Advertisement

Introduction

Failure to read the manual may lead to personal injury, inferior results or damage to the

Ultimaker 2 Go. Always make sure that anyone who uses the 3D printer knows and understands the contents of the manual to make the most out of the Ultimaker 2 Go.

The conditions or methods used for assembling, handling, storage, use or disposal of the device are beyond our control and may be beyond our knowledge. For this and other reasons, we do not assume responsibility and expressly disclaim liability for loss, injuries, damage, or expense arising out of or in any way connected with the assembly, handling, storage, use or disposal of the product.

The information in this document was obtained from sources which we believe are reliable. However, the information is provided without any warranty, express or implied, regarding its correctness.

Intended use

Ultimaker 3D printers are designed and built for fused deposition modeling for various high quality plastics like PLA, ABS, CPE within a commercial/business environment. The mixture of precision and speed makes the Ultimaker 3D printers the perfect machines for concept models, functional prototypes and also the production of small series. Although we achieved a very high standard in the reproduction of 3D models with the usage of Cura, the user remains responsible to qualify and validate the application of the printed object for its intended use. While being an open filament platform the best results will be achieved with Ultimaker certified filament, while effort has been made in order to match material properties with machine settings.

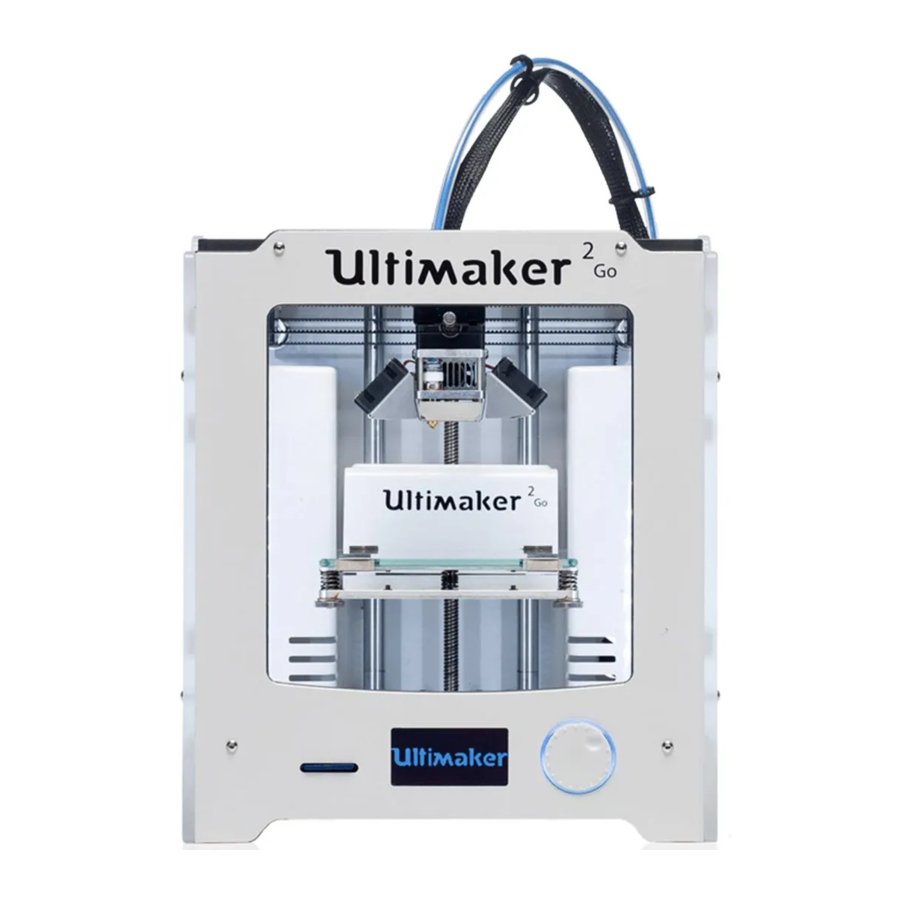

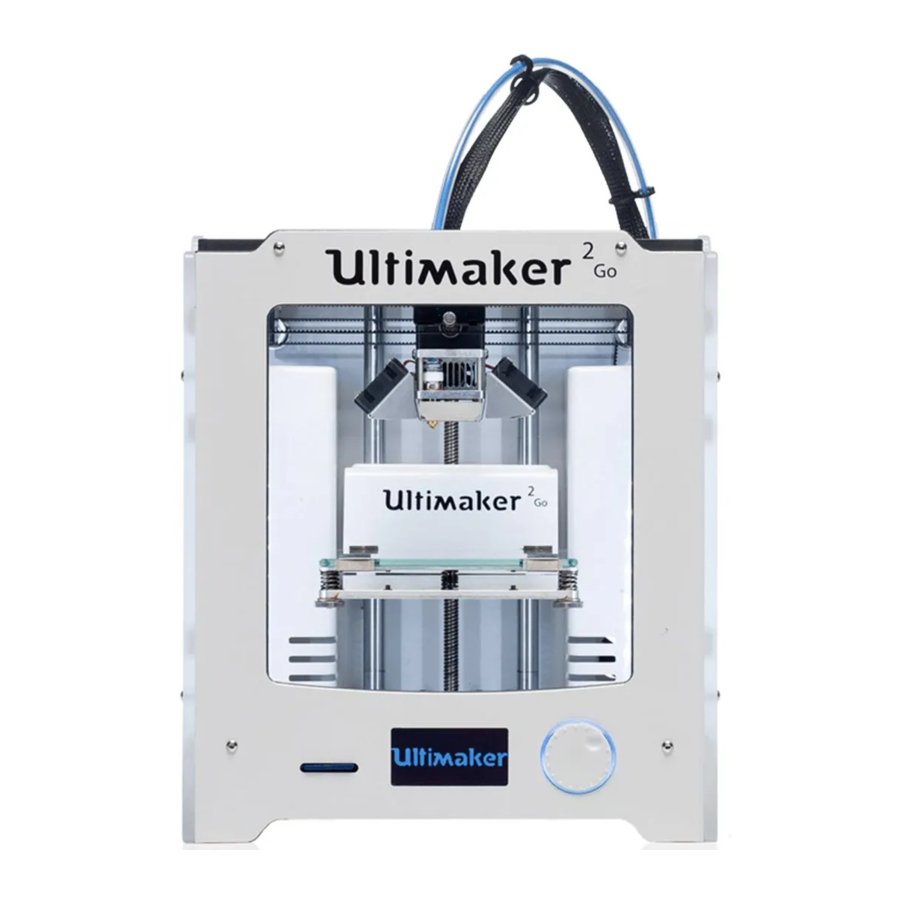

ULTIMAKER 2 GO

This user manual is designed to help you start your Ultimaker 2 Go experience. Learn everything about using your Ultimaker 2 Go by following the instructions in this user manual and experience how easy it is to produce great quality prints.

