Table of Contents

Advertisement

Quick Links

Save This Manual

_

For Future Reference

S£/ARS

owner's

manual

MODEL NO.

113.196380

Serial

Number

Modet and serial numbers

may be found

at the front

of the base,

You should record both

model

and serial number

in

a safe place

for future use.

FOR YOUR

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY

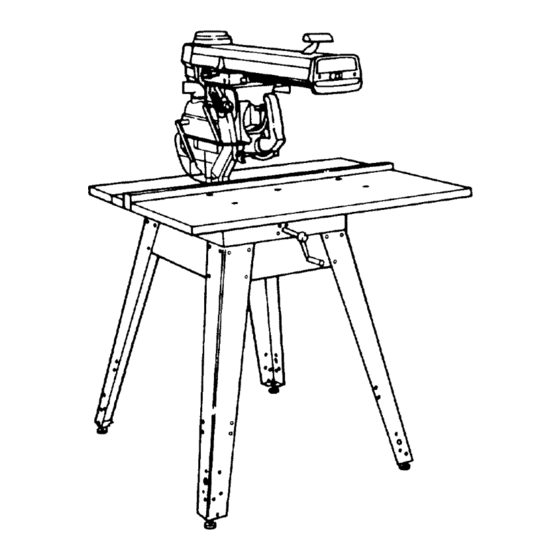

SEARS/CRAFTSMAN

10-1NCH RADIAL SAW

• assembly

• operating

• repair parts

\

J

Sears Roebuck

and Co., Hoffman

Estates, IL 60179

U.S.A.

Part

No, SP5976

Printed

in U,S.A,

Advertisement

Table of Contents

Summary of Contents for Craftsman 113.196380

- Page 1 Number Modet and serial numbers may be found at the front of the base, You should record both model and serial number SEARS/CRAFTSMAN a safe place for future use. 10-1NCH RADIAL SAW FOR YOUR SAFETY: • assembly • operating READ ALL •...

- Page 2 Ripping ........................Cutting Aides ......................Accessories ......................Maintenance ......................Troubleshooting ..................... Repair Parts ......................FULL ONE YEAR WARRANTY ON CRAFTSMAN STATIONARY TOOL If, this stationary tool fails due to a defect in material or workmanship within year from the date of purchase,...

- Page 3 Safety Major Hazards This manual has safety information instructions to help users eliminate or reduce Three major hazards are associated with the risk of accidents and injuries, including: using the radial arm saw for ripping. They 1. Severe cuts, and loss of fingers or other are outfeed zone hazard,...

- Page 4 Safety Kickback Hazard Kickback is the uncontrolled propelling WARNING the workpiece back toward the user during ripping. The cause of kickback is the binding or ,0._.._ pinching of the blade in the workpiece. Several conditions can cause the blade to bind or pinch.

- Page 5 Safety Guard Function and Features "I]_eguard is a very important safety feature, designed to reduce the risk of injury associ- ated with blade contact. Install the guard correctly. Follow the specific instructions in the ripping and crosscutting sections to set and use the guard correctly for each type of cut.

- Page 6 Safety the riving knife/pawls knob. When lowered for crosscutting, it acts as a barrier to the leading edge of the blade. 6. Set of pawls to be lowered to the work- piece surface for ripping. They allow workpiece to pass freely from infeed to out- feed side, but help stop the kickback...

- Page 7 Safety Safety Instructions Read and follow all safety instructions. Personal Safety Instructions 1. Wear safety goggles labeled "ANSI Safety Goggles Z87.1" on the package. It means the goggles meet impact standards set by the American National Standards Institute. Regular eye- glasses are not safety goggles.

- Page 8 Safety Saw Safety Instructions 1. Use guard, pawls and riving knife accord- 6. Before turning on saw, clear table of all ing to instructions. Keep them in working objects except workpiece to be cut and nec- order. essary fixtures, clamps, or feather-boards.

- Page 9 Safety 3. Rip only workpieces longer than the diameter of the blade. Do not rip workpieces that are shorter than the diameter of the blade being used. 4. Workpieces that extend beyond the saw table can shift, twist, rise up from the table, or fall as they are cut or afterwards.

