Subscribe to Our Youtube Channel

Summary of Contents for Proceq canin+

-

Page 1: Operating Instructions

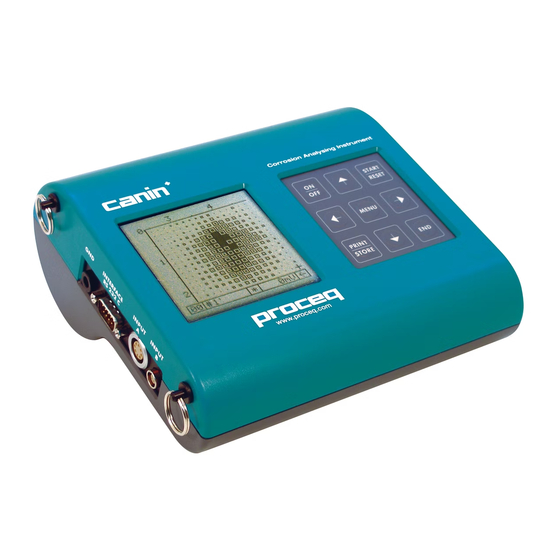

canin Operating Instructions Corrosion Analyzing Instrument ... more than 50 years of know-how you can measure! Made in Switzerland... -

Page 2: Table Of Contents

Table of Contents Safety and Liability General Information Liability Safety Instructions Symbols used in the operating instructions Correct Usage Tutorial The Half-Cell Potential Measurement Principle Factors affecting the Potential Measurement Application Limits of the Potential Measurement Technique The Electrical Resistivity Measurement Principle Influence of Rebars on Electrical Resisitivity Measurements Effect of Electrical Resistivity on Half-cell Potential Measurements Getting Started... - Page 3 General Settings Backlight Navigating around the menus Selecting the operating mode Configuring the instrument for potential measurement (See Fig 5.1) Configuring the instrument for electrical resisitivity measurement (See Fig 5.2) CANIN ProVista Software Installing CANIN ProVista Starting CANIN ProVista Downloading and Saving Data Renaming Files Opening and Editing Files Configuration...

-

Page 4: Safety And Liability

Accessories should only be installed or connected to the instrument if they are expressly autho- rized by Proceq. If other accessories are installed or connected to the instrument then Proceq will accept no liability and the product guarantee is forfeit. -

Page 5: Tutorial

R = 10 MΩ) to the steel reinforcement and is moved in a grid over the concrete surface. The reference electrode of the Canin system is a Cu/CuSO half-cell. It consists of a copper rod immersed in a saturated copper sulphate solution, which maintains a constant, known potential. © 2012 by Proceq SA... -

Page 6: Factors Affecting The Potential Measurement

Without checking the actual corrosion state this may lead to misinterpretation of the potential data. The air permeability of the concrete may be tested with Proceq’s Torrent instrument. Application Limits of the Potential Measurement Technique The potential field measurement even with a coarse grid delivers good results for chloride induced corrosion. -

Page 7: The Electrical Resistivity Measurement Principle

In this case the measuring grid must be made finer, in order to be able to locate an anode with a very steep gradient. However, the more potentials may be misinterpreted as passive areas when only considering the absolute value of the potential. © 2012 by Proceq SA... -

Page 8: Getting Started

Getting Started Note: First time user: Complete the tutorial OR see a demo by a qualified Proceq representative. Prepare the electrode(s) Rod Electrode - Before filling, remove the cap with the wooden plug and soak it in water for about an hour to allow the wood to saturate and swell. -

Page 9: Power On And Select The Correct Operating Mode

Meter. (See 5.3) Press MENU or END. Functional check of the equipment Perform a functional check of the equipment as described in sections 4.5 and 11. Congratulations! Your Canin is fully operational and you can now start your measurements. © 2012 by Proceq SA... -

Page 10: Real Tests - Potential Measurements

Remove the surface coating 4.8, 4.9 Pre-moisten the surface if required and carry out the measurement 4.10 Evaluate the data 4.11 Confirm and refine corrosion hotspot positions at openings in the concrete © 2012 by Proceq SA... -

Page 11: Planning And Preparation

1.50 m without any visual damage.) Here also stable values should be obtained, whereby the measured values in the damaged area should be significantly more negative than the values from the undamaged area. © 2012 by Proceq SA... -

Page 12: Preparation Of The Test Surface

In the case of the wheel electrode with its continual automatic measurement, it is not possible to monitor whether or not the measured value is stable. Therefore it is recommended to pre-moisten the surface section wise and to measure in intervals of a few minutes. © 2012 by Proceq SA... -

Page 13: Carrying Out The Measurement

6 – Indications (Switch between the two by pressing MENU whilst in the measuring screen): Indicator Probe type Indication Rod Electrode XY-grid Rod Electrode coarse grid Wheel Electrode Measurements will be automatically overwritten Wheel Electrode Measurements will not be overwritten © 2012 by Proceq SA... -

Page 14: Measuring With The Rod Electrode

This is useful for marking the position of cracks etc. When you have finished making all of the measurements you require on the concrete press the END button. The measured values are stored automatically. © 2012 by Proceq SA... -

Page 15: Measuring With The Wheel Electrode

To delete an existing reading, move the cursor to the point you wish to delete and press PRINT for two seconds. Once the reading has been deleted, the cursor will move to the next measuring point along the axis indicated by the direction arrow. © 2012 by Proceq SA... -

Page 16: Evaluation

Once these cursor lines have been set, the surfaces in this potential range will be automatically displayed in the corresponding colour in the CANIN ProVista “Chipping Plot”. In the example the red cursor line marks this threshold. A typical “Chipping Plot” taken from a practi- cal example is shown below. © 2012 by Proceq SA... -

Page 17: Confirmation And Refining Of Hotspot Positions

Prior to making the opening it is recommended to locate the exact posi- tion of the reinforcement bars by means of a rebar locator (e.g. Proceq’s Profometer, Profoscope). Moreover a fine measurement with the Rod Electrode using a small grid is recommended to deter- mine the actual “Hotspot”... - Page 18 Fig 5.1 Menu Overview for Potential Measuring © 2012 by Proceq SA...

