ESAB Aristo Origo Feed 4804 Instruction Manual

Hide thumbs

Also See for Aristo Origo Feed 4804:

- Service manual (40 pages) ,

- Instruction manual (28 pages) ,

- Instruction manual (28 pages)

Summary of Contents for ESAB Aristo Origo Feed 4804

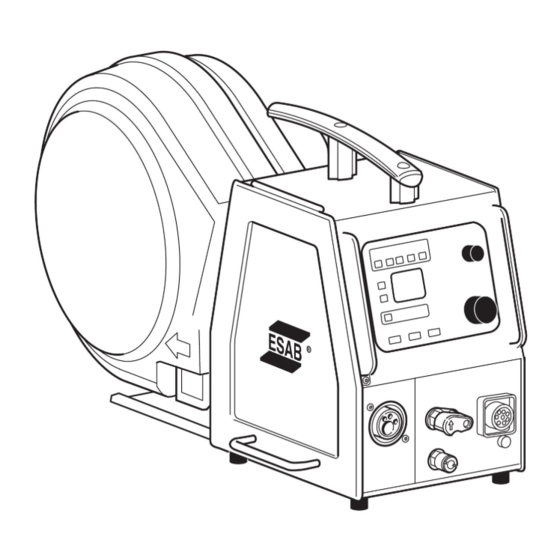

- Page 1 Aristo®, Origo™ Feed 3004, Feed 4804 Instruction manual Valid for: serial no. 745-, 910-, 236-, 540-, 628-xxx-xxxx 0444 408 201 GB 20171124...

-

Page 3: Table Of Contents

Changing feed rollers on Feed 3004............. Changing feed rollers on Feed 4804............. MAINTENANCE ................... Inspection and cleaning................. ORDERING SPARE PARTS ................ DIAGRAM ......................WEAR PARTS....................... ORDERING NUMBERS ..................ACCESSORIES ....................Rights reserved to alter specifications without notice. 0444 408 201 © ESAB AB 2017... -

Page 4: Safety

Data Sheets (SDSs). Safety precautions Users of ESAB equipment have the ultimate responsibility for ensuring that anyone who works on or near the equipment observes all the relevant safety precautions. Safety precautions must meet the requirements that apply to this type of equipment. The following recommendations should be observed in addition to the standard regulations that apply to the workplace. - Page 5 • Keep your head out of the fumes • Use ventilation, extraction at the arc, or both, to take fumes and gases away from your breathing zone and the general area 0444 408 201 - 5 - © ESAB AB 2017...

- Page 6 As the person responsible for the equipment, it is your responsibility to obtain information on approved collection stations. For further information contact the nearest ESAB dealer. 0444 408 201 - 6 - © ESAB AB 2017...

- Page 7 1 SAFETY ESAB has an assortment of welding accessories and personal protection equipment for purchase. For ordering information contact your local ESAB dealer or visit us on our website. 0444 408 201 - 7 - © ESAB AB 2017...

-

Page 8: Introduction

The wire feed units contain four-wheel drive wire feed mechanisms as well as control electronics. They can be used together with wire on ESAB's MarathonPac™, or on wire bobbin (standard Ø 300 mm, accessory Ø 440 mm). The wire feed unit can be installed either on the power source trolley, suspended above the workplace, on a counter balance device or on the floor with or without wheel set. - Page 9 Knobs for setting the voltage / QSet™ and the wire feed speed / current. Other settings with push buttons. MA25 Pulse See the separate instruction manual for a detailed description of the control panels. 0444 408 201 - 9 - © ESAB AB 2017...

-

Page 10: Technical Data

MIG/MAG welding MIG/MAG welding max pressure 0.5 MPa ( 5 bar) 0.5 MPa ( 5 bar) Coolant ESAB's ready mixed coolant ESAB's ready mixed coolant max pressure 0.5 MPa ( 5 bar) 0.5 MPa ( 5 bar) Maximum permissible load at... -

Page 11: Installation

Lifting instructions Order number for lifting eyelet can be found in chapter "ACCESSORIES". NOTE! If another mounting device is used, this must be electrically insulated from the wire feed unit. 0444 408 201 - 11 - © ESAB AB 2017... -

Page 12: Operation

Secure the equipment, especially if used on an uneven or sloping surface. WARNING! Risk of crushing when replacing the wire bobbin! Do not use safety gloves when inserting the welding wire between the feed rollers. 0444 408 201 - 12 - © ESAB AB 2017... -

Page 13: Connections And Control Devices

* ELP = ESAB Logic Pump, see section "WATER CONNECTION". Water connections The wire feed unit with water connection is equipped with a detection system ELP (ESAB Logic Pump) which checks that the water hoses are connected. When connecting a water-cooled welding torch, the water pump starts. -

Page 14: Replacing And Inserting Feed 3004 Wire

• Make sure that the wire goes properly into the feed roller's track and into the outflow nozzle or wire guide. • Reinstall the bogie. • Close the side panel. 0444 408 201 - 14 - © ESAB AB 2017... -

