Table of Contents

Advertisement

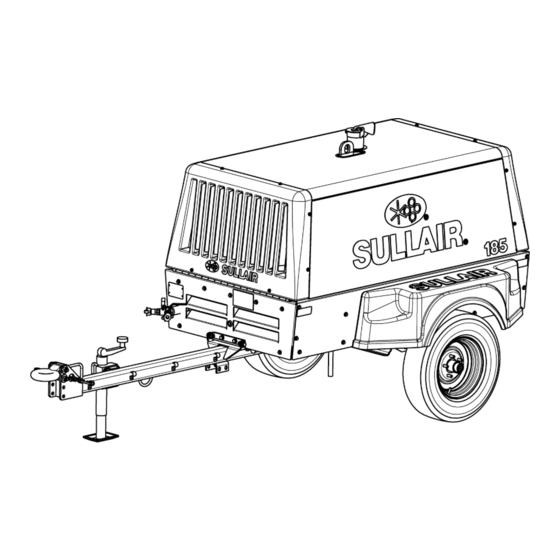

Portable Air Compressor

SAFETY WARNING

Users are required to read the

entire User Manual before han-

dling or using the product.

USER MANUAL

185

Tier 3

Kubota

WARRANTY NOTICE

Failure to follow the instructions

and procedures in this manual,

or misuse of this equipment, will

void its warranty.

Subject to EAR, ECCN EAR99 and related export control restrictions.

PART NUMBER:

02250223-054 R01

The information in this manual is current as of its

publication date and applies to compressor models

indicated on this cover with serial number:

201605020000

and all subsequent serial numbers.

Publication date: 06/07/2016

Copyright © 2016 Sullair, LLC. All rights reserved.

Advertisement

Table of Contents

Summary of Contents for Sullair 185Tier 3 Kubota

- Page 1 Publication date: 06/07/2016 void its warranty. Copyright © 2016 Sullair, LLC. All rights reserved. Subject to EAR, ECCN EAR99 and related export control restrictions.

- Page 2 Air Care Seminar Training Sullair Air Care Seminars are courses that provide hands-on instruction for the proper operation, maintenance, and servicing of Sullair products. Individual seminars on Portable compressors are offered at regular intervals throughout the year at Sullair’s training facility located in Michigan City, Indiana.

- Page 3 Symbols and references................11 Section 2: Description....................15 Introduction....................15 Description of components ............... 15 Sullair compressor air end, functional description ........15 Compressor cooling & lubrication system, functional description..... 15 Compressor discharge system, functional description ......17 Capacity control system, functional description........19 Piping and instrumentation—compressor system ........

- Page 4 Table of Contents 185 T3 Kubota User Manual Section 3: Specifications..................29 Specifications—185 Tier 3 Kubota............29 Lubrication guide—compressor ..............30 Lubrication guide—engine ................ 30 Application guide..................31 Identification—DPQ .................. 32 Identification—DLQ...................34 Section 4: Operation ....................37 General ..................... 37 Purpose of controls ...................37 Starting the compressor................38 Shutting down the compressor ..............

-

Page 5: Section 1: Safety

1.1 General protective clothing, protective shields and barriers Sullair designs and manufactures all of its products so they and electrical protective equipment, as well as noise can be operated safely. However, the responsibility for safe... -

Page 6: Fire And Explosion

1: Safety 185 T3 Kubota User Manual E. Provide an appropriate flow-limiting valve for each cap completely. Remove radiator filler cap only when additional 75 feet (23 m) of hose in runs of air hose cool enough to touch with a bare hand. exceeding 1/2″... -

Page 7: Moving Parts

185 T3 Kubota User Manual 1: Safety uids or fluid film within the material. DO NOT use P. DO NOT attempt to use ether as a starting aid in gas- flammable solvents for cleaning purposes. oline engines or diesel engines with glow plugs as serious personnel injury or property damage may E. -

Page 8: Hot Surfaces, Sharp Edges And Sharp Corners

1: Safety 185 T3 Kubota User Manual C. Wear snug-fitting clothing and confine long hair when Standards 29 CFR 1920 and any other Federal, State working around this compressor, especially when or Local codes or regulations. exposed to hot or moving parts. D. -

