Table of Contents

Advertisement

Quick Links

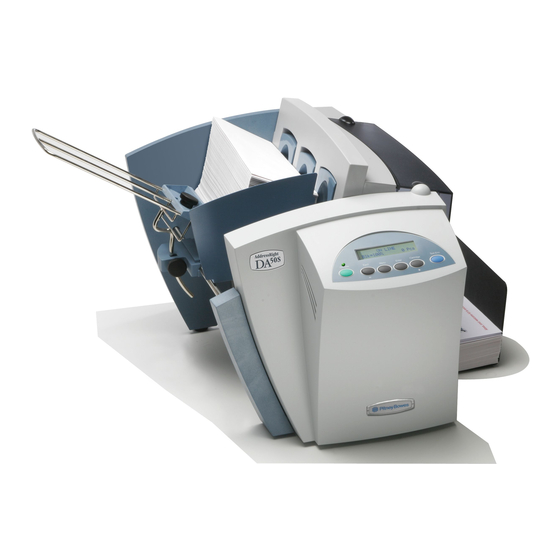

DA / SA Series AddressRight Printers

Frequently Asked Questions (FAQs)

This document/data record is the property of Pitney Bowes Inc. and contains PROPRIETARY and CONFIDENTIAL

information, and is not to be reproduced or distributed to any third parties without the express written authorization of

Pitney Bowes, Inc. Any authorized reproduction of this document/data record or of information taken from it shall

display this notice.

Shuttle Head Models:

DA30S/DA50S/DA55S/DA70S/DA75S

SA3000/SA3100/SA3150/SA3300/SA3500

Fixed Head Models:

DA80F/DA95F

SA5000/SA5300

Date: December 8, 2010

Advertisement

Table of Contents

Summary of Contents for Pitney Bowes DA Series

- Page 1 This document/data record is the property of Pitney Bowes Inc. and contains PROPRIETARY and CONFIDENTIAL information, and is not to be reproduced or distributed to any third parties without the express written authorization of Pitney Bowes, Inc. Any authorized reproduction of this document/data record or of information taken from it shall display this notice.

-

Page 2: Table Of Contents

Table of Contents Customer ..............................4 General ............................. 4 Display Panel ..........................10 Control Panel............................10 Why are the majority of the Control Panel software tabs and options grayed out? (Both) .... 10 How do I best track my ink consumption? (Both) ................. 10 What is the status of the Bundle Break and Tray Break mode features? (Shuttle)...... - Page 3 Installation hangs on Preparing to Install screen with a “1603 Error installing Microsoft .NET Framework” message. (Both)........................25 Error List .............................. 25 Standard Errors ..........................25 Internal Errors ..........................26 Fixed Head Power-Up Errors......................27 Process Maps ............................27 Adjusting Feed Gap (Fixed)......................27 Sensor Operation Check.........................

-

Page 4: Customer

1. Customer 1.1 General 1.1.1 What are the documents available for the customer? (Both) SV62381 DA30S/DA50S/DA55S Operator Guide SV61665 DA70S/DA75S Operator Guide SV61722 DA80F Operator Guide SV61749 DA95F Operator Guide SV62442 SA3000/SA3100/SA3150 Operator Guide SV61665 SA3300/SA3350 Operator Guide SV61723 SA5000 Operator Guide SV61750 SA5300... - Page 5 Press Menu to move up a level (for example, to move from a setting to a menu option or from a menu option to –OFF LINE--). Fixed Head Models Press - or + to scroll through the menu options. Press Enter to select the desired menu option or a submenu option. Press - or + to scroll through the submenus within a menu option or the settings within a menu/submenu option.

- Page 6 1.1.7 What is Envelope Designer Plus? (Both) The Pitney Bowes Envelope Designer Plus (available in the US only), is an easy-to-use program that helps to create professional-looking envelope layouts quickly. With Envelope Designer Plus, you can create and position a mailing address, return address, single or multi-line messages, barcode, and graphics.

- Page 7 Options and Tabs displayed may differ depending on which printer drivers are installed. 1.1.9 Why doesn't my printer respond when I turn ON the power? (Both) Possible causes of non-response are: Power switch is OFF on printer. Check that the power cord is securely connected to the wall outlet and the printer. ...

- Page 8 1.1.14 Why, after moving the printer to another USB port (same PC), does the printer not print? (Both) Unlike other USB devices, unplugging the printer USB cable and plugging it in to another USB port on the same PC may create a new print device in the Windows Printers folder and another USB port number. Depending on the software configuration and/or default printer selection, this may cause the printer to stop printing.

- Page 9 Select create a new form and fill in the material definitions. When done, press OK. This will make it available to the printer as a material type. 1.1.19 Are there any daily maintenance actions I should take? (Both) After any large run or before each shift of operation the paper path and sensors should be cleaned or blown out.

