Summary of Contents for Munters EDC18

- Page 1 EDC - EDX Manual for use and maintenance + CE Declaration of conformity EDC - EDX Air circulation fan Models: EDC18 - EDX18 EDC24 - EDX26 Ag/MIT/UmGB-2086-04/13 rev1.0...

- Page 2 Munters Italy S.p.A. reserves the right to effect modifications to the apparatus in accordance with technical and legal developments.

- Page 3 1.1 Disclaimer 1.2 Introduction 1.3 Notes SAFETY ASPECTS BEFORE USING 3.1 Packaging and transport 3.2 Structure OPERATING CONDITIONS INSTALLATION 5.1 Use COMMISSIONING TECHNICAL DATA 7.1 Dimensions 7.2 Motor specifications 7.3 Technical specifications MAINTENANCE SPARE PART LIST WARRANTY © Munters AB, 2013...

- Page 4 BY APPARATUS DIRECTIvE 2006/42/EC WITH PARTICULAR REfERENCE TO THE fOLLOWING PROvISIONS: UNI EN 953:2009, UNI EN ISO 12100:2010, UNI EN ISO 12499:2009, UNI EN ISO 13857:2008, CEI EN 60204-1:2006 (CEI 44-5). Chiusavecchia, 22 April 2013 Marco Scomparin Legal representative © Munters AB, 2013...

- Page 5 The information contained herein has been prepared by qualified experts within Munters. While we believe the information is accurate and complete, we make no warranty or representation for any particular purposes. The information is offered in good faith and with the understanding that any use of the units or accessories in breach of the directions and warnings in this document is at the sole discretion and risk of the user.

-

Page 6: Safety Aspects

Safety aspects The safety of fans is assured by Munters in compliance with the safety requirements indicated by the CE label. Safe functioning is assured only when the installation procedures and the instructions for use have been carefully followed.The following points must be stressed: • proper transport procedure must be followed;... -

Page 7: Before Using

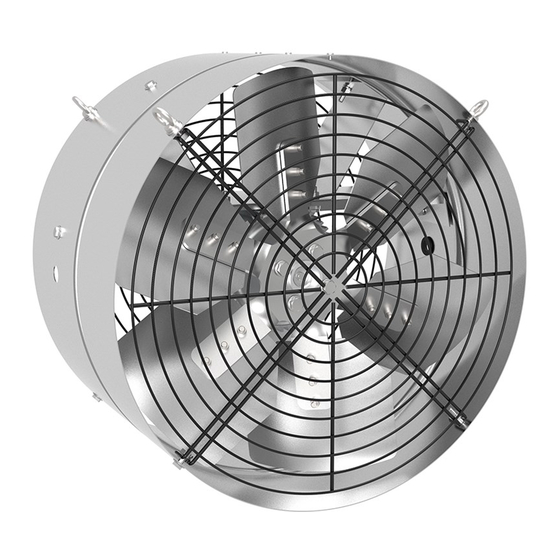

• blades fixed with aeronautical rivets (except EDC18 blades fixed with M6 screws class 8.8 or higher); • asynchronous three-phases electric motor (single-phase on request), 50/60Hz, IP55 protection class, fixed or adjustable speed; • flow straightener; • one or two safety meshes. © Munters AB, 2013... -

Page 8: Operating Conditions

Working ambient temperature limits are -25°C to +50°C. Maximum altitude is 1000 m above sea level. If a fan is required to operate at a higher altitude, the loss in mass flow (heat removing capacity) due to lower air density should be taken into consideration. © Munters AB, 2013... -

Page 9: Installation

The electrical cable must be tense inside the body to avoid any interference with Warning the propeller. © Munters AB, 2013... - Page 10 Switching on and switching off Switching on and switching off operations pass through not supplied equipments. Operating conditions Looking at the airflow rectifier, the propeller should turn clockwise (fig.3). © Munters AB, 2013...

- Page 11 During cleaning operations the power switch must be in the off position and locked by a padlock. It is necessary to perform periodic cleaning of safety meshes, airflow rectifier and blades using brushes or compressed air. In order to avoid any damage, cleaning the motor directly with water jets must Warning be avoided. © Munters AB, 2013...

- Page 12 Wait until the electrical power has been Warning switched off and the fan has come to a complete stand still. Lock the electrical switch in the off position with a pad lock while working on the fan. © Munters AB, 2013...