Page 9: Electrical Shock

185 T3 Kubota User Manual 1: Safety pound to air line anti-icer systems. Keep openings of B. Inspect lifting bail and points of attachment for valve or atomizer tube of ether starting aid system cracked welds and for cracked, bent, corroded or pointed away from yourself and other personnel. -

Page 10: Jump Starting

1: Safety 185 T3 Kubota User Manual trical or other energy source, would cause personal injury 8. Release stored energy and bring the equip- or equipment damage. The power source on any ment to a “zero mechanical state”. machine shall be locked out by each employee doing the 9. - Page 11 185 T3 Kubota User Manual 1: Safety D. Remove all vent caps (if so equipped) from the bat- ing vehicle is provided with two (2) 12V batteries con- tery or batteries in the compressor. DO NOT permit nected in series, connect the jumper cable to the dirt or foreign matter to enter the open cells.

-

Page 12: Towing

1: Safety 185 T3 Kubota User Manual each chain to itself by passing the grab hook over 1.13 Towing (not through) a link. Cross chains under the front of drawbar before passing them through points of 1.13.1 Preparing to tow attachment on towing vehicle to support the front of drawbar in case it should accidentally become uncoupled. -

Page 13: Towing

185 T3 Kubota User Manual 1: Safety H. On two-wheeled models, fully retract front screw jack 1.13.2 Towing and any rear stabilizer legs. If a caster wheel is pro- A. Observe all Federal, State, and Local laws while tow- vided on the screw jack it is part of the screw jack, ing this equipment (including those specifying mini- and can not be removed. - Page 14 1: Safety 185 T3 Kubota User Manual C. Park or locate compressor so the wind, if any, tends CAUTION to carry the exhaust fumes and radiator heat away from the compressor air inlet openings, and also where the compressor will not be exposed to exces- Retract the front screw jack only after attaching sive dust from the work site.

-

Page 15: Symbols And References

185 T3 Kubota User Manual 1: Safety 1.14 Symbols and references The symbols below may or may not be used. Please refer to the decals set forth on the machine for applicable sym- bols. DIESEL FUEL HEARING PROTECTION ROTARY COMPRESSOR HARD HAT TEST RUN DRAIN... - Page 16 1: Safety 185 T3 Kubota User Manual ENGINE START DANGEROUS OUTLET ENGINE ECM REMOTELY CONTROLLED READ/WRITE DATA CORROSIVE INTAKE AIR EXHAUST GAS WARNING FAN GUARD DO NOT MAINTENANCE BELT GUARD BELOW TEMPERATURE DO NOT TOW SERVICE POINT BAR/PSI LOW TEMPERATURE BATTERY STD AIR BATTERY DISCONNECT...

- Page 17 185 T3 Kubota User Manual 1: Safety RADIATOR HOUR METER COMPRESSOR AIR AIR-CIRCULATING PRESSURE START AIR-COOLED OIL COOLER CONTROL LIQUID-COOLED OIL COOLER ENGINE PREHEAT LOW TEMP AID LUBRICATION ENGINE WARNING TRAILER TOWING MODE FUEL LEVEL AXEL ENGINE RPM LUBRICANT GREASE ENGINE OIL EXAMINE, CHECK PRESSURE...

- Page 18 1: Safety 185 T3 Kubota User Manual DO NOT OPERATE WATER DRAIN WHILE STACKED PRESSURIZED SPRING SEVER (FAN) DO NOT MIX FLUIDS DEF FLUID ONLY AUTO START/STOP FLUID DRAIN LOW FUEL HEST: HIGH EMISSIONS DPF: DIESEL SYSTEM TEMPERATURE PARTICULATE FILTER EMISSIONS DPF REGEN.

-

Page 19: Section 2: Description

(pulse-free) compression to meet 2.1 Introduction various demand loads. Sullair compressors require no The Sullair 185 T3 Kubota standard portable air com- routine maintenance or inspection of their internal parts pressor offers superior performance, reliability and or systems. The compressor works by injecting fluid into require a minimal amount of maintenance. - Page 20 2: Description 185 T3 Kubota User Manual 1. Compressor unit 8. Radiator/fluid cooler assembly 2. Battery 9. Pressure regulator & blowdown manifold 3. Fluid fill 10. Service valves 4. Fluid level sight glass 11. Fuel tank 5. Receiver tank 12. Compressor air filter 6.

