MakerBot Replicator 2X User Manual

Experimental 3d printer

Hide thumbs

Also See for Replicator 2X:

- User manual (116 pages) ,

- Troubleshooting and maintenance (40 pages) ,

- Replacement manual (5 pages)

Table of Contents

Advertisement

Quick Links

Download this manual

See also:

User Manual

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for MakerBot Replicator 2X

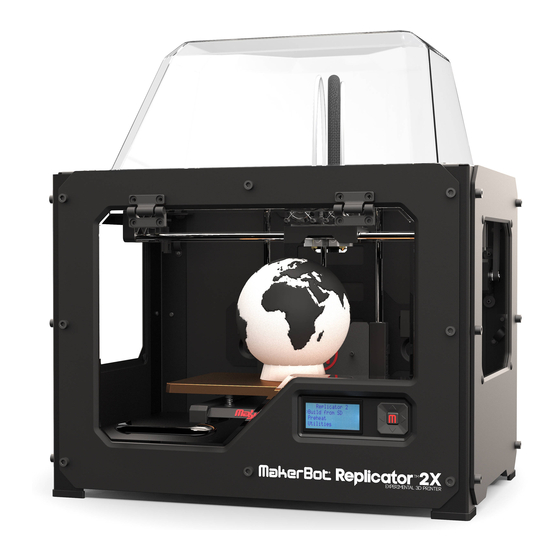

- Page 1 ® USER MANUAL...

- Page 2 The product may differ slightly from the images and instructions in this manual as we continue to improve the MakerBot Ecosystem. Please see www.makerbot.com/um_rep_2X for the latest version of the manual.

-

Page 3: Table Of Contents

Active Build Menu Leveling the Build Plate Loading Makerbot Filament MAKERBOT DESKTOP Downloading and Installing MakerBot Desktop About MakerBot Desktop The Prepare Screen PRINTING WITH YOUR MAKERBOT REPLICATOR 2X Choosing a Model Preparing a Model Printing a Model ADVANCED SETTINGS Quality Temperature... - Page 4 TABLE OF CONTENTS CONTINUED Tightening the X and Y-Axis Pulleys Filament Care TROUBLESHOOTING Printing Issues LCD Error Messages Misaligned Nozzles Dos and Don’ts Useful Tools Diagnosing Print Quality Issues REFERENCE Specifications Glossary Contact Us Notes WELCOME...

-

Page 5: Welcome

WELCOME Welcome to the User Manual for the MakerBot Replicator 2X Experimental 3D Printer. Your MakerBot Replicator 2X is optimized for ABS, a traditional thermoplastic that can be tricky and unpredictable. In order to achieve great results, you will need to experiment and tinker. That’s why it’s so crucial to take the time to learn about your new 3D printer. -

Page 6: Legal Notices

LEGAL NOTICES PRODUCT WARRANTY The MakerBot Replicator 2X Experimental 3D Printer is covered by a limited warranty. For terms and conditions, see makerbot.com/legal. OVERALL PROVISIONS All information in this user manual is subject to change at any time without notice and is provided for convenience purposes only. - Page 7 MakerBot makes no warranties to those defined as “consumer” in the Magnuson-Moss Warranty-Federal Trade Commission Improvement Act. In connection with your use of this user manual, MakerBot shall not be liable to you for any damages whatsoever, be they direct, economic, commercial, special, consequential,...

-

Page 8: Safety And Compliance

Changes and Modifications not expressly approved by the manufacturer or registrant of this equipment can void your authority to operate this equipment under Federal Communications Commission rules. MANUFACTURER MakerBot Industries, LLC One MetroTech Center, 21st Floor Brooklyn, NY 11201 347.334.6800 I. - Page 9 Always allow the MakerBot Replicator 2X to cool down before reaching inside. WARNING: The MakerBot Replicator 2X includes moving parts that can cause injury. Never reach inside the MakerBot Replicator 2X while it is in operation. WARNING: Do not leave the MakerBot Replicator 2X unattended during operation.

-

Page 10: Diagrams

MAKERBOT REPLICATOR 2X DIAGRAMS Gantry System LCD Panel Heated Build Plate Build Platform Threaded Z-Axis Rod Enclosure Door Handle Filament Guide Tubes Extruder Cable Extruders Filament Spool Spool Holders WELCOME... - Page 11 MAKERBOT REPLICATOR 2X DIAGRAMS CONTINUED Fan Guards Extruder Fans Extruder Nozzles Fan Bolts Cartridge Heaters Thermal Cores Drive Blocks Extruder Cable Mount Front view of extruders Motor Cable Connectors Extruder Motors Heat Sinks Bar Mount Spacers Extruder Carriage Extruder Arms...

