Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Samoa OMEGA 10:1 EXT

- Page 1 OMEGA 10:1 EXT Pneumatic pump for extrusion ATEX Ex II 2 G c IIB T6 certified pump https://www.larius.com/wp-content/uploads/OMEGA_10_1_EXT_I.pdf 7457 OMEGA 10:1 Stainless steel neumatic pump https://www.larius.com/wp-content/uploads/OMEGA_10_1_EXT_UK.pdf...

- Page 2 This manual is to be considered as an English language translation of the original manual in Italian. The manufacturer shall bear no responsibility for any damages or inconveniences that may arise due to the incorrect translation of the instructions contained within the original manual in Italian. Due to a constant product improvement programme, the factory reserves the right to modify technical details mentioned in this manual without prior notice.

-

Page 3: Table Of Contents

WE ADVISE THE USE OF THIS EQUIPMENT ONLY BY PROFESSIONAL OPERATORS. ONLY USE THIS MACHINE FOR USAGE SPECIFICALLY MENTIONED IN THIS MANUAL. Thank you for choosing a SAMOA product. As well as the product purchased, you will receive a range of support services enabling you to achieve the results desired, quickly and professionally. -

Page 4: Awarnings

OMEGA 10:1 EXT WARNINGS The table below provides the meaning of the symbols used in this manual in relation to using, earthing, operating, maintaining, and repairing of this equipment. • Read this operator’s manual carefully before using the equipment. • An improper use of this machine can cause injuries to people or things. -

Page 5: Btransport And Unpacking

OMEGA 10:1 EXT TRANSPORT AND SAFETY RULES UNPACKAGING Read carefully and entirely the following • The packed parts should be handled as indicated in the symbols instructions before using the product. Please and markings on the outside of the packing. - Page 6 OMEGA 10:1 EXT • (IF PROVIDED) TIGHTEN AND CHECK ALL THE FITTINGS The machine is equipped with an anti-freeze FOR CONNECTION BETWEEN PUMP, FLEXIBLE HOSE AND system that allows it to work even at very low SPRAY GUN BEFORE USING THE EQUIPMENT.

-

Page 7: Eworking Principle

OMEGA 10:1 EXT WORKING PRINCIPLE OMEGA 10:1 EXT is a high pressure pneumatic pump used for transmitted through a connecting rod to the material pumping piston ending with a shovel plate allowing to suck very visous extrusion and transferring of high viscosity products. -

Page 8: Ftechnical Data

OMEGA 10:1 EXT TECHNICAL DATA OMEGA OMEGA Fluid outlet thread 3/4" BSPP (F) Pump pressure ratio 10:1 Fluid inlet thread 1 1/2" BSPP (F) Air pressure range 3-8 bar / 40-120 psi Pump tube material AISI 303 - Copper Maximum fluid outlet pressure... -

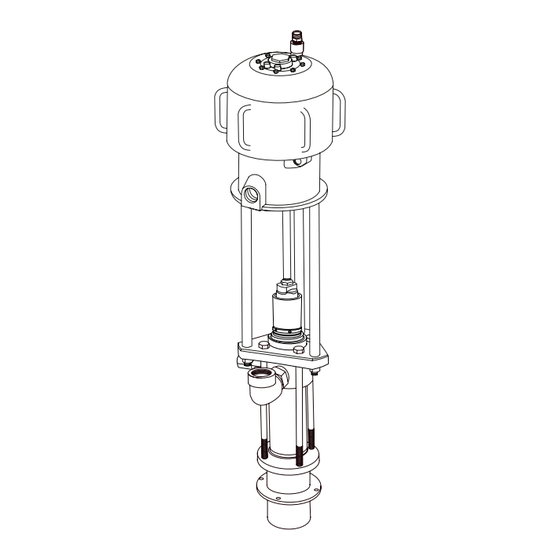

Page 9: Gdescription F The Equipment

OMEGA 10:1 EXT DESCRIPTION OF THE EQUIPMENT Fig. 1 Pos. Pos. Description Description Pos. Pos. Description Description Escape valve Escape valve Pump feed air inlet Pump feed air inlet Lubrificant cap Lubrificant cap Pneumatic motor Pneumatic motor Ring gasket press... -

Page 10: Htypical Installation

For pump feed use a hose with an internal diameter no lower than 20 mm. OMEGA 10:1 EXT pump can be installed on pneumatic double post ram whit shovel plate (see the picture - purely illustrative). Install at the pump inlet an air pressure regulator... -

Page 11: Kcleaning At The End Of The Work

OMEGA 10:1 EXT CLEANING AT THE END OF THE WORK By cleaning at the end of the work we mean the cleaning to carry out in case of use with a different product or if a long period of downtime is foreseen. -

Page 12: Mtroubleshooting

OMEGA 10:1 EXT TROUBLESHOOTING Problem Possible cause Solution The pump does not start Feeding air is not enough; Check the air supply. Increase the diameter of the feeding hose; Outlet product line clogged; Clean. Disconnect the outlet product pipe. Feed pump at minimum pressure and check if the pump starts without the outlet pipe;... -

Page 13: Ndisassembly Of The Pneumatic Motor

OMEGA 10:1 EXT DISASSEMBLY OF THE PNEUMATIC MOTOR • Turn counterclockwise the screws (8) [take care to the washers Always close the compressed air supply (9)] and remove the support (7) together with the rollers (10) and release the pressure in the plant before and the pins (11). - Page 14 OMEGA 10:1 EXT • Pull upwards the seat (17) so as to take out the valves (18), the O-rings (19) and the springs (20) (clean and/or replace the worn parts). • Unscrew the lock nut (21) [take care of the washer (22)] by keeping the bush (23) blocked using a wrench.