-

Page 21: Compressor Discharge System, Functional Description

The fluid flows through the fluid filter and on to the Refer to Figure 2-3 on page 18. The Sullair compressor compressor unit bypassing the cooler. As the compressor unit discharges a compressed air/fluid mixture into the continues to operate, the temperature of the fluid rises receiver tank. - Page 22 2: Description 185 T3 Kubota User Manual pressed air collects on the surface of the separator ele- conditions. Keeping this pressure level stable is neces- ment as the compressed air flows through the separator. sary for proper air/fluid separation and proper fluid circu- As more fluid collects on the element surface, it then lation.

-

Page 23: Capacity Control System, Functional Description

185 T3 Kubota User Manual 2: Description above 80 psig (5.6 bar). At this time, the inlet valve 2.6 Capacity control system, remains fully open for maximum air output. The engine functional description will continue to run at full speed during this phase of Refer to Figure 2-3 or Figure 2-4. -

Page 24: Piping And Instrumentation—Compressor System

2.7 Piping and instrumentation—compressor system 02250223-875 R00 (sh1) - Page 25 2.7 Piping and instrumentation—compressor system Key Description FILTER, AIR GAUGE, FILTER RESTRICTION (OPTONAL) INLET VALVE COMPRESSOR GAUGE, TEMPERATURE SWITCH, TEMPERATURE VALVE, RELIEF RECEIVER, AIR/OIL GLASS, SIGHT OIL LEVEL VALVE, MINIMUM PRESSURE/CHECK VALVE, BALL CYLINDER, SPEED ORIFICE VALVE, BLOWDOWN N.C. STRAINER VALVE, THERMAL BYPASS COOLER, OIL FILTER, OIL...

-

Page 26: Piping And Instrumentation—Engine System

2.8 Piping and instrumentation—engine system 02250223-875 R00 (sh2) - Page 27 2.8 Piping and instrumentation—engine system Key Description MUFFLER, ENGINE FUEL LEVEL SENDER (OPTIONAL) RAIN CAP, EXHAUST SYSTEM FUEL FILTER W/ WATER SEPARATOR FUEL TRANSFER PUMP FILTER, FUEL GAUGE, FUEL LEVEL (OPTIONAL) FUEL TANK CAP W/VENT THERMOSTAT, THERMOCORD (OPTIONAL) OIL PUMP (INTEGRAL TO ENGINE) BY-PASS VALVE (INTERNAL TO ENGINE) COOLER, OIL (INTERNAL TO ENGINE) FILTER, OIL...

-

Page 28: Air Inlet System, Functional Description

2: Description 185 T3 Kubota User Manual • The hourmeter indicates the accumulated 2.9 Air inlet system, functional hours of operation. description • The cold weather starting aid glow plugs should The air inlet system consists of two air filters, a compres- be used for starting in cold weather. - Page 29 185 T3 Kubota User Manual 2: Description 1. Hourmeter 7. Engine voltage (optional) 2. System air pressure 8. Engine RPM (optional) 3. START/STOP switch 9. Fuel level (optional) 4. Warm-up control 10. Engine coolant temperature (optional) 5. Cold weather starting (glow plugs) 11.

-

Page 30: Wiring Diagram

2.11 Wiring diagram 02250221-582 R02... -

Page 31: Electrical System, Functional Description

185 T3 Kubota User Manual 2: Description the event of a shutdown condition, the SSAM will shut 2.12 Electrical system, functional down the compressor and display (flashing) the appropri- description ate code on the instrument panel annunciator light. The The electrical system consists of the basic electrical ele- display will continue flashing until the ignition switch is ments required to operate the compressor and also has a turned OFF. - Page 32 2: Description 185 T3 Kubota User Manual Notes: 02250223-054 R01 Subject to EAR, ECCN EAR99 and related export control restrictions.

