Summarization of Contents

General Pump Information

Document Information

Details document purpose, scope, and target audience.

Manufacturer and Customer Service Contact

Provides essential contact information for GEA Hilge.

EU Declaration of Conformity

States machine compliance with EC Machinery Directive.

Safety Precautions and Guidelines

Intended Use and Fluid Compatibility

Specifies acceptable media and particle size limits for pump operation.

Connections and Piping Safety

Guidelines for safe and correct plumbing connections and setup.

Switching Frequency Limit

Specifies the maximum permissible switching operations per hour.

General Operating Safety Precautions

Basic precautions for installation, operation, and maintenance.

Operator Safety Instructions

Key safety warnings and instructions for operators.

Consequences of Non-compliance

Outlines hazards and liabilities from ignoring safety information.

Safe Work Practices

Emphasizes safety-conscious behavior and adherence to regulations.

Unauthorized Modifications and Spare Parts

Policies on altering the machine and using non-original parts.

Staff Qualifications and Training

Requirements for personnel competence in pump operation and maintenance.

Safety Equipment Requirements

Instructions regarding machine-mounted safety signs and instructions.

Pump Description and Features

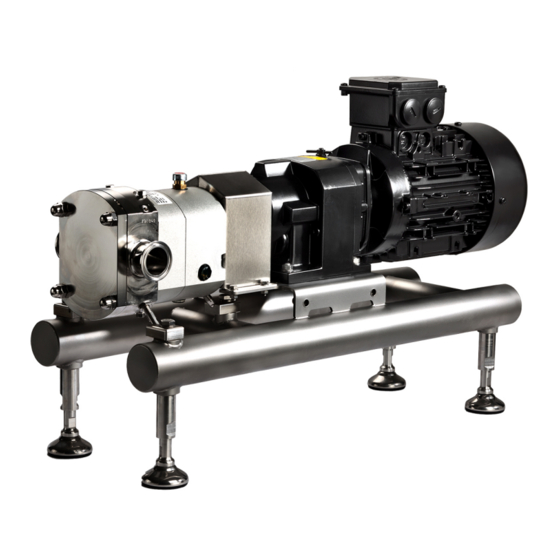

Pump Overview and Diagrams

Visual representation of the pump and its main components.

Pump Description and Applications

Detailed description of the pump's design and typical industrial applications.

Pump Naming and Nameplate Details

Explains pump designation conventions and the information on the nameplate.

Transport and Storage Procedures

Personnel Qualification for Handling

Specifies required qualifications for personnel involved in transport and storage.

Transport and Storage Safety Precautions

Critical safety measures to prevent accidents during transport and storage.

Dimensions, Weights, Unpacking, and Storage

Physical specifications, unpacking procedures, and guidelines for pump storage.

Packaging Material Disposal

Guidance on the environmentally sound disposal of packaging materials.

Technical Data and Specifications

Identification, Performance, Noise, Temperature, and Pressure Data

Key technical specifications including serial number, performance, noise, and operational limits.

Heatable Component Data and Seal Rotation Limits

Technical data for heatable parts and permissible rotation speeds for seals.

Gap Dimensions

Critical internal gap measurements for optimal pump performance and wear.

Oil Sight Glass and Valve Positions

Explains the location and function of key components like sight glasses and valves.

Assembly and Installation

Installation Safety Precautions

Essential safety measures before and during pump installation, covering mechanical, electrical, and operational hazards.

Personnel Qualification for Installation

Specifies required qualifications for personnel performing installation.

Setup, Installation, and Connection Procedures

Step-by-step guide for physically setting up and connecting the pump.

Coupling Alignment and Adjustment

Detailed steps for accurately aligning pump and motor couplings for longevity.

Permissible Coupling Displacement Values

Tables specifying acceptable shaft offset values for couplings.

Piping Installation and Suction Optimization

Guidance on piping connection, focusing on optimal suction conditions.

Mechanical Seal Usage and Care

Instructions for proper use and prevention of dry running for mechanical seals.