You might be familiar with other types of Ultimakers or 3D printers. It is however essential that you read this manual carefully in order to make the most out of your Ultimaker 2 Go.

ULTIMAKER 2 GO AT A GLANCE

- Display

- SD card slot

- Push/rotate button

- Build plate

- Build plate clamps

- Build plate screws

- Print head

- Bowden tube

- Print head cable

- Spool holder

- Power socket

SPECIFICATIONS

| Printing | |

| Print technology | Fused Filament Fabrication |

| Build volume | 120 mm / 120 mm / 115 mm |

| Layer resolution | Fast: 200 micron (0.2 mm) Normal: 100 micron (0.1 mm) High: 60 micron (0.06 mm) Ulti: 40 micron (0.04 mm) |

| Positioning precision | 12.5 micron / 12.5 micron / 5 micron |

| Filament diameter | 2.85 mm (generally known as 3 mm filament) |

| Nozzle diameter | 0.4 mm |

| Print speed | 30 mm/s - 300 mm/s |

| Travel speed | 30 mm/s - 350 mm/s |

| Software | |

| Supplied software | Cura - Official Ultimaker Software |

| File types | STL / OBJ / DAE / AMF |

| Supported OS | Windows / Mac / Linux |

| Electrical | |

| AC Input | 100 - 240 V Approx. 1.4 AMPS 50 - 60 Hz 120 Watt max. |

| Connectivity | Stand-alone SD card printing |

| Physical dimensions | |

| Desktop space | 258 mm / 250 mm / 287.5 mm |

| Shipping dimensions | 400 mm / 310 mm / 550 mm |

| Weight | 6.2 kg |

| Shipping weight | 14.0 kg |

| Temperature | |

| Ambient operation temperature | 15 - 32°C |

| Storage temperature | 0 - 32°C |

| Nozzle operation temperature | 180 - 260°C |

| Sound | |

| Average operational noise | 49 dBA |

The Ultimaker 2 Go generates high temperatures and has hot moving parts that can cause injury. Never reach inside of the Ultimaker 2 Go while it is in operation. Always control the Ultimaker 2 Go with the button on the front or with the power switch on the back. Allow the Ultimaker 2 Go to cool down for 5 minutes before reaching inside.