-

Page 12: How It Works

MakerBot Replicator 2X via USB cable or SD card. The MakerBot Replicator 2X will melt the filament and squeeze it out onto the build plate in thin lines to build your object layer by layer. This method is called fused deposition modeling. -

Page 13: Accessory Checklist

ACCESSORY CHECKLIST MakerBot ABS Filament guide tubes Spool holders Handle and bolts Filament [1 lb Spool] Power supply USB-A to USB-B MakerBot tape Kapton tape sheets cable and cable applicator SD card Hex wrenches PTFE-based grease Support card store.makerbot.com/abs-filament More options available at... -

Page 14: Filament

FILAMENT Your MakerBot Replicator 2X Experimental 3D Printer is optimized to print objects using ABS plastic filament, 1.75 mm in diameter. The Makerbot Replicator 2X can also use 1.75 mm filament made from other plastics with similar properties. Similar filament,... - Page 15 ABS is tough and somewhat flexible. It becomes softer with increased temperatures, but at the extrusion temperatures used in a MakerBot Replicator 2X it remains fairly viscous. That means that ABS melts quickly inside the extruder but doesn’t drip during travel moves.

-

Page 16: Onboard Operations

ONBOARD OPERATIONS The MakerBot Replicator 2X Experimental 3D Printer has an onboard LCD panel through which you can initiate a number of processes, such as leveling the build plate or loading filament. You can also use the LCD panel to choose settings such as LED color or view information like your printer’s statistics. -

Page 17: The Lcd Panel

THE STARTUP SCRIPT The first time you turn on your MakerBot Replicator 2X, the printer will run a startup script on the LCD panel. Follow those instructions to level the build plate, load filament, and print a test print. If you don’t see the startup script, use the up and down arrow buttons to scroll through the top-level menu on the LCD panel, and use the M button to select Utilities. -

Page 18: Lcd Menus

Preheat. Preheating reduces the information about your MakerBot amount of time it takes to heat the plate Replicator 2X and allows you to change and extruders when you begin a print. settings on your MakerBot Replicator 2X. • Choose the parts of the MakerBot... -

Page 19: Utilities Menu

UTILITIES MENU The Utilities menu contains controls for your MakerBot Replicator 2X and scripts for processes like loading filament and leveling the build plate. Monitor Mode. This entry displays the To cancel the Level Build Plate script, current temperature of your extruders and press the left arrow button and select build plate. - Page 20 The Startup Script runs a script that allows the MakerBot automatically the first time you power on Replicator 2X to correctly locate the two the MakerBot Replicator 2X. The Startup extruder nozzles. Use this script if your Script walks you through the steps for dual extrusion prints don’t appear to line...

-

Page 21: Info And Settings Menu

THE INFO AND SETTINGS MENU The Info and Settings Menu displays information about your MakerBot Replicator 2X and allows you to change settings on your MakerBot Replicator 2X. Bot Statistics. This entry displays the total build time, in hours and minutes, during the lifetime of your MakerBot Replicator 2X. - Page 22 Turning it OFF provides abbreviated eliminate all sound made by your MakerBot help text during scripts. Replicator 2X. The sounds you hear during Heat LEDS. This entry toggles heat printing come from the stepper motors and cannot be turned off.

- Page 23 CONTINUED Preheat Settings. This entry lets you Restore Defaults. This entry restores change the preheat temperatures for the your MakerBot Replicator 2X to the extruders and build plate. Remember default, factory settings. This option that that the temperatures are in affects only settings that you can change degrees Celsius.

-

Page 24: Active Build Menu

MakerBot does not recommend allowing Z Pause Height. This entry allows you to a heated nozzle to remain stationary set a height at which your Replicator 2X and in contact with your print for a long will pause. When you select this option, you will see two additional settings: Z period of time. - Page 25 CONTINUED LED Color. This entry allows you to change the color of the LEDs in the frame of the MakerBot Replicator 2X. The LEDs can be set to WHITE, RED, ORANGE, PINK, GREEN, BLUE or PURPLE, or turned OFF. Use the up and down arrow buttons to scroll through the available colors.

