Advertisement

Quick Links

InBio160 Installation and Connection Guide

1.Cautions

Please note the following cautions. Mis-operation may lead to personal injury or

equipment failure:

1)Do not energize the system before installation is complete; never carry out

installation activities when the system is energized.

2)All peripheral devices must be grounded.

3)The conduits of wires under relay must be matched with metaled conduits, other wires

can use PVC conduits.

4)It is strongly recommended that the length of exposed part of any connection cable

should not be longer than 4 mm. Professional clamping tools may be used to avoid

unintentional contact of exposed wires to avoid short-circuit or communication failure.

5)It is recommended that card readers and buttons be installed at height of 1.4m-1.5m

above ground.

6)It is recommended to use the power supply for control panel, and external power

supply for each lock.

7)The appliance shall be installed and wired in accordance with national electrical

code and by qualified personnel only

Description of normal working state:

Connect the system to the power supply. If the system works properly, the POWER

indicator (red) is lit constantly and the RUN indicator (green) flashes.

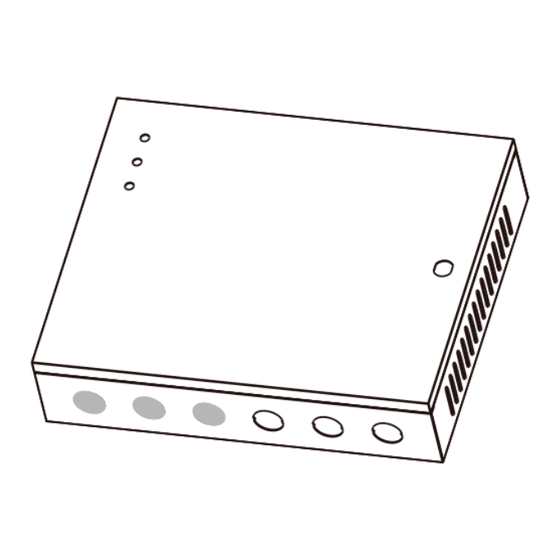

2.Components

State Indicator

Box Lock Hole

Heat

Dissipation Hole

Thread Hole

Panel Box Appearance

Version: 1.3 Date: Nov., 2015

Valve regulated lead-acid battery:

Constant voltage charge voltage regulation

Cycle use : 14.5V~14.9V(25)

Initial current: less than 2.88A

Standby use: 13.6V~13.8V(25)

Capacity: 12V, 7.2Ah/20hr

Battery Type: LC-RA127R2T1

Caution:

Do not charge in a gas tight container.

Do not short the battery terminals.

Do not incinerate

Flush with water at once if contact is made with

electrolyte (Acid)

Do not attempt to disassemble the battery.

Backup Battery

Control Panel

Temper Switch

Air Switch

Panel Track

Power Supply

Get the Panel off the track

Panel Box Insaid

3.Installation

After the following installation, fix the panel to the track first, and then install other components .

Thread holes

1) Get through the thread hole

4.LED Indicators and Wire Illustration

1) Meaning of LED indicators:

LINK indicator (green): Constant light always indicates TCP/IP communication is normal.

ACT indicator (yellow): Flashing indicates data is transmitting through TCP/IP communication.

EXT RS485 indicator (yellow&green): Flashing indicates it is sending or receiving data through RS485 communication.

PC RS485 indicator (yellow&green): Flashing indicates it is sending or receiving data through RS485 communication.

POWER indicator (red): Light always indicates the control panel is power on.

RUN indicator (green): Flashing indicates that system is working normally.

CARD indicator (yellow): Flashing indicates a card is punched on reader.

2) Recommended use of wires:

Interface

Power (A)

Wiegand (B)

Control Panel

Electric Lock (C)

1

Button (D)

EXT485 (E)

2

3) The auxiliary input may be connected to infrared body detectors, alarm switches, etc.

4 The auxiliary output may be connected to door bells, alarms, etc.

)

5) State Indicators are connected to the panel box, that is power indicator, run status indicator and communication status indicator.

1

Screws

2) Fix the box

Wire Specification

Network cable

Maximum length

18AWG*2PIN

/

1.5M

24AWG*6PIN

CAT-5 or above network cable, one

(6PIN, 8PIN, 10PIN for different

way DC impedance is less than 100Ω

100M

readers)

/KM

18AWG*2PIN+24AWG*2PIN,

18AWG*2PIN for lock connection,

/

50M

24AWG*2PIN

for

door

sensor

connection.

24AWG*2PIN

/

100M

CAT-5 or above network cable, one

20AWG*2PIN+24AWG*2PIN,

Share power with control panel: 100M

way DC impedance less than 100 Ω

20AWG*2PIN

for

reader

power

Use

independence

/KM. In wire connection, +12V and

supply, 24AWG*2PIN for RS485

(connect RS485 signal interface only):

GND of power supply need to be

communication

1000M

parallel and use double wires.

Control Panel

1

Panel Track

2

3) Install other components

power

supply

2

Advertisement

Summary of Contents for ZKTeco InBio160

- Page 1 3.Installation InBio160 Installation and Connection Guide After the following installation, fix the panel to the track first, and then install other components . Version: 1.3 Date: Nov., 2015 Screws Control Panel 1.Cautions Please note the following cautions. Mis-operation may lead to personal injury or...

- Page 2 5.DIP Switch Settings AUX Output 1 connect to alarm, door bell and so on; AUX Input 1 connect to the infrared human 1) Switches1-6 are used to set the control panel number in RS485 communication: It is adopted binary coding and Port (NO, COM, NC) Electrical Parameters: body induction, wireless exit button, windows MAX Voltage: 36V(DC)

- Page 3 8.Equipment Communication Insert a screw driver to the rectangular hole in the four corner of the panel back, push it in until hearing the “click” sound. Then remove the case from the panel. The following is “ we t m ode” lock connection with external power supply. The PC software can communicate with the panel according to the communication protocols (RS485 and TCP/IP) for data exchange and remote management.

Need help?

Do you have a question about the InBio160 and is the answer not in the manual?

Questions and answers