When opening the Ultimaker 2 Go for service, ensure that the power supply is turned off and the power cable is disconnected from the wall socket.

Only use the power supply provided with your Ultimaker 2 Go.

GETTING STARTED

Now your Ultimaker 2 Go has arrived you're ready to unpack it and set it up! Carefully unpack your Ultimaker 2 Go and set it up according to the instructions on the next pages.

When you use your Ultimaker 2 Go for the first time, it will guide you through some steps to set it up and calibrate it. Follow the bed leveling and filament loading steps carefully in order to set up your Ultimaker 2 Go correctly.

UNBOXING

The Ultimaker 2 Go comes in reusable, durable packaging that has been specially designed to protect your Ultimaker 2 Go in transport. To properly unpack your Ultimaker 2 Go, please follow the steps described below.

START UNBOXING

After having opened the cardboard box in which your Ultimaker 2 Go was delivered the unboxing can begin. Start unpacking by taking the Ultimaker 2 Go out of the cardboard box. You can best do this by carrying the belt and holding the cardboard box while lifting the Ultimaker 2 Go.

OPEN IT UP

When the Ultimaker 2 Go has been taken out of the box you can loosen the belt that's placed around the foam packaging. This allows you to open the top cover, where you will find the quick start guide and accessories.

REMOVE THE PACKAGING

Open up the complete packaging by lifting it at the hole at the side of the packaging. Now you can take out the spool with PLA filament and place the Ultimaker 2 Go on your desk. Make sure you hold the Ultimaker 2 Go on the frame and don't hold it on the belts or axes while carrying it.

PLACE IT ON YOUR DESK

There is some packaging material under the build plate. You can easily remove it by lifting the build plate with your hands. At last, cut the zip tie with which the print head is secured and your Ultimaker 2 Go is ready to use!

WHAT'S INCLUDED?

Supplied with your Ultimaker 2 Go is an SD card in the 3D printer and several other accessories as well. This is everything you need to start printing. Before continuing make sure to check if all accessories are included.

- Power supply and cable

- Spool holder

- Glass plate

- 0.75 kg filament

- USB cable

- Blue tape

- Grease

- Hex wrenches (1.5 mm, 2 mm, 2.5 mm)

- Calibration card

- Test print

- Spare parts (hot end, PT100 sensor)

INSTALLATION

SPOOL HOLDER

The first step of setting up your Ultimaker 2 Go is attaching the spool holder at the back side of the Ultimaker 2 Go. Make sure to install the spool holder as described below.

- Take the spool holder and insert the top part in the corresponding hole at the back of the Ultimaker 2 Go.

![Ultimaker - 2 Go - SPOOL HOLDER - Step 1 SPOOL HOLDER - Step 1]()

- Push the spool holder down until it snaps into place.

![Ultimaker - 2 Go - SPOOL HOLDER - Step 2 SPOOL HOLDER - Step 2]()

GLASS PLATE

The glass plate, with blue tape applied to it, is the print surface for prints on your Ultimaker 2 Go. It will be installed the following way.

- Place strokes of the blue tape next to each other on the glass plate and make sure they don't overlap.

- Open up the two build plate clamps at the front side of the build plate with a hex wrench.

- Gently slide the glass plate on the build plate and make sure it snaps into the build plate clamps at the back.

- Close the two build plate clamps at the front to secure the glass plate.

The build plate clamps can be sharp, therefore it is advised to use one of the hex wrenches for opening the build plate clamps.

POWER SUPPLY

To finish the installation the power supply will be connected. Before connecting it, make sure the power switch is in the "off" position.

- Connect the power cable to the power brick.

- Plug the power cable in the wall socket and connect the other side to the Ultimaker 2 Go. The flat side of this cable needs to point downwards.

FIRST USE

After finishing the installation it's time to turn the Ultimaker 2 Go on!

CONTROL

The display at the front side of the Ultimaker 2 Go shows all the necessary information for setting up and using your Ultimaker 2 Go. You can navigate through menus by rotating and/or pushing the button at the right side of the display. Rotating allows you to select or control an action; by pushing you can confirm an action. When pushing the button you will hear a "beeping" sound to confirm the action. A blinking button means the Ultimaker 2 Go is waiting for user input.

BED LEVELING

After the "Welcome" screen, the Ultimaker 2 Go will guide you through some steps for calibrating the build plate. For printing it is very important that the first layer is nicely squished into the glass plate and sticks well to it. If the distance between the nozzle and build plate is too big, your print won't stick properly to the glass plate. On the other hand, if the nozzle is too close to the build plate it can prevent the filament from extruding from the nozzle.