-

Page 10: Display Panel

1.1.22 Why is there a line drawn after my ZIP Code in my address? (Both) You are probably using the ~123 after the ZIP Code to create the POSTNET™ barcode. If these additional characters are underlined, the underline is printed even if the characters are not printed. The solution is to not underline any character as part of any Tilde ‘~xxx’... -

Page 11: Why Can't I Connect Via The Control Panel Software When Normal Printing Works? (Both)

2.5 Why can’t I connect via the Control Panel software when normal printing works? (Both) When the USB option is selected and OK is clicked in the Control Panel Connect dialog, the Connection Failed dialog (see below) is displayed. Communication (via USB) to the Control Panel software requires the proper installation of the XML CP_TO_PRTR driver. -

Page 12: Why Does My Printer Multi-Feed Media? (Both)

D. Lower only the H-Blocks that come in direct contact with the material and let them touch the material. E. Lock each separator in place. When lowering the H-Blocks, check that the material is between the separator tabs and the feed roller. 3.1.3 Clean feed rollers and or remove paper dust (yellow or white residue) which could block feed sensor ... -

Page 13: What Media Size Does Microsoft Add Printer Wizard Print Test Page Require? (Both)

compressed air are available from many computer supply houses. The separator gap may not be set properly. Adjust the separators to the thickness of the mail piece. A. Loosen the lock knobs to unlock all three H-Blocks. B. Lift the H-Blocks to their highest position and lock in place. C. -

Page 14: Can I Print A Permit Or Other Graphic On Windowed Envelopes? (Both)

(stuffed or empty) is welcome to do so. However we reserve the right to inform the customer that Pitney Bowes is not responsible for the overall performance of the printer on such a job. -

Page 15: Error Correction (Both)

4.1.4 I am running short material (less than 7.5") and am getting multiple errors on each piece when nothing seems wrong. (Fixed) The system requires a lead edge to lead edge minimum distance of eight (8) inches. Increasing the Feed for this material to provide at least an 8"... - Page 16 4.4 WF81 4.4.1 When running material 1/8" or thicker such as brown kraft booklets print shift and roller abrasion are seen on the bottom of the material. The H blocks are probably set too tight. The proper set up for very thick material is to use one normal piece and at least one or more additional envelopes (no more than 1/4 the thickness of a piece) on top of the piece when setting up the H blocks for normal running.

-

Page 17: Shuttle Head

4.5.4 How do I do a vertical alignment between heads 3 and 4? Head 3 is in Module A and head 4 is in Module B. In order to do a vertical alignment between then, print the alignment verification pattern and manually adjust the heads until the knit line is satisfactory. 4.5.5 Can I use a legacy feeder on the WF96 or a new feeder on a DA950/SA50? No, either type of mismatch will cause destruction of boards in either the feeder or the printer. - Page 18 5.1.2.7 Maintenance Station The wipers and the caps in the maintenance station could accumulate ink after extended usage. Use water to dampen a soft cloth and remove the ink from the caps and the wipers with the machine powered down, the capping sled pushed to the back, and the print head moved out.

- Page 19 5.1.5 Why are multiple copies of the same document being printed? When the printer has a jam, it will reprint any pieces it thinks are involved in the jam. If the PC thinks it lost communications to the printer, it may restart the entire job. This is normal printer and print spooler behavior for all Windows-based printers.

- Page 20 Slow network connection … Try printing to another printer on the same network. If printing was not successful, the network may be causing the problems (have customer contact their IT department for further diagnostics). Bad memory in printer … Turn printer OFF and ON. If problem persists, it could be a hardware problem.

- Page 21 5.1.11 What does the Clear Memory button do that is found on the Status tab of the Control Panel software? The Clear Memory button ONLY clears the stored address recovery memory in the printer (it does the same thing as the Clear Memory option in 5. Address Recovery in the Main Menu on the printer LCD). 5.1.12 During power up, the printer hangs at the 'Printer Starting Please Wait…' message.

