Summary of Contents for St. Croix SCF-Revolution

- Page 1 Installation & Operations Manual SCF-REVOLUTION MULTI-FUEL FURNACE 1108 SCF-Revolution Manual...

-

Page 2: Table Of Contents

Combustion Air ......................17 Connecting to Existing Duct Work................. 18, 19 Mobile Home Installation ................... 20 Thermostat Connections ..................... 21 SCF-Revolution Operation ................... 22 Installation Check ..................22 Preventing Chimney Fires................22 Approved Fuels......................23 Pellets, Corn, Wheat, Rye, cherry Pits & Distiller’s Grain......23 The Revolution Burn System...................24-26... - Page 3 Shutting Off the furnace................. 34 Combustion Air Damper................34-37 Diagnostic & Safety Features ..............38, 39 Pilot Settings & Thermostat Control ............. 39 SCF-Revolution Maintenance..................40 Daily Maintenance ......................40 Periodic Maintenance....................41-43 Yearly Maintenance ....................44, 45 Safe Operation ......................45 Wiring Schematic......................

-

Page 4: General Information

Since Even Temp Company has no control over the installation of the furnace, Even Temp Company grants no warranty, implied or stated, for the installation of the furnace and assumes no responsibility for any special, incidental or consequential damages. MANUFACTURED BY: Even Temp Inc Hwy 34 Waco, NE, 68467 SCF-Revolution Manual... -

Page 5: Installation Check List

Furnace should be well ventilated. 4. Caution: The high temperature paint can be easily scratched prior to burning the Furnace. CAUTION FAILURE TO FOLLOW THE INSTRUCTIONS IN THE INSTALLATIONS MANUAL MAY RESULT IN A HOUSE FIRE. PLEASE FOLLOW INSTALLATION AND MAINTENANCE INSTRUCTIONS. SCF-Revolution Manual... -

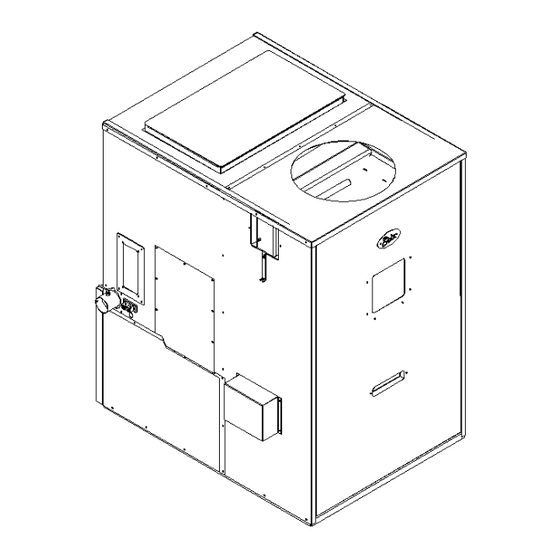

Page 6: Furnace Layout Diagram

Furnace Layout Figure 1 The SCF-Revolution has a large Heat Exchange system, allowing for more heat to be exchanged. The burn system used in the furnace is the St. Croix Patent Pending Revolution Burn System”. This burn system is Self-Cleaning and Self-Igniting during operation. There are 2 versions of this Burn System, one designed for pellets and the other designed for corn or other biomass fuels. -

Page 7: Furnace Dimensions, Location & Clearances

Fan, Vacuum Switch and Proof of Fire Switch. The larger cover allows access to the Convection Blower for maintenance when needed. The Fan Limit Control is also located on the left side. Supply Air. The SCF-Revolution Furnace may be connected to a gas, oil or Electric/Heat pump system with existing ductwork. - Page 8 RIGHT SIDE – Minimum clearance to combustibles on the right side of the furnace is 2” ACCESS FOR SERVICE AND MAINTENANCE – The remaining clearances shown above are required to allow access to components during service and maintenance. SCF-Revolution Manual...