NOTE: If you don't see the configuration wizard, navigate to "Maintenance" > "Advanced" and confirm for a Factory reset. You can use this function at any time.

Before the bed leveling can be done, the Ultimaker 2 Go will first do the "homing". This means that it will move the print head to the left back corner and the build plate towards the bottom, in order to set the origin point. After this, you can follow the steps below for leveling the build plate.

- The first step is to roughly level the build plate by rotating the button at the front of your Ultimaker 2 Go until there is approximately 1 mm distance between the nozzle and build plate. The measurement here is not critical; just make sure that the nozzle is close to the build plate without touching it.

- Next, a rough adjustment will be done on the front left and right side by turning the build plate screws. Turning the build plate screws to the left means that the build plate will get closer to the nozzle. Again there should be a distance of approximately 1 mm between the nozzle and build plate.

- The last step will be fine-tuning of the build plate with the "calibration card". Place the calibration card in between the nozzle and build plate on all 3 points and adjust the build plate screws until you feel slight friction when moving the card.

NOTE: Don't push on the build plate while fine-tuning with the calibration card; this will lead to inaccuracies.

LOADING FILAMENT

After bed leveling it is time to further prepare the Ultimaker 2 Go for the first print by loading filament.

Now you can start loading the filament in the following way.

- Before loading the filament, the spool with filament has to be placed on the spool holder. Make sure to place it with the filament in clockwise direction, so that the filament can enter the feeder from the bottom. It's also recommended to straighten the filament a bit so it can easily enter the feeder.

- Next, wait a minute while the print head is heating up. By heating it up we ensure that the filament is being melted when it goes through the nozzle.

- Take the end of the filament, insert it into the bottom of the feeder and push it until the filament is being grabbed by the knurled wheel. This may require some force. Once the knurled wheel has grabbed the filament, it will slowly move it further into the bowden tube.

- Wait till the filament reaches the first black bowden tube clip and then press the button to continue. The Ultimaker 2 Go will automatically load the filament through the bowden tube, into the print head.

Now you just have to wait until the filament is coming out of the nozzle. You may notice a ticking sound at the feeder; this is nothing to worry about. If necessary you can manually push the filament in order to get it through the nozzle with a bit more force.

Make sure to not touch the nozzle/hot end during this procedure as it will become hot.

NOTE: Don't be surprised if the filament that initially comes out of the nozzle is not the color you expect. There is probably some residue from the factory test print left in the nozzle. Wait until you see the color of the filament that you loaded coming out of the nozzle.

START A PRINT

Now the build plate has been leveled and filament loaded you're ready to start your first print! We've placed some print files on the SD card to start with. Simply select one of the files and press the button to start.

After a print file has been chosen the Ultimaker 2 Go will prepare itself by homing the print head and build plate and heating up the build plate and nozzle. This may take a few minutes.

While printing, the display will show the progress of the print and the remaining time for completion. When the print has finished, wait for the build plate to cool down and grab the print from the build plate.

Don't touch the print head/nozzle while it is heating, printing or cooling down. Temperatures can reach up to 260°C.

THE BASICS

This chapter will explain you more about the basic procedures for using your Ultimaker 2 Go. You will for example find information on changing filament and bed leveling, but also the use of our software Cura is explained here.

CHANGING FILAMENT

If you want to switch between different (colors of) materials you first need to unload the filament that is already in the Ultimaker 2 Go, after which you can insert the new filament.

REMOVE OLD FILAMENT

Removing the filament can simply be done by following the steps below.

- Access the material change menu on your Ultimaker 2 Go by going to "Material" > "Change".

- Wait a minute while the print head is heating up. By heating it up we ensure that the filament is being melted before retracting it from the nozzle.

- When the nozzle is hot, the Ultimaker 2 Go will automatically start turning the feeder wheel, through which the filament will be rewinded completely. If the filament doesn't come out of the feeder completely you can simply pull it out by hand.

Note: Make sure there are no small pieces of filament left in the feeder before inserting new material. For removing small pieces of filament you can use tweezers. For easier access you can loosen the bowden tube at the top of the feeder by removing the clamp clip, pressing down the tube coupling collet and pulling out the bowden tube.

LOAD NEW FILAMENT

After removing the filament you can start loading the new filament in the same way as done during the first setup of your Ultimaker 2 Go. Make sure the old spool with filament is removed from the spool holder and the new one is placed.

- Take the end of the filament, insert it into the bottom of the material feeder and push it until the filament is being grabbed by the knurled wheel. This may require some force. Once the knurled wheel has grabbed the filament, it will slowly move it further into the bowden tube.

