Summary of Contents for ESAB YardFeed 200

- Page 1 ESABFeed 30- 2 YardFeed 200 Origot M13y ESAB YardFeed 200 Service manual 0740 800 148 060619 Valid for serial no. 238- -xxx- -xxxx to 612- -xxx- -xxxx...

-

Page 2: Table Of Contents

......Spare parts for connection sets, YardFeed 200 ........ -

Page 3: Read This First

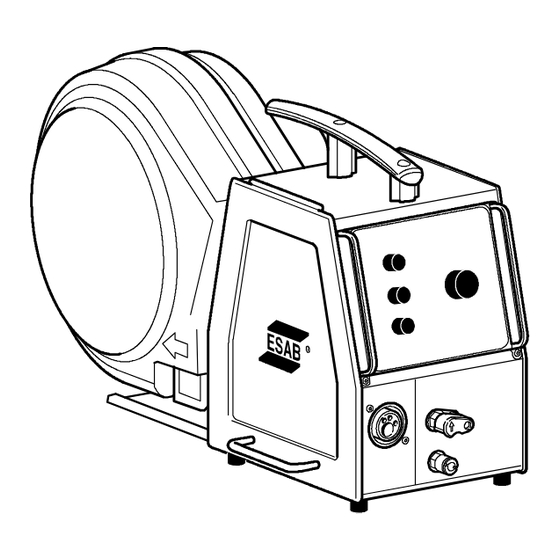

The wire feed unit YardFeed 200 with control panel M13y, is intended for MIG/MAG welding together with stepped and thyristor--controlled welding power sources. - Page 4 S0740 800 148/E060619/P30 - - 4 - - cwfu2de1...

-

Page 5: Technical Data

TECHNICAL DATA ESABFeed 30- -2 YardFeed 200 Power supply 42 V 50 -- 60 Hz 42 V 50 -- 60 Hz Power requirement 150 VA 150 VA Motor current I 3.5 A 3.5 A Settings data Wire feed speed 1.9 -- 20.0 m/min 1.9 -- 25.0 m/min... -

Page 6: Wiring Diagram

This component description refers to the wiring diagrams. In the description of operation on page 10 there is a more detailed description of the components and their function. Component Description ESAB YardFeed Feed M11 Main circuit board with control electronics. -

Page 7: Esabfeed 30- -2 M11

ESABFeed 30- -2 S0740 800 148/E060619/P30 - - 7 - - cwfu2de1... -

Page 8: Yardfeed 200

YardFeed 200 S0740 800 148/E060619/P30 - - 8 - - cwfu2de1... - Page 9 S0740 800 148/E060619/P30 - - 9 - - cwfu2de1...

-

Page 10: Description Of Operation

From serial no. 410--xxx--xxxx a new version of the control board (0487 162 880) is fitted to the ESABFeed 30--2 M11. The new and old versions of the control board are fully interchangeable. Control board 0487 162 881 is used for the YardFeed 200. 13AP1:1 Power supply ESABFeed 30- -2 M11 The feeder obtains a 42 V supply from the power source. -

Page 11: 13Ap1:2 2--Stroke / 4--Stroke

The power supply in the YardFeed 200 works as described on previous page with one exception: switch 13S2. See: ’Safety contact switch YardFeed 200’ on page 26. YardFeed 200 13AP1:2 2- - stroke / 4- - stroke 2- -stroke When the switch is open, the unit operates in 2--stroke mode. Operating the trigger on the welding gun starts the motor, opens the gas valve and energises the power source contactor. -

Page 12: 13Ap1:3 Start / Stop

13AP1:3 Start / Stop The welding gun switch is supplied with 42 V AC. Closing the switch activates optocoupler IC1, causing the voltage across C35 to go low. The new version of the control board, 0487 162 880 When wire feed starts, the power source generates welding voltage. If this is not followed by a flow of welding current within three seconds, the power source shuts down the welding power supply, although wire feed continues until the welding gun switch is released. -

Page 13: 13Ap1:5 Motor Driving / Braking

The first version of the control board, 0486 991 880 If the current relay does not operate within one second after starting, the motor speed increases to the set speed in any case. YardFeed 200 The creep start function is always activated. 13AP1:5... -