-

Page 26: Leveling The Build Plate

• If the build plate is too close to the extruder nozzles, the build plate can block the MakerBot Filament from extruding from the nozzles. This can also tear the Kapton tape applied to the build plate and scratch the aluminum surface underneath. - Page 27 As you adjust each knob, make sure the MakerBot Support card just slides between the nozzles and build plate. You should feel some friction on the card but still be able to easily pass...

-

Page 28: Loading Makerbot Filament

1. Remove the Enclosure Lid Filament Lift the enclosure lid from the top of Guide Tubes the MakerBot Replicator 2X and set it aside. 2. Detach the Filament Guide Tube Locate where the filament guide tube enters the extruder. Detach the guide tube by gently pulling it out of the extruder. - Page 29 LCD panel will prompt you to load filament into the extruder. Press through the message until your MakerBot Replicator 2X asks you to press the M when you see plastic extruding. 6. Push the Filament into the Extruder Press the M...

- Page 30 LOADING MAKERBOT FILAMENT CONTINUED filament. Maintain pressure for another five seconds and then let go. 7. Stop Extrusion After a few moments, you should see a thin string of plastic come out of the extruder nozzle. The filament might curl and then straighten; this is normal.

- Page 31 LOADING MAKERBOT FILAMENT CONTINUED Unloading MakerBot ABS Filament Just like with loading filament, the MakerBot Replicator 2X will heat the selected extruder to 230° C and then direct you to pull the filament free of the extruder. To unload filament, navigate to Utilities >...

-

Page 32: Makerbot Desktop

MAKERBOT DESKTOP MakerBot Desktop is a free app for preparing 3D prints and managing your 3D content. Use MakerBot Desktop to explore Thingiverse , organize ® your files, and prepare 3D models for printing. WELCOME... -

Page 33: Downloading And Installing Makerbot Desktop

MakerBot Desktop will automatically detect your printer. C. Last, you’ll be asked to either Sign in to MakerBot Desktop or to Create an Account. If you have a MakerBot Thingiverse account or a MakerBot Store account, you already have... - Page 34 If not, you can create one now. This is your MakerBot account, and you can use it to log into MakerBot Desktop, Thingiverse, and other MakerBot sites. You can use MakerBot Desktop without logging in, but...

-

Page 35: About Makerbot Desktop

ABOUT MAKERBOT DESKTOP MakerBot Desktop is a free app for preparing 3D prints and managing your 3D content. It consists of five sections: Explore, Library, Prepare, Store, and Learn. 1. Explore gives you access to MakerBot 4. STORE lets you buy print files for Thingiverse and the hundreds of thousands premium 3D models. -

Page 36: The Prepare Screen

• In View mode, hold the Shift key and click and drag with your mouse to pan. • Click the View button again to open the Change View submenu and access preset views. 4. Move • Click the Move button or press the M key to enter Move mode. MAKERBOT DESKTOP... - Page 37 • Select which extruder you would like to print each object on your build plate. • You can set each extruder’s display color by navigating to Edit > App Settings in MakerBot Desktop. • To have all objects printed by the same extruder, select the appropriate extruder and then click Select All.

- Page 38 11. Save to Library • Click Save to Library to open a Save dialog. • If you are logged into your MakerBot account, you can choose to save to your Library or to your local computer. • If you are not logged into your MakerBot account or if you are working offline, you will be able to save your file only to your local computer.

-

Page 39: Printing With Your Makerbot Replicator 2X

This chapter will walk you through finding a model to print, preparing that model, and then finally printing the model. This chapter assumes you have already downloaded and installed MakerBot Desktop. If you have not installed MakerBot Desktop, see the section in chapter 3 on Downloading and Installing MakerBot Desktop. WELCOME... -

Page 40: Choosing A Model

CHOOSING A MODEL You can download a model from Thingiverse, open a 3D printable .STL, .OBJ, or .Thing file from any source, or access objects that are already saved in your MakerBot Cloud Library. FINDING A MODEL ON THINGIVERSE IMPORTING A MODEL FROM YOUR LOCAL COMPUTER 1. -

Page 41: Preparing A Model

1. Filament Type Set each extruder to the type of filament you plan to print with. If you are not printing with dual extrusion, MakerBot Desktop will ignore the filament type set for the unused extruder. 2. Resolution Choose Low, Standard, or High resolution to specify the surface quality of your 3D print. - Page 42 4. Supports Choose if you want your object to print with supports. MakerBot Desktop will automatically generate supports for any overhanging sections of your object. Supports will be easily removable once you remove your finished object from the build plate.

