Advertisement

Quick Links

INSTRUCTION MANUAL

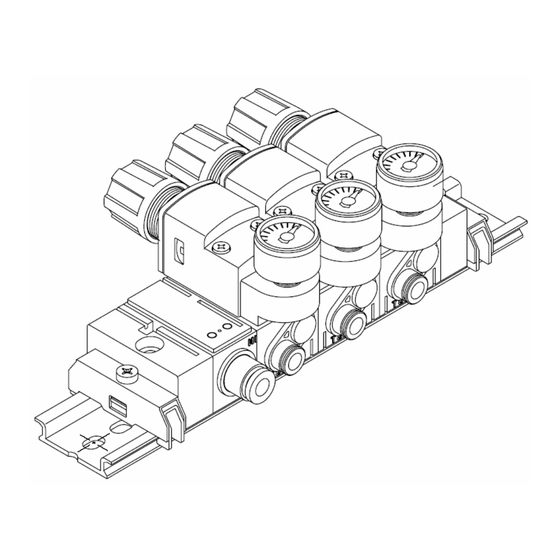

COMPACT DIRECT OPERATING PRECISION REGULATOR

MIX MANIFOLD OF RJB500

● Please read this instruction manual carefully before using

this product, particularly the section describing safety.

● Retain this instruction manual with the product for

further consultation whenever necessary.

MNRJB500 Series

SM-288427-A

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for CKD MNRJB500 Series

- Page 1 SM-288427-A INSTRUCTION MANUAL COMPACT DIRECT OPERATING PRECISION REGULATOR MIX MANIFOLD OF RJB500 MNRJB500 Series ● Please read this instruction manual carefully before using this product, particularly the section describing safety. ● Retain this instruction manual with the product for further consultation whenever necessary....

- Page 2 1.This product is designed and manufactured as a general industrial machine part It must be handled by someone having sufficient knowledge and experience. 2.Use this product within its specifications. Consult with CKD for details when using the product beyond the unique specification range, outdoors, or in the following conditions or environment: Additionally, the product must not be modified or machined. ① Use for special applications requiring safety including nuclear energy, railroad, aviation, ship, vehicle, medical equipment, equipment or applications coming into contact with...

- Page 3 If any failure for which CKD CORPORATION is recognized to be responsible occurs within the above warranty period, a substitute or necessary replacement parts shall be provided free of charge, or the product shall be repaired free of charge at the plant of CKD CORPORATION. However, the guarantee excludes following cases: ①...

- Page 4 SM-288427-A 【 INDEX 】 1. UNPUCKING …………………………………………… 2. INSTALLATION Installation Environment ……………………… 4 Piping …………………………………………… 4 Installation ……………………………………… 6 3. OPERATION Precautions …… …… …… …… …………………7 4. MAINTENANCE Inspection …… …… …………………………… 8 Disassembling and Replacing the Regulator Block and the Supply Block …… 9 5. TROUBLE SHOOTING ……………………………...

- Page 5 SM-288427-A 1. UNPACKING 1) Make sure that the model number indicated on the product is matched with that you have ordered. 2) Check the exterior of the product for damage. 3) When the instruction manual supplied with the product thoroughly read this manual as well as that before starting operation.

- Page 6 SM-288427-A 5) Applicable piping tubes. A push in joint is used in connection. Tube coming off or air leakage could occur depending with outer diameter precision, wall thickness or hardness of piping tube. Use CKD specified tube. Outer Outer diameter...

- Page 7 SM-288427-A 2.3 Installation 1) Do not move or swing the regulator by holding the pressure adjustment knob. 2) Install the regulator as close to the intended pneumatic unit as possible. 3) When disassembling the regulator, secure enouth spase for disassembly. 4) When installing the block manifold DIN rail-mounted type, fix the DIN rail, and secure the DIN rail fixtures on the outer side of the right and left end blocks that are attached to both end faces of the manifold.

- Page 8 SM-288427-A 3. OPERATION 3.1 Precautions 1) Check the primary pressure before setting the pressure. 2) Pressure higher then the primary pressure can not be set. 3) Pull the pressure adjustment knob to unlock it Push the pressure adjustment knob in to lock it.

- Page 9 0.7MPa. In this case, lower the primary pressure. Consult with CKD if pulsations or oscillating sound may still does not cease. 4) When pressure setting, confirm the set pressure to change directional control valve.

- Page 10 SM-288427-A 4.2 Disassembling and Replacing the Regulator Block and the Supply Block 1) When replacing the rail-mounted type DIN, first unfasten the DIN rail fixture set screws. In the case of the direct mounted type that does not use the DIN rail, remove the end block fixing screws.

- Page 11 SM-288427-A 5. TROUBLE SHOOTING Trouble symptom Cause Remedy Air leaks from the The compressed air flows from the Cut off the compressed air, and connect the bottom of the knob ①. OUT port to the IN port. piping to the IN and OUT ports correctly. Shut off the compressed air, disassemble The body packing is shrunken or Air leaks ②...

Need help?

Do you have a question about the MNRJB500 Series and is the answer not in the manual?

Questions and answers