LulzBot mini User Manual

Hide thumbs

Also See for LulzBot mini:

- User manual (148 pages) ,

- Quick start manual (32 pages) ,

- Quick start manual (6 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for LulzBot LulzBot mini

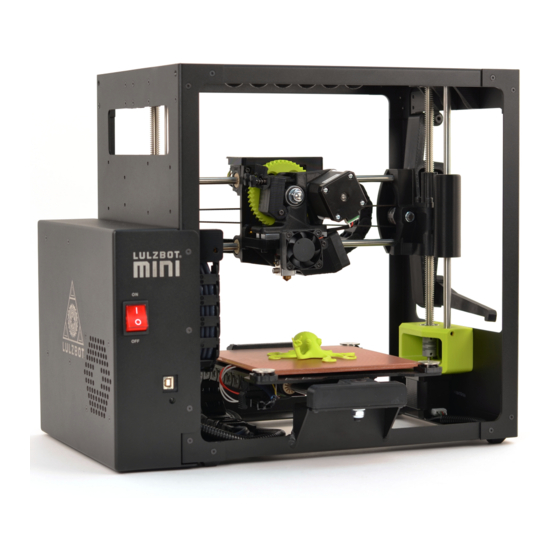

- Page 1 LulzBot Mini User Manual Aleph Objects, Inc.

- Page 2 Creative Commons Attribution 4.0 International Public License (CC BY-SA 4.0). Published by Aleph Objects, Inc., 626 West 66th Street, Loveland, Colorado, 80538 USA. For more information, call +1-970-377-1111 or go to LulzBot.com and AlephObjects.com. ISBN: 978-0-9893784-6-8 6.0-20161006...

-

Page 3: Table Of Contents

· · · · · · · · · · · · 1.4 CAD and 3D Modeling Software · · · · · · · · 1.5 Alternative Printer Host Software · · · · · · 2 Cura LulzBot Edition · ·... - Page 4 · · 6.1 LulzBot · · · · · · · · · · · · · · · · · 6.2 Support · · · · · · · · · · · · · · · · ·...

- Page 5 CONTENTS 8.2 Sales · · · · · · · · · · · · · · · · · · 8.3 Regional Phone Numbers · · · · · · · · · · · 8.4 Websites · · · · · · · · · · · · · · · · Index ·...

- Page 6 List of Figures 2.1 Quick Print Settings · · · · · · · · · · · · · · 2.2 Options after selecting model · · · · · · · · · · · 2.3 Rotating your Model · · · · · · · · · · · · · · 2.4 Scaling your Model ·...

-

Page 7: Warnings

WARNINGS Safety Information... -

Page 8: Hazards And Warnings

READ THIS MANUAL COMPLETELY BEFORE UNPACKING AND POWERING UP YOUR PRINTER. Hazards and Warnings Your LulzBot Mini 3D printer has motorized and heated parts. Always be aware of possible hazards when the printer is operational. Electric Shock Hazard Never open the electronics case when the printer is powered on. Before removing the electronics case cover, always power down the printer and completely turn off and unplug the printer. - Page 9 Modifications and Repairs Warning At Aleph Objects, Inc., we respect your freedom to modify your LulzBot desktop 3D printer. However any modifications or attempted repairs that cause damage are not covered under the Warranty. Questions? Contact Technical Support by emailing support@lulzbot.com, or by calling +1-...

-

Page 11: Regulatory Statements

Regulatory Statements... -

Page 12: Regulatory Compliance Statement Class B

Regulatory Statements Regulatory Compliance Statement Class B Federal Communications Commission Statement This device complies with part 15 class B of the FCC Rules. Operation is subject to the following two conditions: 1. This device may not cause harmful interference and 2. - Page 13 REGULATORY COMPLIANCE STATEMENT CLASS B Australian Communications and Media Authority Statement This device has been tested and found to comply with the limits for a Class B digital device, pursuant to the Australian/New Zealand standard AS/NZS CISPR 22:2009 + A1:2010. xiii...

