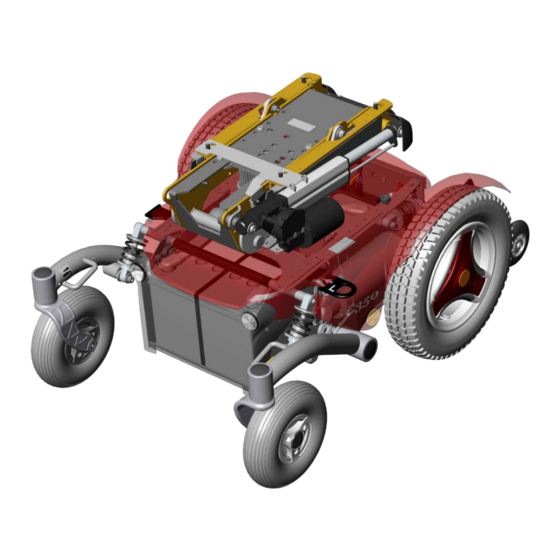

Permobil C350 Service Manual

Power wheelchair

Hide thumbs

Also See for C350:

- Owner's manual (112 pages) ,

- Assembly instruction manual (26 pages) ,

- Owner's manual (40 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Permobil C350

- Page 1 SERVICE MANUAL Permobil C350 Power Wheelchair...

- Page 3 How to contact Permobil Head Office of the Permobil group Produced and published by Permobil AB, Sweden Version 2, 2009-08 Article no.: 205219-US-0...

-

Page 4: Table Of Contents

Contents Contents Introduction ...................... 5 Rating plates ....................6 Covers ....................... 8 Batteries ......................10 Rear wheels ....................12 Support wheels ....................14 Front wheels ....................16 Wheel fork ...................... 17 Shock absorbers .................... 18 Link arms ......................20 Brake release ....................22 Release controls .................. -

Page 5: Introduction

It is important for everyone who performs maintenance and repairs as described in this manual to read and understand the contents of the manual so that the work is performed expertly. Always state the chassis number when you contact Permobil to ensure that you get the right informa- tion. -

Page 6: Rating Plates

Rating plates Rating plates Chassis Chassis ID number Rnet output stage Rnet output stage ID number Rnet control panel Control panel Pilot+ ID number... - Page 7 Rating plates Rating plates VR2 output stage VR2 output stage ID number VR2 control panel VR2 control panel ID number VR2 lights module Control panel Pilot+ ID number...

-

Page 8: Covers

Covers Covers Removing the upper chassis cover The cover is fixed with two knobs (see illustration). 1. Move/fold the leg rests out and, if necessary, raise the seat. 2. Switch off the main power switch on the con- trol panel. 3. - Page 9 Covers Covers Removing the front chassis cover The cover is fixed by means of Velcro on its upper/rear edges. 1. Move/fold the leg rests out. 2. Switch off the main power switch on the con- trol panel. 3. Lift the rear edge of the cover upwards and forwards so the Velcro on the inside of the cover comes undone.

-

Page 10: Batteries

Batteries Batteries Be careful when using metal objects when working with bat- teries. A short-circuit can easily cause an explosion. Always use safety gloves and safety goggles. Removing the front battery 1. Place the wheelchair on a level surface. 2. Move/fold the leg rests out and, if possible, raise the seat lift. - Page 11 Batteries Batteries Removing the rear battery 1. Place the wheelchair on a level surface. 2. Switch off the main power switch on the con- trol panel. 3. Remove the rear chassis cover. See page 9. 4. Remove the output stage bracket by first loos- ening the two screws (A) and then lifting the bracket straight up while turning it upside down.

-

Page 12: Rear Wheels

Rear wheels Rear wheels Removal 1. Switch off the main power switch on the control panel. 2. Lift up and chock up the wheelchair chassis so that the wheel in question is free of the ground. 3. Remove the hub cap by pulling it straight out. If necessary, carefully lever it out using a screwdriver in the slot on the cap. - Page 13 Rear wheels Rear wheels Taking the rim apart The rim can be taken apart to make it possible to fit/remove solid or pneumatic tires. 1. Remove the wheel in question from the wheelchair. See the previous page. 2. If the tire is pneumatic, release the air. WARNING Ensure that pneumatic tires are not pressurized before the rim is taken apart, otherwise there is a risk of personal injury.

