Table of Contents

Advertisement

Quick Links

INSTALLATION INSTRUCTIONS

Recognize this symbol as an indication of important Safety Information!

!

OWNER INSTRUCTIONS, DO NOT DESTROY

NOTE: FLUE GAS TEMPERATURES MUST NOT EXCEED 301

575

o

F AT VENT SYSTEM INLET.

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND

OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUST-

MENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRI-

CAL SHOCK, CARBON MONOXIDE POISONING, EXPLOSION, OR PERSONAL

INJURY OR PROPERTY DAMAGE.

DO NOT DESTROY. PLEASE READ CAREFULLY AND

KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

Copyright © 1995, Tjernlund Products, Inc. All rights reserved.

TJERNLUND PRODUCTS, INC.

1601 Ninth Street • White Bear Lake, MN 55110-6794

PHONE (800) 255-4208 • (651) 426-2993 • FAX (651) 426-9547

Visit our web site • www.tjernlund.com

MODEL SS1C

REV. 4 5/95

C

o

P/N 8504040

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for TJERNLUND SS1C SIDESHOT (DISCONTINUED VERSION-PRE UC1 UNIVERSAL CONTROL) 8504040 REV 4 0595

-

Page 1: Installation Instructions

MENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRI- CAL SHOCK, CARBON MONOXIDE POISONING, EXPLOSION, OR PERSONAL INJURY OR PROPERTY DAMAGE. DO NOT DESTROY. PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE. Copyright © 1995, Tjernlund Products, Inc. All rights reserved. P/N 8504040... -

Page 2: Table Of Contents

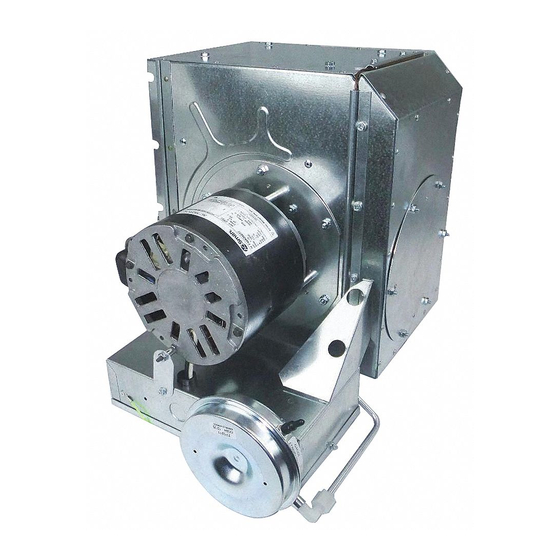

Template A Vent Hood Terminus ........................21 SideShot ® is a registered trademark of Tjernlund Products, Inc. for their Model SS1C Vent System. DESCRIPTION The SideShot is a mechanical vent system designed and listed for use with natural draft oil heating equipment. It is factory assembled and wired. -

Page 3: Installation Restrictions

GENERAL INFORMATION These units have been factory tested and rated in accordance with the following Canadian Standards: CAN/CSA - B140.0-M87 General Requirements For Oil Burning Equipment; CAN/CSA - B139-M91 Installation Code For Oil Burning Equipment; CAN3 - B255-M81 Mechanical Flue - Gas Exhausters. Each SideShot is electrically factory line tested before shipment. -

Page 4: Safety Inspection Of A Previously Used Appliance

3. The SideShot must be installed by a qualified installer (an individual properly licensed and/or trained) in accordance with all local codes or, in their absence, in accordance with “The National Building Code of Canada” CSA Std B139 & “The Canadian Electrical Code”... -

Page 5: Termination Clearances

PLENUM AND VENT HOOD CLEARANCE FROM COMBUSTIBLES With an inlet flue gas temperature of 301 o C (575 o F) or below, the SideShot has been Listed for the following clearances from combustible materials: IMPORTANT Vent Hood and top of Plenum: Zero Clearance Plenum front and sides: 1.3cm (1/2 inch) Plenum rear: 7.6cm (3 inches) VENT HOOD TERMINATION CLEARANCES... -

Page 6: Installation

INSTALLATION Tools required: • Reciprocating Saw • 1/2", 7/16", 5/8" Wrench • Drill and 1/8", 1/4", 1/2" Bits • 1/4" Masonry Drill Bit • Blade Screwdriver • 1/4", 5/16”, 11/32" Nut Runner or Socket • Wire Cutter/Stripper • Hammer • Tube Cutter INSTALLING VENT HOOD TERMINUS 1. -

Page 7: Installation Of Rain Shield

8. Slide the Vent Hood through the wall while taking care installing the rain shield as shown, (See Diagram E). The nuts located on the Vent Hood outermost casing should be facing up when sliding it through the wall. Mount Vent Hood to the exterior using four #8 x 3"... -