- Wait till the filament reaches the first black bowden tube clip and then press the button to continue. The Ultimaker 2 Go will automatically load the filament through the bowden tube, into the print head.

Now you just have to wait until the filament is coming out of the nozzle. You may notice a ticking sound at the feeder; this is nothing to worry about. If necessary you can manually push the filament in order to get it through the nozzle with a bit more force.

BED LEVELING

As explained in GETTING STARTED chapter the first layer of a print is very important. Therefore regular bed leveling is advised. Always relevel the build plate when you notice that the plastic is not equally placed on the glass plate. After transportation of your Ultimaker 2 Go it is also advised to re-level the build plate to ensure your 3D prints stuck well to the build plate.

BED LEVELING PROCEDURE

The basic steps for bed leveling are described below.

- Go to "Maintenance" > "Build plate" to start the bed leveling process on your Ultimaker 2 Go.

- Wait for the Ultimaker 2 Go to do its homing procedure and continue when the print head is in the center at the back of the build plate.

- The first calibration step is to roughly level the build plate by rotating the button at the front of your Ultimaker 2 Go until there is approximately 1 mm distance between the nozzle and build plate. The measurement here is not critical; just make sure that the nozzle is close to the build plate without touching it.

- Next, a rough adjustment will be done on the front left and right side by turning the build plate screws. Turning the build plate screws to the left means that the build plate will get closer to the nozzle. Again there should be a distance of approximately 1 mm between the nozzle and build plate.

- The last step will be fine-tuning of the build plate with the calibration card. Place the calibration card in between the nozzle and build plate on all 3 points and adjust the build plate screws until you feel slight friction when moving the card.

Note: Don't push on the build plate while fine-tuning with the calibration card; this will lead to inaccuracies.

CURA SOFTWARE

For the Ultimaker 2 Go, we recommend our free Cura software to prepare your 3D print files. Cura quickly and accurately converts 3D models into 3D print files within seconds, showing you a preview of the print so you can be sure everything is as you would like it to be.

INSTALLATION

The Cura software can be found at www.ultimaker.com/software. After downloading, open the installer and run the installation wizard to complete the installation. When opening Cura for the first time, you will be asked to select your 3D printer; select the Ultimaker 2 Go. No other configuration is required and you can directly start using Cura.

USING CURA

The basic process of converting a 3D model to a print file in Cura is described below.

- Load a 3D model (STL, OBJ, DAE or AMF file) into Cura via the "Load" button.

- Choose your desired settings and wait for Cura to slice the model.

- When Cura has converted the file you can save the print file (GCode) via the "Save" button. If the SD card has been inserted it will directly save the file to the SD card.

- Remove the SD card from your computer - make sure to safely remove it - and insert it in your Ultimaker 2 Go to start printing.

When using Cura for the first time you will see the "Quickprint" profiles. This is perfect for beginners, but when you're a more experienced user and want to have more control over the print settings you can also switch to the "Advanced" mode. For more information on using Cura you can visit the Cura support pages: www.ultimaker.com/support/software

UPDATING FIRMWARE

Regularly a new Cura version is released, including a new firmware version as well. Make sure to install the latest version of Cura and firmware once available in order to stay up to date. The latest version of Cura can always be found at www.ultimaker.com/software

In order to install the latest firmware to your Ultimaker 2 Go, please take the following steps:

- Connect the Ultimaker 2 Go to your computer with the USB cable.

- Attach the power supply and turn the Ultimaker 2 Go on.

- Start Cura and go to "Machine" > "Install default firmware" (make sure the Ultimaker 2 Go is selected in the "Machine" menu). Cura will now automatically upload the latest firmware to your Ultimaker 2 Go.

DISPLAY AND CONTROLLER

When turning on your Ultimaker 2 Go, you will always see the Ultimaker logo first after which you will go to the main menu. The main menu offers three options: PRINT, MATERIAL and MAINTENANCE.

PRINT

The "Print" menu simply allows you to select one of the print files on the SD card and will automatically start the print after that.

MATERIAL

In the "Material" menu you can either change the filament on your Ultimaker 2 Go or change the settings of material profiles. When selecting "Change" the Ultimaker 2 Go will start the procedure as described in THE BASICS chapter. In the "Settings" menu you can select material profiles and change their settings in the "Customize" menu.

MAINTENANCE

The "Maintenance" menu offers various options. By selecting "Build plate" you will be guided through the bed leveling steps. In the "Advanced" menu several options can be selected in order to manually do certain actions or change machine settings. Below a short overview of all these options is shown.