- Page 14 Support wheel bracket Support wheel bracket Removal 1. Switch off the main power switch on the con- trol panel. 2. Remove the rear wheel on the side in ques- tion. See the illustration above. 3. Remove the two screws (2) that hold the sup- port wheel bracket in place at the rear (see illustration).

-

Page 15: Support Wheels

Support wheels Support wheels Support wheels may be fitted in three different positions: low, medium and high. These fitting positions are marked L, M and H. With the support wheels fitted in the lower position, low, the wheelchair inclines less before the support wheels meet the ground, but the accessibility of the wheelchair is reduced somewhat. -

Page 16: Front Wheels

Front wheels Front wheels Removal 1. Switch off the main power switch on the control panel. 2. Lift up and chock up the wheelchair chassis so that the wheel in question is free of the ground. 3. Remove the hub cap 1. 4. -

Page 17: Wheel Fork

Wheel forks Wheel forks Removal 1. Switch off the main power switch on the con- trol panel. 2. Lift up and chock up the wheelchair chassis so that the wheel in question is free of the ground. 3. Remove the cap (1) from the top of the link arm. -

Page 18: Shock Absorbers

Shock absorbers Shock absorbers Removing the rear shock absorber 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually. - Page 19 Shock absorbers Shock absorbers Removing the front shock absorber 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually.

-

Page 20: Link Arms

Link arms Link arms Removing the front link arm 1. Switch off the main power switch on the con- trol panel. 2. Lift up and chock up the wheelchair chassis so that the wheel in question is free of the ground. 3. - Page 21 Link arms Link arms Removing the rear link arm 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually.

-

Page 22: Brake Release

Brake release Brake release The brake release consists of a release control, a brake release switch and a magnetic brake on each drive motor. Removing the release control 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. -

Page 23: Magnetic Brake

Brake release Brake release Removing the magnetic brake 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually. -

Page 24: Brake Release Switch

Brake release Brake release Removing the brake release switch 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually. -

Page 25: Drive Motor

Drive motor Drive motor Removal 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually. -

Page 26: Electric Seat Lift

Electric seat lift Electric seat lift Manual raising/lowering of electric seat lift If the seat lift does not work normally because the batteries are discharged or the adjustment device is defective, the seat can be raised/lowered manu- ally. 1. Switch off the main power switch on the con- trol panel. -

Page 27: Removing The Seat Lift

Electric seat lift Electric seat lift Removing the electric seat lift 1. Raise the seat to the highest position manual- ly. See the previous page. 2. Switch off the main power switch on the con- trol panel. 3. Remove the upper chassis cover. See page 8. 4. -

Page 28: Fixed Seat Tube

Fixed seat tube Fixed seat tube Service position The fixed seat tube can be raised to the service position to make it easier to set the fixed seat height and other service tasks on the wheelchair. 1. Loosen the screw that locks the fixed height position of the seat tube (see illustration). -

Page 29: Removing The Fixed Seat Tube

Fixed seat tube Fixed seat tube 3. Undo the screw locking the seat tube height position, and push the seat downwards. Turn the seat so that the head of the height adjust- ment screw is in the groove in the outer tube of the seat tube (see illustration). -

Page 30: Seat Angle Mechanism

Seat angle mechanism Seat angle mechanism Removal 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually. - Page 31 Seat angle mechanism Seat angle mechanism C350 Corpus, C350 TS Seat angle mechanism fitted in hole configuration for mounting on C350 with Corpus- or TS-seat C350 PS Seat angle mechanism fitted in hole configuration for mounting on C350 with PS seat...

-

Page 32: Corpus Seat

Corpus seat Corpus seat Removal from chassis without seat angle 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually. - Page 33 Corpus seat Corpus seat 4. On chassis with VR2 Disconnect the adjustment device cabling from the output stage. See the diagram of out- put stage cable connections on page 38. Cut the cable ties holding the cabling in place, not- ing the position of the cable ties for subse- quent fitting.

