Summary of Contents for Danfoss Series 40 M46 Tandem

- Page 1 Service Manual Axial Piston Variable Pumps Series 40 M46 Tandem powersolutions.danfoss.com...

- Page 2 Service Manual Series 40 M46 Tandem Variable Pumps Revision history Table of revisions Date Changed September 2017 minor edit - Displacement limiter torque change 0202 November 2014 Danfoss layout September 2010 New Back Page March 2010 Fix Osaka address March 2009...

-

Page 3: Table Of Contents

Service Manual Series 40 M46 Tandem Variable Pumps Contents Introduction Overview......................................4 Warranty......................................4 General instructions..................................4 Safety precautions....................................4 Symbols used in Danfoss literature............................6 Design........................................6 The system circuit.....................................7 Pump schematic....................................9 Fluid and filter maintenance Fluid and filter recommendations............................10 Initial startup procedures General ......................................11... -

Page 4: Overview

A worldwide network of Danfoss Global Service Partners is available for major repairs. Danfoss Global Service Partners are trained by the factory and certified on a regular basis. You can locate your nearest Global Service Partner using the distributor locator at www.sauer-danfoss.com. -

Page 5: Danfoss | September

Service Manual Series 40 M46 Tandem Variable Pumps Introduction Unintended machine movement Warning Unintended movement of the machine or mechanism may cause injury to the technician or bystanders. To protect against unintended movement, secure the machine or disable/disconnect the mechanism while servicing. -

Page 6: Symbols Used In Danfoss Literature

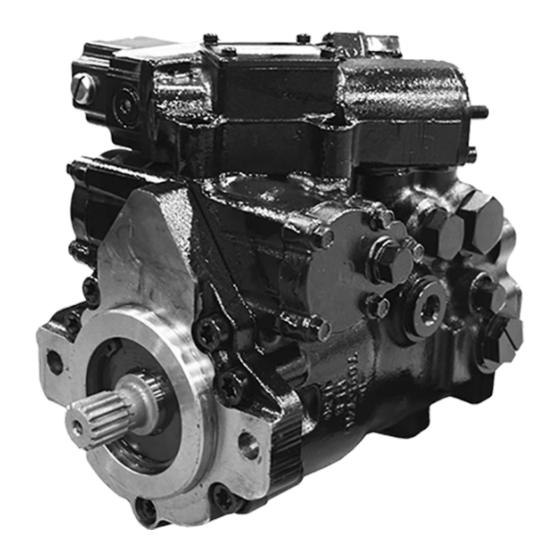

The legend above defines each symbol and explains its purpose. Design Danfoss Series 40 M46 closed circuit piston pumps convert input torque into hydraulic power. Rotational force is transmitted through the input shaft to the cylinder block. The input shaft is supported by bearings at the front and rear of the pump and is splined into the cylinder block. -

Page 7: The System Circuit

Service Manual Series 40 M46 Tandem Variable Pumps Introduction Cross section view Ball bearing Slipper Gerotor Piston Ball bearing Piston Valve plate Valve plate Slipper Shaft Journal Journal bearing bearing Swashplate Swashplate bearing pin bearing pin Cylinder block Servo piston... - Page 8 Service Manual Series 40 M46 Tandem Variable Pumps Introduction System circuit diagram Reservoir Heat exchanger bypass Control handle Filter Displacement Heat control exchanger valve Variable Cylinder block displacement assembly motor Cylinder block assembly Charge relief valve Bypass valve Output shaft...

-

Page 9: Pump Schematic

Service Manual Series 40 M46 Tandem Variable Pumps Introduction Pump schematic Pump schematic B N A P100 587E Above schematic shows the function of a Series 40 M46 axial piston variable displacement pump. 11029852 | AX00000030en-US0202 | 9 © Danfoss | September 2017... -

Page 10: Fluid And Filter Maintenance

Service Manual Series 40 M46 Tandem Variable Pumps Fluid and filter maintenance Fluid and filter recommendations To ensure optimum life, perform regular maintenance of the fluid and filter. Contaminated fluid is the main cause of unit failure. Take care to maintain fluid cleanliness when servicing. -

Page 11: Initial Startup Procedures

Service Manual Series 40 M46 Tandem Variable Pumps Initial startup procedures General Follow this procedure when starting-up a new pump installation or when restarting an installation in which the pump has been removed and re-installed on a machine. Ensure pump has been thoroughly tested on a test stand before installing on a machine. - Page 12 Service Manual Series 40 M46 Tandem Variable Pumps Initial startup procedures 11. Shut off engine. Connect pump control signal. Start engine, checking to be certain pump remains in neutral. Run engine at normal operating speed and carefully check for forward and reverse control operation.