Installation Space and Damping

Specifies minimum installation clearances and vibration damping considerations.

Flush Ports, Fluid, and Systems

Information on flush ports, required fluid properties, and system types.

Flushing Connection and Electrical Connection

Steps for connecting flushing systems and guidelines for electrical hook-up.

Direction of Rotation Check and Earthing

Procedures to verify rotation direction and ensure proper grounding.

Pump Operation Principle

Explanation of how the rotary pistons move fluid through the pump.

Commissioning Procedures

Commissioning Personnel Qualification

Specifies required qualifications for personnel performing commissioning.

Commissioning Safety Instructions

Critical safety warnings and precautions during the commissioning phase.

Initial Startup and Commissioning Steps

Procedures for checking conditions, performing initial startup, and completing commissioning.

Mechanical Seal Functional Test

Procedure to test the mechanical seal for leaks after commissioning.

Operation with Trolley Control Unit

Instructions for operating pumps equipped with a control unit on a trolley.

Cleaning Procedures

Cleaning Personnel Qualification

Specifies required qualifications for personnel performing cleaning procedures.

Cleaning Safety Instructions

Crucial safety warnings related to cleaning agents, hot surfaces, and steam.

CIP (Cleaning-in-Place) Procedures

Details approved cleaning agents, concentrations, and parameters for CIP.

SIP (Sterilization-in-Place) Procedures

Guidelines for sterilizing the pump using superheated steam.

Maintenance and Servicing

Maintenance and Servicing Safety

Essential safety precautions to be followed during maintenance activities.

Maintenance Personnel Qualification

Specifies required qualifications for personnel performing maintenance.

Pump Maintenance and O-ring Replacement

Routine pump upkeep tasks, including daily checks and O-ring replacement.

Gear Lubrication Details

Comprehensive guidance on gear lubrication, including intervals, quantities, and types of oils.

Motor Maintenance Information

Guidance on obtaining motor maintenance details from its nameplate.

Malfunctions, Troubleshooting, and Repairs

Repair Personnel Qualification

Specifies required qualifications for personnel undertaking repair work.

Safety Instructions for Repairs

Critical safety warnings and procedures before starting any repair.

Troubleshooting Common Malfunctions

A guide to identifying and resolving typical pump issues and their causes.

Repair Process and Documentation

Information on initiating repair orders and required documentation.

Parts Identification: NOVALOBE and Gear Unit

Visual guides and lists for identifying pump and gear unit components.

Pre-Assembly Instructions for Repair

Guidelines for preparing components and ensuring hygiene before reassembly.

Component Cleaning and Seal Variants

Procedures for cleaning parts and overview of available mechanical seal types.

Disassembly of Rotors and Seals

Step-by-step instructions for safely removing pump rotors and mechanical seals.

Installation of Rotors and Seals

Detailed procedures for correctly installing new or cleaned rotors and mechanical seals.

Installation Torque Specifications

Torque values required for tightening rotor bolts and cap nuts during installation.

Decommissioning Procedures

Decommissioning Personnel Qualification

Specifies required qualifications for personnel performing decommissioning.

Decommissioning Safety Instructions

Key safety warnings and precautions related to pump shutdown.

Temporary Decommissioning Procedure

Steps for safely taking the pump out of service temporarily.

Pump Disposal Guidelines

Instructions for environmentally responsible disposal of the pump at end-of-life.

Appendix and Additional Information

Assembly Instructions for Free Shaft Pumps

Specific assembly procedures for pumps without motors or base frames.

Personnel Qualification and Operating Data

Required qualifications and guidance on selecting operating data for assembly.

Customer Pump Installation: Motor and Coupling

Instructions for installing the pump, motor, and coupling at the customer's site.

Shaft Alignment, Coupling Guard, and ATEX Compliance

Procedures for shaft alignment, coupling guard installation, and ATEX directive considerations.

Certificate of Non-Objection

Form for documenting pump condition before inspection or repair.

Need help?

Do you have a question about the NOVALOBE 40 and is the answer not in the manual?

Questions and answers