Page 14: 13Ap1:6 Tachometer Input

discharge capacitor C43 (15 V) to the gate of transistor Q3. The transistor conducts and short--circuits the motor voltage through resistors R51 and R64, which limit the current to about 20 A. 13AP1:6 Tachometer input Tachometer 13G1 is fitted in the motor casing. Comparator IC4/IC11:2 converts the sine wave signal from the tachometer to a square wave at the same frequency. -

Page 15: 13Ap1:9 Gas Valve

Gas purging, flushes gas without voltage or wire feed starting. Wire inching is used to feed wire without welding voltage being applied. The gas purge and inching functions are only used by the YardFeed 200. S0740 800 148/E060619/P30 - - 15 - -... -

Page 16: 13Ap1:12 Processor, Starting Sequence

13AP1:12 Processor, Starting sequence Processor The processor stores the machine program. It monitors the power supply voltages: if the voltages drop to too low a level, wire feed is stopped, as described in section 13AP1:1 above. Starting sequence, circuit board 0487 162 880 / 0487 162 881 The circuit board displays the starting sequence from power--up. -

Page 17: 13Ap1 Component Positions

13AP1 Component positions The new version of the control board, 0487 162 880 / 0487 162 881 S0740 800 148/E060619/P30 - - 17 - - cwfu2de1... - Page 18 The first version of the control board, 0486 991 880 S0740 800 148/E060619/P30 - - 18 - - cwfu2de1...

-

Page 19: 13Ap2 Digital Display

13AP2 Digital display The digital display unit is standard or can be ordered as an accessory to the YardFeed 200. The digital display unit can be used only when the wire feeder is connected to a Mig 400t, Mig 500t, ESABMig 400t, ESABMig 500t or a LAW power source. -

Page 20: 13Ap2 Circuit Diagram

13AP2 Circuit diagram S0740 800 148/E060619/P30 - - 20 - - cwfu2de1... -

Page 21: Service Instructions

Work surfaces, carts and containers must be conductive and grounded. Use only antistatic packaging materials. Overall, handling of ESD--sensitive devices should be minimized to prevent damage. Dismantling of YardFeed 200 S0740 800 148/E060619/P30 - - 21 - - cwfu2de1... -

Page 22: Spare Parts For Connection Sets, Esabfeed 30- -2 M11

Spare parts for connection sets, ESABFeed 30- -2 S0740 800 148/E060619/P30 - - 22 - - cwfu2se1... -

Page 23: Spare Parts For Connection Sets, Yardfeed 200

Spare parts for connection sets, YardFeed 200 S0740 800 148/E060619/P30 - - 23 - - cwfu2se1... -

Page 24: Instructions

Ordering number for the lifting eye can be found in the accessory/spare parts list. Note! If another mounting device is used, this should be insulated from the wire feed unit. Lifting instructions YardFeed 200 S0740 800 148/E060619/P30 - - 24 - -... -

Page 25: Operation

12 Connection for shielding gas welding gun NOTE! Cooling water connections only available on certain models. * ELP = ESAB Logic Pump, see “Water connection” on next page. Connections and control devices YardFeed 200 Connection for welding current from power... -

Page 26: Water Connection

Off position and the cooling unit switch must be in position “ELP/0”. The wire feed unit with water connection is equipped with a detection system ELP (ESAB Logic Pump), which checks that the water hoses are connected. When connecting a water--cooled welding gun, the water pump starts. -

Page 27: Maintenance

The spare parts list for the ESABFeed 30--2 is published in a separate document with filename 0459 206 990 The spare parts list for the YardFeed 200 is published in a separate document with filename 0459 839 005. S0740 800 148/E060619/P30... -

Page 28: Notes

NOTES S0740 800 148/E060619/P30 - - 28 - - notes... - Page 29 S0740 800 148/E060619/P30 - - 29 - - notes...

- Page 30 ESAB subsidiaries and representative offices Europe Asia/Pacific Representative offices NORWAY AS ESAB AUSTRIA BULGARIA CHINA Larvik ESAB Ges.m.b.H ESAB Representative Office Shanghai ESAB A/P Tel: +47 33 12 10 00 Vienna- -Liesing Sofia Shanghai Fax: +47 33 11 52 03...

Need help?

Do you have a question about the YardFeed 200 and is the answer not in the manual?

Questions and answers