Table of Contents

Advertisement

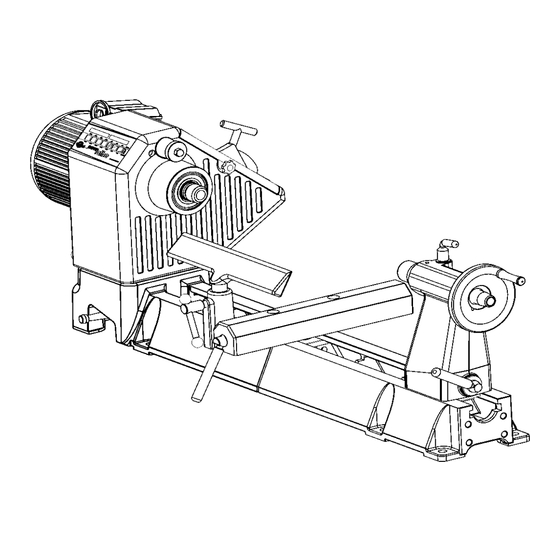

NOVA 1624 II

WOODLATHE

Smart Tools Powerful Solutions

Your new NOVA 1624 II Woodlathe comes with additional safety feature, and is fitted with an

emergency stop button on the motor.

This button is for "Emergencies" only. The machine will coast to a stop if this button is pushed in.

Important: Once this Emergency stop button is pushed, you must release into the "OUT" position before

you can use the lathe again. You must twist to release it into the OUT position before you can turn on

the lathe.

·

Use the regular STOP button if you want the lathe to come to a stop.

·

To turn the machine on and off, use the on/off switch on the motor.

www.teknatool.com

IMPORTANT Please Note:

TM

Publication No:111-0214-007

Advertisement

Table of Contents

Summary of Contents for Teknatool NOVA 1624 II

- Page 1 IMPORTANT Please Note: Your new NOVA 1624 II Woodlathe comes with additional safety feature, and is fitted with an emergency stop button on the motor. This button is for "Emergencies" only. The machine will coast to a stop if this button is pushed in.

- Page 2 Welcome Thank you for choosing our Nova 1624 II Woodlathe and welcome to the NOVA Product Family. Your choice shows that you want the best for your woodturning and recognise the superior and unique features that the Nova 162 II lathe offers.

- Page 3 Speed Range The Nova 1624 II lathe has an eight speed range, one of the very best available. From very low speeds for large and out of balance work through to very high speeds for small and finishing work. Some markets also have the added advantage of a variable speed motor option (check with your reseller).

- Page 4 Contact Teknatool New Zealand Teknatool International Ltd Phone: (+64) 9 477 5600 Email: service@teknatool.com Website: www.teknatool.com United States NOVA Customer Care & Innovation Center Phone: 727-954-3433 Email: service@teknatool.com Website: www.teknatool.com Or contact the Reseller where you purchased the NOVA 1624-44 Wood Lathe, see our website for their contact details in your country www.teknatool.com...

-

Page 5: Table Of Contents

Index ..........................31 Warranty .......................... 32 © Copyright 1999-2016 by Teknatool International; All Rights Reserved. Nova 1624 II is a registered trademark of Teknatool International. The information and specifications contained herein are subject to change. Teknatool is not responsible for errors or omissions herein or for incidental damages in connection with the furnishing or use of this information. -

Page 6: General Safety Rules

GENERAL SAFETY RULES FOR YOUR OWN SAFETY, READ THE 14. KEEP GUARDS IN PLACE and in working order. MANUAL BEFORE OPERATING THE TOOL. 15. USE RIGHT TOOL. Do not use a tool or attachment to Learn the machine’s application and limitations do a job for which it was not designed. -

Page 7: Additional Safety Rules For Woodlathes

ADDITIONAL SAFETY RULES FOR WOODLATHES Warning! Failure to follow these rules may result in serious personal injury. DO NOT MODIFY OR USE LATHE FOR USES 15. USE CORRECT LATHE TOOLS. Do not use OTHER THAN FOR WHICH IT WAS spindle turning chisels for faceplate mounted work, DESIGNED. -

