Summarization of Contents

Important Safety Instructions

Skill Level and Safety Precautions

Project requires advanced knowledge; handle with care.

Machine Operation Safety

Never reach into the machine while running; disconnect power for maintenance.

Handling Sharp Edges Safely

Sand sharp edges on metal parts for safety.

Electrical Wiring Safety

Ensure secure connections when lengthening wires.

Firmware Update Considerations

Update firmware for new volume; no support provided.

Before You Begin

Document Your Printer Setup

Take pictures of detail areas like motors and wiring before disassembly.

Perform Kit Inventory Check

Inventory all kit parts before disassembly to address issues early.

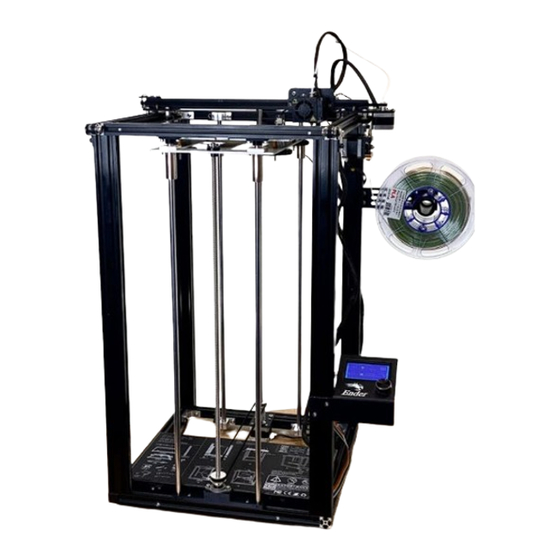

Ender 5 Machine Overview

Identify Key Components

Identify vertical extrusions, smooth rods, and lead screw.

Step 1: Inventory the Kit Contents

Frame and Rod Components

Four vertical extrusions and rear lead screw/rods.

Front Rods and Hardware

Front lead screw/rods and flange bearings/screws.

Wire Extensions

Extensions for heated bed, nozzle heater, thermistors, and fans.

Drive and Mounting Parts

Stepper motor extensions, pulleys, belts, and tensioner kit.

Brackets and Plates

Rod mounting brackets and aluminum carriage plate.

Step 2: Ender 5 Non-Pro and Pro Differences

Z-Axis Lead Screw Variations

Differences in Z-axis lead screw between Non-Pro and Pro models.

Step 3: Disassemble the Ender 5

Disconnect Power and Remove Bed

Disconnect power cable and remove bed print surface, wheels, springs, screws.

Loosen Rod Mounting Screws

Loosen smooth rod mounting screws from top and bottom supports.

Remove Lead Screw Nut

Remove M3 screws and nuts from the lead screw brass nut.

Remove Smooth Rods

Remove the two smooth rods from the printer frame.

Remove Carriage Plate

Remove the black carriage plate from the Z-axis assembly.

Remove Flange Bearings

Remove and keep the left/ride flange bearings for reuse.

Lead Screw Coupler Adjustment

Loosen lead screw set screw and remove lead screw from coupler.

Remove Top Front Frame Member

Remove top front frame member and associated screws.

Step 4: Assemble the Base Plate

Gather Base Plate Components

Gather original flange bearings, screws, and kit aluminum base plate.

Clean and Lubricate Parts

Clean and lubricate rods, lead screw, and bearings with grease.

Install Bearings and Screws

Insert bearings into corners and attach screws loosely.

Prepare Brass Nuts

Locate two brass nuts and eight screws for the base plate.

Attach Brass Nuts to Plate

Mount brass nuts from underside of plate with cylinder portion pointing down.

Step 5: Assemble Front Rod Support Brackets

Top Rod Mounting Bracket

Gather parts and affix M5 lock washers to M5x20 screws for the top bracket.

Mount Top Rod Bracket

Insert M5x20 screws and attach M5 t-slot nuts to the top rod mounting bracket.

Bottom Rod Mounting Bracket Prep

Gather parts for the bottom bracket including M4x16 screws and KFL08 bearing.

Attach Bottom Rod Bracket Hardware

Insert M4x16 screws into flange bearing holes and attach to bottom rod mounting bracket.

Step 6: Assemble the Belt Tensioner

Gather Belt Tensioner Parts

Collect parts for the belt tensioner, including bracket, bearings, and screws.

Assemble Tensioner Bracket

Attach M5 lock washers and screws to the tensioner bracket.

Attach Bearings to Support

Ensure flange bearings are on the outer edge of the printed bearing support.

Secure Tensioner Bearing Support

Attach M5 flat washer and screw to the bearing support.

Final Tensioner Assembly

Screw M5x40 hex cap screw into tensioner bracket securely but without overtightening.

Step 7: Mount Rod Brackets to Frame

Position Top Rod Mounting Bracket

Temporarily attach top frame member and position rod bracket using t-slot nuts.

Attach Bottom Rod Bracket

Attach the bottom rod mounting bracket to the bottom frame member.

Position Carriage Plate

Position carriage plate over power supply, aligning bearings with rod brackets.

Insert Front Smooth Rods

Insert front 10mm smooth rods through bearings into the rod mounting bracket.

Insert Rear Smooth Rods

Insert rear 10mm smooth rods through rear bearings into rod support mounts.

Tighten Rear Rod Support Screws

Tighten bottom rear rod support screws first, then top rear rod support screws.

Insert Rods into Bottom Bracket

Insert the 10mm smooth rods into the bottom mounting bracket.

Install Rear Lead Screw and Coupler

Insert rear lead screw, place pulley, and connect to Z motor coupler.

Loosen KFL08 Bearing Set Screw

Loosen the KFL08 flange bearing set screw to allow lead screw insertion.

Position Belt on Bearings

Position the closed loop belt over the Z motor coupler and front flange bearing.

Insert Lead Screw and Pulley

Insert lead screw through brass nut, place pulley, and into KFL08 bearing.

Attach Top Front Frame Member

Attach top front frame member, position rods, center bracket, tighten screws.

Tighten M5x20 Screws

Insert and tighten M5x20 hex cap screws as needed.

Tighten Inner M4 Screws

Insert and tighten inner M4 button head screws as needed.

Level Carriage Plate

Move carriage to top, adjust front/rear height for even positioning.

Position Tensioner Unit

Position tensioner unit between Z motor bracket and left rear rod bracket; set screws loose.

Loop Belt Over Bearing

Loop the drive belt over the bearing for tensioning.

Align Belt and Pulleys

Check belt and pulley alignment for even height and no angle.

Tighten Tensioner Screws

Hold tension on pulley and tighten M5 hex cap screws on the tensioner.

Final Carriage Plate Check

Check carriage plate distance front/back and move X axis for measuring.

Tighten Pulley Set Screws

Once carriage plate is even, tighten the pulley set screws.

Step 8: Wire Extensions

Connect Wire Extensions

Attach wire extensions to control board and wiring harness, ensuring they are labeled.

Slicer Settings

Cura Configuration Overview

Focus on Cura for larger bed printing with updated firmware.

Firmware and G-code Commands

Discusses Marlin firmware, M211 command for software endstops.

Manage Printer Profiles

Select and manage printer profiles within Cura.

Machine Settings and G-Code

Adjust X, Y, Z size and review Start G-Code.

Configure Printer Dimensions

Set X, Y, Z dimensions (400x400x500mm) and printhead limits in Cura.

Disable Software Endstops

Ensure M211 S0 is in Start G-code to disable software endstops.

Need help?

Do you have a question about the XL and is the answer not in the manual?

Questions and answers