- LED settings

Change the settings of the LED lights in your Ultimaker 2 Go - Heatup nozzle

Set custom temperature to manually heat up the nozzle - Home head

Homes the head in the left back corner of the Ultimaker 2 Go - Lower buildplate

Moves the build plate to the bottom of the Ultimaker 2 Go - Raise buildplate

Moves the build plate to the top of the Ultimaker 2 Go - Insert material

Heats up the nozzle after which you can insert filament - Move material

Heats up the nozzle after which you can use the scroll wheel to forward the material - Set fan speed

Set the speed of the two fans at the sides of the print head - Retraction settings

Customize the settings for retraction - Version

Shows the current firmware version on the Ultimaker 2 Go - Runtime stats

Shows for how much time the Ultimaker 2 Go has been on and printing - Factory reset

A complete reset of your Ultimaker 2 Go through which you can completely recalibrate it

FINE-TUNING

The Ultimaker 2 Go also offers you the possibility to fine-tune settings during the printing process. This allows you to get full control over the printing process and helps you achieving the best print results. You can do this by accessing the "Tune" menu during printing. The Tune menu basically shows you the same settings as in the Advanced menu, which means that you can change settings like for example the temperature and speed of printing. Furthermore, it is possible to select "Pause", after which you can change the filament in the middle of a print and resume again.

BASIC MAINTENANCE

In order to have a smoothly working Ultimaker 2 Go it is important to maintain it correctly. In this chapter the most important maintenance tips are described. It is recommended to read them carefully in order to achieve the best results with your Ultimaker 2 Go.

BLUE TAPE

REPLACING THE BLUE TAPE

After a lot of printing, the blue tape that is on the glass plate may wear or damage a little bit. This can cause an uneven print surface or bad adhesion to the print and it is therefore recommended to replace it once in a while. When doing this, always make sure that the Ultimaker 2 Go is turned off.

- Before taking out the glass plate, manually move the build plate to the bottom of the Ultimaker 2 Go. This way damage on the print head or Z trapezoidal leadscrew is prevented.

- Open up the build plate clamps at the front side by using a hex wrench and slide the glass plate to the front of the build plate until you can take it out of the Ultimaker 2 Go.

- Remove the damaged tape and place new strokes of blue tape on the glass plate. Place them next to each other and make sure they are not placed over each other. It is also advised to not put tape on the place where the build plate clamps cover the glass plate.

- The glass plate can simply be place back by sliding it onto the build plate until it snaps into the build plate clamps at the back of the build plate. Close the build plate clamps at the front side by hand in order to secure it.

NOTE: In order to be sure about a successful next print we recommend to re-level the build plate after having repositioned the glass plate.

THE FEEDER

Using the feeder in the right way and keeping it clean is important for a good extrusion. Tips on maintaining the feeder are described below.

FEEDER TENSION

In order to guide the filament properly through the feeder into the bowden tube and print head, it's important that the tension on the feeder is set correctly. If the tension is too high, it means that the knurled wheel of the feeder will dig into the filament, through which it flattens or - even worse - completely gets stuck. This is what we call grinding.

To prevent grinding of the filament it is therefore important to set the tension on the feeder as loose as possible, meaning that the white insert clip should be completely at the top. You can achieve this by inserting one of the hex wrenches in the hole on top of the feeder and turning it clockwise.

CLEANING THE FEEDER

After a lot of printing, the knurled wheel in the material feeder can accumulate small plastic particles. You can clean this by blowing air on the knurled wheel or using a simple brush. It is also recommended to clean the feeder when you notice grinding of the filament.

LUBRICATING THE AXES

To maintain your Ultimaker 2 Go correctly and keep it running smoothly it is recommended to lubricate the axes once in a while.

X AND Y AXES

When you notice small ridges on the surfaces of your 3D printed objects or feel that the X and Y axes are dry it is advised to put a single drop of sewing machine oil onto the X and Y axes. This will help your Ultimaker 2 Go running smoothly. Sewing machine oil is not included in the Ultimaker 2 Go package, but we highly recommend to only use this for lubricating the X and Y axes.

Z TRAPEZOIDAL LEADSCREW

Once every half year the Z trapezoidal leadscrew has to be lubricated with Magnalube. This is the green grease that was delivered with your Ultimaker 2 Go. Make sure to spread 10 drops of grease over the entire threaded rod. With your next print the Ultimaker 2 Go will lubricate the axis itself by moving up and down.