-

Page 34: Ps Seat

PS seat PS seat Removal from chassis without seat angle 1. Raise the seat; electric seat lift to the highest position; fixed seat tube to the service position. See page 28. If the electric seat lift does not work normally because the batteries are dis- charged or the adjustment device is defective, the seat can be raised/lowered manually. - Page 35 PS seat PS seat Removal from chassis with seat angle 1. Switch on the main power switch on the con- trol panel. Raise the seat angle. Switch off the main power switch on the control panel. If the seat angle will not run due to discharged batteries or defective adjustment device, remove the front mounting screw of the adjust- ment device (see illustration).

-

Page 36: Control Panel R-Net

Control panel Control panel R-net Removal 1. Switch off the main power switch on the con- trol panel. 2. Remove the cable ties holding the control panel cabling in place under the arm rest. Note the positions of the cable ties for subsequent fitting. -

Page 37: Output Stage R-Net

Output stage Output stage R-net Removal 1. Switch off the main power switch on the control panel. 2. Switch the main fuse to OFF. See page 40. 3. Remove the chassis covers. See page 8. 4. Disconnect the electrical connections from the output stage. Note their positions (see illustration below). -

Page 38: Output Stage Vr2

Output stage Output stage VR2 Removal 1. Switch off the main power switch on the control panel. 2. Switch the main fuse to OFF. See page 40. Remove the chassis covers. See page 8. 4. Disconnect the electrical connections from the output stage. Note their positions (see illustration below). -

Page 39: Lights Module

Lights module and ICS master module Lights module (Only applies to chassis with VR2 and lights.) Removal 1. Switch off the main power switch on the con- trol panel. 2. Remove the chassis cover and rear battery cover. See page 8. 3. -

Page 40: Fuses

Fuses Fuses Resetting the main fuse The main fuse also functions as a battery isolator but it is usually called the main fuse. It is not normally necessary to replace the main fuse as it is automatic and can be reset when it has been triggered. -

Page 41: Control System

The control system can also be programmed in order to make adjustments needed for a spe- cific user. Standard parameter files can be downloaded from Permobil’s website, www.permobil.se . For more information on programming the VR2 control system and obtaining parameter files, see the technical user manual for programming Pilot+ / VSI / VR2 (Art.no. -

Page 42: Lights

Lights Lights (accessories) Removing the front lights 1. Switch off the main power switch on the con- trol panel. 2. Remove the front and upper chassis cover. See pages 8–9. 3. Divide the lights’ cabling at the contact on the cabling. - Page 43 Lights Lights (accessories) Bulb replacement front 1. Switch off the main power switch on the con- trol panel. 2. Unscrew and remove the two screws holding the light insert in place. Remove the insert (see illustration). 3. Remove the bulb holder by pulling it straight out, and replace the defective bulb.

-

Page 44: Troubleshooting Guide R-Net

The following troubleshooting guide describes a number of faults and events which may occur when you use your wheelchair, together with suggested remedies. Note that this guide cannot describe all the problems and events which may occur and you should always contact your service contact or Permobil in case of doubt. -

Page 45: Rnet Diagnostics

Diagnostics should only be performed by persons with sound knowledge of the wheelchair’s electronic control system. Incorrect or poorly performed repair works may make it dangerous to use the wheelchair. Permobil accepts no liability for any personal injury or damage to the wheelchair and its surroundings that occurs on account of incorrect or poorly performed repair work. - Page 46 Troubleshooting Troubleshooting R-net Example of a screen showing a system fault Identified module Error message Controller Fault Low Battery Error code 0506 2C00 Identified module This indicates the control system module that detected the problem. Power module JSM= Joystick module Error message The error message provides a brief description of the error type.

- Page 47 The system log is accessed by means of programming directly in the system (On Board Programming, OBP). Contact Permobil or your repair engineer for more information on OBP. Go to OBP mode • Select System from the menu.

- Page 48 Troubleshooting Troubleshooting R-net Definitions of diagnostics messages When an error message has been displayed and the defective module has been identified, you can use the following definitions to determine the possible cause of the error and what remedial action is required to correct it.

- Page 49 Troubleshooting Troubleshooting R-net Joystick Error The commonest cause for this error is that the joystick was moved away from its central position before and during the time at which the control system was switched on. The screen for a shifted joystick is dis- played for 5 seconds.

