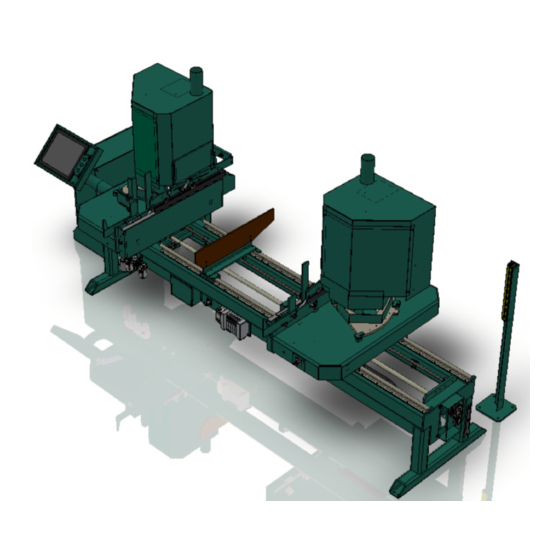

Kval 979-2 Manuals

Manuals and User Guides for Kval 979-2. We have 6 Kval 979-2 manuals available for free PDF download: Operation And Service Manual, Operation Manual, System Reference Manual, Service Manual, Manual

Kval 979-2 Operation Manual (108 pages)

Miter Trim Saw System

Brand: Kval

|

Category: Industrial Equipment

|

Size: 20 MB

Table of Contents

Advertisement

Advertisement

Advertisement