Page 8: Plenum Installation

CONNECTING THE PLENUM TO THE VENT HOOD NOTES: Cut any nails which are protruding downward from the subfloor that may come in contact with the SideShot. Place both slip joint drivers in your pocket before continuing. Minimum clearances from the Plenum to any combustible materials must be maintained as listed on page 4. Note: Blower - Motor/Wheel assembly can be removed to make Plenum section lighter &... -

Page 9: Installation Of Vent Pipe

If installing the bracket into a masonry wall, drill 2 holes at each point established in step 3 with a 1/4" masonry drill bit approximately 1" deep. Tap the masonry anchors into the holes drilled in step 4. Screw the wall bracket onto the wall. 5. -

Page 10: Electrical Wiring

5. Attach the vent pipe inlet collar to the rear inlet port making sure that the sensing tube is orientated as shown, (See Diagram M, Page 8). NOTE: Alignment marks on the inlet collar and plenum casing must match. 6. Attach 90 o compression fitting to the short tube on the inlet collar. 7. -

Page 11: Wiring To Oil Fired Appliance

SEQUENCE OF OPERATION WITH SIDESHOT INSTALLED ON OIL FIRED APPLIANCES: As the thermostat/aquastat senses a need for heat, the internal switch of the thermostat/aquastat will close. The switch closure sends current through the internal controls of appliance (e.g. high limit, low limit and all other safety controls the appliance is equipped with) and continues through the R8184G primary control. -

Page 12: Alternative Wiring Diagrams

SIDESHOT CONNECTED TO AN R8184G WITH THE APPLIANCE BURNER MOTOR LESS THAN 6.2 AMPS @ 120 VAC CONNECTION DIAGRAM LADDER DIAGRAM NOTES: The SideShot is always interlocked with the primary control of the appliance. Wire all other furnace/boiler controls as normally done when conventional venting before continuing. - Page 13 HONEYWELL ST9103 WIRING WITH BURNER MOTOR POST PURGE SIDESHOT CONNECTED TO A RIELLO BURNER SIDESHOT CONNECTED TO A PHELON CONTROL...

-

Page 14: Draft Adjustment

DRAFT ADJUSTMENT OIL The SideShot Vent system will properly vent a wide range of BTU/hr. input capacities. To compensate for different burner capaci- ties, vent connector lengths and wind conditions it features a draft adjustment located on the outside of the Vent Hood. In general, positioning the draft adjustment inward will cause the SideShot to operate at lowest capacity. -

Page 15: Combustion Air

DRAFT ADJUSTMENT OIL OTES: All draft adjustments are approximate. This chart is to be used for initial draft adjustment only. Subsequent draft adjustments may be required to compensate for vari- ous field conditions: wind, vent pipe resistance, building pressure, multiple appliances, etc. BTU/HR input ratings assume 30% or less excess air for flame retention burners and 50% to 100% excess air for conventional oil burners. -

Page 16: Troubleshooting Oil Odors

Accessory air intakes are available that connect to the burner motor, using it to pull in the outdoor air. The Tjernlund IN-FORCER Combustion Air Intake tempers the raw outdoor air as it is delivered to the burner. -

Page 17: Troubleshooting Electrical Problems

Extreme caution must be exercised to prevent injury. If you are unable to determine the defective part with the use of this guide, call your Tjernlund distributor or Tjernlund Products direct at 1-800-255- 4208 for further assistance. SYMPTOM 1: SIDESHOT MOTOR WILL NOT OPERATE Step 1. - Page 18 SYMPTOM 3: APPLIANCE WILL NOT OPERATE, BUT SIDESHOT DOES Step1. Set draft adjustment according to "Draft Verify draft adjustment has been made. Adjustment Procedure" on Pages 13 & 14. Step 2. SideShot and appliance are not interlocked With the appliance calling for heat and SideShot correctly or malfunction of appliance controls.

-

Page 19: Maintenance

MAINTENANCE DIAGRAM N WHEEL INSPECTION (DIAGRAM N) 1. The SideShot blower wheel must be inspected annually. Particulates, such as soot, oil impurities and sheet rock dust, can prevent proper venting and will cause noise and vibration. Follow instructions, below for motor/wheel assembly removal. 2. -

Page 20: Warranty

Tjernlund Products, Inc. will issue credit or provide a free part to replace one that becomes defective during the two year warranty period. If the part is over 30 months old, proof of date of the installation in the form of the contractor sales/installation receipt is necessary to prove the unit has been in service for under two years.

Need help?

Do you have a question about the SS1C SIDESHOT (DISCONTINUED VERSION-PRE UC1 UNIVERSAL CONTROL) 8504040 REV 4 0595 and is the answer not in the manual?

Questions and answers