- Page 10 Safety On-Product Safety Labels Note where they are located on the saw. Read and follow the safety information There are several safety labels on the saw. and instructions in these labels. Refer They alert the user to hazards explained the manual for detailed explanations the manual...

- Page 11 Safety Near the saw handle is this safety label to kWARNING alert you to thrown objects and to remind you to wear safety goggles: On the clear plastic guard is this OSHA required label: TO AVOID INJURY SHUT OFF POWER BEFORE CLEANING WARNING:...

- Page 12 Assembly Introduction In order to get the most enjoyment out of your radial saw it is important that the machine by properly assembled, adjusted, and aligned. This procedure, although not difficult, takes time; perhaps eight hours or longer for the inexperienced user.

-

Page 13: Table Of Contents

Assembly 5/16" diam. hex nut (4) i i,,,,.,,,,,,,o square head'screw 1/4" diam. hex nut (4) @l,lilllllllllllllllll! 1/4.-;ox long pan head screw 1/4" hex "L_ 1/4" - 20 x 1-3/4" long pan head screw 3116" hex "L_ @]_l]_ #6 - 32 x 112 pan head screw wrench (2) IIIIIIIII ILl #10 - 32 x 7t8"... - Page 14 Assembly crank arm cap © 1/4" external tooth 1/4" diam. x 5/8" long truss head screw (24) lockwasher (24) foot (4) leveling 5/16" diam. external lockwasher 3/8" diam. hex nut 11/32" x 11/16" x 1/16" washer (8) 5/16" diam. hex nut 5/16"...

- Page 15 Assembly WARNING 5. Install one 3/8-16 hex nut completely onto each of the leveling feet. Insert one leveling Plugging in saw during assembly foot through hole in bottom of each leg and could result in electrical shock, install a 3/8-16 hex nut.

- Page 16 X in top of Stiffener legs. 3. Install screws, washers and nuts as shown. If you mount the saw on any other Craftsman base or flat bench, make sure Elevation Crank has proper clearance rotate.

- Page 17 Assembly Attaching Carriage - Motor to Arm Remove carriage stop screw, lockwasher tag. Read and understand warning tag before discarding. Lock miter/arm lock before proceeding. Push toward rear of saw to lock Holding carriage assembly with both hands, Miter/Arm Lock Lever carefully start and slide the carriage onto the...

- Page 18 Assembly Remove saw blade. 1. Tighten carriage lock knob, located right side of ann. 2. Loosen guard clamp screw approximately 4 turns. Pull down to loosen 3. U_ one hand to lift the clear plastic guard Blade at the front of the saw. Rotation 4.

- Page 19 Adjustments Arm Lock Adjusting Wheel Miter/Arm Lock Lever With the aml at an "'unindexed" position the miter lock applied, the locking action should feel tight and secure. Considerable effort should be required move the arm back towards 0 °. Its is always possible to force the arm because of the...

- Page 20 Adjustments Yoke Clamp Adjustment Yoke Lock Handle lb check the yoke clamp adjustment follow these steps: 1. Pull the yoke lock handle towards front of saw to unlock yoke. Pull forward the yoke index lever (on the left side of car- riage) to disengage index...

- Page 21 Adjustments Bevel Lock Lever The purpose of the bevel lock lever is to lock the motor at any angle. To check follow these steps: Bevel 1. Unlock the bevel lock lever. Move Index bevel index pin to the left and rotate the saw to approximately 30 °.

- Page 22 Adjustments Arm to Column Adjustment If you can move the end of the radial arm up and down when the ann is unlocked, adjust as directed below: 318-16 Bolts a. Remove two (2) screws from rear cover plate. Tighten evmfly top two 3/8-16 bolts until arm moves firmly.

- Page 23 Adjustments 3. Rotational Alignment Check: While holding the ann with one hand, hold fingers of other hand as shown, between column tube and coluiml support. Apply gentle side-to-side pressure at end of arm. Any side-to-side or rotational movement can be felt with finger at arrow location.

- Page 24 Adjustments Adjusting Carriage Bearings If the carriage bearings are loose it not only allows the saw blade to move up, down, sideways but also results in inaccurate cuts. Before following these steps make sure the tracks (steel rods) and carriage bearings have been cleaned...