-

Page 33: Section 3: Specifications

185 T3 Kubota User Manual 3: Specifications Section 3 Specifications 3.1 Specifications—185 Tier 3 Kubota Table 3-1: Package specifications Table 3-2: Compressor specifications Model series Model series 49HP 185 Type Rotary screw Package 2175 2020 Working weight Actual delivery 1937 1883 psig Dry weight... -

Page 34: Lubrication Guide—Compressor

Kubota ® 1 Sullair AWF 1500 -20 to 120 -29 to 49 Model V2403 Sullair AWF part numbers: 250030-757 (5 gallons/18.9 liters) and 250030-758 (55 gallon/208 liter drum) U.S. EPA Tier 3 Emissions level European Stage IIIA 3.3 Lubrication guide—engine... -

Page 35: Application Guide

(for example, the ambient temperature is outside the recommended temperature range for Sul- lair AWF). Sullair encourages users to participate in a fluid analysis program. The analysis might indicate a need for change intervals different from those recommended in this man- ual (for example, to maximize the life of the machine in dirty environments). -

Page 36: Identification—Dpq

3.5 Identification—DPQ 02250220-829 R01... - Page 37 3.5 Identification—DPQ Drawing notes DIMENSIONS ARE IN INCHES. [ ] DIMENSIONS ARE IN MILLIMETERS. REFERENCE: A STANDARD CONTAINER SIZE IS 92" WIDE X 94" TALL X 232" LONG. REFERENCE: ONE COMPRESSOR CAN FIT IN A STANDARD CONTAINER. ALL DIMENSIONS ARE +/- .50" [12.7mm] ENGINE COOLANT DRAIN ENGINE OIL DRAIN COMPRESSOR OIL DRAIN...

-

Page 38: Identification—Dlq

3.6 Identification—DLQ 02250224-297 R01... - Page 39 3.6 Identification—DLQ Drawing notes DIMENSIONS ARE IN INCHES. [ ] DIMENSIONS ARE IN MILLIMETERS. REFERENCE: A STANDARD CONTAINER SIZE IS 92" WIDE X 94" TALL X 232" LONG. ALL DIMENSIONS ARE +/- .50" [12.7mm] ENGINE COOLANT DRAIN ENGINE OIL DRAIN COMPRESSOR OIL DRAIN LIFTING BAIL EYE (APPROX.

- Page 40 3: Specifications 185 T3 Kubota User Manual Notes: 02250223-054 R01 Subject to EAR, ECCN EAR99 and related export control restrictions.

-

Page 41: Section 4: Operation

Compressor discharge temperature switch Opens the electrical circuit to shut down the compressor While Sullair has built into this compressor a complete when the discharge temperature reaches a specific value set of controls and indicators that allow the operator to (see Table 3-2: Compressor specifications on page 29). -

Page 42: Starting The Compressor

4: Operation 185 T3 Kubota User Manual 6. Crack open one service line. 4.3 Starting the compressor 7. Turn the WARM-UP CONTROL control to the START position. WARNING 8. Toggle the START/ON/OFF switch to the ON position. Do not us aerosol types of starting aids such as 9. -

Page 43: Section 5: Maintenance

5.2 Engine coolant requirement for radiators NOTE The coolant provided with Sullair portable air compres- sors is ethylene glycol based, 50/50 mixture, and should Dispose of fluids in accordance with applicable never be mixed with a different coolant type, color or federal, state and local regulations. -

Page 44: Maintenance Every 50 Hours

• Clean the radiator and cooler exterior surfaces. • Check the Engine Operator’s Manual for ser- 5.8 Maintenance every 1500 hours vice requirements. • Change the compressor fluid with new Sullair ® and replace the fluid filter element. (See Section 5.9.1: Compressor fluid change proce- 5.7 Maintenance every 250 hours... -

Page 45: Compressor Fluid Filter Element Replacement

185 T3 Kubota User Manual 5: Maintenance 5.9.2 Compressor fluid filter element 5.9.3 Air filter maintenance replacement 1. Filter body 2. Filter cover 3. Primary element 1. Fluid filter 4. Safety element (optional) 2. Compressor unit Replacement primary element P/N: 02250102-158 3. -