-

Page 22: Drivers

5.1.20 Why does any print with a colored background not print correctly? The color on color capability in windows applications is based on a complex layering scheme and rules. Imbedding any portion of these in the printer causes problems with color print on a blank background to occur. -

Page 23: Address Recovery

memory, and then print it (overlay) the logo on the envelope with your print job that may contain addresses only. You can access this feature via either the LCD control panel (Main Menu > 8. Image Overlay), or the Control Panel software (Job Control Tab > Job and Overlay Options). Accessing the feature from the Control Panel software provides you more options (see the software Help for more information). -

Page 24: Service Actions

5.5.2 Firmware download displays progress bar dialog, but the process hangs and never shuts down the printer. The print driver data port is configured incorrectly for the printer. For example, this would happen if you were trying to download the firmware via USB communications when in fact you have set up a TCP/IP mode of data communications with the printer via Ethernet. -

Page 25: Installation

7. Installation 7.1 Installation hangs on Preparing to Install screen with a “1603 Error installing Microsoft .NET Framework” message. (Both) .NET Hot Fix is installed and the installation program can't install .NET v1.1 SP1 with .NET Hot Fix on the computer. Microsoft workaround is to uninstall the Hot Fix and then run our XCAL installation that will install the .NET v1.1 SP1 then reinstall the .NET Hot Fix. -

Page 26: Internal Errors

PAPER TRANS ERR #1 Adjust feeder and clean sensors PAPER TRANS ERR #2 Adjust feeder and clean sensors PAPER TRANS ERR #3 Adjust feeder and clean sensors PAPER TRANS ERR #4 Adjust feeder and clean sensors PAPER TRANS ERR #5 Adjust feeder and clean sensors PAPER TRANS ERR #6 Adjust feeder and clean sensors... -

Page 27: Fixed Head Power-Up Errors

8040 Internal IP Comm IO Socket Connect Error 8044 Internal IP Comm IO Socket Write Error 8048 Internal IP Comm IO Socket Read Error 8052 Internal Buffer Manager Logic Error 8056 Internal FIFO push error in the push media of Media Object Collection 8060 Internal Get Next Error in the push media of Media Object Collection 8064... -

Page 28: Sensor Operation Check

2. Use + key to scroll down to 8. Feed Gap and press the Enter key. 3. Press the Enter key again to go into the A. Feed Gap Type submenu. 4. Use + key to scroll down to Selectable Gap and press the Enter key. Make sure the * symbol appears in front of the Selectable Gap. -

Page 29: Clear Communications Buffer

9.4 Clear Communications Buffer 1. Take printer OFF LINE by pressing On Line until green power LED goes off. 2. Enter Setup Menu by holding down the Menu key until the Setup Menu shows up. 3. Press the + key four times to go to the Communications menu. 4. -

Page 30: Set Purge On First Piece (Fixed)

9.7 Set Purge on First Piece (Fixed) 1. With printer OFF LINE, enter the Setup Menu by pressing and holding the MENU key. 2. Use – key to scroll to 10. Pre-Purge menu and press the Enter key. 3. Press the Enter key again to enter A. Purge at Start submenu. 4. -

Page 31: Setup Stacker/Conveyor (Fixed)

3. Press the Enter key again to go into the A. Feeder type submenu. 4. Use the + key to select Other and press the Enter key to confirm the selection. Make sure the * symbol appears in front of the selection. 5. -

Page 32: Address Recovery

For Conveyors: 6. Use the + key to select Conveyor as Conveyor type and press the Enter key to confirm the selection. Make sure the * symbol appears in front of the selection. 7. Press the Menu key to go back up one level and use + key to scroll down to C. Activate Polarity, press the Enter key. -

Page 33: Send .Prn File To Printer

Select the target printer driver from the Install Printer Drivers listbox. Click Remove. Click Yes to the Are You Sure prompt. Click OK to close the Printer Server Properties dialog. 5. Reboot the PC. 9.14 Send .PRN File to Printer Send .PRN file to printer as follows: 1. -

Page 34: Glossary

3. Check Break1 Enable. 4. Select Location – stop before break piece is printed (Before Address) or stop after break piece is printed (After Address). 5. Set Break Characters. Enter exact break string that will appear as characters in print stream. Table 1 –... - Page 35 Address Counter ADDRESS LAYOUT ADDRESS RECOVERY The process of reprinting specific addresses damaged by jams or printing problems. Bar Width Width of the bar in a postal barcode. BARCODE Generic for any scan-able symbology. BARCODE LOCATION Location option of Above, Below, Lower Right for POSTNET™ barcode in USPS lexicon.

- Page 36 Get Addr (batch) Get Addr (inter) Hex Dump IMAGE OVERLAY INK CARTRIDGE The milliliters (ml) of ink contained in the cartridge when full. VOLUME Ink Count The amount of ink (drops) printed from the cartridge since new. INVERTED PRINTING Inverting the entire image to be printed on the piece. IP Address Part of the network setup when using ethernet communications.

- Page 37 STOP WHEN EMPTY Stream Feeding Subnet Mask Super Draft (150) A print quality selection. Symbol Set aka ISO CHARACTER SET. TCP/IP aka Ethernet. Communications option. Transport Speed TRAY BREAK USE CONVEYOR VERT ADJ: HDS X-Y Warning Threshold Page 37 of 37...