Munters Euroemme EM50 Manual For Use And Maintenance

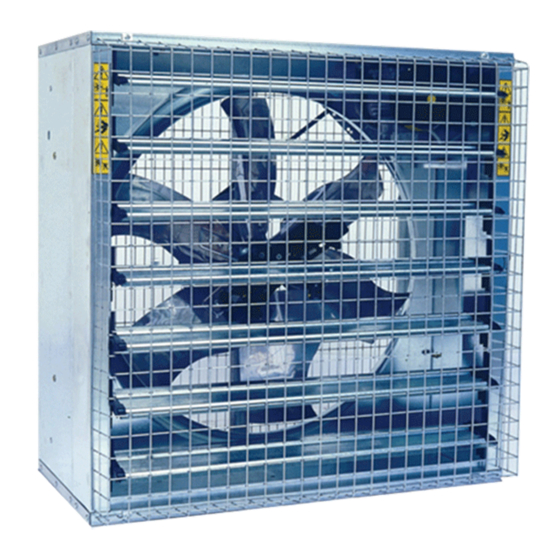

Air extraction fan

Hide thumbs

Also See for Euroemme EM50:

- Use and maintenance manual (41 pages) ,

- Assembly manual (24 pages) ,

- Manual for use and maintenance (63 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Munters Euroemme EM50

- Page 1 EM50 Manual for use and maintenance EM50 Air extraction fan...

- Page 2 This document is destined for the user of the apparatus: it may not be reproduced in whole or in part, committed to computer memory as a file or delivered to third parties without the prior authorisation of the assembler of the system. Munters Italy S.p.A.

-

Page 3: Table Of Contents

8.7 Fan bearing lubrication ......................25 8.8 Replacement of shutter opening device (centrifugal system) ..........25 9. SPARE PART LIST ............................... 26 WARNING All the components and spare parts MUST be storaged in dry and clean environment. © Munters AB, 2020... -

Page 4: Introduction

The information contained herein has been prepared by qualified experts within Munters. While we believe the information is accurate and complete, we make no warranty or representation for any particular purposes. The information is offered in good faith and with the understanding that any use of the units or accessories in breach of the directions and warnings in this document is at the sole discretion and risk of the user. -

Page 5: Safety Aspects

• do not for any reason modify parts of the fan in order to fit additional devices. © Munters AB, 2020... -

Page 6: Safety Devices

Dimensions and positioning in accordance with the instructions in Guard of fixed type made of metal Outlet side of fan the standard UNI EN 13857. mesh. Removable only by means of special tool. fig.2 © Munters AB, 2020... -

Page 7: Residual Risks

(danger resulting from the presence of live parts), the level of voltage present, the prohibition of tampering by unauthorized personnel and the prohibition on the use of liquids on electrical apparatus in the event of fire. fig.5 © Munters AB, 2020... - Page 8 The fan must only be used if it is in perfect operating condition, by personnel, aged more than 14 years who are perfectly aware of the safety measures and possible hazards, and in strict compliance with the instructions given in this manual. NOTE There are no components in the devices containing mercury and asbestos. © Munters AB, 2020...

-

Page 9: Before Using

Fans should not be permanently stocked one upon the other, regardless if they are delivered with or without packaging. Handling of the fans should not be done manually as the fans have no handles or grips. Consequently one of the following alternatives should be used: © Munters AB, 2020... -

Page 10: Structure

Munters Protect coated steel, which pivots on UV protected plastic bushes and pins; • propeller with six blades in stainless or Munters Protect coated steel; blades are fixed to the propeller by high- strength pop rivets; •... -

Page 11: Operating Conditions

Original spare parts ensure the reliability and safety of the operation of the fan: in the event of maintenance/replacement, consult the spare parts list, the list of parts and components used and the relevant technical documentation attached to this manual. © Munters AB, 2020... - Page 12 The metal sheets used for constructing the fan housing and shutter blades have a surface coating made of an alloy of Zinc, Aluminum and Magnesium (‘Munters Protect’), classified as ZM120 (equivalent to 9 μm of coating thickness on each side of the panels) which corresponds to a corrosion resistance in salty mist of 1800 hours.

-

Page 13: Installation

The area adjacent to the fan in the premises from which air is being extracted must be kept clear to allow the air to exit freely. It is also prohibited for anyone to remain in this area, because of the presence of organic gases and dust which may be present in the airflow. © Munters AB, 2020... -

Page 14: Installing Series Em Fans

When the outer frame is properly built-in, i.e. perfectly level and upright, insert the fan, screwing four M8 bolts type 8.8 (not supplied with the fan) into the threaded inserts provided on the sides of the bodywork, two per side. fig.12 © Munters AB, 2020... -

Page 15: Connection To The Electrical System

16 WARNING Do not supply power to the fan during installation stage. Installer must issue a declaration of correct installation in accordance with applicable legislation in the country of use. © Munters AB, 2020... - Page 16 • check that the intensity of the short-circuit expected at the connection terminals is compatible with the breaking power of the protection switch upstream of the electrical panel; © Munters AB, 2020...