- Page 9 PL Vent with the use of corn. ATTENTION BATTERY BACKUP: Battery backup system are useful if the furnace is installed using horizontal venting only. This prevents any smoke from entering your home in the event of a power failure. SCF-Revolution Manual...

-

Page 10: Exhaust Venting

High temperature ceramic roping reduces potential fly ash escaping through joints. Stainless steel inner liners resist corrosive flue gas damage to the system. Flex pipe should be stainless steel, 4 ply construction with a total thickness of approx. .07 inches. SCF-Revolution Manual... -

Page 11: Venting-Typical Pl Vent Components

TYPICAL PL VENT COMPONENTS RAIN CAP VERTICAL OR WALL THIMBLE CHIMNEY SUPPORT BRACKET HORIZONTAL ADAPTER ADJUSTABLE LENGTH SINGLE TEE SINGLE REDUCTION DOUBLE TEE PIPE w/TEE CAP TEE w/TEE CAP w/TEE CAP PIPE ADAPTER INCREASER ELBOW ELBOW SCF-Revolution Manual... -

Page 12: Venting: Determining Materials

PL vent elbow (45 or 90 degrees). Note: End caps or elbows must vent exhaust gases away from the building. 4. For termination above the building roofline a rain cap is required. 5. The exhaust pipe on all Furnaces is 4” O.D. to accommodate a pipe adaptor. SCF-Revolution Manual... -

Page 13: Venting: Termination Requirements

4a. Figure 4a 4’ (1.2 m) BELOW a door, window, cavity, or air vent 4’ (1.2 m) HORIZONTALLY FROM a door, window, cavity, or air vent 1’ (305 mm) ABOVE a door, window, cavity, or air vent SCF-Revolution Manual... - Page 14 50000 BTU/Hr shall be located not less than 12” from the opening. Figure 4b 1’ (305 mm) ABOVE, BELOW OR HORIZONTALLY FROM a door, window, cavity, or air vent. SCF-Revolution Manual...

-

Page 15: Venting: Termination Clearance Requirements

1’(305 mm) FROM The wall penetration point 3’ (915mm) FROM a gas meter/regulator assembly 2’ (610 mm) FROM any adjacent combustibles such as: Adjacent buildings, fences, protruding parts of the structure, roof eaves or overhangs, plants, shrubs, etc. SCF-Revolution Manual... -

Page 16: Venting Into An Existing Chimney

3. Venting into the side of an existing masonry chimney must be done through a masonry thimble. When wall penetration is necessary to access a masonry chimney, use a listed PL vent wall thimble. (Figure 6). 4. When venting into a Class A steel chimney use an appropriate PL Vent adapter. SCF-Revolution Manual... -

Page 17: Combustion Air

Use an elbow or shield to prevent prevailing winds from blowing directly into the outside air intake pipe. NOTE: Mesh screen should be no smaller than one-fourth inch (1/4”) by one-fourth inch (1/4”). WARNING: OUTSIDE COMBUSTION AIR IS REQUIRED FOR ALL MOBILE HOME INSTALLATIONS! SCF-Revolution Manual... -

Page 18: Connecting To Existing Duct Work

SCF-Revolution connects to the Supply Plenum of the existing furnace. Back Draft Dampers must be used in the SCF-Revolution Warm Air duct and in the Warm Air Plenum of the existing furnace to prevent the airflow from reversing. It is recommended to enter the Supply plenum of the existing furnace above the Air Conditioning A coil. -

Page 19: Fan Limit Control

Factory settings are shown in figure 10. The Fan limit has a Break-Away Tab that has been removed. When replacing a Fan Limit Control, be sure to remove the tab as shown in figure 10. Figure 10 SCF-Revolution Manual... -