- Page 50 Troubleshooting Troubleshooting R-net Joystick Calibration Error This occurs when joystick calibration has been unsuccessful. • Go to OBP mode and recalibrate. If the error persists, the joystick module may be defective. Read more in section 5. Latched Timeout This occurs when the control system detects that the programmed block time has been exceeded. This can, for example, be due to the signal units (joystick, main steering device, suction and blowing device, etc.) not having been used frequently enough.

- Page 51 Programming should only be performed by persons with sound knowledge of control systems from PGDT. Incorrect program- ming can mean that the wheelchair is not safe to use. Permobil cannot be held responsible for losses of any kind if the control...

- Page 52 Troubleshooting Troubleshooting R-net 3.19 Bad Cable This occurs when the control system detects a connection error in the communication cables between the modules. • Check all cables and connections to ensure there is no stoppage. • Replace any cables with visible damage. Then cycle the voltage. •...

- Page 53 Troubleshooting Troubleshooting R-net 3.22 System Error This occurs when the control system detects an error that cannot be ascribed to a specific module. • Check all cables and connections. • Cycle the voltage. If the error persists and the system includes third-party modules: •...

- Page 54 The necessary information on other tests is available in the wheel- chair service manual. Permobil cannot be held responsible for losses of any kind that may arise when these tests are conduct- ed, or that arise as a consequence of further relevant tests not being conducted.

- Page 55 Troubleshooting Troubleshooting R-net Brake test These tests should be carried out on an even surface with at least one meter of free space around the wheelchair. • Switch on the control system. • Check that the screen remains on after start-up. •...

- Page 56 If any part is replaced without Permobil’s approval, the control system’s warranty lapses. Permobil cannot be held responsible for losses of any kind arising as a result of a component of the Rnet control system being opened, adjusted or modified without permission.

- Page 57 Diagnostics should only be performed by persons with sound knowledge of the wheelchair’s electronic control system. Incorrect or poorly performed repair works may make it dangerous to use the wheelchair. Permobil cannot be held responsible for any personal injury or damage to the wheelchair and its surroundings that occurs on account of incorrect or poorly performed repair...

-

Page 58: Example Of A Screen Showing A System Fault

Permobil-approved repairer for repair. If any part is replaced without Permobil’s approval, the wheelchair’s warranty lapses. Permobil cannot be held responsible for losses of any kind arising as a result of a component of the Rnet control system being opened, adjusted or modified without per-... -

Page 59: Troubleshooting Guide Vr2

The following troubleshooting guide describes a number of faults and events which may occur when you use your wheelchair, together with suggested remedies. Note that this guide cannot describe all the problems and events which may occur and you should always contact your service contact or Permobil in case of doubt. - Page 60 Diagnostics should only be performed by persons with sound knowledge of the wheelchair’s electronic control system. Incorrect or poorly performed repair works may make it dangerous to use the wheelchair. Permobil cannot be held responsible for any personal injury or damage to the wheelchair and its surroundings that occurs on account of incorrect or poorly performed repair work.

- Page 61 Troubleshooting Troubleshooting VR2 ERROR SIGNAL ERROR INDICATION - REMEDY 1 Lamp - Low battery voltage Check the condition of the battery. Check the contact between the battery and the control unit. 2 Lamps - Failure in left drive motor Check the connection to the left drive motor. 3 Lamps - Short-circuit in left drive motor Check the drive motor’s contacts and cables.

-

Page 62: Cabling Overview Rnet

Cabling overview... - Page 63 Cabling overview Cabling overview R-net...

-

Page 64: Cabling Overview Vr2

Cabling overview... - Page 65 Cabling overview Cabling overview VR2...

-

Page 66: Index

Index Index Batteries ..........10 Maintenance ........5 Brake release ........22 Output stage Rnet ......37 Cabling overview Rnet ....62 Output stage VR2 ......38 Cabling overview VR2 ...... 64 Contents ..........4 Control panel R-net ......36 PS seat.......... - Page 68 Article no.: 205219-US-0...

Need help?

Do you have a question about the C350 and is the answer not in the manual?

Questions and answers