Table of Contents

Advertisement

Advertisement

Table of Contents

Summarization of Contents

Documentation Notes

Disclaimer

Covers documentation care, revisions, trademarks, and patent information for Beckhoff products.

Trademarks

Lists registered and licensed brands of Beckhoff Automation GmbH & Co. KG.

Patents

Details patent rights for EtherCAT and TwinCAT technologies.

Limitation of Liability

Defines Beckhoff's liability and exclusions related to product modifications and documentation compliance.

Copyright

States restrictions on copying, distribution, and utilization of the document without authorization.

Version Numbers

Details the version history and changes introduced in different issues of the operating instructions.

Scope of Documentation

Lists the documents that constitute the complete documentation for the AS2000 series.

Staff Qualification

Specifies the required knowledge and experience for personnel handling the product.

Safety and Instruction

Emphasizes reading safety instructions and warning notices for safe product handling.

Explanation of Symbols

Defines various symbols used for clear arrangement and to identify important text passages.

Pictograms

Explains the meaning of warning triangles, notes, information signs, and example symbols.

Beckhoff Services

Provides contact information and details for support, training, and service from Beckhoff.

For Your Safety

Safety Pictograms

Explains safety pictograms found on products and their protective function.

Warning of a Hot Surface

Alerts users to burn risks from hot motor housing and advises on cooling time.

Avoid Shocks to the Shaft

Warns about potential damage to optical encoder systems from excessive axial/radial forces.

General Safety Instructions

Provides general safety notes for handling motors, emphasizing proper installation and operation.

Before Operation Safety Checks

Lists key safety checks and preparations required before operating the motors.

During Operation Safety Precautions

Details safety precautions to be observed while the motor is in operation.

After Operation Safety Steps

Outlines safety steps to be taken after the motor has finished operation.

Product Overview

Name Plate Information

Describes the information found on the motor's name plate and the meaning of each item.

Type Key Explained

Explains the structure of the AS2000 series type key for product identification.

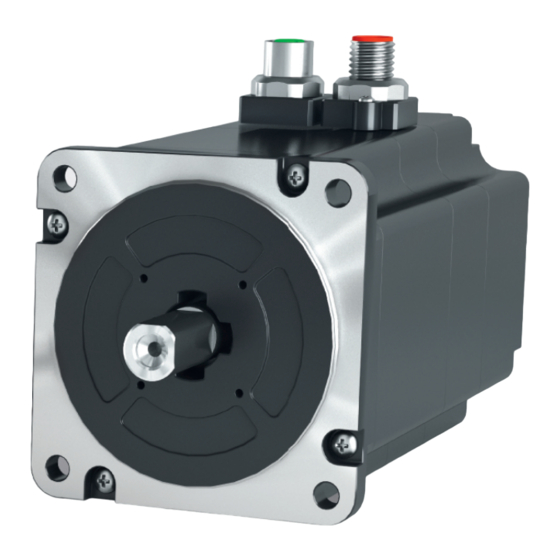

Key Product Characteristics

Highlights key features like NEMA flange sizes, step angle, power range, and protection class.

Ordering Options and Retrofitting

Details how ordering options are defined via the type key and that components cannot be retrofitted.

Intended Use and Documentation

Specifies the intended applications for AS2000 series motors and required documentation.

Improper Use Definition

Defines improper use, exceeding permissible values, and unsuitable operating areas for the motors.

Technical Data

Definitions and Terms

Provides definitions for technical terms, environmental conditions, and operating details for the motors.

Operation and Environment Data

Specifies environmental requirements and conditions for intended use to ensure product longevity.

Step Mode and Limit Speeds

Details step modes and corresponding limit speeds for the stepper motor terminals.

AS202x Electrical and Mechanical Data

Presents electrical and mechanical data for the AS202x series stepper motors.

AS202x Dimensional Drawings

Provides dimensional drawings for AS2021, AS2022, and AS2023 motors with and without encoder.

AS2021 Torque-Speed Curves

Shows torque-speed curves for AS2021-0D00 and AS2021-0D10 motors under different operating conditions.

AS2022 Torque-Speed Curves

Displays torque-speed curves for AS2022-0H00 and AS2022-0H10 motors under various operating conditions.

AS2023 Torque-Speed Curves

Presents torque-speed curves for AS2023-0H00 and AS2023-0H10 motors under different operating modes.

AS2023-0J Torque-Speed Curves

Shows torque-speed curves for AS2023-0J00 and AS2023-0J10 motors in open loop and vector control.

AS204x Electrical and Mechanical Data

Lists electrical and mechanical data for the AS2041, AS2042, and AS2043 stepper motor series.

AS204x Dimensional Drawings

Includes dimensional drawings for AS2041, AS2042, and AS2043 motors with and without encoder.

AS2041-1H Torque-Speed Curves (Open Loop)

Displays torque-speed curves for AS2041-1H00 and AS2041-1H10 motors in open loop operation.