- Page 25 Adjustments Positioning Table Supports/Installing Front Table!Leveling Front Table Note: The goal in adjusting the table supports" and leveling the front table is to make sure that the table is the same dis'tance from the radial arm at all points. This ensures that when the table and blade are installed the clearance...

-

Page 26: Diam. Hex

Adjustments Installing Front Table 1. Set out: - front table - tee nut - 1/4" U-clip - 1/4" diam. x 7/8" long cup point set DIlllll llllllltD screw - four 1/4" diam x 1" long pan head screws - 1/4" diam. x 1-3/4" long pan head screw - five 17/64"... - Page 27 Adjustments 5. Drop a flat washer into each counter- bored hole. 1/4-20 x 1" 6. Start 1-3/4" long pan head screw through Pan Head Screw 1/4-20 x !-314" 17/64" center hole and into U-clip, but do not fully Pan Head Screw Flat Washer tighten.

- Page 28 Alignment _WARNING This section applies to all three models cov- ered by this manual. Plugging in saw during alignment could result in accidental start-up The saw and blade must be aligned correctly and severe cuts from contact with for two reasons: spinning blade.

- Page 29 Ali nment 3. Lower ann until saw blade just clears Miter/Arm Lock Lever front table. Lock the yoke lock handle bevel lock lever. 4. Place a framing square on the table, as shown, with one leg of square firmly against rear edge of front table.

-

Page 30: Table Clamp

Alignment Install Table Clamps 1. Insert fence, then spacer table, then rear table. Front Spacer Rear Table Fence Table Table 2. Set out two unassembled table clamps: - two cup washers - two clamp brackets - two square nuts - two thumbscrews 3. - Page 31 AI" nment Bevel Square Blade to Table Indicator Crosscutting The goal of this adjustment is to make blade square to the table so that crosscuts will be accurate; otherwise all crosscuts will have a slight bevel angle. 1. Lower blade until it just clears front table. Lock bevel, miter, rip, and yoke locks.

- Page 32 Alignment Square Blade to Fence The goal in setting the blade square to the Left Hand fence is to reduce the risk of kickback when Carriage Cover ripping. This adjustment will also reduce splintering of the workpiece and burning the kerf during ripping and crosscutting.

-

Page 33: Fiat

Alignment Make Blade Parallel to Table The goal of this adjustment is to keep the workpiece from being thrown or damaged. This adjustment will also reduce splintering of the workpiece and burning of the kerf during ripping and crosscutting. 1, Lock arm in straight crosscut position. -

Page 34: Rip Scale

Alignment Installing and Adjusting Rip Scale Indicators. Screw #6-32 x 1/2 Note: The rip scales and pointers are intended to be used for quick settings. For greater accuracy, take direct measurement between blade and fence. Rip Scale 1. Pre-assemble indicator and twin nut. Indicator Loosen but do not remove two screws which attach left hand carriage cover. - Page 35 Alignment 6. The blade "Out-Rip" scale indicator left hand side of the radial am1 is adjusted essentially the same manner as blade "In- Rip" indicator, except position blade with 2 inches between fence and face of saw blade. The rip-scale indicator should be positioned...

- Page 36 Alignment Align Riving Knife to Blade The goal of this adjustment is to position riving knife directly in line with the blade. Riving knife alignment is an important safe- Pawls ty factor. The riving knife tides in the keff of Fence the cut workpiece during...

-

Page 37: Yellow

Controls Bevel index Lever Miter/Arm Lock Lever On-Off Switch Yellow Key Function Control Operation/Commen Miter/Arm Lock Pull lever forward to release Frees radial arm to move; locks in any desired position; pre-set index then swing arm left or indexed positions at 0°, 45°L, right 45°R HoM in unlocked... - Page 38 Controls Yokelndex Lever Table Clamp Bevel Lock Lever Elevation Cran_ Function Control Operation/Comments Bevel LockLever Frees motor to rotate; locks in Pull lever to release and push to lock any desired position Support motor before unlocla'ng because it can swing down quickly Bevel...