Page 20: Mobile Home Installation

MOBILE HOME! FAILURE TO DO SO MAY CREATE NEGATIVE PRESSURE WITHIN THE MOBILE HOME AND COULD DISRUPT PROPER VENTING AND OPERATION OF THE PELLET FURNACE. CAUTION: THE STRUCTURAL INTEGRITY OF THE FLOORS, WALLS, CEILING AND ROOF MUST BE MAINTAINED. Figure 11 SCF-Revolution Manual... -

Page 21: Thermostat Connections

10. PL Vent must be used for exhaust venting. (Single wall vent is not allowed). Follow PL Vent manufacturer’s installation directions and observe all listed clearances to combustibles. DO NOT CONNECT THE SCF-REVOLUTION FURNACE TO A DOWN FLOW FURNACE SYSTEM. -

Page 22: Scf-Revolution Operation

The chimney and chimney connector should be inspected at least once every two months during the heating season to prevent the system from getting plugged with Fly ash. Clean the exhaust system if needed. Use of an appropriately sized chimney brush or the Services of a Professional chimney sweep are recommended. SCF-Revolution Manual... -

Page 23: Approved Fuels

Read the section covering Daily, Periodic and Yearly Maintenance for proper Maintenance Schedules. The Furnace is not warranted against damage caused by using poor pellets or other fuels not approved for use in this furnace, incorrect operation, improper maintenance, or incorrect installation. SCF-Revolution Manual... -

Page 24: The Revolution Burn System

CAUTION: For more information on the proper alignment of all of the parts before removing and replacing the Revolution Pot, see figure 14 on the following page. Please familiarize yourself with the proper alignment before attempting to remove the pot. SCF-Revolution Manual... - Page 25 4 – Remove the side shields. (See figure 13) 5 – Remove the screw that holds the burnpot in place and lift the burnpot up and out of the stove. (See figure 13) 6 – Reverse steps to re-install the Revolution pot. SCF-Revolution Manual...

- Page 26 Clinker Cutters on the other. The drum will now drop out the bottom of the Pot Assembly. To Re-assemble the Pot Assembly reverse the steps above. (Be sure to place the drum with the drive coupling facing the Revolution gear motor) SCF-Revolution Manual...

-

Page 27: Self Ignition

Self ignition Figure 16 The Multi-Fuel pot used in the SCF-Revolution furnace uses a Dual Hopper (See Figure 16). The Dual Hopper feature is a Patent Pending Ignition System using pellets to ignite the furnace and automatically switch over to Corn, Wheat, Rye, Cherry Pits or Distiller’s Grain after ignition has taken place. -

Page 28: Operating Instructions

OPERATING INSTRUCTIONS A different type of heater. The SCF-Revolution is a furnace. FOLLOW THESE OPERATING INSTRUCTIONS EXACTLY AS STATED TO ENSURE SAFE AND RELIABLE OPERATION. 1. Carefully read this “Operation and Maintenance” manual in its entirety BEFORE lighting your Furnace for the first time. -

Page 29: Control Board Features

Thermostat Mode and an LED Light bar that indicates which of the 5 Heat Settings the Furnace is running on. The LED Light bar is also used during the Diagnostic process, see page 38 for more details. Figure 17 SCF-Revolution Manual... -

Page 30: Thermostat Function

If the Thermostat does not call for heat during that hour the furnace shuts off and re-lights itself the next time the Thermostat calls for heat. This setting is best used during early Fall or late Spring, when constant heat is not needed. SCF-Revolution Manual... -

Page 31: Pre-Lighting Instructions

The damper must be adjusted for each specific fuel as well and should be set before the first fire as well. To adjust the damper for other types of fuel, use the following procedures: First turn the setscrew clockwise until it stops against the tube. See figure 18. Figure 18 SCF-Revolution Manual... -

Page 32: Changing The Program On The Control Board

Flash will indicate which program running. Program 1 – LED lights flash once Program 2 – LED lights flash twice Program 3 –LED lights flash three times Program 4 – LED lights flash four times Figure 20 SCF-Revolution Manual... -