-

Page 13: Technical Data

Technical data 7.1 Dimensions Dimensions fig.4 EDC18 - EDX18 EDC24 EDX26 © Munters AB, 2013... - Page 14 9.2 [5.4] 11 [6.5] 11.2 [6.6] 17.9 [10.5] Propeller diameter [mm] [inch] 450 [18] 450 [18] 450 [18] 600 [24] 650 [26] Number of blades IEC protective class of electric motor IP55 IP55 IP55 IP55 IP55 © Munters AB, 2013...

- Page 15 Technical data Electric motor winding insulation grade Max noise level at 1.95m 71.5 75.5 75.7 76.5 * all values refer to 3 phases 50Hz single speed motors. note: airflow data are measured at standard conditions (20°C, 1,013hPa) © Munters AB, 2013...

-

Page 16: Maintenance

• open the electrical control panel: • check the absence of electrical continuity between the terminals upstream and downstream the thermo-magnetic switch; in case of electrical continuity replace the switch; • close the electrical control panel; • switch on the fan. © Munters AB, 2013... -

Page 17: Spare Part List

HEX BOLT M5X16 UNI 5739 SPRING WASHER 5 DIN 128 PLAIN WASHER LARGE 5X20 ISO 7089 COMPLETE PROPELLER (HUB, BLADES, BOLTS&SCREWS) MOTOR SUPPORT HEX NUT M6 UNI 5588 SPRING WASHER 6 DIN 128 HEX BOLT M6X20 UNI 5739 © Munters AB, 2013... - Page 18 AIRfLOW STRAIGHTENER, SHORT POP UP RIvET D3.9X7 ALUMINUM fRAME DOUBLE-SIDED GROMMET HEX BOLT M5X20 S.S. UNI 5739 SPRING WASHER 5 S.S. DIN 128 PLAIN WASHER LARGE 5X20 S.S. ISO 7089 HEX BOLT M8X20 S.S. UNI 5739 © Munters AB, 2013...

- Page 19 PLAIN WASHER 6X18 ISO 7093 CAGE NUT M6 HEX BOLT M6X16 ISO 4018 AIRfLOW STRAIGHTENER, LONG AIRfLOW STRAIGHTENER, SHORT POP UP RIvET D3.9X7 ALUMINUM fRAME DOUBLE-SIDED GROMMET HEX BOLT M6X20 ISO 4018 SPRING WASHER 6 DIN 128 © Munters AB, 2013...

- Page 20 S.S. GP PROPELLER 50Hz GALvANIzED GP PROPELLER 50Hz GALvANIzED AM PROPELLER 50Hz PRECOATED AM PROPELLER 50Hz S.S. AM PROPELLER 50Hz MULTISPEED 1PHASE MOTOR HP0,5 230 60Hz GALvANIzED AM PROPELLER 60Hz PRECOATED AM PROPELLER 60Hz S.S. AM PROPELLER 60Hz © Munters AB, 2013...

- Page 21 HEX NUT M8 S.S. UNI 5588 SPRING WASHER 8 S.S. DIN 128 PLAIN WASHER 8 S.S. ISO 7089 HEX BOLT M8X30 S.S. UNI 5739 MOTOR SUPPORT, SHORT HEX NUT M6 S.S. UNI 5588 MOTOR SUPPORT, LONG © Munters AB, 2013...

- Page 22 ONE SPEED 3PHASES MOTOR HP0,5 400 50/60Hz S.S. 304 GP PROPELLER 50Hz S.S. GP PROPELLER 60Hz MULTISPEED 3PHASES MOTOR HP0,5 400 50/60Hz S.S. 304 GP PROPELLER 50Hz S.S. GP PROPELLER 60Hz MULTISPEED 1PHASE MOTOR HP0,5 230 50Hz S.S. 304 GP PROPELLER 50Hz © Munters AB, 2013...

-

Page 23: Warranty

Munters plant was required: if this is not done, the user is fully responsible for the damage which they could suffer. - Page 24 Requests for technical assistance and spare parts must be made directly to the manufacturer, at the following address: Munters Italy S.p.A Strada Piani, 2 18027 Chiusavecchia (IM), Italy Tel: +39 0183 52 11 fax: +39 0183 521 333 © Munters AB, 2013...

- Page 25 Munters Brasil Industria e Comercio Ltda, Phone +55 41 3317 5050, Canada Munters Corporation Mason, Phone +1 517 676 7070, China Munters Air Treatment Equipment (Beijing) Co. Ltd, Phone +86 10 80 481 121, Denmark Munters A/S, Phone +45 9862 3311, India...

Need help?

Do you have a question about the EDC18 and is the answer not in the manual?

Questions and answers