- Page 39 Controls Rip Scale & Rip Indicator Rip Lock Yoke Lock Handle Handle Bevel Lock Lever Control Function Operatior(Comments Yoke Lock Handle Locks yoke in rip or crosscut Pull handle forward to release; position push handle reward to tighten Yoke index lever must be un- indexed before rotating...

- Page 40 Controls Guard Clamp Screw Guard p,_-J_J| Pawls/Riving Knife Knob "°_nDo;Wn Riving Knife Bracket HoldDown Control Function Operation/Comments Secures guard to motor; frees Turn counterclockwise Guard Clamp Screw guard for removal loosen, clockwise to tighten Guard Protects against contact with Upper part remains fixed in upper blade;...

- Page 41 Controls Pawls/Riving Knife Knob Guard Pawls Riving Knife Function Control Operation!Comments Guard Provides manual way to raise Push and hold until workpiece clear plastic guard during rip- clears guard, then release ping when workpiece fails to raise it Turn counterclockwise Pawls/Riving Frees pawls and riving...

- Page 42 Electrical Connections WARNING Motor Specifications If not properly grounded, this power °12qe AC motor used on this saw is a capaci- tool could cause electrical shock, tor-start, non-reversible type. The model particularly when used in damp covered in this manual has the following locations.

- Page 43 Electrical Connections WARNING Grounding To maintain proper tool grounding, if outlet you are planning to use for this power tool is a 2-prong type do 3-Prong _=_===_ Make .Sure This not remove or alter grounding prong in any manner. A Known Ground An adapter is available for connecting P%__ Is Connected...

- Page 44 Electrical Connections Dual Voltage Motors Models 113.196321 and 113.196421 ONLY! To Change Motor Voltage to 240 A.C. Under normal home workshop conditions, full voltage is supplied to the motor, your saw will operate efficiently on 120V. If any of the following conditions exist, it will be advisable...

- Page 45 Crosscutting Straight Bevel Crosscutting Defined Miter Compound Crosscutting is cutting a workpiece length. Tile workpiece is held firmly against the fence, and the blade is pulled through the workpiece to make the cut. Straight, bevel, miter, and compound cuts can be made. Rolling Carriage Crosscutting...

- Page 46 Crosscuttin Crosscut Kerfs A keff or shallow cut is needed in the table and fence to serve as a path for the blade to ensure that the blade cuts all the way through the workpiece. A kerr is needed each different cutting path.

- Page 47 Crosscuttin Making Crosscuts Follow these steps to make crosscuts. 1. Prepare table: - put fence in front position - tighten table clamps 2. Prepare blade: - lock blade in crosscut position - lock radial arm at desired miter angle - lock motor at desired bevel angle*...

- Page 48 Crosscutting Repetitive Crosscutting Carriage Stop Repetitive crosscutting is the repeated and continuous cutting of many pieces of lumber to the same length. Carriage and length stops can help make this type of crosscutting more efficient. A carriage stop defines the distance needed to pull the blade through to complete each cut.

- Page 49 Ripping Ripping Defined Ripping is changing the width of a work- piece by cutting along its length. The work- piece is fed into the blade, which rotates in a fixed position, parallel to the fence and a set distance from the fence. A solid fence (no kerfs) serves as a guide for the workpiece.

- Page 50 Ripping Workpiece Positioning Always set up so that the wider part of the workpiece is between the blade fence. This gives you greater clearance push sticks, and allows better stability feeding the workpiece. Push Sticks and Push Blocks Use push sticks and push blocks instead of Example: To rip 2"...

- Page 51 Ripping Outfeed Zone Hazard DANGER Rotational force of blade can pull kDANGER hands and fingers back into blade. Touching, holding, or pulling outfeed side of workpiece while blade is still spinning will result in fingers, hand or arm being cut off. To reduce risk of outfeed hazard: v' Set pawls and riving knife;...

- Page 52 Ripping To reduce risk of kickback: _/Push workpiece through from infeed to outfeed side until it is completely past Set pawls and riving knife according pawls. ripping set-up procedure. Correctly set _/Use featherboard (see Cutting Aides). riving knife is more likely to prevent workpiece from binding or pinching ",/Keep hands away from outfeed side.

