Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for TYROLIT Hydrostress FSD1049 Series

- Page 1 Operating Instructions Floor Saw FSD1049 Index 001 10993834 EN / 10.11.2014...

- Page 2 Any repair work must be carried out by trained personnel only. Should you need more details concerning your TYROLIT Hydrostress unit in order to keep it in perfect condition, please contact our after-sales service for further information.

- Page 3 TYROLIT Hydrostress AG 1 Safety These instructions are just one part of the documentation which is supplied together with the floor saw. These instructions go together with the "Safety Manual / System Description for Floor Saws" to form a complete set of documentation.

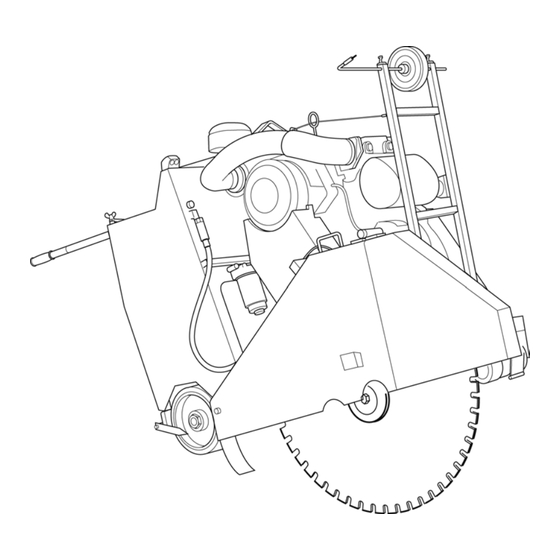

- Page 4 TYROLIT Hydrostress AG 2 Design Components Operating console Shaft cover Drive wheel Name plate Blade guard 10 Rear cut guide Main motor Saw blade 11 Water feed Front cut guide Rocker wheel 2.1 Saw blade drive Saw blade drive (schematic)

-

Page 5: Travel Drive

TYROLIT Hydrostress AG 2.2 Lift drive Lift drive (schematic) Hydraulic cylinder 2.3 Travel drive Travel drive (schematic) Drive shaft (main motor) Hydrostatic motors Drive chain Hydrostat drive belt Wheel drive shaft Drive wheel Floor Saw FSD1049 Page 5... - Page 6 TYROLIT Hydrostress AG 3 Transport DANGER Inexpert transport may result in death or serious injury. ► Floor saws must only be transported with the main motor switched off. ► Remove the blade before moving the flat saw with engaged motor while off-cut (transports).

-

Page 7: Initial Start-Up

TYROLIT Hydrostress AG 4 Initial start-up 4.1 Fitting battery ► Fit battery (for type see Technical Data). Floor Saw FSD1049 Page 7... -

Page 8: Assembly & Set-Up

TYROLIT Hydrostress AG 5 Assembly / Set-up 5.1 Mounting grip ► 5.2 Mounting saw blade 1. Apply hand brake Page 8 Floor Saw FSD1049... - Page 9 TYROLIT Hydrostress AG DANGER Parts that fly off (segments, concrete splinters, saw blade, etc.) may cause serious injury or even death. ► Floor saws must only be operated with a blade guard. ► When assembling the saw blade on the right-hand side use the anchoring screw with the left-hand thread.

- Page 10 TYROLIT Hydrostress AG To prevent the saw blade rotating while being tightened, carefully place the saw blade on the floor. 5.3 Mounting saw blade on the other side 5.3.1 Disassemble the blade guard ► Page 10 Floor Saw FSD1049...

- Page 11 TYROLIT Hydrostress AG 5.3.2 Disassemble the shaft cover ► 5.3.3 Assembling the blade guard and shaft cover on the other side Assembly of the blade guard and the shaft cover is performed in the opposite order to disassembly. 5.4 Connecting water line ►...