-

Page 13: Pressure Measurements

Service Manual Series 40 M46 Tandem Variable Pumps Pressure measurements Required tools The service procedures described in this manual can be performed using common mechanic’s hand tools. Special tools, if required, are shown. When testing system pressures, calibrate pressure gauges frequently to ensure accuracy. - Page 14 Service Manual Series 40 M46 Tandem Variable Pumps Pressure measurements Port locations P106663 11029852 | AX00000030en-US0202 14 | © Danfoss | September 2017...

-

Page 15: Troubleshooting

Service Manual Series 40 M46 Tandem Variable Pumps Troubleshooting Overview This section provides general steps to follow if undesirable system conditions are observed. Follow the steps listed until the problem is solved. Some of the items will be system specific. For areas covered in this manual, a section is referenced. -

Page 16: System Will Not Operate In One Direction

Service Manual Series 40 M46 Tandem Variable Pumps Troubleshooting Item Description Action Oil filters Clogged oil filters may result in an insufficient Inspect the oil filters and verify that they are still supply of cool oil to the system. operable. Replace them if necessary. -

Page 17: Neutral Difficult Or Impossible To Find

Service Manual Series 40 M46 Tandem Variable Pumps Troubleshooting Item Description Action SCR (system check / relief) valves The SCR valves are malfunctioning or improperly Verify that the SCR valves are operating and set. properly set. Repair or replace them as necessary. -

Page 18: Electrical Troubleshooting

Service Manual Series 40 M46 Tandem Variable Pumps Troubleshooting Item Description Action Servo pressure There is insufficient pressure differential across the Check servo pressures at port M4 and M5 to verify servo piston. sufficient pressure delta. Verify that the servo supply and drain paths are unobstructed and that each orifice is of the correct size and free of debris. -

Page 19: Adjustments

6. Drain and flush the hydraulic system and replace all filters. 7. Before re-installing the pump, perform a leakage test per Sauer-Danfoss leakage test HPP 112. Warranty Performing installation, maintenance, and minor repairs according to the procedures in this manual will not affect your warranty. -

Page 20: Engaging The Bypass Function

Service Manual Series 40 M46 Tandem Variable Pumps Adjustments 8. Remove gages. Operate pump and check for leaks. Charge pressure adjustment 1 in. 11/16 in Charge pressure gage port P106 666E Engaging the bypass function Test bypass function with pump installed on machine. The bypass function is engaged by unscrewing the bypass valve. -

Page 21: System Check/Relief (Scr) Valves

Service Manual Series 40 M46 Tandem Variable Pumps Adjustments Using the bypass function Bypass valve 5/8 in Bypass valve 5/8 in P106667 System check/relief (SCR) valves The SCR valve is a high pressure relief valve and a system check valve in combination. Whenever an SCR valve has been replaced or opened, the pump should be operated in its full range of functions to ensure proper machine operation. -

Page 22: Displacement Limiter Adjustment

Service Manual Series 40 M46 Tandem Variable Pumps Adjustments 6. Using a 1-1/4 hex wrench install relief valve plug (166). Torque to 174 Nm [128 ft•lb]. Adjusting the HPRV’s 1-1/4 in 174 Nm [128 ft•lb] 1103 1103 1-1/4 in 174 Nm [128 ft•lb]... -

Page 23: Displacement Limiter Adjustment Data

Service Manual Series 40 M46 Tandem Variable Pumps Adjustments 5. One full turn of the adjusting screw will change the maximum displacement approximately as shown in the table below. Displacement limiter adjustment 9/16 in P106 672E Displacement limiter adjustment data... -

Page 24: Manual Displacement Control Bracket Neutral Adjustment

Service Manual Series 40 M46 Tandem Variable Pumps Adjustments Measured data • System pressure at MA or MC • System pressure at MB or MC • Pressure differential between MA and MB or MC and MD (optional) Pump Setup 1. Attach 600 bar [10,000 psi] gauge to system pressure gage ports MA and MB or MC and MD 2. -

Page 25: Electronic Displacement Control/Hydraulic Displacement Control Neutral Adjustment

Service Manual Series 40 M46 Tandem Variable Pumps Adjustments Verify swashplate neutral adjustment (see Swashplate neutral adjustment on page 23) before performing control neutral adjustment. Measured data • Servo pressure at M4 • Servo pressure at M5 • Pressure differential between M4 and M5 (optional) Procedure 1. - Page 26 Service Manual Series 40 M46 Tandem Variable Pumps Adjustments Measured data • Servo pressure at M4 (refer to Port locations and gauge installation on page 13) • Servo pressure at M5 (refer to Port locations and gauge installation on page 13) •...