-

Page 15: Printer Software

3D Printer Software... -

Page 16: Software Overview

We recommend that new users start with Cura LulzBot Edition as it includes a slicing engine as well. Slicers These programs take the 3D model (typically STL/OBJ/etc) and determine the 3D printer toolpath based on the options selected. -

Page 17: Installing Drivers

1.3 Installing Drivers GNU/Linux and OS X users will not need to install a driver to communicate with the LulzBot Mini 3D printer. Windows users will need to install the drivers. Using Cura LulzBot Edition as your printer host and slicing software is recommended, as the drivers will automatically be installed during the Cura installation process. -

Page 18: Alternative Printer Host Software

3D Printer Software OpenSCAD is different than FreeCAD in that it is script based. Rather than using a GUI to generate CAD designs, OpenSCAD CAD designs are created using script based renderings. Users with programming experience would find this useful. Also, OpenSCAD uses a simple script language that is easy for users with little or no programming experience to learn. - Page 19 Aleph Objects, Inc., the maker of the LulzBot Mini 3D printer, completely supports Free Software, Libre Innovation, and Open Source Hardware. Along with the LulzBot Mini 3D printer being a Free Software and Open Source Hardware design, it has been tested to work with 100% Free/Libre Software.

- Page 21 Cura LulzBot Edition...

-

Page 22: Cura Lulzbot Edition

Cura LulzBot Edition 2.1 Cura LulzBot Edition Installation and Setup Cura LulzBot Edition is available for download on our website at LulzBot.com/Cura. Uninstall any previous versions of Cura you may have been using when upgrading. Cura is designed for Fused Filament Fabrication (FFF) 3D printers. -

Page 23: Quick Print Settings

Different manufacturers have different formulations for their specific brand. These different formulations may have different ideal settings. We typically consume 6kg - 10kg of filament when developing these profile settings. highly recommend using the filament brands listed in Cura LulzBot Edition. - Page 24 Printing Support Material The LulzBot Mini 3D printer is able to print models that have angles and overhangs, even without support material depending on the overhang distance and angle. Turn this option on if sections of your model are extending in mid air.

- Page 25 2.2. QUICK PRINT SETTINGS Brim Brim is used to increase surface area of the part you’re printing, thereby ensuring proper part adhesion. This will print a single layer high edge around the base of the part, helping first layer adhesion and minimizing warping.

-

Page 26: Options After Selecting Model

Cura LulzBot Edition Figure 2.2: Options after selecting model Rotate The Rotate button will give you the ability to orient your model in along all three axes. Once you click the rotate button, three circles will surround your model. The red circle will allow you to rotate around the Z-axis. -

Page 27: Rotating Your Model

2.2. QUICK PRINT SETTINGS Figure 2.3: Rotating your Model Lay Flat The Lay Flat button will ensure that the flat portion of your print is securely attached to the bed. It is highly recommended to use this option after rotating your model in the Z direction, as it will help prevent potential adhesion issues during the print. -

Page 28: View Options

Cura LulzBot Edition of the scaling window. Figure 2.4: Scaling your Model 2.3 View Options Different modes allow you to view your model in a variety of ways. This can be helpful for spotting issues before the print even starts. -

Page 29: View In Normal Mode

2.3. VIEW OPTIONS Figure 2.5: View in Normal Mode Overhang Overhang mode shows where your model may need support material. In Fig. 2.6, page 29 the red highlighted areas show overhangs and more severe angles and areas where support material is recommended. The overhang threshold can be defined in Expert Settings. -

Page 30: View In Ghost

Cura LulzBot Edition Ghost Ghost view mode makes the model translucent to allow you to see what is behind it. Figure 2.7: View in Ghost Xray X-ray allows you to look inside of the object. This is helpful for detecting any manifold errors or other possible issues with your model. -

Page 31: View In Xray

2.3. VIEW OPTIONS Figure 2.8: View in Xray Layers To view the tool path of your print head and to ensure no skipped layers or gaps use this option. Use the slide bar on the right hand side of the window to move up and down through the tool path layers. -

Page 32: Starting Your First Print

Figure 2.11: Viewing An Individual Layer 2.4 Starting Your First Print Once you have your model, profile, and filament loaded, it is time for your first print! Refer to the Quick Start Guide included with your 3D printer. A PDF version is available at LulzBot.com/downloads. -

Page 33: Control Screen

2.4. STARTING YOUR FIRST PRINT Figure 2.12: Control Screen Pausing Mid-Print You will notice after you click the print button through Cura, it will change to a pause button. When activated, it will pause your print and automatically move your print head away from your object. This will allow color changes or material changes mid print. - Page 34 Recommended Temperatures Different filaments have different ideal temperatures for extrusion, bed ad- hesion, and part removal. Your LulzBot Mini will have these automatically set when using our recommended profiles. We have found that for certain materials a glue stick is required for successful bed adhesion and/or part release.