- Page 43 To better understand how to prepare a dual extrusion print, we will use an example object from Thingiverse. In MakerBot Desktop, click on the Explore tab. 2. In the Search field in the upper right of the page, enter “Lotus Flower.”...

- Page 44 11. In the Object Information submenu, in the Extruder dropdown menu, select the other extruder to print Lotus_color2.stl. NOTE: To change the display colors of your extruders, go to Edit > App Settings in MakerBot Desktop. PRINTING WITH YOUR MAKERBOT REPLICATOR 2X...

-

Page 45: Printing A Model

PRINTING A MODEL Once you’ve saved your settings in MakerBot Desktop, it’s time to print. Your MakerBot Replicator 2X can print via SD card or via USB. FILE TYPES STLs are compatible with many different MakerBot Desktop can open the following... - Page 46 PRINTING A MODEL CONTINUED individual models in relation to each other. The Thing format works only with MakerBot X3G is the compact format in which Desktop, so you should not save as Thing MakerBot Desktop sends instructions to if you are saving a file for use with another your MakerBot Replicator 2X.

- Page 47 • Formatted for FAT16 •No larger than 2GB 2. In MakerBot Desktop, click Export Print File. MakerBot Desktop will slice your model. 3. Once your model is sliced, a dialog will appear with an estimated print time and estimated filament usage, as well as an opportunity to view a print preview.

- Page 48 SD card from your computer and insert it into the SD card slot at the Remove Raft and/or Supports top of the LCD panel on your MakerBot When your print finishes, wait for the Replicator 2X. extruders to cool. Remove the print from the build plate, and peel off the raft from 7.

-

Page 49: Advanced Settings

ADVANCED SETTINGS This chapter describes the advanced printing options in MakerBot Desktop. WELCOME... - Page 50 NOTE: The settings in Advanced Options do not edit the base profiles; they only override them. MakerBot Desktop will save the set of overrides for you, but you can always return the profile to its original state by clicking the Use Defaults button at the lower left of the Advanced Options area.

-

Page 51: Quality

QUALITY The settings in the Quality tab affect the strength and finish of printed objects. Each Quality option affects particular sections of an object. INFILL Infill provides your object with an internal support structure. The number that you enter in this field defines the solidity of the printed object’s infill. Higher infill percentages will result in more threads of infill extrusion that are closer together, increasing the strength and weight of your object. - Page 52 CONTINUED SHELLS The MakerBot Replicator 2X starts each new layer of an object by printing some number of outlines of that layer. These are called shells. Every object you print must have at least one shell. If there is more than one shell, the additional shells will be nested inside the first one.

-

Page 53: Temperature

TEMPERATURE Temperature settings for the extruders and the build plate are grouped together under the Temperature tab. EXTRUDERS The extruders will need to be heated to approximately 230° C to melt and extrude the plastic filament at normal operating speeds. Extrusion temperature is tied very closely to both extrusion speed and the material being extruded. -

Page 54: Speed

SPEED Everyone wants their MakerBot to move faster so they can print things more quickly. Our default print speed is 80 mm/s, and if you want to print faster, you might have to adjust more settings than the extrusion speed. Print speeds are closely tied to temperature settings and to the mechanical capabilities of your MakerBot Replicator 2X. -

Page 55: Custom Profiles

Additional advanced options are available through Custom Profiles. Custom profiles allow you to edit the slicing engine’s profile settings directly instead of overriding them by using the Advanced Options settings. Visit the Using Custom Slicing Profiles page at www.makerbot.com/support/new/Desktop for more information. ADVANCED SETTINGS... -

Page 56: Maintenance

MAINTENANCE We’ve made the MakerBot Replicator 2X incredibly easy to take care of, but there are a couple of things you’ll want to do from time to time to keep it running as smoothly as possible. WELCOME... -

Page 57: Leveling The Build Plate

LEVELING THE BUILD PLATE One of the best things you can do to keep your MakerBot Replicator 2X in top shape is to level your build plate frequently. It never hurts to re-level, but forgetting to do so can hurt your success rate. - Page 58 LEVELING THE BUILD PLATE CONTINUED Here are a few tips to keep in mind when you level your build plate: • Make sure to take your fingers off the leveling knobs and platform when you test the friction on your paper or feeler gauge; pressure from your hands can affect platform height.

