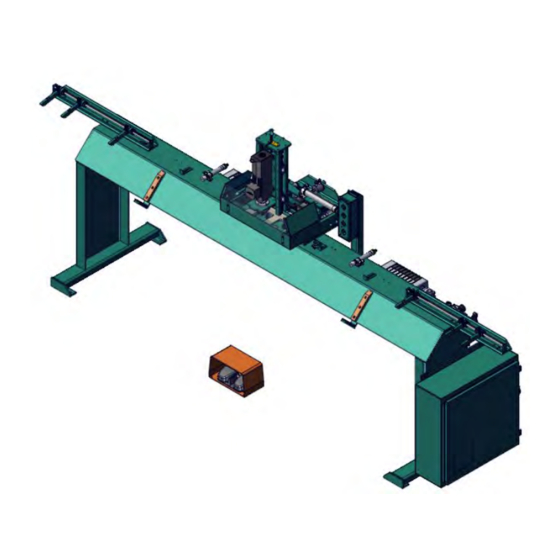

Kval 960-3 Manuals

Manuals and User Guides for Kval 960-3. We have 2 Kval 960-3 manuals available for free PDF download: Operation And Service Manual

Kval 960-3 Operation And Service Manual (68 pages)

Strike Jamb Router

Brand: Kval

|

Category: Industrial Equipment

|

Size: 2 MB

Table of Contents

Advertisement

Kval 960-3 Operation And Service Manual (68 pages)

Strike Jamb Router With Shifting Cutter Head

Brand: Kval

|

Category: Industrial Equipment

|

Size: 1 MB

Table of Contents

Advertisement