- Page 53 Ripping Hold Down Function ]-he hold down must be set correctly during ripping to act as barrier against the infeed side of the blade, to help keep the workpiece flat on the table, and to deflect workpiece chips. It must be lowered to just clear the workpiece.

- Page 54 Ripping WARNING Ripping Set-up Procedure If workpiece is pushed along fence Follow these steps before ripping. with kerfs, workpiece could These steps must be repeated each time a caught on kerf, pinch blade different thickness workpiece is ripped. cause kickback. Do not use cross- kerf must be made...

- Page 55 Ripping 8. Remove workpiece from table. 9. Ready push stick or push block. 10. Set up table extension(s) and support their outer ends. Do not use another person to support workpieces because this can cause kickback and it exposes helper to polential hazards at outfeed side.

- Page 56 Ripping 2. Insert yellow key and turn saw on. 3. Stand at infeed side and out of line of workpiece, in case of kickback. Start finish cut from infeed side. 4. Put workpiece on table, in front of hold down, and tight against fence.

- Page 57 Ripping Dado Blades, Molding Heads Sec, Accessories for information on safety, installation and use of dado blades and molding heads. Edging Edging is the use of a dado blade or molding head in the horizontal position. It is an advanced technique that requires a molding...

- Page 58 Cutting Aides Before cutting any wood on your saw, study Push Stick SLIGHTLY LESS THAN THICKNESS OF WORKPIECE all of the Crosscutting and Ripping Instructions found on pages 45 through 57. a/4" up TO a/8"-.x. As you learn new radial arm saw wood- working techniques, you'll see that many 1.

- Page 59 Cutting Aides Making the Handle: Cutting out the handle • Miter crosscut a piece of 3/4" thick ply- wood to the shape and size shown. mitered corners can be any size that looks like the drawing (about 1-1/2" by 1-1/2"). 1-112"...

- Page 60 Cutting Aides Clamp the featherboard to the front table, so that the angled edge of the featherboard against the workpiece on the infeed side of the blade. Do not clamp the featherboard against the cut off part (out-feed side) of the workpiece.

- Page 61 Accessories Information for Dado Accessories Safety 1. Use o1_y accessories listed in this section. 1. Put inside loose collar on arbor shaft first, Use of any other accessory' or attachment then install dado. Tighten blade nut directly might increase the risk of injury to you or against outside...

- Page 62 Accessories Accessories for this Saw These accessories are designed to fit this saw. Read and follow instructions that come with accessory. Item ............. Catalog Auxiliary Table Cover ........see catalog Blades (10" with 5/8" hole) ......see catalog Dado Blades Adjustable Dado 7"-24 tooth carbide ........

- Page 63 Maintenance General Information Here When new, the saw requires no lubrication. "llw saw has been partially aligned and all bearings are lubricated and sealed for life. In time, in order to keep the saw in good work- ing order, it will be necessary to clean, lubri- cate and re-align.

- Page 64 Maintenance Replacing Pawls Make sure the teeth of the pawls are always sharp. If they become dull the pawls must be replaced: 1. Use 7/16" wrench to remove hex nut. Remove old pawls. 2. Install new pawls. Place spacers exactly as shown.

- Page 65 Troubleshooting HAVE YOU FOLLOWED ALL STEPS OF THE ALIGNMENT PROCEDURE? IF YOU HAVE FOLLOWED THEM IN THEIR PROPER SEQUENCE, YOU CANNOT EXPECT ACCU- RATE CUTTING RESULTS. In addition to the proper alignment of your This Edge of Board Against Fence For All Cuts Fence saw, you must also become familiar...

- Page 66 Troubleshooting What to Do Motor Problem Possible Cause(s) Motor overheats or stalls Reduce line load by removing Overloaded power line other lights, appliances Slow down rate of feed Feeding rate too fast Vacuum sawdust from motor to Improper motor cooling allow normal air circulation Saw blade has heel Check alignment...

- Page 67 Troubleshooting What to Do Cutting Problem Possible Cause(s) Inaccurate Loose locks Check miter, rip, bevel, and swivel locks. See Adjustments section Saw blade out of alignment Check alignment Crosscuts not accurate at indexed Sawdust between workpiece Keep front table clean fence miter positions Replace fence...