- Page 35 2.4. STARTING YOUR FIRST PRINT Filament Type Bed Preparation Hot End Temp Bed Temp Removal Temp Clean PEI 230-250 Clean PEI 195-215 HIPS Clean PEI 230-250 Laywoo-D3 Clean PEI 175-195 bambooFill Clean PEI 185-195 corkFill Clean PEI 185-195 woodFill Clean PEI 185-195 Linen Clean PEI...

-

Page 36: Removing Your First Print

TO MANUALLY LOAD ONE. As new filament is released for sale in the LulzBot store tested profiles will be available here: LulzBot.com/Cura. Download the profile that matches your filament and quality needs and load the file into Cura by selecting File > Open Profile. This will... -

Page 37: Transferring A Profile

2.6. FULL SETTINGS Figure 2.13: Transferring a Profile Once the switch has been made to full settings, you will now have access to a wide variety of options. You will notice 4 new tabs: Basic, Advanced, Plugins, Start/End-Gcode. In the following sections we will describe each option, and how they will affect your prints. -

Page 38: Basic Tab Options

Cura LulzBot Edition Figure 2.14: View in Full Settings 2.7 Basic Tab Options Layer Height The thickness of each printed layer is known as the “Layer Height”. The smaller the layer height, the smoother curves will appear. Larger layer heights are better for bridging and overhangs. Smaller layer heights will... -

Page 39: Differences In Layer Height

This defines the number of vertical walls that comprise the outside of your model. We recommend keeping this set to multiples of your nozzle width. Your LulzBot Mini 3D printer is equipped with a 0.5mm nozzle. A setting of 1.0mm or 1.5mm is a sufficient for most prints. - Page 40 Cura LulzBot Edition Fill Density This number is expressed as a percentage. 0% will give a completely hollow print, while 100% will give you a completely solid object. We have found that 20% to 40% fill density is functional for most prints.

-

Page 41: Support Types

2.7. BASIC TAB OPTIONS between 0 to 45 degrees. It is highly recommended to orient or design your object so that it minimizes or eliminates the need for support. Touching Buildplate This causes the support material to build up between the heated bed and the object. -

Page 42: Filament Diameter

Cura LulzBot Edition Brim Brim will create a single layer of filament, contacting and surrounding your model. This will increase the surface area of the part contacting the build platform thereby preventing it from popping off the heated bed. Brim will also help in situations where you are seeing corner lift. -

Page 43: Advanced Tab Options

2.8. ADVANCED TAB OPTIONS 2.8 Advanced Tab Options Figure 2.17: View of Advanced Tab Nozzle Size (mm) This defines your nozzle size. The slicing engine uses this value combined with your other settings to determine how quickly to feed filament into your hot end, and how to generate the tool path. - Page 44 All of our standard profiles have a 0.425mm initial layer height. This eliminates the need for adjustments when switching between filaments. Your LulzBot Mini automatic bed leveling system could be affected if you change this from the standard profiles. Adjust at your own risk.

-

Page 45: Cutoff Example

2.8. ADVANCED TAB OPTIONS cut your part in half for printing one object as two (or more) pieces. (Fig. 2.18, page 45) Figure 2.18: Cutoff Example Dual Extrusion Overlap This will determine how far your Dual Extruders will overlap when laying down material. - Page 46 Cura LulzBot Edition Bottom Layer Speed This will control your initial layer speed. In general, a slower initial layer speed will help with first layer adhesion. Infill Speed This is how fast your print head speed will be while laying down the interior portion of your model.

-

Page 47: Plugins

2.9. PLUGINS Enable Cooling Fan Enables operation of your extruder active cooling fan. The fan settings can be adjusted in the Expert Settings options. See section 2.14 on page 52 for details. In general, smaller parts will require more cooling for proper results. -

Page 48: Start And End Gcode Settings

A comprehensive list of Gcode commands can be found here: http://reprap.org/wiki/G-code We recommend new users to leave this as provided in the profiles at LulzBot.com/download Mini Specific Considerations Please be cautious when changing any of these start and end GCODE settings. -

Page 49: Expert Settings

2.11. EXPERT SETTINGS quickprint settings, you may need to adjust these temperatures for optimal probing. In the start GCODE section, there will be three separate temperatures you can adjust. What these GCODE lines do will be described in the green text to the right of the command. -