Page 8: Nova 1624 Ii Specifications

Nova 1624 II Woodlathe Specifications Size: see drawing below. Standard Equipment: Weight: 72 kg (158.7 lb) (without motor) 300 mm (12 in.) Toolrest, Poly Vee Drive Belt, Motor Pulley, Motor Mounting Kit, 150 mm (6 in.) Faceplate (Not all Swing Over Bed: 400 mm (16 in.) countries, see notes below), Spur Center, and Live Center Distance Between Centers: 600 mm (24 in.);... -

Page 9: Setting Up Your Workshop

Lathe Stand Recommendations A sturdy and rigid stand is required so that the Nova 1624 II Woodlathe can deliver optimum performance. A common flaw with many woodlathe installations is an inadequate stand for the lathe. The larger the size of your turnings, the greater the importance of the lathe stand design. -

Page 10: Motor Recommendations

Example of Shop-made Lathe Stand 43 x 16 x 2 in. Upper Leg Brace (2) 1-1/2 x 3-1/2 x 13 in. Machine Bolt (12) Upper Rail (2) 1-1/2 x 3-1/2 x 33 in. plywood bottom (compartment for sand) Lower Rail (2) 1-1/2 x 7-1/2 x 33 in. -

Page 11: Assembling The Nova 1624 Ii

Clean any parts coated with rust preventative with a cloth moistened with a petroleum-based solvent or cleanser. Coat the lathe bed with paste wax. Nova 1624 II Components after Unpacking Screw the Headstock Lockpin into the Installing the Headstock Lockpin threaded hole at the bottom of the headstock. - Page 12 Remove the headstock guard from the lathe. Place the motor mount plate with attached motor over both the Headstock studs Tip: To ease holding the motor while fastening the guard hole (Motor cam end). You may engage the belt at 570 rpm. By engaging the belt at 570 rpm the weight of the motor is supported by the headstock pulley.

- Page 13 Installing the Motor and Guard Fit the belt over both pulleys. Adjust the position of the motor pulley on the motor shaft so the belt is aligned square between the pulleys. Tighten the M8 set screw on the motor pulley. Note: The drive belts correct positioning is with the belt overhanging the outside of the pulley by one rib.

-

Page 14: Adding An Extension Bed

If you are unsure of the use or the application of this accessory, contact the technical support department of Teknatool International or your reseller. Further information can also be found in your lathe manual. - Page 15 Check that the tailstock runs smoothly over the mating joint, and also over the full length of the extension. Although all components manufactured by Teknatool International are made to closest possible tolerances, it is possible for a difference of approximately 0.1mm to put the bed 'out of true'.

-

Page 16: Mounting The Lathe To A Support Surface

Mounting the Lathe to a Support Surface Bolt tightening sequence Mounting Holes (6) The lathe must be fastened to a support surface, such as a lathe stand or bench. Maximum of 25 mm (1 in.) (Required only for mounting the Place the lathe on the stand top. -

Page 17: Using The Nova 1624 Ii

Using the Nova 1624 II Recommended Turning Speeds Work Diameter (inches) Warning! 12 14 16 18 3000 3630 Turn out of balance work at 2900 2400 slowest speed. 2180 1800 1) Find work diameter. 1450 1200 2) Follow vertical line to mark. -

Page 18: Changing Speeds

Changing Speeds Change speeds by moving the belt position on the two 8-step pulleys. The speeds vary due to the rpm's of the motor. Speed position can be checked by viewing the belt through the window at the front of the headstock. -

Page 19: Swiveling The Headstock

Swiveling the Headstock 1. Stop the lathe. Insert the operating bar into a hole in the Headstock Lockpin. Loosen the Lockpin half a turn. 1. Slide the Headstock Release Handle towards Inboard end of lathe, and rotate the headstock to a detent position. Do not push down on the handle. -