-

Page 12: Operation

TYROLIT Hydrostress AG 6 Operation 6.1 Overview of operating elements Operating elements Battery display Cutting depth indicator 13 Feed adjuster (forward / Motor temperature display Bit stop locking backward travel) Oil temperature display 10 On / Off control for internal... -

Page 13: Checking Oil Level

TYROLIT Hydrostress AG 6.2 Checking oil level ► Note the details from the motor manufacturer. 6.3 Checking the air filter The display in the window (1) has the following significance: Display colour Significance Yellow Air filter in good order Air filter blocked ►... -

Page 14: Checking The Fuel Level

TYROLIT Hydrostress AG 6.4 Checking the fuel level ► Check the tank display (1) and top up with diesel as necessary. 6.5 Positioning the floor saw 1. Release the hand brake. 2. Slide floor saw into the working position. 3. Fit the cutting guides to the floor saw. - Page 15 TYROLIT Hydrostress AG 6.7 Switch on motor Symbol Significance Coupling lever in coupled position Coupling lever in uncoupled position Coupling lever (6) is in the uncoupled position EMERGENCY STOP switch (5) has been released 1. Turn ignition key (2) to the preheat position in order to preheat the motor.

- Page 16 TYROLIT Hydrostress AG 6.8 Lowering / raising saw blade 6.8.1 Lowering example 1. Press the Lower button (3) until the saw blade touches the material to be cut. 2. Set the cutting depth indicator (1) in the 0 position. 3. Using the Lower key, lower the saw blade to the desired cutting depth.

-

Page 17: Adjusting The Feed

TYROLIT Hydrostress AG 6.9 Adjusting the feed Symbol Significance Coupling lever in coupled position Coupling lever in uncoupled position Feed adjuster in the forwards direction of travel Feed adjuster in the backwards direction of travel Feed adjuster is in the neutral position ... - Page 18 TYROLIT Hydrostress AG 6.10 Correcting the tracking Correcting the tracking Saw blade ► If the saw blade drifts, adjust the rear axle with the adjusting screw. Page 18 Floor Saw FSD1049...

- Page 19 TYROLIT Hydrostress AG 6.11 Gear selection procedure for 3-speed gearbox DANGER Failure to follow instructions can result in death or serious injury. The gear can only be changed if the motor is stationary. Never tamper with the gear selection mechanism with the motor running.

-

Page 20: Maintenance

TYROLIT Hydrostress AG 7 Maintenance When? What? ► Check oil level. Daily ► Perform a visual check for damage. ► Check belt and chain tension and adjust as Weekly necessary. ► Lubricate grease nipples. Every 50 hours of operation ► Arrange a major service by TYROLIT... - Page 21 TYROLIT Hydrostress AG 7.3 Tensioning chain on travel drive ► Tensioning chain Chain Floor Saw FSD1049 Page 21...

- Page 22 Feed not working Operation of the control rods impaired necessary. ► Check hydrostat and if necessary have Defective hydrostat this repaired by a TYROLIT Hydrostress engineer. ► Have the chain replaced by a TYROLIT Defective chain Hydrostress engineer. ► Check belt for wear and if necessary...

-

Page 23: Technical Data

TYROLIT Hydrostress AG 9 Technical data 9.1 Dimensions Parameter Value Weight 775 kg Cutting depth (max.) 430 mm Blade uptake diameter 25.4 mm Max. saw blade diameter 900 mm Dimensions (transport dimensions with blade L: 1,390 mm guard folded up) - Page 24 TYROLIT Hydrostress AG 9.5 Noise level and vibrations Parameter Value Noise level at workplace (L 91.4 dB(A)* Sound power level in accordance with 111.4 dB(A)* ISO 3744 (L Vibrations DIN EN ISO 5349-2 < 2.5 m/s² *Value applies under the following condition: Travel drive is switched off and the saw blade is not engaged.

-

Page 25: Cutting Data

TYROLIT Hydrostress AG 9.7 Cutting data Blade diameter Blade rpm operation Motor rpm Depth of cut 500 mm 2700 2700 (High) 700 mm 1800 2700 (Medium) 1000 mm 1200 2700 (Low) The gear may only be changed if the motor is stationary. Never tamper with the gear selection mechanism with the motor running. -

Page 26: Ec Declaration Of Conformity

TYROLIT Hydrostress AG EC declaration of conformity Description Floor Saw Type designation FSD1049 Year of construction 2007 Manufacturer TYROLIT Hydrostress AG We declare under our own liability that this product complies with the following directives and standards: Directive applied Machine Directive...

Need help?

Do you have a question about the FSD1049 Series and is the answer not in the manual?

Questions and answers