-

Page 27: Minor Repair

1. Before replacing the pump on the machine, replace all filters and drain the hydraulic system. Fill the system with the correct hydraulic fluid. 2. Flush the lines before replacing the hydraulic fluid. For repair part information, see Danfoss publication Series 40 M46 Variable Pump Parts Manual BLN-2-41702 for your model. Displacement limiter Removal 1. -

Page 28: Pressure Filtration Adapter

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair Inspection Inspect all parts for damage. Inspect the mating surfaces of the servo cover (902) and motor housing for scratches, grooves, and other damage. Inspect threads of screws and nuts for damage. Replace any damaged parts. -

Page 29: Charge Pump

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair Inspection Inspect the machined surface on the control. If any nicks or scratches are found, replace the damaged component. Reassembly 1. Install new gasket (805) and filtration cover (801). 2. Using a 1/2 hex wrench, install three bolts (806). Torque to 30 Nm [22 ft•lb]. - Page 30 Service Manual Series 40 M46 Tandem Variable Pumps Minor repair Charge pump removal 2407 2408 2304 2403 2404 2144 3/4 in 102 Nm 2150 [75 ft•lb] 2142 2147 1/2 in 102 Nm 2145 [75 ft•lb] 2405 Inspection Inspect the gerotor (2403) and gerotor cover (2304) for wear, scratches or pitting. If any component shows signs of wear, scratching, or pitting, replace all damaged components.

-

Page 31: Shaft Seal

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair Shaft seal The shaft assembly is serviceable without removing the front cover of the pump. Orient the pump on the work surface so the shaft is pointing up. Removal 1. Using a snap-ring pliers, remove snap-ring (2132) from pump cover. -

Page 32: Scr Valves

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair 2. Install Snap-ring (2132) using a snapring pliers. Shaft seal installation tool 7 in 2.75 in 0.750 in 0.370 in 1.24 in 1.5 in 2.45 in P106652 3 in SCR valves The SCR valves are factory set and are not field adjustable. -

Page 33: Charge Pressure Relief Valve

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair 2. Lubricate and install new O-ring (106) onto plug (166). Using a 1-1/4 hex wrench install relief valve plug (166). Torque to 174 Nm [128 ft•lb]. High pressure relief valves 1-1/4 in 174 Nm [128 ft•lb]... -

Page 34: Bypass Valve

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair 3. Operate pump at full range of controls to ensure proper machine operation. Charge pressure relief valve 1 in Bypass valve Removal 1. Using a 5/8 hex wrench, remove bypass valve (1001). -

Page 35: Manual Displacement Control

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair 3. Operate pump at full range of controls to ensure proper machine operation. Bypass valve 1001 5/8 in 20 Nm [15 ft•lb] 1002 1003 1003 1001 5/8 in 20 Nm [15 ft•lb]... -

Page 36: Electronic Displacement Control/Hydraulic Displacement Control

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair 3. Install neutral return spring (1214), neutral return bracket (1216), handle (1215), and washer (1235) onto spool (1207). Install control spool (1207) with alignment slot facing servo piston. Alignment slot... - Page 37 Service Manual Series 40 M46 Tandem Variable Pumps Minor repair 1. Using a 3/16 internal hex wrench, remove screws (1203 and 1204) or (1226 and 1224). 2. Remove control housing (1201) or control housing (1223) and manifold (1225). Remove and discard O-rings (1220 and 304) or (1227, 1228, and 1229).

-

Page 38: Mdc Orifice Repair

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair 2. Using a 3/16 internal hex wrench, install screws (1203 and 1204) or (1226). Torque to 14 Nm [10 ft•lb]. If necessary, install control housing (1223). Using a 4 mm internal hex wrench, install screws (1224). -

Page 39: Edc/Hdc Orifice Repair

Service Manual Series 40 M46 Tandem Variable Pumps Minor repair MDC orifice repair 1401 1/8 in 1219 3/16 in P106 680E EDC/HDC orifice repair Removal 1. Remove servo covers. See Displacement limiter on page 27, for servo cover removal and installation instructions. - Page 40 Service Manual Series 40 M46 Tandem Variable Pumps Minor repair 2. Install servo covers. EDC/HDC orifice repair 3/8 in 2161 1403 1404 P106 681E 3/8 in 9/16 in 11029852 | AX00000030en-US0202 40 | © Danfoss | September 2017...

-

Page 41: Torque Chart

Service Manual Series 40 M46 Tandem Variable Pumps Torque chart Fastener size and torque chart Item Fastener Wrench size Torque Servo piston cover screws 3/8 hex 15 N•m [11 ft•lb] Servo piston cover screws 3/8 hex 15 N•m [11 ft•lb]... - Page 42 Service Manual Series 40 M46 Tandem Variable Pumps Torque chart Hardware locations 2147 2107 2155 4115 1001 4135 4135 (3X) (3X) 2111 2111 1210 2504 2144 2110 1213 2148 1210 2110 2148 1213 (3X) 1001 2111 2111 2115 2115 4135...

- Page 43 Service Manual Series 40 M46 Tandem Variable Pumps 11029852 | AX00000030en-US0202 | 45 © Danfoss | September 2017...

- Page 44 Phone: +86 21 3418 5200 Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alterations can be made without changes being necessary in specifications already agreed.