Page 50: Retraction

Cura LulzBot Edition Figure 2.20: View Expert Settings 2.12 Retraction Retraction pulls filament out of your nozzle when it is not extruding to prevent your print head from dripping on your object. This section is where you will control how your extruder retracts its filament. -

Page 51: Skirt

2.13. SKIRT Minimal Extrusion Before Retracting This will prevent a retraction move, if your extruder has input X mm of filament into the hot end. This is length of filament input into the hot end, not length extruded. Z Hop When Retracting This will raise your print head Xmm while retracting. -

Page 52: Cool

Cura LulzBot Edition 2.14 Cool This section will define how your extruder cooling fan will operate during the print. If your print speeds are slowed down due to minimal layer time, the fan will run between minimum and maximum speed based upon how much the layer is slowed down. -

Page 53: Black Magic

2.16. BLACK MAGIC line option will produce lines in along the Y-axis for support. The grid will provide stronger support than the line option, but will be harder to remove. Overhang Angle for Support This will determine where support material is generated. In general you will be able to print a model with 45 to 90 degree angles in relation to the bed without support. -

Page 54: Brim

Cura LulzBot Edition smoother surface. This setting is typically only used for artistic objects as they will be fragile. Only Follow Mesh Surface This will cause your print to follow the outside of your model, building it completely hollow with a single wall outer shell. This will also ignore the base layer, and the top layer. - Page 55 2.18. RAFT Line Spacing This will determine the spacing between “support” lines for the raft. A small spacing makes the support structures closer together improving strength of the raft, but uses more material. Base Thickness This defines the raft thickness. Base Line Width This will define how wide your “support”...

-

Page 56: Fix Horrible

Cura LulzBot Edition 2.19 Fix Horrible These are some of the more advanced and experimental options. They are designed to help repair models with errors to make them suitable for 3D printing. They do not always work. Please be cautious when using these options as they can have unintended effects on your print quality. - Page 57 2.20. 3D MODEL ATTRIBUTION Rocktopus.stl Rocktopus by Kent Johnson is licensed under CC BY-SA 4.0 and derived from work by dietz1 and yeoldebrian. LulzBot.com/rocktopus Support.stl Support Model by Aleph Objects, Inc is licensed under CC BY-SA 4.0 license. Overhang_test.stl Make: 2015 3D Printer Shoot Out Test Models by MAKE was used under the CC BY-SA license.

-

Page 59: Maintaining Your 3D Printer

Maintaining Your 3D Printer... -

Page 60: Overview

Maintaining Your 3D Printer 3.1 Overview Little maintenance is required keep your LulzBot Mini 3D printer running. Depending on your rate of use you will want to perform a quick check of your printer every 2 to 4 weeks. The following maintenance guidelines will keep your printer printing quality parts. -

Page 61: Belts

Replacement nozzle wiping pads are available in our online store at http://LulzBot.com. Do not attempt to use a plastic or polymer based wiping pad as it can melt, rather than clean the nozzle. -

Page 62: Cooling Fans

Maintaining Your 3D Printer calibration process the print surface or tool head may be damaged. Never attempt to clean the bed leveling washers during the probing sequence as it may lead to personal injury. 3.9 Cooling Fans Every 2-4 weeks carefully clean your hot end cooling fans by powering off the 3D printer and unplugging the tool head from the extruder harness. -

Page 63: Advanced Usage

Advanced Usage... -

Page 64: Intro

After you become familiar with printing using the default settings, a few advanced techniques may help in getting better and more consistent prints from the LulzBot Mini 3D printer. Some of these instructions are items and materials not included with the Mini. With any of these additional items or materials, follow safety and usage guidelines as instructed by the manufacturer. -

Page 65: Z Offset

Default Firmware. 4.4 Z Offset Your LulzBot Mini 3D printer has the ability to change the first layer height (Z offset) directly through Cura. In the lower right hand corner of the Control Window in Cura, enter the following commands. (The green text explains the command, do not enter it.) -

Page 66: Using 1.75Mm Filament

4.6 Using 1.75mm filament Your LulzBot Mini 3D printer is set up to use 3mm plastic filament by default and may be capable of printing 1.75mm filament with no hardware modification. -

Page 67: Hardware And Software Source Code

Hardware and Software Source Code... - Page 68 Hardware and Software Source Code The LulzBot Mini 3D printer is a Free Software and Open Source Hardware design. All of the source files are available at http://download.lulzbot.com/Mini including: • The latest version of this document, with L T E X source code.