-

Page 59: Replacing Kapton Tape

Peel off the old Kapton tape and discard it. 2. Locate the extra sheets of Kapton tape that were included with your MakerBot Replicator 2X. If you have used up these sheets, Kapton tape is available for purchase store.makerbot.com/parts-accessories.html. 3. On one of the short sides of the sheet, peel back the plastic backing approximately 1/4 inch from the edge, so that 1/4 inch of the sticky side of the Kapton tape is exposed. - Page 60 REPLACING KAPTON TAPE CONTINUED 8. When the Kapton tape is applied as smoothly as possible, trim the edges of the sheet or fold them over the sides of the build plate. NOTE: To view a video of this process, visit mbot.co/1u9NCuC. MAINTENANCE...

-

Page 61: Lubricating The Z-Axis Rod And Idler Pulley

Make sure you get the grease inside the threads themselves. 4. Grasp both sides of the build platform and move it to the top of the MakerBot Replicator 2X. 5. Use a clean, lint-free rag [or your finger] to spread the PTFE-based grease onto the bottom section of the threaded rod. - Page 62 LUBRICATING THE Z-AXIS ROD & IDLER PULLEY CONTINUED X-axis pulley 7. Squeeze a small amount of the PTFE-based grease directly onto the exposed area of the metal rod inside the idler pulley and manually move the pulley back and forth to spread the grease.

-

Page 63: Realigning The Gantry

To determine whether your gantry is aligned correctly, push the extruders all the way to the front of the MakerBot Replicator 2X. Hold the right side of the gantry against the front of the MakerBot Replicator 2X. Then try pushing the left side forwards. It should not move. If it does move, perform the following steps. - Page 64 NOTE: If you cannot see one of the set screws, hold both sides of the gantry and very gently push it away from the back of the MakerBot Replicator 2X. Make sure to exert an equal amount of pressure on both sides of the gantry. Push only until you can see the hidden set screw.

-

Page 65: Tightening The X And Y-Axis Pulleys

Makerbot Replicator 2X. Slide the extruders to the front of the Makerbot Replicator 2X until you have access to the set screw holding the pulley to the motor shaft. Use the 1.5mm hex wrench from the accessory box to tighten the set screw. -

Page 66: Filament Care

FILAMENT CARE Your MakerBot Replicator 2X Experimental 3D Printer is optimized to print with 1.75 mm MakerBot ABS plastic filament. For maximum performance, you must keep your ABS filament cool and dry. Heat and humidity can cause the ABS plastic to absorb moisture and swell. -

Page 67: Troubleshooting

TROUBLESHOOTING WELCOME... -

Page 68: Printing Issues

• Increase the temperature of the build plate by five degrees. You can change the temperature of the build plate in the Advanced Options section of the Settings dialog in MakerBot Desktop. • If you continue to have adhesion problems, loosen each of the plate-leveling knobs about a quarter of a turn to bring the plate slightly closer to the nozzles. - Page 69 • Is the nozzle clogged? Go to the LCD menu on your MakerBot Replicator 2X and navigate to Utilities > Change Filament > Load right or Load left. Run the Load script.

- Page 70 MakerBot Replicator 2X. To check and change the Acceleration setting, go to the LCD menu on your Replicator MakerBot 2X and navigate to Info and Settings > General Settings > Accelerate. You can turn acceleration off and on.

- Page 71 PRINTING ISSUES CONTINUED FILAMENT STUCK Filament can swell inside the extruder and get stuck. If you cannot unload filament from one of the extruders, do the following: On the LCD panel, navigate to Utilities > Change Filament > Unload. This option heats the extruders.

- Page 72 Utilities > Change Filament > Unload on the LCD panel. 2. Switch off the power on the MakerBot Replicator 2X and unplug the power supply. Pull on the connector to release it from the power input port.

-

Page 73: Lcd Error Messages

If your MakerBot Replicator 2X encounters problems during operation, the LCD menu will display an error message. The following table describes each possible error message. NOTE: If you see an error message in an unexpected context, submit a case to MakerBot www.makerbot.com/support/submit-a-case/... - Page 74 To clear Heating Errors 3 and 4, you will have to restart your MakerBot Replicator 2X. Your MakerBot Replicator 2X cannot read SD cards larger than 2GB. Try a smaller card.

