Summary of Contents for Teknatool NOVA 3000

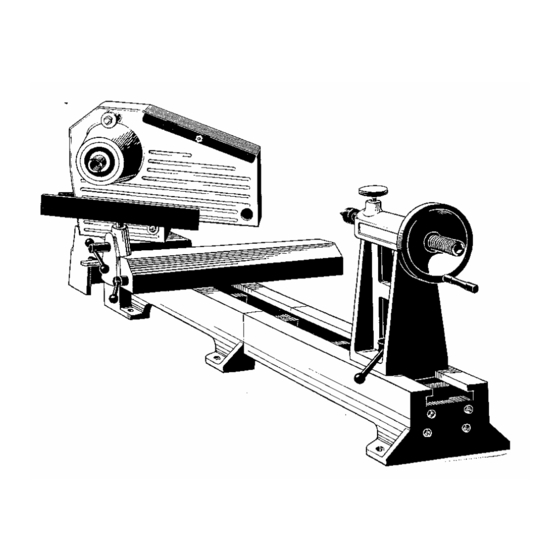

- Page 1 NOVA 3000 WOODLATHE Publication No. 92-0106-017 Last updated 14 October 2003...

- Page 2 The Nova 3000 lathe can be easily and quickly swivelled to any position (360 degrees). It can be solidly locked in any position plus it has the added security of a detent pin lock at 0,22.5,45,90 plus 315 (for left hand use).

- Page 3 Welcome Thank you for choosing our Nova 3000 Woodlathe and welcome to the Teknatool product family. Your choice shows you want the best for your woodturning and recognise the superior and unique features the Nova 3000 lathe offers. We strive to achieve the best value for your money - providing quality...

- Page 4 Phone: (+44) 114 225 0700 This is the list of Countries/Resellers that currently stock Fax: (+44) 114 225 0710 and sell the Nova 3000 Woodlathe. In addition, Email: sales@robert-sorby.co.uk Teknatool sells a more limited range into many other Website: www.robert-sorby.co.uk countries.

-

Page 5: Table Of Contents

Index..........................29 Warranty........................30 © Copyright 1999 by Teknatool International; All Rights Reserved. Nova 3000 is a registered trademark of Teknatool International and Latalex Ltd. The information and specifications contained herein are subject to change. Teknatool is not responsible for errors or omissions herein or for incidental damages in connection with the furnishing or use of this information. -

Page 6: General Safety Rules

GENERAL SAFETY RULES Warning! Failure to follow these rules may result in serious personal injury. FOR YOUR OWN SAFETY, READ THE 14. KEEP GUARDS IN PLACE and in working MANUAL BEFORE OPERATING THE TOOL. order. Learn the machine’s application and limitations 15. -

Page 7: Additional Safety Rules For Woodlathes

ADDITIONAL SAFETY RULES FOR WOODLATHES Warning! Failure to follow these rules may result in serious personal injury. DO NOT MODIFY OR USE LATHE FOR USES 15. USE CORRECT LATHE TOOLS. Do not use OTHER THAN FOR WHICH IT WAS spindle turning chisels for faceplace mounted work, and vice versa. -

Page 8: Nova 3000 Specifications

510 mm (20 in.) units with Spur Center, and Live Center add-on Bed sections. Nova 3000 Bowl Lathe Version: Swing Outboard: 740 mm (29 in.) with headstock Specifically for bowl turning, does not include bed at 90° with outrigger toolrest. -

Page 9: Setting Up Your Workshop

Lathe Stand Recommendations A sturdy and rigid stand is required so that the Nova 3000 Woodlathe can deliver optimum performance. A common flaw with many woodlathe installations is an inadequate stand for the lathe. The larger the size of your turnings, the greater the importance of the lathe stand design. -

Page 10: Motor Recommendations

Motor Recommendations The Nova 3000 can be purchased with or without a motor. In the USA, the 1HP AC Motor is included with the lathe, in accordance with the recommendations outlined below. However, in most markets, the motor is an optional extra. -

Page 11: Assembling The Nova 3000

Cover Screws Note: The Faceplate is not standard equipment in all countries. In some countries, a 1HP AC Motor is also supplied with the Nova 3000 Lathe as standard equipment. Check with your reseller if you are unsure. Remove the plastic shipping tubing from headstock base. - Page 12 Flange Mounted Motor For Flange Mounted Motor Only. Screw the motor mount plate to the motor using four flathead Allen screws Motor (M6x20 Metric or 3/8 x 1 for Flathead USA/Canada). If the motor has an Screws (4) integral on/off switch, make sure the motor is oriented for access to the Motor switch.

- Page 13 Installing the Motor and Guard Motor Screw Knob Pulley Belt Headstock Headstock Studs Motor Mount Plate Teebar Motor Mount Cam Nyloc Nut Headstock Guard Screws (5) 12. Fit the belt over both pulleys. Adjust the position of the motor pulley on the motor shaft so the belt is aligned square between the pulleys.