Page 46: Separator Element Replacement

5: Maintenance 185 T3 Kubota User Manual strainer and orifice, and the blowdown valve; and all are 5.9.3.2 Element inspection in satisfactory condition, the separator element must be 1. Insert a bright light source into the element replaced with kit number 250034-112 (element for air/ and look for any light leaks which indicate fluid separator). -

Page 47: Setting Speed And Pressure Controls On Portable Compressors Equipped With Poppet Valves

This information is provided in Section 3: Specifications or can be obtained Figure 5-4: Fuel/water separator by contacting a Sullair representative. The following procedure applies to a compressor with full-load pressure rating of 100 psig (6.9 bar). -

Page 48: Bearing Lubrication

5: Maintenance 185 T3 Kubota User Manual 3. Adjust the pressure regulator so that the engine speed and control response. Close compressor maintains 115 psig (8 bar). the service valve and allow the compressor to cycle and re-check low engine speed 4. - Page 49 185 T3 Kubota User Manual 5: Maintenance 1. Rubber plug 5. Metal end cap 2. Outer bearing 6. Inner bearing 3. Grease flow 7. Spring-loaded double lip seal 4. Grease fitting Figure 5-6: Typical E-Z lube axle 10924 or a high temperature one such as lithium complex 2.

-

Page 50: Troubleshooting

If the troubleshooting remedy does not work, or the mal- prevent additional damage or abnormal operation. function is not covered in this troubleshooting chart, con- tact your nearest Sullair representative or Sullair for technical assistance. Table 5-1: Troubleshooting guide—engine stops, does not crank, or cranks but does not start... - Page 51 185 T3 Kubota User Manual 5: Maintenance Table 5-1: Troubleshooting guide—engine stops, does not crank, or cranks but does not start Symptom Probable cause Remedy Check wiring connection to the switch and tighten if necessary Engine coolant temperature switch is open Check switch continuity to ground and replace if necessary Clean cooler and check for proper ven-...

- Page 52 5: Maintenance 185 T3 Kubota User Manual Table 5-1: Troubleshooting guide—engine stops, does not crank, or cranks but does not start Symptom Probable cause Remedy For compressors with idle warm-up Run/start switch not in run position controls, switch toggle to RUN for full operation Check service lines for leaks or open Air demand is excessive...

-

Page 53: Section 6: Noise Control

6.1 Noise emissions warranty mate purchaser or while it is in use. Sullair warrants to the ultimate purchaser and each sub- 2. The use of the compressor after such device sequent purchaser that this air compressor was... -

Page 54: Noise Emissions Maintenance And Maintenance Record Log

6: Noise Control 185 T3 Kubota User Manual 6.3 Noise emissions maintenance and maintenance record log The following instructions and maintenance record log book, for the proper maintenance, use and repair of this com- pressor, is intended to prevent noise emission degradation. Table 6-1: Annual muffler and exhaust system inspection At least annually inspect muffler(s) and engine exhaust system to make sure all parts are securely mounted, that all joints and connections are tight, and that the muffler is in good condition. - Page 55 185 T3 Kubota User Manual 6: Noise Control Table 6-3: Annual engine vibration mount inspection At least annually inspect engine vibration mounts for security of attachment and to make sure the resilient parts are intact. Do not operate compressor with defective engine mounting system. Remove and replace defective parts by ordering with part numbers indicated in Parts List.

- Page 56 6: Noise Control 185 T3 Kubota User Manual Table 6-5: Annual acoustical materials inspection At least annually inspect all acoustical materials, if any, for security of attachment. Make sure that there is not any material missing or damaged (refer to Parts List). Clean or replace, if necessary. Do not operate compressor with defective acoustical material.

- Page 57 Subject to EAR, ECCN EAR99 and related export control restrictions.

- Page 58 Sullair, LLC 3700 East Michigan Boulevard Michigan City, IN 46360 USA www.sullair.com 1-219-879-5451 (non-USA) Information and specifications are subject to change without prior notice. Subject to EAR, ECCN EAR99 and related export control restrictions.

Need help?

Do you have a question about the 185Tier 3 Kubota and is the answer not in the manual?

Questions and answers