Page 20: Headstock

Headstock The headstock houses the motor pulley, headstock pulley, bearings, and the spindle. The headstock spindle accepts centers and accessories with no. 2 Morse taper (#2 MT), plus threaded faceplates and chucks. Spindle Thread Size Country Threads 1-1/4 x 8 TPI RH United States, Canada, UK Europe M33 x 3.5 RH... -

Page 21: Toolrest

Toolrest To move the toolslide along the bed, loosen the Toolslide Clamp Handle, move the slide to the desired position, and tighten the clamp handle. To adjust the toolrest, loosen the Toolrest Clamp Handle, position the toolrest, and tighten the clamp handle. Adjust the toolrest close to the work piece. -

Page 22: Tailstock

Tailstock Warning! Never loosen the tailstock quill or tailstock while the work piece is turning. To move the tailstock along the bed, loosen the Tailstock Clamp Handle, slide the tailstock to the desired position, and tighten the clamp handle. To move the tailstock quill in or out, loosen the Quill Lock and turn the Handwheel. -

Page 23: Maintaining The Nova 1624 Ii

Maintaining the Nova 1624 II General Maintenance Interval Maintenance After each use Clean the work area and lathe. Vacuum scraps and dust from the inside the headstock, between the lathe bed rails, and under the toolslide and tailstock. Monthly Wax exposed cast iron parts with a good quality paste wax, especially the bed rails. -

Page 24: Cleaning The Tailstock

Note: Tailstock alignment can be made easier by using the Teknatool Acruline Accessory Center in place of the centers. 3. Move the tailstock close to the headstock so the two centers nearly touch;... -

Page 25: Troubleshooting Guide

Troubleshooting Guide Problem Possible Cause and Solution Excessive vibration. Out of balance, or large work piece. Reduce lathe speed to the lowest speed possible and turn the work piece to a true circle. Work piece is not held in the center. Check work piece mounting and correct. - Page 26 Troubleshooting Guide Problem Possible Cause and Solution Tailstock and Tailstock not aligned to headstock; adjust as described under "Aligning headstock center not the Tailstock". lining up correctly. Bed incorrectly bolted to stand causing twist. Ensure stand and lathe are correctly installed. Headstock not returned to detent position after it has been rotated.

-

Page 27: Nova 1624 Ii Woodlathe Parts List

Nova 1624 II Woodlathe Parts List See the parts list on page 26. 111-0516-008... - Page 28 Nova 1624 II Woodlathe Parts List Most items are applicable to all countries; items listed with a "4" are applicable to Europe. Item Part No. Description Item Part No. Description Circlip External 30mm Bed Extension - Machined 38 (4) EC30...

-

Page 29: Accessories

Accessories Add On Bed Extension Extend the bed of your Nova 1624 II Woodlathe for greater capacity for turning between centers. Each bed unit adds 516 mm (20.3 in.) Lathe Cast Iron Stand The stand pieces are cast from a high grade of... - Page 30 For further details about the NOVA lathe accessories please contact your local retailer for more information, or contact us for a free product catalogue. This catalogue can also be downloaded from our website - at www.teknatool.com. 111-0516-008...

-

Page 31: Index

Tailstock parts list, 28 Handwheel, 30 Tailstock, 8, 17, 22,24 Headstock Lockpin, 11, 17, 18 Teebar, 13,17, 18 Headstock, 8, 17, 20 Teknatool, 4 Lathe Stand Requirements, 9,16 Toolrest Options, 29 Live Center, 22 Toolrest Parts List, 28 Lubrication, 23... -

Page 32: Warranty

Teknatool Five Year Limited Warranty This Teknatool product is backed by a FIVE YEAR warranty from the date of purchase. Teknatool International Ltd will repair or replace, at its expense and option, this Teknatool product which in normal use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to an authorized Teknatool service center with proof of purchase of the product within TWO YEARS and provides Teknatool with reasonable opportunity to verify the alleged defect by inspection. - Page 33 111-0516-008...

- Page 34 Nova 1624 II Woodlathe Manual Publication Code: 111-0516-008 © Teknatool International 2016 111-0516-008...

Need help?

Do you have a question about the NOVA 1624 II and is the answer not in the manual?

Questions and answers