-

Page 14: Adding An Extension Bed

Adding an Extension Bed Each cast iron extension bed adds 510 mm (20 in.) to the lathe's capacity to mating surface turn between centers. Capscrew (2) Clean the joining ends of both bed sections with a petroleum-based solvent. Make sure there are no dents or burrs on either mating surface. -

Page 15: Mounting The Lathe To A Support Surface

Mounting the Lathe to a Support Surface Bolt tightening sequence 3r d Mounting Holes (6) The lathe must be fastened to a support surface, such as a lathe stand or bench. Maximum of 25 mm (1 in.) (Required only for mounting the Outrigger Unit option.) Place the lathe on the stand top. -

Page 16: Using The Nova 3000

Using the Nova 3000 Recommended Turning Speeds Work Diameter (inches) Warning! 12 14 16 18 Turn out of 3630 3000 balance work at 2900 2400 slowest speed. 2180 1800 1) Find work diameter. 1450 1200 2) Follow vertical line to mark. -

Page 17: Changing Speeds

Changing Speeds Change speeds by moving the belt position on the two 8-step pulleys. The speeds vary due to the rpm's of the motor. Speed position can be checked by viewing the belt through the window at the front of the headstock. -

Page 18: Spindle Index

Spindle Index The spindle index pin locks the headstock spindle. It is selectable in 15 degree increments (24 divisions). There is sight hole to read index Index pin shown numbers (0 through 23). in safe (operation) position 1. Stop the lathe. Index Knob 2. -

Page 19: Toolrest

Using a spur center Mark stock centers For softwoods - Mount the spur center to the work punch centers piece as shown and then insert the spur center and work piece into the headstock spindle. Warning! Do not pound work piece into headstock drive center when turning between centers or you may damage the headstock. -

Page 20: Tailstock

Tailstock Warning! Never loosen the tailstock quill or tailstock while the work piece is turning. To move the tailstock along the bed, loosen the Tailstock Clamp Handle, slide the tailstock to the desired position, and tighten the clamp handle. To move the tailstock quill in or out, loosen the Quill Lock and turn the Handwheel. -

Page 21: Maintaining The Nova 3000

Maintaining the Nova 3000 General Maintenance Interval Maintenance After each use Clean the work area and lathe. Vacuum scraps and dust from the inside the headstock, between the lathe bed rails, and under the toolslide and tailstock. Monthly Wax exposed cast iron parts with a good quality paste wax, especially the bed rails. -

Page 22: Cleaning The Tailstock

Note:Tailstock alignment can be made easier by using the Teknatool Acruline Accessory Center in place of the centers. 3. Move the tailstock close to the headstock so the two centers nearly touch;... -

Page 23: Troubleshooting Guide

Troubleshooting Guide Problem Possible Cause and Solution Excessive vibration. Out of balance, or large work piece. Reduce lathe speed to the lowest speed possible and turn the work piece to a true circle. Work piece is not held in the center. Check work piece mounting and correct. - Page 24 Troubleshooting Guide Problem Possible Cause and Solution Difficulty in Adding The alignment pins for the bed extension can be a very tight fit - to help Bed Extensions. ensure accurate bed/tailstock alignment. Try putting the pins in the freezer overnight, and heating up the bed segments with a hot air gun or dryer.

-

Page 25: Nova 3000 Woodlathe Parts List

Nova 3000 Woodlathe Parts List See the parts list on page 26. 92-0106-017... - Page 26 Nova 3000 Woodlathe Parts List Most items are applicable to all countries; items listed with an "Y" are applicable to United States and Canada; items listed with "Q" are applicable to New Zealand, Australia, UK, Europe, and South Africa. Item Part No.

-

Page 27: Accessories

Lathe Stand Strong, rigid, 4 mm thick sheet metal lathe stand, 86 cm (34 in.) high for the Nova 3000. The legs have an extra flange to allow you to insert a piece of plywood to create a boxed leg for filling with sand for even extra vibration dampening. - Page 28 For further details about Teknatool's lathe accessories please contact your local retailer for more information, or contact us for a free product catalogue. This catalogue can also be downloaded from our website - at www.teknatool.com.

-

Page 29: Index

Ornamental Turner, 28 Accessories, 27,28 Outrigger Unit, 28 Aligning the Tailstock, 22 Parts List, 25,26 Assembling, 11 Parts of the Nova 3000, 11, 16, 25, 26 Bed, Lathe, 14,27 Power, 15 Belt Tension, 17 Problems, 23 Bowl version, 8 Quill, 8, 16, 22... -

Page 30: Warranty

Teknatool Five Year Limited Warranty This Teknatool product is backed by a FIVE YEAR warranty from the date of purchase. Teknatool International Ltd will repair or replace, at its expense and option, this Teknatool product which in normal use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to an authorized Teknatool service center with proof of purchase of the product within TWO YEARS and provides Teknatool with reasonable opportunity to verify the alleged defect by inspection. - Page 31 Steps to registering your Warranty by Mail: 1. Fill out the information on page 30, duplicate your serial number here for your future reference: Serial Number:________________________ 2. Cut along the dotted line as indicated by the scissors icon. 3. Take the cut out, and fold along dotted line as shown. 4.

- Page 32 Nova 3000 Woodlathe Manual Publication Code: 92-0106-017 © Teknatool International 2003 92-0106-017...

Need help?

Do you have a question about the NOVA 3000 and is the answer not in the manual?

Questions and answers

How to change bearings on nova 3000 lathe

To change the bearings on a Teknatool Nova 3000 lathe:

1. Remove the handwheel: It has a left-handed thread. Turn it right to loosen (opposite of standard threads).

2. Remove the cover: Once the handwheel is off, remove the cover held by four screws.

3. Access the bearings: After removing the cover, the bearings can be accessed. The full bearing replacement process involves further disassembly not fully detailed in the available instructions.

Note: The official document for bearing replacement is generic and may not cover all steps specific to the Nova 3000.

This answer is automatically generated