-

Page 69: Printer Support

3D Printer Support... -

Page 70: Lulzbot

For common technical support questions for your LulzBot Mini 3D printer please visit LulzBot.com/support. Also, visit Forum.LulzBot.com for support and tips from the LulzBot 3D printer community. If you have fur- ther questions, e-mail our support team at Support@LulzBot.com. Please completely read this manual before contacting for support questions or help. -

Page 71: Warranty Information

Warranty Information... -

Page 72: Warranty

Warranty Information 7.1 Warranty Warranty information for your LulzBot Mini 3D printer can be found at https://www.lulzbot.com/support/warranty Extended Warranty Optional extended warranty terms are available for purchase at https://www.lulzbot.com/store/parts/lulzbot-mini-extended-warranty. 7.2 Modification Warning WARNING: At Aleph Objects, Inc., we respect your freedom to modify your LulzBot desktop 3D printer. -

Page 73: Contact Information

Contact Information... -

Page 74: Sales

• Netherlands (Amsterdam ) : +31-208004975 • Spain (Madrid ): +34-912901413 • Switzerland (Zurich ) : +41-445087565 • United States (Loveland): +1-970-377-1111 8.4 Websites Aleph Objects, Inc., makers of the LulzBot brand of 3D Printers: AlephObjects.com LulzBot 3D Printers and parts: LulzBot.com Forum.LulzBot.com... -

Page 75: Index

Base Line Width, 55 contact info, 74 Base Thickness, 55 Cooling, 52 Basic Options, 38 Cura, 22 bed adhesion, 66 Cura LulzBot Edition, 22, 68 bed plate, 68 Cura Plugins, 47 bed temperature, 40 Custom Gcode, 48 belts, 61 Cut Off Object, 44... - Page 76 INDEX damage, 72 g-code, 16 download, 16, 68 GCODE, 16 driver, 16 gcode, 68 Dual Extrusion Overlap, 45 Ghost View, 30 glass, 60, 61 glue stick, 66 electronics, viii, 62, 68 GNU/Linux, 16–18 Enabling Cooling Fan, 47 End Gcode, 48 hardware, 68 Expert Settings, 49 hazards, viii...

- Page 77 INDEX layers view, 31 Overhang Angle, 53 leveling, 61 Overhang View, 29 Line Count, 51 Line Spacing, 55 Pause at Z Height, 48 Load Model, 25 pause print, 33 load model, 25 pausing in the printing process, 33 lubricant, 60 PEI, 65 PEI surface, 60 maintenance, 60...

- Page 78 INDEX school glue, 66 Vase Mode, 53 SemiFlex, 65 View Options, 28 Shell Thickness, 39 Skirt, 51 warnings, viii slicers, 16 warping, 65 slicing, 16 warranty, 72 slicing profiles, 68 white glue, 66 smooth rods, 60 Windows, 16–18 software, 16, 18, 68 wiping pad, 61 Source Code, 68 wiping temperature, 48...

- Page 79 3D model data, through the deposition of a material in accumulative layers. ABS Acrylonitrile butadiene styrene thermoplastic. Usually extrudes at 230°C with the Budaschnozzle and 240°C - 250°C with the LulzBot Hexagon Hot End. Acetone A colorless, volatile, flammable liquid ketone, (CH3)2CO, used as a solvent for ABS.

- Page 80 Budaschnozzle and 230°C with the LulzBot Hexagon Hot End Hot end The hot end is the whole part where the plastic melts, including the nozzle, heater block, thermistor, and heat sink. The LulzBot Hexagon Hot End comes standard on the Mini.

- Page 81 Joynnyr of UltiMachine. Resolution In general terms, the resolution you print at can be determined by the layer height you use. The LulzBot Mini can print at a layer heights of 0.05mm to 0.50mm with the standard tool head.

-

Page 83: Glossary

Notes Use the following pages to record notes and any personal preferences or tweaks you make to your LulzBot 3D printer for future reference. - Page 84 This page is intentionally left blank...

- Page 85 This page is intentionally left blank...

- Page 86 This page is intentionally left blank...

- Page 87 NOTES...

- Page 89 Colophon Created with 100% Free/Libre Software GNU/Linux T E X Memoir...

Need help?

Do you have a question about the LulzBot mini and is the answer not in the manual?

Questions and answers