning Institute.) IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com...

- Page 39 On- reduction in unit trips by detecting a loss of flow signal (>5 Sec) NOTE: The setpoints listed in Table 11 should only be changed by a Daikin Applied technician. Contact a Daikin Applied service representative for more information. www.DaikinApplied.com IOM 1210-7 •...

- Page 40 Select setpoint that will enable economizer to open Economizer Close 100-120 Select setpoint that will enable economizer to close Economizer Superheat 6.0 ∆°F 1-10 Select setpoint for economizer superheat control Setpoint IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 41 Setpoints 1 and 2 in Table 14 on page 40. The setpoints listed in Table 13 should only be changed by a Daikin Applied technician. Contact a Daikin Applied service representative for more information. www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 42 Temperature for fan stage #2 on Stage #1 On (Temp) 70 °F 40 to 120 °F Temperature for fan stage #1 on Stage Differential (Lift) 6.0 psi 1.0 to 20.0 psi Fan staging deadband with SP1=Lift IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 43 SP (also called Valve Target) and is adjustable. (III) VALVE STAGE: This control strategy is tower staging (up to four stages) with a stage-controlled bypass valve. In this mode, the bypass valve controls between fan stages Fan Stages www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 44 (Up to 4 fans) Tower Control Panel 0-10 VDC w/ Fan Signal MicroTech ® Controller Temperature (°F) % VFD Speed (4 Fan Stages) % VFD Speed (1 Fan Stage) Condenser % Valve Opening IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 45 65°F. This temperature is the Valve SP (also Daikin Applied startup technician. Setup instructions for each of called Valve Target) and is adjustable. BAS Alternate the five tower control strategies are provided next.

- Page 46 SP15. Set the control gain for slope. The default 1. Use all of the same setpoint settings as those outlined is 1. in section II.B [the VALVE Setpoint Screen section for control strategy (II) VALVE SP]. IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 47 Lag Start Speed 0 to 100% Select percentage of available speed range. NOTE: Setpoints that have a technician level password (T) should only be changed by a Daikin Applied technician. Contact a Daikin Applied service representative for more information. CAUTION * Chiller Nameplate RLA MUST match chiller dataplate per compressor.

- Page 48 (chiller mode = COOL) is limited at all times by the value, the unit will begin capacity decreases. Maximum Rate setpoint. If the rate exceeds this setpoint, capacity increases are inhibited. IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 49 Relay #1 and #2 Configurable Relay #1: Evap Water Pump #2, Relay #2: Cond Water Pump #1 NOTE: If both compressors have the same sequence number, they will automatically balance starts and run-hours. www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 50 When the chiller mode = COOL, the Active Leaving Water note that all reset functions are designed with a filter to prevent variable is reset using the following parameters: chiller shutdown in the case of a sudden delta change. IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 51 4 mA and 20 mA. An example of this action is shown below. Figure 51: LWT Reset NOTE: Temperatures in above figures are examples only. www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 52 HMI software identification number. scroll to the correct time. Use the drop down menu in the “Time These numbers may be required by Daikin Applied to answer Zone” tab to change the time zone to the correct area.

- Page 53 HMI screen (not the HMI PC) is off or in sleep mode. For actual motor speed. details on how to download the trend history, reference the "Alarm History Screen" section starting on page www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 54 (Figure 56) via USB. In order to download the trend or alarm history, first insert a USB drive into the left side of the monitor as seen in the following figure. IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 55 If a directory screen opens when the USB drive is inserted, personal use. If tech support is requested, the original close out of that screen and continue with the directions (un-manipulated) .csv files must be sent to Daikin instructed below. Applied. Any other file formats are NOT accepted.

- Page 56 The alarm notice will be deleted from the screen. If the cause of the alarm is not remedied, the alarm is still active and the alarm message will remain open. The unit will not begin its starting sequence. IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 57 Reset is dependent on specific alarm (previously used for WMC general compressor fault) COMPR STOP - Compressor Fault Starter Fault Compressor 2 Reset is dependent on specific alarm (previously used for WMC general compressor fault) www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 58 Table 22: Compressor Warning Alarms Description HMI Alarm Message Alarm Reset Repower After Power Loss 1 COMPR STOP - Line Voltage Low Auto-clears Repower After Power Loss 2 COMPR STOP - Line Voltage Low Auto-clears IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 59 ALARM, VIEW, SET, etc. This mode is entered by pressing the MENU key. For ease of use, a pathway connects the appropriate button to its respective label on the screen. . www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 60 % Unit Load 0 to 10 VDC 0 to 125% (8V = 100%) NOTE: “Sensor Range” in Table 27 indicates the range of the output, NOT the operating range of the chiller. IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 61 O = Operator (the password number for operator level is 100) M = Manager (the password number for manager level is 2001) T = Technician (the password number for technician level is only provided to Daikin Applied technicians) Table 29: Controller Setpoints...

- Page 62 Minimum Start Position 0 to 100% Minimum Position @ 60 °F 0 to 100 °F Maximum Start Position 100% 0 to 100% Maximum Position @ 90 °F 0 to 100 °F IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

- Page 63 1 to 99 °F Surge High Suction SH - Run 12°F 2 to 25 °F Service Unload Timer 120 sec 5 to 300 sec Interlock Timer 10 sec 1 to 240 sec www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®...

- Page 64 Please note an unsynchronized interface installation manual was shipped with the unit. If transfer switch may result in an alarm shutdown of the chiller. necessary, contact your local Daikin Applied sales office for a replacement manual or obtain one from www.DaikinApplied.

-

Page 65: Maintenance

Daikin Applied offers a variety of maintenance services through Recommended maintenance includes the following: the local Daikin Applied service office and can tailor these • Check the sensor tip for buildup. services to suit the needs of the building owner. Most popular •... - Page 66 A. Check and record line voltage B. Inspect power components for signs of overheating C. Check and tighten unit electrical components Key: O = Performed by owner personnel X = Performed by qualified service personnel IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com ®...

-

Page 67: Appendix

The default setting for Lenient Flow logic in the WMC code is water temperature. It is calculated by taking readings of the On. Turning it off converts the flow loss alarms, to timer based. www.DaikinApplied.com IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS ®... - Page 68 If so, it clears timers, enables the pumps, and clears power loss alarms. Evaporator water flow IOM 1210-7 • MAGNITUDE MODEL WMC CHILLERS www.DaikinApplied.com...

- Page 69 (collectively “Owner”) that Company, at it’s option, will repair or replace defective parts in the event any product manufactured by Company, including products sold under the brand name Daikin and used in the United States or Canada, proves defective in material or workmanship within twelve (12) months from initial startup or eighteen (18) months from the date shipped by Company, whichever occurs first.

- Page 70 Daikin Applied Training and Development Now that you have made an investment in modern, efficient Daikin Applied equipment, its care should be a high priority. For training information on all Daikin Applied HVAC products, please visit us at www.DaikinApplied.com and click on Training, or call 540-248-9646 and ask for the Training Department.

Need help?

Do you have a question about the Magnitude and is the answer not in the manual?

Questions and answers