- Page 75 Make sure your SD card has not been removed from the MakerBot Replicator 2X during printing. If the card is still in its port on the MakerBot Replicator 2X, there might be a problem with the card itself. Make sure the card is formatted correctly.

-

Page 76: Misaligned Nozzles

2. To start the nozzle alignment script, go to the LCD menu and navigate to Utilities > Calibrate Nozzles. 3. The MakerBot Replicator 2X will heat the build plate and extruders and then print a test print for aligning the nozzles. - Page 77 8. Use the arrow buttons to select a line number and the M button to select a line number. The MakerBot Replicator 2X will store this information about the locations of the extruder nozzles and use them to make future prints align better.

-

Page 78: Dos And Don'ts

• Don’t use sharp tools to remove objects from the build plate – using a knife or a razor blade to remove prints is just as likely to hurt you as it is to help. • Don’t turn your MakerBot Replicator 2X off immediately after finishing a print. Give the extruder fans time to cool the extruder first. -

Page 79: Useful Tools

USEFUL TOOLS Your MakerBot Replicator 2X package includes everything you need to start printing, but here are a few other things that might come in handy as you begin to experiment. A Craft Spatula. A thin metal craft spatula is a great tool for removing stubborn prints form the build plate. -

Page 80: Diagnosing Print Quality Issues

When your print is surrounded by warm air, newly-printed layers will cool at a slower rate and adjacent layers will be closer in temperature. This is why the MakerBot Replicator 2X is fully enclosed. The enclosure keeps the heat from the extruders within the build area and keeps prints at a more constant temperature. - Page 81 Change the first “feedDiameter” setting if you are printing using the right extruder on your MakerBot Replicator 2X and change the second “feedDiameter” setting if you are using the left extruder.

- Page 82 DIAGNOSING PRINT QUALITY ISSUES CONTINUED If you are overextruding, increase the “feedstockMultiplier” setting by 0.05, save the config file, and print again. File Name: 3D mouse Design by: DDStarkey Thingiverse: 61909 Overextrusion If you are underextruding, decrease the “feedstockMultiplier” setting by 0.05, save the config file, and print your file again.

- Page 83 This is the result of skipping on speeds. Reduce your print speed in the the X or Y-axis. This problem has multiple Advanced Options section of MakerBot Desktop’s Settings dialog. Axis Drift possible causes.

- Page 84 DIAGNOSING PRINT QUALITY ISSUES CONTINUED holding the drive block to the extruder motor. Remove the drive block and set 5. Return the extruder motor assembly to it aside. Be careful with the drive block the extruder carriage. – if any of the pieces are detached, you might have a difficult time putting it 6.

-

Page 85: Reference

REFERENCE WELCOME... -

Page 86: Specifications

PRINTING TEMPERATURE Print Technology: Fused deposition modeling Ambient Operation: 15°–32° C [60°–90° F] Filament: 1.75 mm MakerBot ABS Filament Storage Temperature: 0°–32° C [32°–90° F] 1.75 mm MakerBot ELECTRICAL Dissolvable Filament Build Volume: 24.6 cm x 16.3 cm x 15.5 cm AC Input: 100–240V, ~4 amps, 50–60 Hz... -

Page 87: Glossary

MakerBot Filament into the heated part of the extruder. to describe the toolpath your MakerBot Replicator 2X will use to 3D print an DUAL EXTRUSION: A process in which object. GCode is converted to X3G before two extruders loaded with two different... - Page 88 LCD CONTROL PANEL: The liquid- PLA: Polylactic acid is a renewable crystal display at the front lower right corner of the MakerBot Replicator 2X. This bioplastic, and one of the materials from control panel provides status information which MakerBot Filament is made.

- Page 89 TOOLPATH: The set of instructions your MakerBot Replicator 2X will use to build an object. Toolpaths for the MakerBot Replicator 2X must be saved as an X3G file. USB CABLE: A cable that allows your computer to communicate with the MakerBot Replicator 2X.

-

Page 90: Contact Us

At MakerBot, we take pride in offering expert, responsive, friendly customer support to our customers around the world. If you need help resolving an issue with your MakerBot Replicator 2X, open a case with the MakerBot Support Team at the web address above. -

Page 91: Notes

NOTES REFERENCE... - Page 92 MakerBot One MetroTech Center, 21st Floor, Brooklyn, NY makerbot.com...

Need help?

Do you have a question about the Replicator 2X and is the answer not in the manual?

Questions and answers