kval 990-H Manuals

Manuals and User Guides for kval 990-H. We have 4 kval 990-H manuals available for free PDF download: Service Manual, Operation Manual

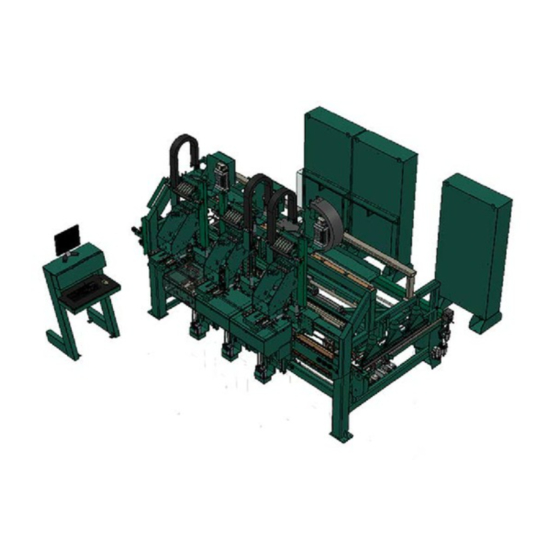

Kval 990-H Service Manual (104 pages)

Pre-Hanging Door System

Brand: Kval

|

Category: Industrial Equipment

|

Size: 4 MB

Table of Contents

Advertisement

Kval 990-H Operation Manual (88 pages)

Pre-Hanging Door System

Brand: Kval

|

Category: Industrial Equipment

|

Size: 5 MB

Table of Contents

Kval 990-H Operation Manual (80 pages)

Pre-Hanging Door System

Brand: Kval

|

Category: Industrial Equipment

|

Size: 6 MB

Table of Contents

Advertisement

Advertisement