Page 15: Changing Feed Rollers On Feed 3004

Place no, one or two driving washers between the outer washer and the feed roller. Groove 1 Groove 2 Groove 3 NOTE! When replacing the pressure rollers (8), the entire bogie is replaced. 0444 408 201 - 15 - © ESAB AB 2017... -

Page 16: Maintenance

The welding torch's wear parts should be cleaned and replaced at regular intervals in order to achieve trouble-free wire feed. Blow the wire guide clean regularly and clean the contact tip. 0444 408 201 - 16 - © ESAB AB 2017... -

Page 17: Ordering Spare Parts

Spare parts and wear parts can be ordered through your nearest ESAB dealer, see the back cover of this document. When ordering, please state product type, serial number, designation and spare part number in accordance with the spare parts list. -

Page 18: Diagram

DIAGRAM DIAGRAM 0444 408 201 - 18 - © ESAB AB 2017... - Page 19 DIAGRAM 0444 408 201 - 19 - © ESAB AB 2017...

-

Page 20: Wear Parts

1.2 A2 & 1.6 mm & 1.6 A2 Only use pressure and feed rollers marked A2, R2 or S2. The rollers are marked with wire dimension in mm, some are also marked with inch. 0444 408 201 - 20 - © ESAB AB 2017... - Page 21 WEAR PARTS 0444 408 201 - 21 - © ESAB AB 2017...

- Page 22 In order to weld with aluminium wire, proper rollers, nozzles and liners for aluminium wire must be used, It is recommended to use 3 m long welding torch for aluminium wire, equipped with appropriate wear parts. 0444 408 201 - 22 - © ESAB AB 2017...

- Page 23 WEAR PARTS 0444 408 201 - 23 - © ESAB AB 2017...

- Page 24 0366 966 885 Feed roller Al 0366 966 899 Feed roller Al 1.0-1.6 Item Ordering no. Denomination Notes HK3 0156 707 001 Distance washer HK4 0156 707 002 Adjustment spacer Screw M5×20 Screw M5×16 0444 408 201 - 24 - © ESAB AB 2017...

- Page 25 WEAR PARTS 0444 408 201 - 25 - © ESAB AB 2017...

- Page 26 0332 318 001 Inlet nozzle (HD) Fe, Ss & Cored Ø 2.4 mm steel for 1.2-2.0 mm 0332 318 002 Inlet nozzle (HD) Fe, Ss & Cored Ø 4 mm steel for 2.4 mm 0444 408 201 - 26 - © ESAB AB 2017...

- Page 27 WEAR PARTS 0444 408 201 - 27 - © ESAB AB 2017...

-

Page 28: Ordering Numbers

Origo™ MA23, Origo™ MA24 0463 459 Instruction manual MA25 Pulse 0459 287 Instruction manual Aristo™ U6 0459 310 Instruction manual Aristo™ U8 Technical documentation is available on the Internet at: www.esab.com 0444 408 201 - 28 - © ESAB AB 2017... -

Page 29: Accessories

0458 704 880 1 Bobbin holder 0455 410 001 2 Adapter for 5 kg bobbin 0459 233 880 1 Adapter for 440 mm bobbin 0458 706 880 1 Lifting eye F102 440 880 2 Quick connector MarathonPac™ 0444 408 201 - 29 - © ESAB AB 2017... - Page 30 0458 705 882 for 440 mm bobbin 0459 491 880 Remote control unit MTA1 CAN MIG/MAG: wire feed speed and voltage MMA: current and arc force TIG: current, pulse and background current 0444 408 201 - 30 - © ESAB AB 2017...

- Page 31 0459 681 880 For Miggytrac / Railtrac 0459 681 881 For MXH 300wPP / MXH 400wPP / PSF RS3 Connection kit 0459 020 883 For MXH 300wPP / MXH 400wPP 0444 408 201 - 31 - © ESAB AB 2017...

- Page 32 0700 200 015 6.0 m 0700 200 016 10.0 m 0700 200 019 10.0 m 45° More informa- Miggytrac 1001, Miggytrac 2000 tion at the Equipment for mechanized welding nearest ESAB agency 0444 408 201 - 32 - © ESAB AB 2017...

- Page 33 Plus Extension cable for U8 (connectors included) 0460 877 891 7.5 m, 12 poles Information on Miggytrack and PSF welding torches can be found in separate brochures. 0444 408 201 - 33 - © ESAB AB 2017...

- Page 34 ESAB subsidiaries and representative offices Europe THE NETHERLANDS North and South America SOUTH KOREA ESAB Nederland B.V. ESAB SeAH Corporation AUSTRIA Amersfoort ARGENTINA Kyungnam ESAB Ges.m.b.H Tel: +31 33 422 35 55 CONARCO Tel: +82 55 269 8170 Vienna-Liesing Fax: +31 33 422 35 44...

Need help?

Do you have a question about the Aristo Origo Feed 4804 and is the answer not in the manual?

Questions and answers