AS2041-1H Torque-Speed Curves (Vector Control)

Presents torque-speed curves for AS2041-1H10 motors in vector control mode.

AS2042-1H Torque-Speed Curves (Open Loop)

Shows torque-speed curves for AS2042-1H00 and AS2042-1H10 motors in open loop operation.

AS2042-1H Torque-Speed Curves (Vector Control)

Displays torque-speed curves for AS2042-1H10 motors in vector control mode.

AS2043-1J Torque-Speed Curves (Open Loop)

Presents torque-speed curves for AS2043-1J00 and AS2043-1J10 motors in open loop operation.

AS2043-1J Torque-Speed Curves (Vector Control)

Shows torque-speed curves for AS2043-1J10 motors in vector control mode.

Elastomer Coupling AX2090-+EC05 Data

Details mechanical data and dimensional drawings for the AX2090-+EC05 elastomer coupling.

AX2090-+EC05 Coupling Drawings

Provides dimensional drawings for elastomer couplings with different shaft diameter combinations.

AX2090-+EC10 Elastomer Coupling Data

Lists mechanical data for the AX2090-+EC10 elastomer coupling with different shaft diameter options.

AX2090-+EC10 Coupling Drawings

Includes dimensional drawings for the AX2090-+EC10 elastomer coupling.

Scope of Supply

Packaging Instructions

Describes items included in the delivery and provides instructions for handling printed on packaging.

Transport and Storage

Transport and Storage Conditions

Outlines conditions for transport and storage, including climate category, temperature, humidity, and stacking height.

Safe Transport Guidelines

Provides warnings and instructions for safe transportation of motors, avoiding impacts and falls.

Long-term Storage Recommendations

Gives guidelines for maximum storage time, recurring inspections, and preventing condensation.

Technical Description

Motor Mounting Positions

Specifies the standard installation positions (IM B5) and warnings about liquid ingress in vertical mounting.

Feedback System Resolution

Provides information on the resolution of the motor feedback systems.

Shaft End A Details

Describes force transmission via coupling/shaft end and radial/axial forces.

Mechanical Installation

Flange Mounting Components

Details components for mounting motors, including bore diameter and tightening torque for cheese-head screws.

Output Elements Safety

Provides warnings about securing moving parts and protecting the motor from inadmissible load and ensuring earthing.

Bearing Load and Toothed Belt Drives

Explains how to avoid mechanically overdetermined support and considerations for radial loads from toothed belt drives.

Mounting Output Elements Safely

Instructs on safe handling of hot output elements and correct mounting of drive elements on the motor shaft.

Dismantling Output Elements

Details the process of dismantling output elements using gear pullers and degreasing the motor shaft.

Elastomer Coupling Preparation

Provides information on preparing for elastomer coupling installation, lubricant compatibility, and assembly.

Coupling Hub Machining and Mounting

Warns against exceeding permissible bore diameter and provides mounting instructions for coupling hubs.

Electrical Installation

Connection Technology and Cables

Overview of cables and connectors, recommending Beckhoff cables and warning about soiling/damage.

Feedback Cable Connection

Guides on connecting feedback cables, ensuring poles and threads are clean and connectors are pushed straight.

Power and Protective Earth Connection

Details connecting power and establishing protective earth, including torque specifications.

EL7037 Terminal Wiring

Provides wiring diagrams and order keys for motor and encoder cables for the EL7037 terminal.

EL7047 Terminal Wiring

Shows wiring diagrams and order keys for motor and encoder cables for the EL7047 terminal.

EP7041 Module Wiring

Details wiring for motor and encoder cables for the EP7041 module for high-speed applications.

Commissioning

Pre-Commissioning Checks

Lists checks required before commissioning, including drive damage, installation, and connections.

Commissioning and Configuration

Outlines steps during commissioning, configuration using TwinCAT DriveManager, and axis setup.

Operational Checks and After-Operation Safety

Lists operational checks and emphasizes safe machine condition and rotor stoppage after operation.

Maintenance and Cleaning

Approved Cleaning Agents

Provides lists of approved and non-approved cleaning agents for the motors.

Component Maintenance Intervals

Details maintenance work and intervals for components like ball bearings, motors, cables, and plugs/sockets.

Accessories

Connection Cables, Gear Units, and Couplings

Describes connection cables, gear units, and elastomer couplings for motor applications.

Fault Correction

Motor Faults: Errors and Causes

Provides a table listing common motor errors, their causes, and corresponding solutions.

Motor Fault Troubleshooting

Continues the fault correction table, detailing solutions for issues like power supply, feedback cable, and connector problems.

Decommissioning

Safe Disassembly and Disposal

Provides instructions for safe disassembly and proper disposal of motors and their components.

Guidelines and Standards

Product Standards and EU Conformity

Lists applicable product standards, directives, and EU conformity requirements for Beckhoff products.

Need help?

Do you have a question about the AS2022-0H10 and is the answer not in the manual?

Questions and answers