-

Page 17: Tests And Checks Before Startup

• check that the guards inside the electrical panel are correctly positioned and fixed; • check that the safety devices are receiving power and are active, and check their effectiveness. © Munters AB, 2020... - Page 18 The minimum frequency of operation of the engines in the case of absence of a forced external ventilation is 30 Hz. In the case of an operating frequency below 30 Hz is necessary to provide an external forced ventilation to the engine. © Munters AB, 2020...

-

Page 19: Commissioning

After an emergency stop, the operating cycle must be reset by following the procedure described below: • reset the actuator by which the emergency stop command was given (by turning the relative mushroom button); • for an exact reset sequence, refer to the instructions given in section 6.2. © Munters AB, 2020... -

Page 20: Technical Data

7. TECHNICAL DATA 7.1 Dimensions Dimensions [mm] fig.20 1,380 1,380 7.2 Motor specifications Nominal Power Frequency Voltage Current Model Phases Speed [Hp] [Hz] EM50 single 230/400 3.5/2 1700 EM50 1100 single 230/400 5.2/3 1700 © Munters AB, 2020... -

Page 21: Technical Specifications

Specific performance at 0 Pa /h /W [cfm /W] 33.9 [20] 27.0 [15.9] Max. operating temperature °C [°F] 40 [104] Max. operating pressure [Pa] Nominal propeller speed [rpm] IEC protective class of electric motor IP55 Electric motor winding insulation grade © Munters AB, 2020... -

Page 22: Maintenance

Check V-belt tension at regular intervals, the correct tension is obtained when maximum deflection (half-way from motor and central pulley) is about 15 mm, when pushed in by thumb. WARNING Tighten fan belt after the fan has been running for 3 days. Without adjusting the tension, transmission components can wear out early. © Munters AB, 2020... -

Page 23: Replacement Of Propeller

Open shutter by hand and take away the pin, which connects central shutter blade to centrifugal system. fig.22 fig.23 fig.22 Loosen motor to propeller V-belt from pulleys throat; unscrew the fixing nut. fig.23 fig 22 © Munters AB, 2020... -

Page 24: Replacement Of Central Pulley

(see n.4,5,6); insert the new shutter bearing assembly; put back the shutter blades and fix the closing springs in their position; fit the cover side plates back (see n.1). fig.27 © Munters AB, 2020... -

Page 25: Fan Bearing Lubrication

• stack the components to allow water to drain out; • keep the packed components in such way to prevent moisture contact with the Munters Protect coated surface. © Munters AB, 2020... -

Page 26: Spare Part List

9. SPARE PART LIST EM50 fig.30 © Munters AB, 2020... - Page 27 Ø6.4X8 POP UP RIVET RUBBER FOR CABLE HOOK FOR SPRING THREADED BUSH M8X12.5 TOP PANEL M8×17.5 THREADED BUSH PROPELLER CENTRIFUGAL SYSTEM Ø8X16 WASHER M8×55 HEX SCREW BRASS PIN CENTRAL RIGHT BEARING W/SPRING RIGHT BEARING SHUTTER BLADE LEFT BEARING © Munters AB, 2020...

- Page 28 M6×30 HEX SCREW M25 HEX NUT CENTRAL PULLEY WATERPROOF DISTANCE PIECE CUP COVER NUT M8 HEX NUT W/FLANGE MOTOR AND PULLEY M8×20 HEX SCREW M10×30 SCREW EXT TOOTHED WASHER D10,5X18 M10 HEX NUT PLASTIC OVAL PLATE © Munters AB, 2020...

- Page 29 CENTRAL SUPPORT SAFETY PROTECTION FOR CENTRAL PULLEY Ø6×24 WASHER MOTOR PULLEY PITCH DIAMETER AND HOLE 1.5HP - 3 PHASE - MULTI SPEED 60HZ 80/24 1HP - 3 PHASE - MULTI SPEED 60HZ 70/19 © Munters AB, 2020...

- Page 30 Munters EM50 extraction fan is developed and produced by Munters Italy S.p.A., Italy www.munters.com Australia Phone + 61 2 8843 1594, agh.info@munters.com.au, Brazil Phone +55 41 3317 5050, contato@munters.com, Canada Phone +1 517 676 7070, aghort.info@munters.com, China Phone +86 10 8048 3493, marketing@munters.cn,...

Need help?

Do you have a question about the Euroemme EM50 and is the answer not in the manual?

Questions and answers

Érdeklődni szeretnék hogy munters em 50 ventilátorhoz centrifugális nyitó van e készleten és mennyibe kerül ? köszönöm mellékelek róla képet köszönöm