Fronius TWIN Push Tandem Welding System Manuals

Manuals and User Guides for Fronius TWIN Push Tandem Welding System. We have 2 Fronius TWIN Push Tandem Welding System manuals available for free PDF download: Operating Instructions Manual

Fronius TWIN Push Operating Instructions Manual (180 pages)

Brand: Fronius

|

Category: Welding System

|

Size: 21 MB

Table of Contents

-

-

General8

-

EMC Measures13

-

EMF Measures14

-

Disposal18

-

Data Backup18

-

Copyright18

-

-

General21

-

Requirements22

-

-

-

-

-

-

-

-

Commissioning151

-

-

Troubleshooting157

-

Safety157

-

-

-

-

Technical Data

165-

TWIN Wirefeeder167

-

WF 30I R /TWIN167

-

-

Torch Hosepack171

-

-

HP 70I173

-

-

Advertisement

Fronius TWIN Push Operating Instructions Manual (160 pages)

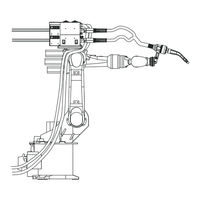

TPS/i Robotics welding system

Brand: Fronius

|

Category: Welding System

|

Size: 24 MB

Table of Contents

-

General7

-

EMC Measures12

-

EMF Measures13

-

Disposal16

-

Data Backup17

-

Copyright17

-

General21

-

Requirements22

-

Intended Use33

-

General39

-

Crashbox40

-

General40

-

Safety42

-

Stick out48

-

TWIN Mode49

-

General50

-

Symbols52

-

Safety67

-

Safety71

-

Safety77

-

General98

-

Commissioning102

-

Requirements102

-

Safety105

-

General133

-

Commissioning136

-

Requirements136

-

Troubleshooting139

-

Safety139

-

General144

-

Safety144

-

Monthly144

-

Every 6 Months145

-

Disposal145

-

Technical Data147

-

TWIN Wirefeeder149

-

WF 30I R /TWIN149

-

MTB 2X500I R150

-

Torch Hosepack154

-

HP 70I156

-

Crashbox /I XXL157

Advertisement