NOTE: Magnalube should be applied to the Z trapezoidal leadscrew only; make sure to not put it on any of the other axes.

ATOMIC METHOD

After a longer time of using your Ultimaker 2 Go you might notice some signs of "under extrusion". This means that your Ultimaker 2 Go can't extrude enough plastic and is usually shown by very thin or missing layers in a print. In most cases, it is caused by some dirt or carbonized material in the nozzle or another hot end part through which a (partial) blockage is created. When under extrusion appears it is recommended to use the Atomic Method in order to clean the nozzle and other hot end parts. Below, the process of this simple though very effective method is described.

NOTE: It is also advised to use the Atomic Method when switching from a material that needs a higher printing temperature to one that uses a lower printing temperature in order to make sure any residue from the previous filament is removed.

REMOVE THE FILAMENT

- Go to MATERIAL > CHANGE in order to remove the filament and instead of inserting new material, select CANCEL

- Keep the print head in the corner

REMOVE THE BOWDEN TUBE

- Open the black plastic clip that is around the bowden tube and print head cable closest to the print head

![Ultimaker - 2 Go - REMOVE THE BOWDEN TUBE - Step 1 REMOVE THE BOWDEN TUBE - Step 1]()

- Remove the (blue or red) clamp clip

![Ultimaker - 2 Go - REMOVE THE BOWDEN TUBE - Step 2 REMOVE THE BOWDEN TUBE - Step 2]()

HEAT UP AND PREPARATION

- Go to MAINTENANCE > ADVANCED > Heatup nozzle and set the temperature to 260 degrees

- Cut off approximately 20 cm of filament with a straight cut and try to straighten the filament as much as possible

- When the temperature is reached, insert the straightened piece of filament manually all the way down to the nozzle

- Push it slightly until either the new filament comes out of the nozzle or until the filament can't be pushed any further

REMOVE THE NEW FILAMENT

- Lower the temperature to 90 degrees (for PLA) or 110 degrees (for ABS)

- Once the temperature has been reached, pull the filament out with a quick, firm pull

- Check the color and shape of the tip of the filament; the goal is to have a clean, cone-shaped tip

- Repeat step 3 and 4 until the filament comes out without any residue and has a cone-like shape

RE-ASSEMBLY

- Insert the bowden tube through the tube coupling collet all the way down into the PTFE coupler

![Ultimaker - 2 Go - RE-ASSEMBLY - Step 1 RE-ASSEMBLY - Step 1]()

- Place the clamp clip around the tube coupling collet so that it secures the bowden tube

![Ultimaker - 2 Go - RE-ASSEMBLY - Step 2 RE-ASSEMBLY - Step 2]()

TROUBLESHOOTING

Below a short overview of the most common issues is shown. And the next page will show an overview of possible errors on the Ultimaker 2 Go. For more instructions please take a look at our website: www.ultimaker.com/support

EXTRUSION PROBLEMS

Extrusion problems can occur in different ways and can have several reasons. The nozzle could simply be completely block, through which no material is coming out of the nozzle at all. But it could also mean that the Ultimaker 2 Go just doesn't extrude enough plastic, leading to very thin or missing layers in a print. This is what is called "under extrusion".

In most cases, extrusion problems are caused by some dirt or carbonized material in the nozzle or another hot end part through which a (partial) blockage is created. In order to get rid of this there are a few things that can be done:

- Check if the filament has not grinded in the feeder. If it did, remove it from the machine first.

- Make sure the tension on the feeder is as loose as possible (white insert clip at the top).

- Try to manually extrude some material by using the 'Move material' option in the Advanced menu. You can put some extra force on it by manually pushing the material at the feeder while doing this.

- Use the Atomic Method to remove any dirt or carbonized material from the hot end.

After having used the Ultimaker 2 Go for a longer time already it could also mean that the PTFE coupler has deformed, causing fritcion to the filament. This consumable item has the tendency to wear over time due to the heat and pressure from the hot end. If none of the above described options works, it is advised to take a closer look at the PTFE coupler. A deformed PTFE coupler can be recognized by a (small) brim on the inside at the bottom. Instructions for this can be found on the website.

CAN'T CONNECT TO CURA

If Cura doesn't recognize your Ultimaker 2 Go when you want to upload firmware, there is a problem with the connection due to software or hardware failure. The following checks are advised in this case:

- Make sure everything is connected properly (power supply and USB cable) and that the Ultimaker 2 Go is turned on when uploading firmware. If possible, you can also try another USB cable.

- Check if the latest version of Cura is installed on your computer.

- Try connecting on a different computer, preferably with a different Operation System.

