Subscribe to Our Youtube Channel

Summary of Contents for TYROLIT Hydrostress WZ

-

Page 1: Operating Instructions

Operating Instructions Wall saw WZ Index 006 10988309 EN / 17.05.2010... - Page 2 Any repair work must be carried out by trained personnel only. Our aftersales service is available to help ensure that your TYROLIT Hydrostress units remain in perfect working order.

- Page 3 Always use the blade guard when operating the wall saw. DANGER Serious injury or material damage as a result of uncontrolled movements of the wall saw. Never connect or disconnect hoses while the drive unit is running. Wall saw WZ Page 3...

-

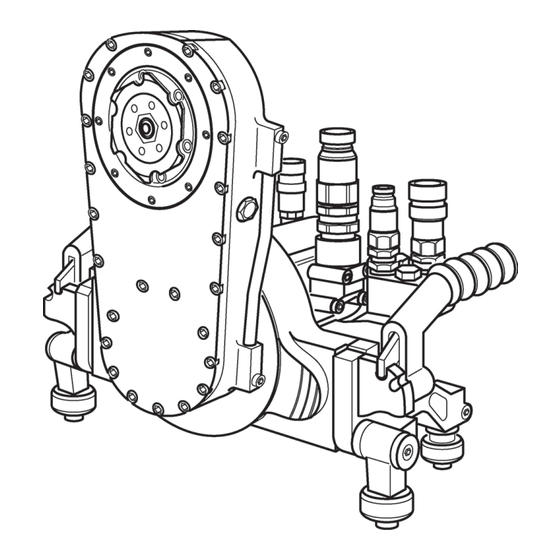

Page 4: Wall Saw System

Feed motor, swivel 2 Water connection Grip / lock unit 3 Saw blade holder Chassis 4 Blade guard holder 10 Water line 5 Name plate 11 Geared swivel arm 6 Blade drive motor 12 Guide roller Page 4 Wall saw WZ... -

Page 5: Adjusting The Guide Rollers

If the grips fail to engage or the wall saw sits too loosely on the guide rail: adjust the guide rollers. Adjusting the guide rollers * The guide rollers must sit in the guide groove, and it must be possible to turn them by hand. Wall saw WZ Page 5... -

Page 6: Mount The Drive Motor

Mount the saw blade DANGER It can cause death or serious injury if the saw blade flies away. Only use original screws and bolts from TYROLIT Hydrostress AG. DANGER Serious injury can be caused by sudden start-up of the saw blade. - Page 7 For normal cuts with saw blades up to Ø 1000 mm 40 Nm 40 Nm For normal cuts with saw blades larger than Ø 1000 mm 15 Nm 15 Nm 40 Nm 40 Nm Wall saw WZ Page 7...

- Page 8 It can cause death or serious injury if the saw blade flies away. Check whether the sleeve and central screw are countersunk. Tighten the central screw to a torque of 60 Nm. 60 Nm 60 Nm Page 8 Wall saw WZ...

- Page 9 Lift out the saw blade unit to the top when removing it. Disassemble the saw blade unit in the reverse order to the installation/assembly process. Mount the blade guard Mount the blade guard according to the instruction leaflet. Wall saw WZ Page 9...

- Page 10 TYROLIT Hydrostress AG Connecting the wall saw to the drive unit The drive unit is isolated from the power supply. Couplings are clean. Hoses are undamaged. Page 10 Wall saw WZ...

-

Page 11: Servicing And Maintenance

Blow out water Saw blade Clean with water Check for wear Service To be performed by TYROLIT Hydros- After 100 / 300 / 500 / 700 hours tress AG or an authorised workshop Wall saw WZ Page 11... -

Page 12: Replacing The Guide Rollers

TYROLIT Hydrostress AG Lubricate lock unit Change gear oil The use of unsuitable oil can damage the wall saw. Use only TYROLIT Hydrostress AG oil containers (no. 10981362, 10 cl). Replacing the guide rollers Defective guide rollers should be replaced with replacement set no. 10977911. -

Page 13: Technical Data

Mounted via quick-release device (size 2) Feed motor Geroller with integral overload and braking function Flush cutting Quick-release flange ST without blade cover Normal cutting Quick-release flange ST with blade cover Water Water connection on chassis Wall saw WZ Page 13... - Page 14 1538 1333 l/min 3750 2813 2500 2045 1731 1500 l/min 4167 3125 2778 2273 1923 1667 l/min 5000 3750 3333 2727 2308 2000 l/min 5833 4375 3889 3182 2692 2333 Operation possible Operation not possible Page 14 Wall saw WZ...

-

Page 15: Feed Motor, Travel

Blade cover mounting on blade flange 2 hexagonal bolts Cutting depth Ø 800 mm 320 mm Ø 1000 mm 420 mm Ø 1200 mm 520 mm Ø 1500 mm 670 mm Ø 1600 mm 720 mm Wall saw WZ Page 15... - Page 16 Lubricating grease (lock unit) Penetration 265 to 295NLGI NLGI Connectable drive units The wall saw must only be operated with the coordinated drive units from TYROLIT Hydrostress. Drive unit power requirements Parameter Value Minimum output: 20 kW (max. operating pressure 260 bar) Maximum performance 25 kW (max.

-

Page 17: Ec Declaration Of Conformity

Safety of machinery – Safety distances to prevent upper limbs reaching danger areas EN 349 Safety of machinery – Safety distances to avoid crushing of body parts EN 982 Safety of machinery – Safety requirements for safety systems and their components - hydraulics Wall saw WZ Page 17...

Need help?

Do you have a question about the WZ and is the answer not in the manual?

Questions and answers