- Page 15 OMEGA 10:1 EXT • Turn counterclockwise the rod guiding screw (31) [take care to the washer (32)] and check the seal inside the screw (31) is undamaged. • Take out the screws (33) [take care of the washers (34)] and...

- Page 16 OMEGA 10:1 EXT • Check the gas ring inside the support (40) is undamaged. • Check the gasket (41) is undamaged and correctly positioned. • Coat the inner walls of the cylinder (42) with a thin layer of vaseline grease.

- Page 17 OMEGA 10:1 EXT • Insert the springs (55) and the valves (56) into the seat (N54). Position the seat on the pump support and lay the manifold (57) on the seat [do not forget the gasket (58)]. • Fasten the manifold with screws (do not tighten) ensuring it is perfectly parallel to the other manifold and the distance between them is 46 mm (see illustration).

-

Page 18: Opumping Group Spare Parts

OMEGA 10:1 EXT PUMPING GROUP SPARE PARTS Long assembly pump - short assembly part WARNING: Always indicate code and quantity for each part required. Fig. 1 Pos. Code Description Q.ty Pos. Code Description Q.ty 95003 Bush 95013 Self-locking nut 95004... - Page 19 OMEGA 10:1 EXT Fig. 3 Pos. Code Description Q.ty Pos. Code Description Q.ty 95008/1 Wet cup 95721 Escape valve 95773 Gasket press 95914 Tie rod 95776 Upper support 95781 Conveyor Pos. Code Description Q.ty 95767 Female ring 95803 PTFE gasket...

- Page 20 OMEGA 10:1 EXT Fig. 6 Pos. Code Description Q.ty Pos. Code Description Q.ty 98003 Material Cylinder 95730 Valve lock 95722 Washer 98039 Lower rod Fig. 7 Pos. Code Description Q.ty Pos. Code Description Q.ty 95754 Shutter 98042 Female ring 98041...

- Page 21 OMEGA 10:1 EXT Fig. 8 Pos. Code Description Q.ty Pos. Code Description Q.ty 95741 95743 Injection plate 95742 Plate 95744 Fig. 9 Pos. Code Description Q.ty Pos. Code Description Q.ty 95721/2 Bush 95721/4 Knob 95721/1 Plug 3637 ED. 02 - 02/2024 - Cod. 150210...

- Page 22 OMEGA 10:1 EXT Fig. 10 Pos. Code Description Q.ty Pos. Code Description Q.ty 95780 Seal 95731 95777 Complete piston rod 98039 Lower rod ED. 02 - 02/2024 - Cod. 150210...

- Page 23 OMEGA 10:1 EXT ED. 02 - 02/2024 - Cod. 150210...

-

Page 24: Pspare Parts For Motor Group Extrusion 95905

OMEGA 10:1 EXT EXPLODED MOTOR GROUP WARNING: Always indicate code and quantity for each part required. Fig. 1 ED. 02 - 02/2024 - Cod. 150210... - Page 25 OMEGA 10:1 EXT Pos. Code Description Q.ty Pos. Code Description Q.ty 95062 Screw 95088 Extension 95063 Washer 95099 Gas ring 7113 Covering 95070 Manifold Front plate 96001 Plug 7118 95065 Screw 95072 Manifold gasket 95066 Washer 95071 Seat valve plate...

-

Page 26: Qatex Certificate

OMEGA 10:1 EXT Pos. Code Description Pos. Code Description 95658 Warning plate 5010 Grounding cable 19256 Atex plate 96210 Ground plate 95136 Adhesive tape Via A. Stoppani, LC-23801 Calolziocorte ITALY - www.larius.eu DESCRIPTION: PRESSURE PART No: RATIO: AIR PRESS. YEAR: RANGE:: MAX. - Page 27 OMEGA 10:1 EXT MARKINGS II 2 G c IIB T6 : -20°C ÷ + 60°C : 60°C Tech. File: OMEGA/ATX/08 • • • max. fluido II = Group II (surfaces) Category 2 (zone 1) Explosive atmosphere containing gasses, vapours or mists Design safety “c”...

- Page 28 OMEGA 10:1 EXT ED. 02 - 02/2024 - Cod. 150210...

-

Page 29: Declaration Of Conformity

OMEGA 10:1 EXT CE DECLARATION OF CONFORMITY Company LARIUS srl Via Antonio Stoppani 21 - 23801 Calolziocorte (LC) ITALY Tel: +39 0341 621152 Fax: +39 0341 621243 E-mail: larius@larius.com Declares under his owns resonsibility that the product: OMEGA 10:1 EXT... - Page 30 TEL. +1 (828) 645-2290 - FAX: +1 (828) 658 0840 TEL.: +44 1942 850600 - FAX: +44 1942 812160 ©Copyright, SAMOA INDUSTRIAL, S.A. SAMOA Industrial, S.A. is an ISO 9001, ISO 14001 and ISO 45001 certified company. Contact us today! Visit www.samoaindustrial.com for more information.

Need help?

Do you have a question about the OMEGA 10:1 EXT and is the answer not in the manual?

Questions and answers