PRINT NOT STICKING TO BUILD PLATE

When you're experiencing difficulties with prints sticking to the build plate, there could be a few things going on. It could either mean that the first layer just doesn't stick well enough or that the prints gets loose due to "warping" of the plastic. Warping basically happens because of the properties of the plastic. Plastics have the tendency to shrink when cooling down fast (some plastics more than others), which could eventually lead to your print curling up (at the corners).

In order to decrease the amount of warping and have a good first layer you can do the following:

- In order to have a nice first layer, make sure that the build plate is properly leveled.

- For good adhesion the blue tape must not be too damaged. Therefore it's important to replace it once in a while.

- A nice feature in Cura to help preventing warping is called "Brim". It will place a single layer thick flat area around your object, thus creating a bigger adhesion surface.

ERROR MESSAGES

ERROR - STOPPED TEMP SENSOR | This refers to a problem with the PT100 B sensor, which is the sensor that measures the temperature of the nozzle. It means that the sensor registers incorrect values and due to safety reasons it will prevent the nozzle from heating up. The most likely reason for this is connection problem, which could either happen due to a bad connection at the main board or damage of the sensor itself. |

ERROR - HEATER ERROR | The heater error can appear when the sensor doesn't register a steady (increase in) temperature. This could mean that the heater cartridge is not connected properly and to prevent overheating of the nozzle it will therefore turn the heater cartridge off. |

Z-SWITCH BROKEN or Z-SWITCH STUCK | If you get one of these errors it means that there is a problem with the Z limit switch. It either tells you that the Z limit switch can't be pressed or that something is preventing the lever of the switch from switching back. |

X OR Y SWITCH BROKEN | This error occurs when either the X or Y limit switch is not activated while the print head is homing. |

SUPPORT

In case you run into any difficulties with your Ultimaker 2 Go or need advice on using your Ultimaker 2 Go, then please take a look at our website: www.ultimaker.com/support

The website contains a wealth of (troubleshooting) information and is a great source for quickly trying to solve issues on your own and getting more experienced with 3D printing. We also have a very active online community with experienced users who are willing to share tips and solutions and can help you getting the best out of your Ultimaker 2 Go as well.

If you ever need personal help resolving an issue with your Ultimaker 2 Go you can also get in touch with one of our local support partners. On the website you can find all the contact details.

SAFETY

ELECTRICAL SAFETY

The Ultimaker 2 Go operates on 24 volts (Extra-low-voltage) and is therefore outside the scope of the low-voltage directive. The power supply meets all CE mark regulations and is protected against short-circuit, overload, over voltage and over temperature. For more information concerning electrical safety aspects we refer you to the Mean Well ECConformity Declaration for the GS220AX power adapters.

Only use the Ultimaker 2 Go with power supplies and cables supplied by Ultimaker B.V..

Always unplug the printer before doing maintenance or modifications.

MECHANICAL SAFETY

The Ultimaker 2 Go contains many moving parts, but the stepper motors do not have enough power to cause serious injuries and moving gears have been covered. Still, it is advised to only reach in the machine when it is turned off.

Always unplug the printer before doing maintenance or modifications.

RISK OF BURNS

There is a potential risk of burns, as the print head can reach temperatures of up to 260°C and the heated bed of up to 120°C. The nozzle of the print head is mostly surrounded by an aluminum cover to prevent contact, but still we advise against reaching in the machine when the print head and/or heated bed are hot.

Always let the printer cool down for at least 30 minutes before doing maintenance or modifications.

HEALTH

The Ultimaker 2 Go is designed to print with PLA filament. The use of other materials is at your own risk.

Printing pure PLA is considered safe, although good ventilation is still advised for possible unknown vapors released from coloring dyes in colored PLA.

Only use your printer in a well-ventilated area.

GENERAL SAFETY INFORMATION

The Ultimaker 2 Go is not intended for use by persons (including children) with reduced physical and/or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning the use of the appliance by a person responsible for their safety.

Children should be under constant supervision when using the printer.

The above information is believed to be correct but does not purport to be all inclusive and shall be used only as a guide.

The conditions or methods used for assembling, handling, storage, use or disposal of the device are beyond our control and may be beyond our knowledge. For this and other reasons, we do not assume responsibility and expressly disclaim liability for loss, injuries, damage, or expense arising out of or in any way connected with the assembly, handling, storage, use or disposal of the product.

The information in this document was obtained from sources which we believe are reliable. However, the information is provided without any warranty, express or implied, regarding its correctness.

Documents / Resources

References

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the 2 Go and is the answer not in the manual?

Questions and answers