Page 33: Lighting Your Furnace

The board will check for P.O.F. again. If the board still fails to sense the Proof of Fire switch the Furnace will go into “Safety shutdown” (See section on Diagnostic Features on page 38.) If this happens, repeat the process. SCF-Revolution Manual... -

Page 34: Shutting Off The Furnace

If you see a lot of unburned fuel in the pot, an adjustment may be needed. In an unbalanced pot, the corn, wheat or rye will quickly stick together and prevent the proper flow of combustion air. The pot will overload and the fire will go out. SCF-Revolution Manual... - Page 35 After making an adjustment wait at least 15 minutes to see how the burn pot reacts to the change. Terminology used when burning Corn, Wheat, Rye of Distiller’s Grain 1. Balanced burn pot. This means the corn rapidly turns into red-hot coals once it is in the burn pot. SCF-Revolution Manual...

- Page 36 Remember: Only turn the setscrew one 1/2 turn clockwise to open the damper. Wait 15 minutes to see if the burn pot becomes balanced. Repeat this step as many times as needed until the burn pot becomes balanced. SCF-Revolution Manual...

- Page 37 ½ turn counterclockwise and bring the damper blade up against the screw. Wait 5 – 10 minutes before attempting another adjustment. An occasional wisp of black smoke is normal every now and then. SCF-Revolution Manual...

-

Page 38: Diagnostic & Safety Features

“Power Reset” - If the board becomes unresponsive for a long period of time, you must unplug the Furnace, wait 10 seconds and plug the Furnace back in to reset the board. SCF-Revolution Manual... -

Page 39: Pilot Settings &Thermostat Control

WARNING: These safety features are designed to protect life and property. Bypassing these features voids all warranties and the safety listing of the Furnace. The SCF-Revolution has been Safety Tested by an accredited, independent laboratory. Pilot Settings &Thermostat Control The Furnace may be controlled with a thermostat to help maintain a more constant temperature. -

Page 40: Scf-Revolution Maintenance

Use of a glass cleaner ONLY permitted when the Furnace is cold. CAUTION: Do not slam the door. Do not operate the Furnace with a broken or cracked glass. Replace only with heat resistant ceramic glass supplied by the manufacturer. SCF-Revolution Manual... -

Page 41: Periodic Maintenance

If the holes in the pot remain plugged, remove the Burnpot, (as shown in Figure 12 on Page 23) and use a small metal object (Nail, Drill Bit, etc) to clean out plugged holes. Figure 22 SCF-Revolution Manual... - Page 42 Figure 24 on the next page) Clean the baffle on a regular basis. Frequency of cleaning depends on amount of fuel being burnt and the quality of the pellets. Fuel with low ash content is recommended. Failure to clean the baffle can cause the Furnace to become plugged with fly ash. SCF-Revolution Manual...

- Page 43 2. Gaskets. Periodically inspect the condition of the rope gasket around the door, window and ash door. Replace as needed. 3. Air Filter. Check the Return Air Filters at least once a month and replace when needed. The size of the filter is 1” X 16” X 25”. SCF-Revolution Manual...

-

Page 44: Yearly Maintenance

Many dealers offer a Service Contract that will cover Yearly Maintenance. Contact your St. Croix Dealer for assistance in maintaining your Furnace in top condition. Yearly Maintenance Yearly maintenance is designed to assure safe operation, prolong the life of the Furnace and help preserve its aesthetic appeal. -

Page 45: Safe Operation

Corn/Pellet-burning heater. If creosote has accumulated, it should be removed to reduce the risk of a chimney fire. 4. Do not Overfire this unit. Follow all instructions regarding the proper use of this heater. SCF-Revolution Manual... -

Page 46: Wiring Schematic

15 Amp. A dedicated circuit for the furnace is recommended. CAUTION: The electrical components of the Furnace are not owner serviceable. Call your dealer for proper diagnosis of electrical problems and service to those components. SCF-Revolution Manual... -

Page 47: Parts Layout

Parts Layout Figure 27 SCF-Revolution Manual... - Page 48 Parts Layout - Continued Figure 28 SCF-Revolution Manual...