- Page 19 Fig. 5.2 Menu Overview for Resistivity Measuring © 2012 by Proceq SA...

-

Page 20: Configuring The Instrument For Potential Measurement (See Fig 5.1)

Clear Memory erases all of the stored measurements for the active mode. It is not possible to delete single objects. Once this has been confirmed, it is not possible to undo the action. The objects for the other mode are unaffected. © 2012 by Proceq SA... -

Page 21: Configuring The Instrument For Electrical Resisitivity Measurement (See Fig 5.2)

ProVista on your PC. It will also create a desktop icon for launching the program. Starting CANIN ProVista Either click on the desktop icon or click on the CaninProVista entry in the “Start” menu. “Start – Programs – CaninProVista”. © 2012 by Proceq SA... -

Page 22: Downloading And Saving Data

210 x 50 pixels. From there it will automatically be copied into the graphs. The Proceq logo is unchange- able. Fig. 6.1: Canin ProVista Main Window There are four sections. The top contains labelling information including a user logo, the middle is the graphical representation of the measurement, the bottom contains additional numerical information regarding the measurement and the graph, and the right hand side contains the navigation pane. -

Page 23: Renaming Files

150x150mm or 305x305mm (1x1ft). The Canin display device accepts the unit length [mm] only. CANIN ProVista can convert and display the scale of length in ft. Fig. 6.3: Orientation selection window Fig. 6.4: Potential Map © 2012 by Proceq SA... -

Page 24: Configuration

Set imperial or metric units for the display with the drop down menu “Unit length”. • “Diagram Orientation” allows the origin of the graph to be changed. • Set the language of the program with the drop down menu. © 2012 by Proceq SA... -

Page 25: Insert File

A or B and finally the insertion direction is selected. Press “OK” to return to the updated potential map. Fig. 6.6: Insert Window Fig. 6.7: Potential Map before and after Insertion © 2012 by Proceq SA... -

Page 26: Edit

• “General View” resets the range of the potential map and chipping graph so that the entire graph is visible again. • “Undo” allows the last 10 edits and insertions to be undone. © 2012 by Proceq SA... -

Page 27: Relative Frequency

The range of the cumulative frequency graph can be changed by entering the desired minimum and maximum values in the respective fields on the x-axis. The limits are -1000 to +1000 mV. The class width can also be changed. © 2012 by Proceq SA... -

Page 28: Chipping Graph

(point, label and arrow) can be moved by left clicking on the annotation and drag- ging it around. If the Lock Name attribute is selected, the name will stay fixed and only the annotation point with the arrow can be moved. © 2012 by Proceq SA... -

Page 29: Measuring The Electrical Resistivity

The rebar grid beneath the surface should be marked out with the help of a rebar locator (e.g. Profometer, Profoscope). The desired measurement grid should be suitably marked out on the surface and mapped to objects. © 2012 by Proceq SA... -

Page 30: Reading The Display Screen

The position in the table where the measurement is stored must be selected manually on the screen (Fig 7.2). Use the ←→ buttons to select a letter from A to P. Use the ↑↓ buttons to select a number from 1 to 16. Fig 7.3 Table for resistivity measurements. © 2012 by Proceq SA... -

Page 31: Transfer Of Electrical Resisitivity Data To A Pc (Windows 2000 / Xp / Vista)

Go to “Settings” • Settings – Do not install a Modem Cancel with «No» – Enter “PROCEQ” and choose an Icon Confirm with «OK» – Select line “Connect using e.g. Com1” Confirm with «OK» – Change the default data to:... -

Page 32: Technical Specifications

Answer the question “Do you want to save the connection named PROCEQ ?” with “Yes”. Display and Processing the Data The text file “Data.txt” in the folder “C:\PROCEQ” can be displayed with any text editor or word processing program. For editing and further processing of the data we recommend MS Excel. -

Page 33: Technical Information Canin Provista Software

Combined Configuration with Rod and Wheel Electrodes and Wenner Probe Basic equipment (see item 330 00 201) Rod Electrode accessories (see item 330 00 201) Wheel Electrode accessories (see item 330 00 205) Wenner Probe accessories (see item 330 00 203) © 2012 by Proceq SA... -

Page 34: Accessories

Reference electrode with Rod Electrode 0 ± 5 mV Reference electrode with wheel electrode 0 + 20 mV If the electrode is out of tolerance, clean it as described below and redo the functional test. © 2012 by Proceq SA... -

Page 35: Maintenance Of The Rod Electrode

In the „actual“ window the reading (e.g. ρ = 12 ± 1 kΩcm.) appears. The value should be accord- • ing to the one mentioned on the test plate. If the value is outside of the tolerance, the instrument should be returned to Proceq for re-calibra- tion. 11.5... - Page 36 Zhao Jia Bang Road Shanghai 200032 Phone +86 21-63177479 +86 21 63175015 info-china@proceq.com www.proceq.com Subject to change without notice. Copyright © 2012by Proceq SA, Schwerzenbach Part number: 820 33 002E ver 04 2012 ... more than 50 years of know-how you can measure!

Need help?

Do you have a question about the canin+ and is the answer not in the manual?

Questions and answers