Table of Contents

Advertisement

Quick Links

AND OPERATION INSTRUCTIONS

CERTIFIED WARNOCK HERSEY BY INTERTEK TESTING SERVICES LTD (ITS) IN

ACCORDANCE WITH STANDARDS UL-727 AND B140.4-1974.

RISK OF EXPLOSION OR FIRE. FOR YOUR SAFETY: DO NOT STORE OR USE GASOLINE OR

OTHER FLAMMABLE LIQUIDS, VAPOURS OR SUBSTANCES IN THE VICINITY OF THIS OR

ANY OTHER APPLIANCES.

DO NOT ATTEMPT TO START THE BURNER WHEN EXCESS OIL HAS ACCUMULATED, WHEN

THE FURNACE IS FULL OF VAPOUR, OR WHEN THE COMBUSTION CHAMBER IS VERY HOT.

ALWAYS KEEP THE VALVE SHUT OFF IF THE BURNER IS SHUT DOWN FOR AN EXTENDED

PERIOD OF TIME.

DO NOT START THE BURNER UNLESS THE BLOWER ACCESS DOOR IS SECURED IN PLACE.

DO NOT TAMPER WITH THE UNIT OR CONTROLS – CALL YOUR SERVICE-MAN.

NEVER BURN GARBAGE OR PAPER IN THE HEATING SYSTEM, AND NEVER LEAVE PAPER

OR RAGS AROUND THE UNIT.

OIL BURNING FURNACES MUST BE CONNECTED TO A CIMNEY WHICH WILL PROVIDE

ADEQUATE DRAUGHT TO ENSURE A PROPER AND SAFE OPERATION OF THE BURNER.

Aug 2005

INSTALLATION

FOR OIL BURNING FURNACE

READ THIS MANUAL THOROUGHLY

BEFORE OPERATING THE FURNACE

PLEASE SAVE THESE DOCUMENTS!

1700, Léon-Harmel

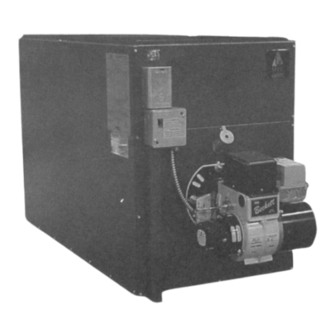

PSG 6000

CAUTION

WARNING

PSG

Québec(Québec)

G1N 4R9

Advertisement

Table of Contents

Summary of Contents for PSG 6000

- Page 1 1700, Léon-Harmel Québec(Québec) G1N 4R9 INSTALLATION AND OPERATION INSTRUCTIONS FOR OIL BURNING FURNACE PSG 6000 READ THIS MANUAL THOROUGHLY BEFORE OPERATING THE FURNACE CERTIFIED WARNOCK HERSEY BY INTERTEK TESTING SERVICES LTD (ITS) IN ACCORDANCE WITH STANDARDS UL-727 AND B140.4-1974. CAUTION RISK OF EXPLOSION OR FIRE.

-

Page 3: Table Of Contents

Table of contents GENERAL NOTES ........................4 1. DRAFT AND CHIMNEY....................... 4 2. OIL TANK AND PIPING ...................... 4 BURNER PUMP ..................................4 3. APPLIANCE INSTALLATION ..................... 5 A- LOCATING THE UNIT..............................5 B. CLEARANCES TO COMBUSTIBLE MATERIALS ....................5 C- POSITIONING THE APPLIANCE .......................... -

Page 4: General Notes

GENERAL NOTES INSTALLATION OF FIRED HEATING UNITS SHALL BE IN ACCORDANCE WITH THE REGULATION OF AUTHORITIES HAVING JURISDICTION AND THE CAN/CSA-B139, CSA-C22.1 NFPA-31 AND ANSI/NFPA-70 STANDARDS. The units are approved for fuel not heavier than No.2 (furnace). Do not use gasoline, crankcase oil or any oil containing gasoline. -

Page 5: Appliance Installation

If the rise is higher than 10 feet, a two stage pump may be required along with an oil return pipe. 3. APPLIANCE INSTALLATION A- LOCATING THE UNIT The furnace must be installed in a location where combustion air is available in sufficient quantity. In airtight houses, the installation of an outside air intake might be required. -

Page 6: E- Combustion Air

E- COMBUSTION AIR If the furnace is located in a room, confined in a restraint area, provide a one square foot opening in the room for each gallon per hour of oil consumption. Take note that an airtight house is liable to lack the fresh air needed for proper combustion, specially if you are using appliances that evacuate air from the house, such as: Range hood Air exchanger... -

Page 7: H- Thermostat

H- THERMOSTAT Thermostats must be installed on an interior wall, in a location where they are not affected by the air draft coming from the furnace’s blower; it must be level and at least 55 inches above the floor. I- FAN CONTROL The fan limit control settings may vary according to the type of building and heating installation;... -

Page 8: K- Combustion Adjustment And Verification

By pressing and holding the reset button, the burner will shut-off until the reset button is released. Then, the control will start over at the beginning of the normal cycle. FOR ADDITIONAL INFORMATIONS ON OPERATION SEQUENCES OF THE BURNER, CONSULT THE BURNER INSTRUCTION MANUAL. -

Page 9: L- Electrodes Setting

L- ELECTRODES SETTING The electrodes must be adjusted by a qualified technician. A proper positioning of the electrodes is important to get an efficient lighting of the oil. ELECTRODE SETTING FOR "F" HEAD ELECTRODE NOZZLE Schéma #2 WARNING: 1. REFER TO THE RATING PLATE FOR THE PUMP PRESSURE AND THE NOZZLE TYPE. 2. - Page 10 NOTE: The shut-off valve must be closed when the appliance is out of service for a prolonged period of time. 6- MAINTENANCE (Including filters) At the beginning of heating season, have the complete installation inspected by a qualified service man, especially the lighting system and the controls.

- Page 11 Burner no.: _______________ Model: __________ Date of installation: _____________________ Service Telephone no.: Day: ______________________ Night: ___________________________ Dealer’s name and address: _______________________________________________________ TEST REPORT : _______% Temp. at stack: ______________ Draft at stack: ________w.c. Nozzle output: _______________GPH Smoke colour: ______________________ Inspected by : _______________________________________________________ FILTERS The furnace should never be operated without filters.

-

Page 12: 6- Electrical Diagrams

6- ELECTRICAL DIAGRAMS WIRING DIAGRAM FOR PSG6000 WHITE RODGERS ON 100°F OFF 100°F LIMIT 250°F LIMIT NOIR RELAIS DU BLANC MISE À LA TERRE BRÛLEUR BLACK 120 VOLT 60 HERTZ WHITE FAN RELAY GROUND SUMMER SWITCH THERMOSTAT BLOWER 4 SPEED BLOWER TERMINAL GROUND... -

Page 13: 7- Technical Data

7- TECHNICAL DATA Approved burners for PSG 6000 Note:PSG6000 is only ,manufactured with a Beckett burner, but can be used with all these burner types. Burner Nozzle Static Pump Temp. Blower Motor model input size cone disc pressure Rise at speed H.P. -

Page 14: 8- Technical Data

8- TECHNICAL DATA Figure #1 Figure #2... - Page 15 Figure #3 Figure #4...

- Page 16 Figure #5 Figure #6...

-

Page 17: Limited Lifetime Warranty

PSG are based on predetermined rate schedule and must not exceed the wholesale price of the replacement part. PSG at its discretion may decide to repair or replace any part or unit after inspection and investigation of the defect. PSG may, at its...

Need help?

Do you have a question about the 6000 and is the answer not in the manual?

Questions and answers