- Page 49 CONTROL COVER ASSEMBLY 80P30333 CONTROL BOARD 80P30431 AUGER MOTOR RELAY 80P20038 PROOF OF FIRE SWITCH 80P30446 COMBUSTION FAN 80P52628 VACUUM SWITCH 80P52710 VACUUM SWITCH BRAKET 80P53805 EXHAUST ADAPTER PLATE ASS. 80P20168 COMBUSTION FAN GASKET 80P53804 QUICK CONNECT PIPE ADAPTER SCF-Revolution Manual...

- Page 50 IGNITER TUBE WELDMENT 80P53887 REVOLUTION POT – MULTI FUEL 80P30316 POT SIDE SHIELD 80P30155 TUBE SCRAPER RODS 80P30094 HOT AIR BOX 80P53800 FIREBOX DOOR - COMPLETE 80P53677 HANDLE MOUNT PLATE - ONLY 80P53707 HANDLE - ONLY 80P53795 CABINET FRONT SCF-Revolution Manual...

-

Page 51: Additional Canadian Installation Requirements

CLEANING OF THE HEAT EXCHANGER, FLUE PIPE, CHIMNEY AND DRAFT INDUCER IS ESPECIALLY IMPORTANT AT THE END OF THE HEATING SEASON TO MINIMIZE CORROSION DURING THE SUMMER MONTHS CAUSED BY ACCUMULATED ASH. h. Do Not Use Chemicals or Fluids to Start The Fire. SCF-Revolution Manual... -

Page 52: Installation

The installation of this furnace should comply with the requirements of CAN/CSA- b365. and changes to the installation should comply with CSA B139 (for oil fired), C22.1 (for electric), or CAN/CGA-B149.2 (for gas fired). SCF-Revolution Manual... -

Page 53: Troubleshooting & Frequently Asked Questions

Proof of Fire Switch no longer senses a fire in the Furnace. First check to see if there are pellets in the hopper. If there are pellets in the hopper, why did the Furnace go out? SCF-Revolution Manual... -

Page 54: Operation

Check the fuse on the back of the control board. Replace with a 125 Volt, 5 Amp fuse. Why is my glass dirty? Normal operation of your St. Croix Corn/Pellet Furnace will produce a white build-up on the glass that wipes off with a dry paper towel. However extended burning on the low setting only will produce a tan color. - Page 55 LED’s. The default setting is the center LED. This gives 2 adjustments increasing the voltage (LED’s 4 & 5) and 2 adjustments decreasing the voltage. (LED’s 1 & 2) The voltage is increased or decreased 2.5 volts with each adjustment. Figure 30 SCF-Revolution Manual...

- Page 56 Step 4 – Observe the LED light flashing as described in point 10 above. Changing the Cycle Time will change the BTU Input of the furnace. The longer the Cycle time the lower the BTU rating. Figure 32 SCF-Revolution Manual...

-

Page 57: Warranty

This warranty gives you specific legal rights, and you may have other rights, which vary from state to state. SCF-Revolution Manual... -

Page 58: Furnace Settings & Notes

PELLETS – CORN – WHEAT - RYE - CHERRY PITS - DISTILLER’S GRAIN PROGRAM: Circle one (see Figure 20 on page 32) Serial Number: Date of Purchase: Dealer Information: Even Temp, Inc. P.O. Box 127 Waco, NE 68460 PHONE: 402-728-5255 FAX: 402-728-5379 EMAIL: SUPPORT@EVENTEMPINC.COM WEB ADDRESS: www.eventempinc.com SCF-Revolution Manual...

Need help?

Do you have a question about the SCF-Revolution and is the answer not in the manual?

Questions and answers