- Page 68 Troubleshooti What to Do Possible Cause(s) Cutting Problem Workpiece strikes riving knife dur- Riving knife not in line with blade Align riving knife to blade ing ripping Saw blade out of alignment Re-align Workpiece binds, smokes, and motor slows or stops when ripping Warped workpiece Do not cut severely warped pieces Feed rate too fast...

- Page 69 Notes...

- Page 70 PARTS LIST FOR CRAFTSMAN 10" RADIAL SAW MODEL NUMBER 113.196380 "0 ImlBB II 24 25 26 27 FIGURE 1...

- Page 71 PARTS LIST FOR CRAFTSMAN 10" RADIAL SAW MODEL NUMBER 113.196380 Always order by Part Number - Not by Key Number FIGURE 1 Part Part Description Description 821368 63518 Cord, with Plug Table, Spacer 63432 75090 Cover, Rear Arm Fence, Rip...

- Page 72 PARTS LIST FOR CRAFTSMAN 10" RADIAL SAW MODEL NUMBER 113.196380 "O "13 FIGURE 2...

- Page 73 PARTS LIST FOR CRAFTSMAN 10" RADIAL SAW MODEL NUMBER 113.196380 FIGURE 2 - YOKE ASSEMBLY Part Part Description Description STD601105 * Screw, Type "T" Pan Rec. Hd 63651 Stud, Motor 10-32 x 1/2 63469 Bushing, Rubber 63661 63642 Yoke Cover, L.H. Carriage...

- Page 74 ,.,q PARTS LIST FOR CRAFTSMAN 10" RADIAL SAW MODEL NUMBER 113.196380 _111 _-----4 43 --..,,._\\ 28 42 41 FIGURE...

- Page 75 PARTS LIST FOR CRAFTSMAN 10" RADIAL SAW MODEL NUMBER 113.196380 Always order by Part Number - Not by Key Number FIGURE - 3 BASE ASSEMBLY Part Part Description Description STD503705 * Screw, Soc. Set 3/8-16 x 1/2 63614 Bearing 63623...

- Page 76 ..,j PARTS LIST FOR CRAFTSMAN 10" RADIAL SAW MODEL NUMBER 113.196380 "O Always order by Part Number - Not by Key Number "O Location of Lower Guard • Screw Guard Slot _J_= "_! Washer Lower Lower Inner Guard DETAIL "A"...

- Page 77 PARTS LIST FOR CRAFTSMAN 10" RADIAL SAW MODEL NUMBER 113.196380 Always order by Part Number - Not by Key Number FIGURE 4 - GUARD Part Part Description Description 820519 821217 Screw, Guard Clamp Nut, Slotted 1/4 - 20 821313 Link, Pulr...

- Page 78 Repair Parts PARTS LIST FOR CRAFTSMAN 10" RADIAL MODEL NUMBER 113.196380 _;k_i/ , l O--__--t) THIS PART IS REMOVED. _'-_ -_L__- - -_- I _ j DISCARD AND REPLACE .8-"_ __J r /I0*1 WITH A NEW PUSH NUT.._.._j...

- Page 79 Repair Parts PARTS LIST FOR CRAFTSMAN 10" RADIAL MODEL NUMBER 113.196380 FIGURE 6 - LEG Part Description Description 821343 STD551031 *Washer, 11/32 x 11/16 x 1/16 60314 STD551131 Screw, Truss Hd. !/4-20 X 5/8 * Lockwasher, External 5/16 821779 STD541231...

- Page 80 SEARS owner's 10-1NCH RADIAL SAW manual SERVICE For the repair or replacement parts you need Call 7 am - 7 pro, 7 days a week MODEL NO. 1-800-366-PART 113.196380 (1-800-366-7278) For in-home major brand repair service Call 24 hours a day, 7 days a week 1-800-4-REPAIR (1-800-473-7247) For the location of a...

Need help?

Do you have a question about the 113.196380 and is the answer not in the manual?

Questions and answers

Do they make wheels to fit the stand on this saw? And if so where can I order , and part number ?